The U.S. pallet manufacturing industry is experiencing steady growth, driven by expanding logistics, warehousing, and e-commerce sectors. According to Grand View Research, the global pallet market was valued at USD 48.9 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A significant share of this demand originates in North America, where standard 48″ x 40″ pallets—sanctioned by the Grocery Manufacturers Association (GMA)—remain the backbone of supply chain efficiency. With over 1.8 billion pallets in circulation across the U.S. and nearly 460 million new units produced annually, per the National Wooden Pallet and Container Association (NWPCA), the need for reliable, high-volume manufacturers has never been greater. As sustainability and supply chain resilience become strategic priorities, leading U.S. pallet producers are leveraging automation, recycled materials, and just-in-time manufacturing to meet rigorous industry standards. This data-driven environment sets the stage for the top eight manufacturers excelling in producing standard U.S. pallet sizes—companies that combine scale, quality, and innovation to power the nation’s logistics infrastructure.

Top 8 Standard Us Pallet Size Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Standard Pallet Sizes

Domain Est. 1996

Website: kampspallets.com

Key Highlights: With specifications established by the Grocery Manufacturers Association (GMA), these pallets typically measure 48” x 40”….

#2 Standard Pallet Dimensions & Specifications

Domain Est. 1998

Website: chep.com

Key Highlights: The standard US pallet size is 48 x 40 inches. Our wide range of CHEP pallets and containers helps you to improve your supply chain efficiency and performance….

#3 National Wooden Pallet and Container Association

Domain Est. 2000

Website: palletcentral.com

Key Highlights: The wooden pallet and container manufacturing industry has a $31 billion economic impact in the USA, generating more than 173,000 jobs, enriching our ……

#4 North American Pallet (GMA): Sizes & Specs

Domain Est. 2003

Website: icontainers.com

Key Highlights: The American pallet sizes typically can carry up to 4600 lbs, and they weigh 37 lbs apiece. The most common American pallet dimensions are 48” x 40”, 42” x 42” ……

#5 GMA Pallets

Domain Est. 2006

Website: gruberpallets.com

Key Highlights: The typical dimensions of a softwood “GMA” pallet are 48 x 3.5 x 1.5-inch stringers, seven 40” wide x 11/16” thick top deck boards, and five ……

#6 North American Pallet Standards

Domain Est. 2011

Website: raymondwest.com

Key Highlights: The 48×40 Standard: A Common Benchmark. The most widely used pallet size in North America is the 48×40 inch pallet. It is often referred to ……

#7 Plastic Pallets: Your Definitive Guide

Domain Est. 2003

Website: igps.net

Key Highlights: Pallets measuring at least 1200 mm (47 inches) are standard for consumer-facing supply chains in North America, Europe, and, increasingly, in Asia. Smaller ……

#8 Standard Pallet Size Guide for Cincinnati, OH

Domain Est. 2013

Website: 48forty.com

Key Highlights: This definitive guide demystifies standard pallet sizes and empowers Cincinnati, OH businesses to select the optimal dimensions for enhanced efficiency….

Expert Sourcing Insights for Standard Us Pallet Size

2026 Market Trends for Standard US Pallet Size

The standard U.S. pallet size, commonly known as the GMA (Grocery Manufacturers Association) pallet, measures 48 inches by 40 inches and remains the most widely used pallet dimension in North American logistics. As the supply chain landscape evolves, several key trends are expected to shape the demand, production, and utilization of standard U.S. pallets by 2026.

Increasing Demand Driven by E-Commerce Growth

E-commerce continues to expand rapidly, placing greater demands on warehousing and distribution networks. By 2026, the need for standardized, efficient pallets that integrate seamlessly into automated fulfillment systems will intensify. The 48×40 pallet’s compatibility with automated material handling equipment (e.g., conveyor systems, robotic palletizers, and AS/RS) makes it a preferred choice. This consistency supports faster order fulfillment and reduces operational friction in high-volume e-commerce fulfillment centers.

Focus on Sustainability and Circular Economy

Sustainability is a growing priority across industries. By 2026, businesses will increasingly favor reusable and recyclable pallets to reduce environmental impact and comply with ESG (Environmental, Social, and Governance) standards. The standard U.S. pallet size benefits from well-established networks for repair, reuse, and recycling—particularly in pooled systems like those operated by iGPS and CHEP. These closed-loop systems are expected to grow, promoting pallet longevity and reducing wood waste.

