The global stainless steel slide market is experiencing robust growth, driven by increasing demand across the food processing, pharmaceutical, automotive, and industrial sectors. According to Grand View Research, the global stainless steel market was valued at USD 135.9 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 4.5% from 2024 to 2030, fueled by the material’s corrosion resistance, durability, and hygienic properties. Mordor Intelligence projects similar momentum, citing rising infrastructure investments and stringent health regulations in the food and beverage industry as key demand drivers. As automation and precision engineering gain traction, the need for high-performance stainless steel linear motion components—particularly slides—has grown significantly. This report evaluates the top 8 stainless steel slide manufacturers shaping the industry through innovation, reliability, and global reach.

Top 8 Stainless Steel Slide Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Stainless steel slides. Producer and designer

Domain Est. 2015

Website: elstal.com.pl

Key Highlights: eLstal from Bydgoszcz is a Polish designer and manufacturer of professional and safe stainless steel slides. We provide a guarantee for our products….

#2 Stainless steel slides

Website: deinox.eu

Key Highlights: We are a manufacturer of stainless steel slides based in Europe, Poland. We create custom designs and pride ourselves on high-quality craftsmanship. Our ……

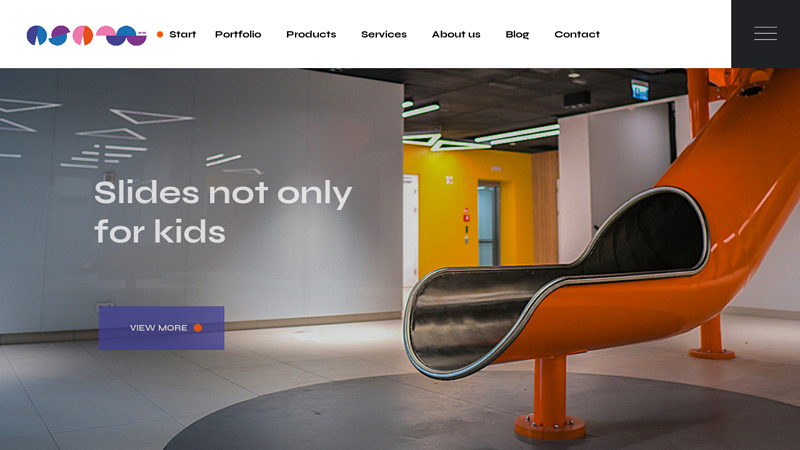

#3 Stainless steel slide supplier

Website: osomgroup.eu

Key Highlights: Manufacturer of tailored, most comfortable stainless steel slides for kids and adults. Tube slides for offices, wide hill slides, halfpipe playground slides ……

#4 Slides made of stainless steel

Domain Est. 1997

Website: wiegandslide.com

Key Highlights: In the children’s and dry slides made of stainless steel segment we supply everything that is fun, starting with standard slides for toddlers to designer ……

#5 Stainless Steel Slide

Domain Est. 1997

Website: playlsi.com

Key Highlights: The PlayShaper Stainless Steel Slide is a playground favorite that kids love. The stainless steel bedway does not emit a static charge….

#6 ST508S

Domain Est. 1999

Website: chambrelan.com

Key Highlights: This reinforced telescopic slide has 3 stainless steel elements and offers full extension. It is designed for heavy loads….

#7 Stainless Steel Straight Slide

Domain Est. 2011

Website: customslides.com

Key Highlights: We offer complete service from design, detailed engineering ,through manufacturing to installation. Many playground slides may be utilized as a pool slide or ……

#8 Custom

Domain Est. 2017

Website: tunnelslides.com

Key Highlights: We are a Czech company focusing on production of custom state-of-the-art stainless-steel slides of various types and shapes. All our slides meet strict EU ……

Expert Sourcing Insights for Stainless Steel Slide

H2: 2026 Market Trends for Stainless Steel Slides

The global stainless steel slide market is poised for notable transformation by 2026, driven by evolving industrial demands, technological advancements, and sustainability imperatives. As industries continue to prioritize durability, corrosion resistance, and low maintenance, stainless steel slides are increasingly favored over alternatives in critical applications. Key trends shaping the market include:

-

Rising Adoption in High-Purity and Hygienic Environments

Stainless steel slides are gaining traction in sectors such as food and beverage, pharmaceuticals, and cleanroom technology due to their non-porous, easy-to-clean surfaces and resistance to microbial growth. Regulatory standards and increasing emphasis on hygiene are accelerating demand, particularly in automated material handling systems. -

Growth in Automation and Industrial Robotics

With the expansion of Industry 4.0, automated manufacturing and logistics systems are integrating more linear motion components. Stainless steel slides offer superior performance in harsh environments where exposure to moisture, chemicals, or extreme temperatures is common. Their use in robotic arms, conveyors, and precision assembly lines is expected to grow steadily through 2026. -

