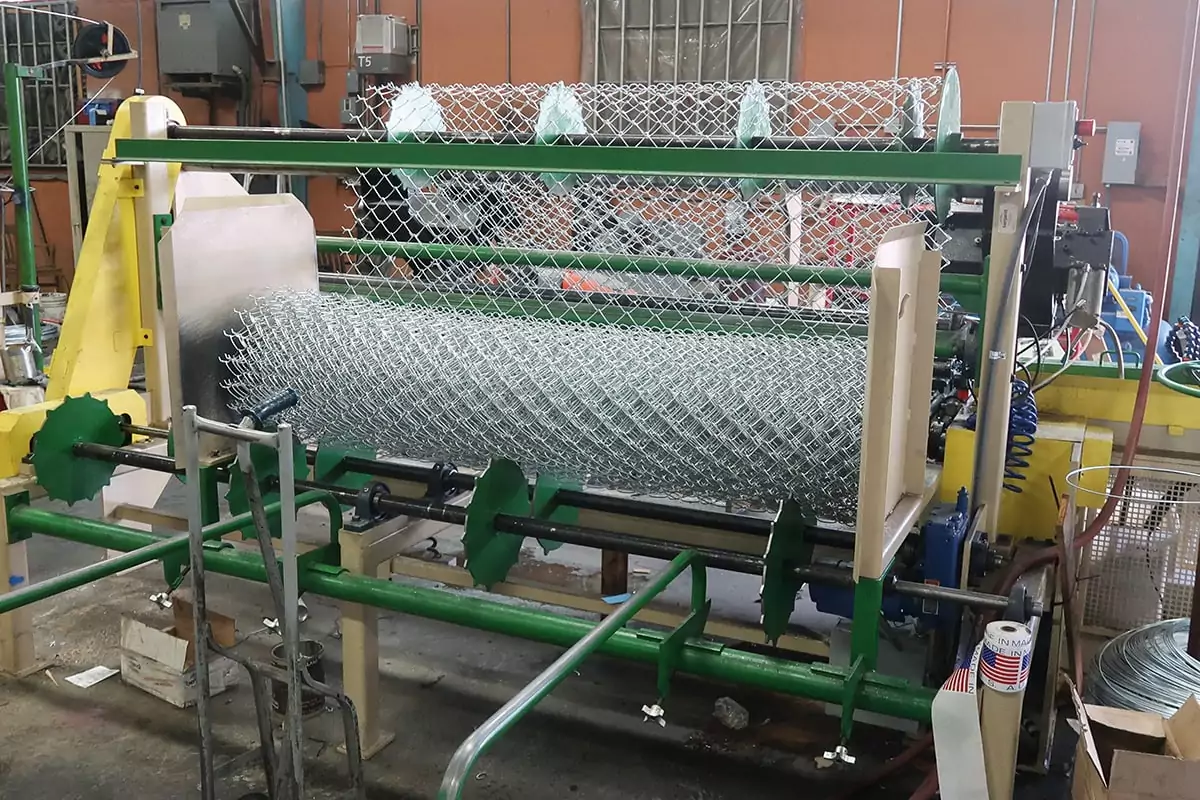

The global wire fencing market is experiencing steady growth, driven by rising demand across agricultural, construction, and security sectors. According to Grand View Research, the global barbed and woven wire fencing market was valued at USD 22.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is fueled by increased infrastructure development, expanding agricultural activities, and growing emphasis on perimeter security in both residential and commercial applications. As one of the essential components in woven and stapling wire fence systems, high-quality manufacturing plays a pivotal role in product durability and performance. Against this backdrop, a select group of manufacturers have emerged as leaders, combining innovation, production capacity, and global reach to meet escalating demand. Based on market presence, product range, and customer reviews, the following nine companies represent the top players in the stapling wire fence manufacturing industry today.

Top 9 Stapling Wire Fence Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Davis Wire

Domain Est. 1996

Website: daviswire.com

Key Highlights: We are the largest galvanized wire manufacturer in the Western United States. With one of the most diverse product lines in the world, Davis Wire is capable of ……

#2 Staples

Domain Est. 1997

Website: moreda.com

Key Highlights: MRT Staples are steel staples with two chamfered points, used to hold and tighten agricultural netting on wooden posts….