Shift Toward Plastic and Composite Materials

While wooden pallets remain dominant, demand for plastic and composite alternatives is rising due to durability, hygiene, and weight advantages. In sectors such as pharmaceuticals, food & beverage, and cold chain logistics, plastic 48×40 pallets are gaining traction. By 2026, innovations in recycled plastics and bio-based composites may further drive adoption, especially where sanitation, moisture resistance, and regulatory compliance are critical.

Supply Chain Resilience and Inventory Optimization

Post-pandemic supply chain disruptions have prompted companies to reevaluate inventory strategies. In 2026, just-in-time logistics will coexist with increased safety stock holdings, necessitating efficient pallet storage and handling. The standard U.S. pallet’s design maximizes trailer and warehouse space utilization, supporting inventory scalability. Enhanced pallet tracking via RFID or IoT sensors—increasingly embedded in standard pallets—will improve visibility and reduce loss, boosting supply chain resilience.

Standardization vs. Customization Tensions

Despite the dominance of the 48×40 standard, certain industries may push for slight modifications or alternative sizes to optimize product protection or space efficiency. However, the cost and complexity of deviating from the U.S. standard are expected to keep it firmly entrenched. Industry collaboration and regulatory support will likely reinforce standardization, particularly in intermodal transport and retail distribution.

Conclusion

By 2026, the standard U.S. pallet size will remain a cornerstone of North American logistics, bolstered by e-commerce growth, sustainability initiatives, and technological integration. While material innovations and digital tracking may transform how pallets are used, the 48×40 footprint will continue to dominate due to its efficiency, compatibility, and economic advantages across supply chains.

Common Pitfalls When Sourcing Standard US Pallet Size (Quality, IP)

Standard US Pallet Size: Logistics & Compliance Guide

Understanding and adhering to standard pallet dimensions in the United States is essential for efficient logistics, warehouse operations, transportation, and regulatory compliance. This guide outlines the most common US pallet size, its applications, and key compliance considerations.