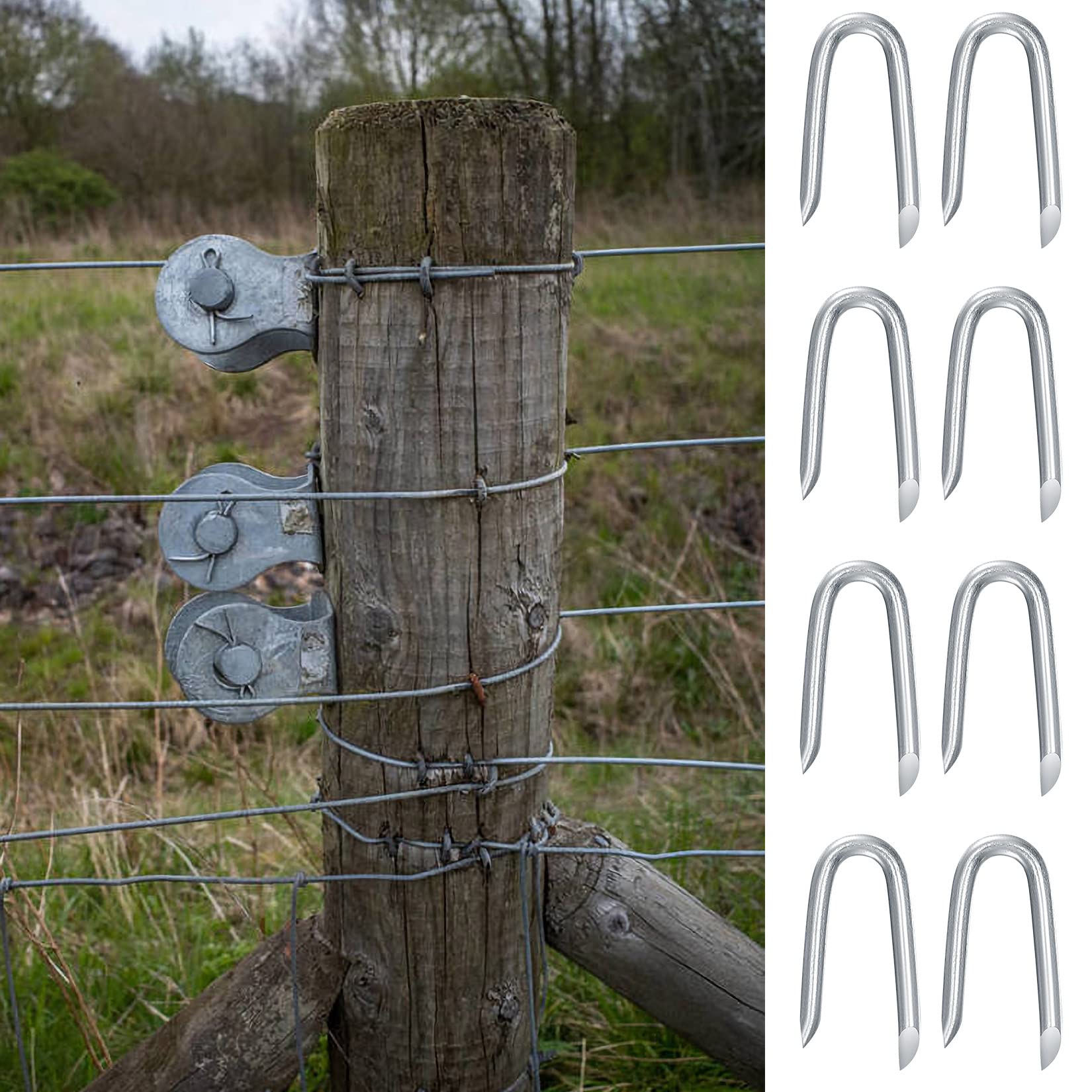

#3 Fence Staples U Nail for Wire Mesh Fencing Fabrics Fixing

Domain Est. 2008

Website: fencestaple.com

Key Highlights: This factory supplies a variety of metal wire mesh fences and stapling nails for securing and installation of the fences. Stapling Nails are hoop nails made of ……

#4 Rangemaster Fence

Domain Est. 2009

Website: rangemasterfence.com

Key Highlights: FENCE PRODUCTS. We supply performance-driven farm & ranch, and residential & commercial wire fence products for the agricultural and construction markets….

#5 Explore our Wide Range of Premium Fence Staples

Domain Est. 1993

Website: fencing.bekaert.com

Key Highlights: Our Barbed Fence Staples are made from premium 8 ga Bezinal® coated wire. These barbed staples feature single or double barbs to maintain fastening and provide ……

#6 Campbell Approved Supplier 11/2GALFENST1LB 1

Domain Est. 1997

Website: mecampbell.com

Key Highlights: In stock Free delivery over $100Staple; Brand Name Pro-Fit; Item Type Fence; Overall Size 1-1/2 Inch L; Finish Hot Dip Galvanized; Application Attaching Woven Wire Fence, Welded Fe…

#7 Fencing staples

Domain Est. 2006

Website: barsandrods.arcelormittal.com

Key Highlights: Presser point staples manufactured from 4Life® wire to provide even longer life. Various sizes and packaging options available to suit the application….

#8 BECK FENCE STAPLE 3.15

Domain Est. 2019

Website: beck-fastening.com

Key Highlights: Staple type special staples. Leg length 25 – 50 mm | 1 – 2″. Leg thickness 2.8 mm | 0.11″. Leg width 3.3 mm | 0.13″. Outside crown 12.8 mm | 0.5″….

#9 Fence Staple

Domain Est. 1996

Website: doitbest.com

Key Highlights: 2-day delivery · Free 30-day returnsBest Fence Staple at a hardware store near you. Buy HILLMAN, Do it, Bekaert Nails at lowest prices. Pick up in-store or get fast delivery….

Expert Sourcing Insights for Stapling Wire Fence

H2: 2026 Market Trends for Stapling Wire Fence

The global market for stapling wire fence is projected to undergo significant transformation by 2026, driven by advancements in materials, growing infrastructure investment, and rising demand across agricultural, residential, and industrial sectors. Key trends shaping the market include technological innovation, sustainability initiatives, regional market dynamics, and evolving construction practices.

-

Increased Adoption in Agricultural and Rural Development

By 2026, the agricultural sector is expected to remain a primary driver of demand for stapling wire fences, especially in developing regions such as Southeast Asia, Sub-Saharan Africa, and Latin America. Governments investing in rural infrastructure and land management are promoting the use of cost-effective fencing solutions. Stapling wire fences offer durability and ease of installation, making them ideal for livestock containment and boundary demarcation. -

Growth in Residential and Perimeter Security Applications

Rising urbanization and increased focus on property security are fueling demand for wire fencing in residential communities and gated developments. Stapling wire systems, known for their quick assembly and compatibility with various fence types (e.g., chain link, woven wire), are gaining favor among contractors. The trend toward smart homes and integrated security systems is also encouraging the use of reinforced wire fencing in conjunction with surveillance technologies. -

Technological Advancements and Automation in Installation

The fencing industry is witnessing a shift toward automated and semi-automated installation tools. By 2026, cordless electric staplers and high-velocity pneumatic tools designed specifically for wire fencing are expected to gain widespread adoption. These innovations reduce labor time and improve installation precision, enhancing productivity on construction and agricultural sites. -

Emphasis on Corrosion Resistance and Durability

Manufacturers are increasingly focusing on galvanized and polymer-coated stapling wires to extend product lifespan and withstand harsh environmental conditions. With climate change leading to more extreme weather patterns, demand for corrosion-resistant materials is on the rise. This trend is particularly evident in coastal and high-humidity regions where rust and degradation are major concerns. -

Sustainability and Recyclability Trends

Environmental regulations and consumer preferences are pushing the industry toward sustainable practices. Stapling wire fences made from recycled steel and fully recyclable components are gaining traction. By 2026, eco-labeling and green certifications are expected to influence procurement decisions, especially in Europe and North America, where sustainability standards are more stringent. -

Regional Market Expansion

Asia-Pacific is anticipated to be the fastest-growing market for stapling wire fences, driven by infrastructure development in India, Indonesia, and Vietnam. In contrast, North America and Europe will see steady growth due to ongoing renovation projects and agricultural modernization. The Middle East and Africa are also emerging as key markets due to urban expansion and oil & gas infrastructure projects requiring perimeter security. -

Supply Chain Optimization and Local Manufacturing

To mitigate disruptions caused by global supply chain volatility, manufacturers are increasingly investing in localized production facilities. By 2026, regional manufacturing hubs in countries like Mexico, Turkey, and Thailand are expected to play a crucial role in meeting demand efficiently and reducing lead times.

In conclusion, the 2026 market for stapling wire fence will be shaped by innovation, sustainability, and geographic diversification. As industries and governments prioritize cost-efficiency and long-term performance, stapling wire fencing systems are poised to remain a vital component of global infrastructure and security solutions.

Common Pitfalls When Sourcing Stapling Wire Fence (Quality, IP)

Sourcing stapling wire fence—commonly used in agriculture, construction, and landscaping—can present several challenges, particularly concerning product quality and intellectual property (IP) compliance. Being aware of these pitfalls helps ensure you receive durable, reliable materials while avoiding legal and reputational risks.

Inconsistent Material Quality

One of the most frequent issues is receiving wire that does not meet specified standards. Poor-quality steel may have inadequate tensile strength or inconsistent gauge thickness, leading to premature rusting, breakage, or failure under tension. Suppliers may cut costs by using recycled or substandard metal, especially when sourcing from regions with lax quality controls.

Lack of Certification and Traceability

Many suppliers fail to provide proper certifications (e.g., ISO, ASTM, or GOST standards), making it difficult to verify material composition or manufacturing processes. Without traceability, it’s challenging to ensure batch consistency or respond effectively to quality failures in the field.

Misrepresentation of Coating Quality

Galvanized or polymer-coated stapling wire fences are often misrepresented in terms of coating weight or thickness. For example, a supplier might claim compliance with Class A galvanizing (e.g., 610 g/m²) but deliver significantly less, resulting in reduced corrosion resistance and shorter lifespan.