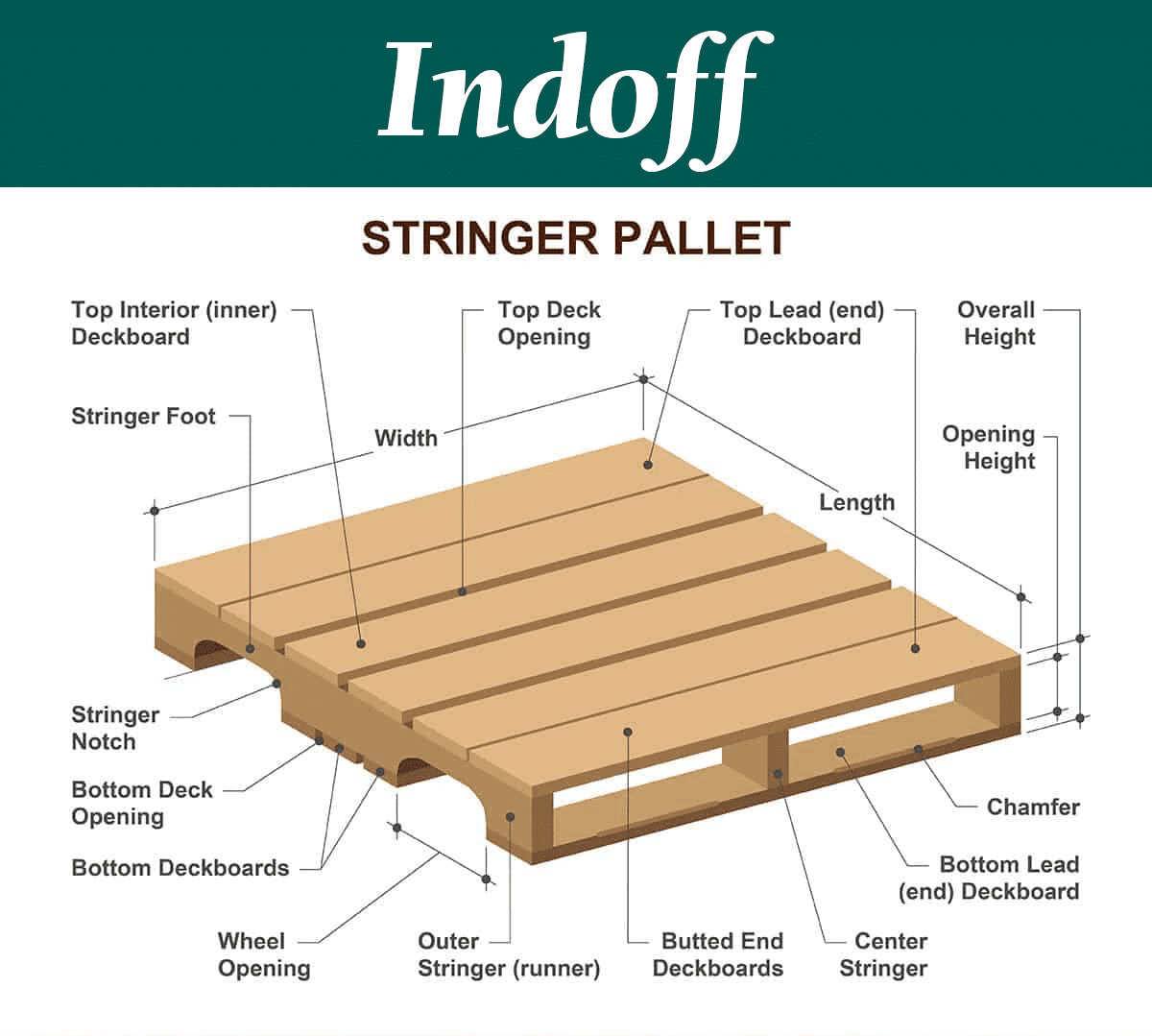

Understanding the Standard US Pallet Size

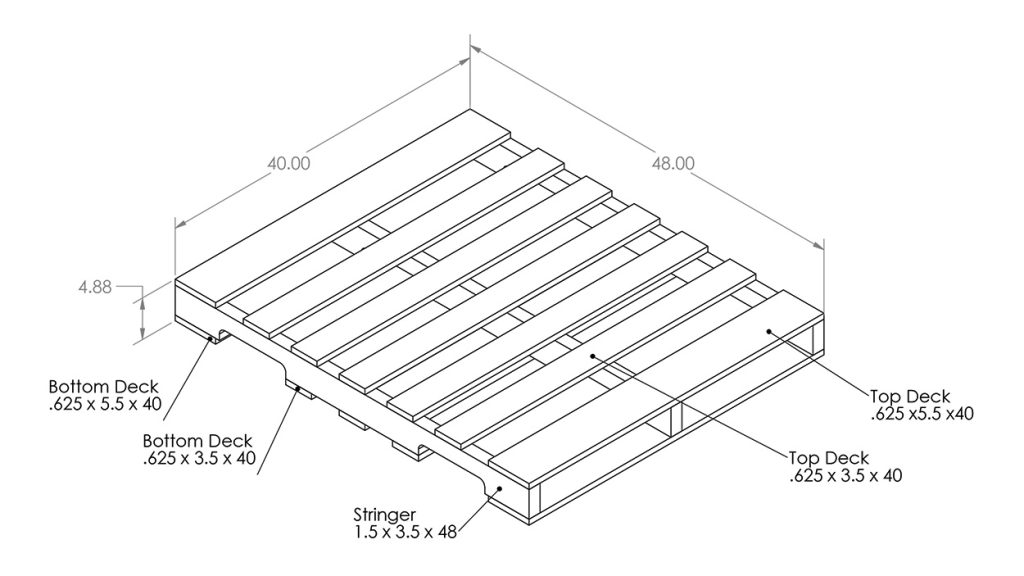

The most widely used pallet in the United States is the GMA (Grocery Manufacturers Association) pallet, also known as the 48×40 pallet. Its standardized dimensions are:

- Length: 48 inches

- Width: 40 inches

- Height: Typically 5.5 to 6.5 inches (varies based on block or stringer design)

This 48×40-inch size has become the de facto standard across industries, particularly in retail, grocery, and consumer goods, due to its compatibility with material handling equipment and shipping containers.

Why the 48×40 Pallet Dominates US Logistics

The 48×40 pallet is optimized for efficiency in North American supply chains:

- Fits Standard Truck Trailers: Two 48-inch sides align perfectly with the 102-inch interior width of standard 53-foot dry van trailers, allowing for tight, stable loads with minimal wasted space.

- Compatibility with Racking Systems: Most warehouse racking is designed to accommodate 48×40 pallets.

- Interoperability: Forklifts, pallet jacks, and automated systems are calibrated for this size.

- Pooling Programs: Organizations like CHEP and iGPS manage large networks of 48×40 pallets, promoting reuse and reducing waste.

Other Common US Pallet Sizes

While 48×40 is standard, other sizes are used for specialized applications:

- 42×42 inches: Common in telecommunications and drum shipping.

- 48×48 inches: Used for square loads, such as carpet or insulation.

- 40×48 inches (rotated): Same footprint but orientation varies.

- 36×36 inches: Often used in the chemical and pharmaceutical industries.

Always confirm pallet size requirements with partners to avoid handling delays.

Logistics Best Practices for Standard Pallets

To ensure smooth operations, follow these logistics guidelines:

- Load Stability: Secure loads with stretch wrap, banding, or shrink film to prevent shifting.

- Weight Distribution: Distribute weight evenly; do not exceed the pallet’s load capacity (typically 2,500–4,600 lbs).

- Stackability: Ensure top and bottom deck boards support stacking when storing or transporting multiple pallets.

- Forklift Access: Maintain four-way entry capability for maximum handling flexibility.

- Condition Checks: Inspect pallets for broken boards, protruding nails, or excessive damage before use.

Regulatory and Compliance Considerations

Compliance ensures safety, avoids fines, and supports international trade:

-

ISPM 15 Regulations (International Shipments):

Wooden pallets used in international trade must comply with ISPM 15 (International Standards for Phytosanitary Measures No. 15). This requires heat treatment (HT) or fumigation (MB) and a stamped certification mark to prevent the spread of pests. Note: This does not apply to domestically shipped wooden pallets within the US. -

Material Safety: Pallets must be free of hazardous materials, including chemical residues or contaminated wood.

-

DOT & FMCSA Guidelines: Overweight or improperly secured palletized loads can violate Department of Transportation (DOT) and Federal Motor Carrier Safety Administration (FMCSA) cargo securement rules.

-

OSHA Standards: Workplace handling of pallets must comply with OSHA safety regulations for material handling, including forklift operation and manual lifting.

-

FDA & Food Safety (FSMA): For food and pharmaceutical shipments, pallets must be clean, dry, and free of contaminants. Plastic or certified heat-treated wood pallets are often preferred.

Sustainability and Pallet Management

Sustainability is increasingly important in supply chain compliance:

- Pallet Pooling: Leasing pallets from providers like CHEP or iGPS reduces waste and improves standardization.

- Recycling Programs: Damaged wood pallets can often be repaired or recycled into mulch or biomass.

- Reusable Plastic Pallets: Offer longer lifespan and easier cleaning, ideal for controlled environments.

Conclusion

The 48×40-inch pallet remains the backbone of US logistics due to its efficiency and widespread adoption. By adhering to standard dimensions, following best practices for handling, and meeting regulatory requirements, businesses can ensure safe, compliant, and cost-effective operations across their supply chains. Always verify pallet specifications with trading partners and stay updated on evolving regulations, particularly for international shipments.

Conclusion:

Sourcing standard U.S. pallet size—commonly the 48″ x 40″ GMA (Grocery Manufacturers Association) pallet—offers significant advantages in terms of compatibility, efficiency, and cost-effectiveness across the North American supply chain. Its widespread adoption ensures seamless integration with racking systems, material handling equipment, and transportation vehicles, reducing handling time and minimizing product damage. Additionally, the availability of new, recycled, and alternative material options (such as wood, plastic, or corrugated) allows businesses to select pallets that align with sustainability goals and budget requirements.

When sourcing, it is essential to consider supplier reliability, quality standards (e.g., ISPM 15 for international shipments), and consistency in dimensions and load capacity. Prioritizing suppliers who adhere to industry specifications ensures operational smoothness and regulatory compliance.

In summary, standard U.S. pallets provide a proven, scalable solution for logistics and distribution needs. By sourcing the 48″ x 40″ pallet from reputable suppliers, businesses can enhance supply chain efficiency, reduce costs, and maintain interoperability across partners and distribution channels.