Inadequate Packaging and Handling

Poor packaging can lead to tangled, kinked, or corroded wire upon delivery. Coils may be loosely wound or improperly sealed, exposing them to moisture during transit. This not only affects usability but also indicates a supplier’s lack of attention to detail and quality assurance.

Intellectual Property Infringement Risks

When sourcing from certain manufacturing regions, there’s a risk of inadvertently purchasing products that violate patented designs or trademarks. For example, some fencing patterns or fastening systems may be protected under IP law. Using counterfeit or cloned products can expose your business to legal action, especially in regulated markets.

Supplier Misrepresentation of Origin and Compliance

Some suppliers falsely declare the country of origin or claim compliance with international standards without verification. This can lead to customs delays, import bans, or non-compliance with project specifications, particularly in public infrastructure or government contracts.

Language and Specification Barriers

Miscommunication due to language differences or vague technical specifications can result in incorrect product delivery. Terms like “high tensile” or “heavy duty” may not have standardized meanings across regions, leading to mismatched expectations.

Hidden Costs and Unreliable Lead Times

Quoted prices may exclude critical costs such as testing, customs duties, or insurance. Additionally, unreliable delivery schedules—especially with overseas suppliers—can disrupt project timelines, increasing overall costs and reducing ROI.

To mitigate these risks, conduct thorough due diligence on suppliers, request third-party testing, verify certifications, and include clear quality and IP compliance clauses in contracts.

Logistics & Compliance Guide for Stapling Wire Fence

Overview of Stapling Wire Fence Products

Stapling wire fence components—typically including wire mesh, tension bars, staples, and support posts—are used in agricultural, construction, and security applications. Proper logistics planning and regulatory compliance are essential to ensure safe, timely, and legal delivery and installation.

Packaging and Handling Requirements

Stapling wire fence materials must be securely packaged to prevent deformation and corrosion during transit. Wire rolls and mesh panels should be wrapped in protective plastic or shrink wrap and mounted on durable spools or pallets. Staples and hardware should be boxed or banded to avoid spillage. All packages must be clearly labeled with product type, specifications, and handling instructions (e.g., “Fragile,” “Do Not Stack”).

Transportation and Freight Considerations

Due to the weight and bulk of wire fencing materials, transportation typically involves flatbed trucks, shipping containers, or palletized freight. Load securing is critical—use straps, braces, and edge protectors to prevent shifting or damage. Choose carriers experienced in handling construction or agricultural materials. International shipments may require adherence to ISPM 15 standards for wooden pallets.

Import/Export Compliance

When shipping stapling wire fence products across borders, ensure compliance with relevant import/export regulations. This includes correct HS (Harmonized System) codes—commonly 7314.31 or 7314.39 for steel fencing products. Exporters must provide commercial invoices, packing lists, and certificates of origin. Some countries impose anti-dumping duties on steel products; verify current tariffs and trade agreements.

Safety and Regulatory Standards

Stapling wire fence products must meet regional safety and quality standards. In the U.S., OSHA and ASTM standards may apply, particularly for strength, corrosion resistance, and installation safety. In the EU, compliance with CE marking under the Construction Products Regulation (CPR) is required. Ensure all products have documentation verifying adherence to these standards.

Environmental and Disposal Regulations

Galvanized or coated wire fences may contain materials regulated under environmental laws (e.g., RoHS in the EU). Proper disposal of packaging and damaged materials must follow local waste management regulations. Recyclability information should be provided, especially for metal components.

Documentation and Traceability

Maintain detailed records for each shipment, including material certifications, test reports, and compliance documentation. Batch traceability is crucial for quality control and recall management. Digital tracking systems are recommended to monitor product movement and ensure compliance throughout the supply chain.

Installation and End-User Compliance

Provide end-users with installation guidelines that align with local building codes and safety regulations. Warn against improper use (e.g., electrifying non-rated fencing). Training or certification may be required in certain jurisdictions for professional installation.

Conclusion

Effective logistics and compliance management for stapling wire fence products ensures product integrity, legal adherence, and customer satisfaction. Proactive planning, documentation, and partner coordination are key to navigating the complexities of global distribution and regulatory environments.

In conclusion, sourcing stapling wire for fence installation requires careful consideration of factors such as material quality, gauge thickness, rust resistance (e.g., galvanized or vinyl-coated options), and compatibility with the fencing material being used. It is essential to purchase from reliable suppliers who offer consistent product standards and competitive pricing, whether sourcing locally or internationally. Evaluating supplier reputation, delivery timelines, and bulk purchasing options can lead to cost efficiencies and ensure project continuity. By selecting the appropriate stapling wire and establishing a dependable supply chain, fencing projects can achieve greater durability, security, and long-term performance.