Emphasis on Sustainability and Recyclability

Sustainability is becoming a core factor in material selection. Stainless steel is 100% recyclable and has a long service life, aligning with corporate environmental goals. Manufacturers are highlighting the eco-friendly attributes of stainless steel slides to appeal to green-certified projects and environmentally conscious buyers. -

Technological Innovations and Customization

Advancements in manufacturing techniques, such as precision CNC machining and surface treatments (e.g., electropolishing), are enhancing the performance and aesthetics of stainless steel slides. Customization for load capacity, stroke length, and environmental sealing is becoming more accessible, allowing tailored solutions for niche applications. -

Regional Market Shifts

Asia-Pacific, particularly China and India, is expected to lead market growth due to rapid industrialization and infrastructure development. Meanwhile, North America and Europe will see steady demand driven by modernization of manufacturing facilities and stringent safety regulations. -

Competitive Landscape and Price Volatility

The market remains competitive, with key players investing in R&D and strategic partnerships. However, fluctuations in raw material prices—especially nickel and chromium—could impact production costs and pricing strategies through 2026.

In summary, the stainless steel slide market in 2026 will be shaped by technological integration, regulatory demands, and sustainability trends. Companies that innovate in design, embrace digital manufacturing, and respond to regional dynamics will be best positioned for growth.

Common Pitfalls When Sourcing Stainless Steel Slides (Quality and IP)

Sourcing stainless steel slides—commonly used in industrial, medical, and food-processing applications—requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to performance failures, compliance issues, or legal risks. Below are key pitfalls to avoid:

Poor Material Quality and Specification Mismatches

One of the most frequent issues is receiving slides made from substandard or incorrectly specified stainless steel. Buyers may assume “stainless steel” implies uniform quality, but grades vary significantly (e.g., 304 vs. 316). Using 304 instead of marine-grade 316 in corrosive environments can lead to premature rusting and failure. Additionally, some suppliers may use thin plating or mixed alloys to cut costs, compromising durability and load capacity.

Tip: Always specify the exact ASTM or ISO grade (e.g., AISI 316L), request mill test certificates, and conduct material verification testing when possible.

Inadequate Corrosion Resistance for Intended Environment

Even with the correct alloy, surface finish and passivation matter. Slides used in cleanrooms or outdoor marine settings require electropolishing or proper passivation to maximize corrosion resistance. Sourcing slides without verifying these treatments can result in pitting, staining, or contamination—especially problematic in pharmaceutical or food-grade applications.

Tip: Define required surface roughness (Ra value) and passivation standards (e.g., ASTM A967) in procurement specifications.

Misrepresentation of Load and Cycle Ratings

Suppliers may inflate load capacities or cycle life based on ideal lab conditions, not real-world use. This is especially problematic with generic or unbranded slides. Overloading can lead to binding, deformation, or catastrophic failure.

Tip: Demand third-party test reports and consider pilot testing under actual operating conditions before full-scale procurement.

Intellectual Property (IP) Infringement Risks

Sourcing low-cost alternatives from certain regions may expose buyers to IP violations. Many high-performance slide designs (e.g., ball-bearing mechanisms, anti-corrosion coatings) are patented. Copying or reverse-engineering protected designs—even unknowingly—can result in legal action, import seizures, or reputational damage.

Tip: Conduct due diligence on suppliers’ design origins. Require written assurance of IP compliance and avoid suppliers offering “identical to Brand X” products at suspiciously low prices.

Lack of Traceability and Certification

In regulated industries (medical, aerospace), full traceability—from raw material to finished product—is essential. Slides lacking proper documentation (e.g., heat numbers, RoHS/REACH compliance, FDA conformity) may fail audits or be rejected during inspection.

Tip: Insist on full certification packages and audit suppliers’ quality management systems (e.g., ISO 9001).

Overlooking Customization and Compatibility

Custom stainless steel slides may be needed for unique applications, but poor communication with suppliers can result in dimensional inaccuracies or incompatible mounting interfaces. This leads to delays, rework, or in-field failures.

Tip: Use detailed engineering drawings, request prototypes, and establish clear approval processes before mass production.

By proactively addressing these quality and IP-related pitfalls, buyers can ensure reliable performance, regulatory compliance, and legal safety when sourcing stainless steel slides.

Logistics & Compliance Guide for Stainless Steel Slides

Overview

Stainless steel slides are commonly used in commercial, industrial, and recreational applications due to their durability, corrosion resistance, and aesthetic appeal. Proper logistics planning and compliance with regulations are essential to ensure safe transportation, legal import/export, and adherence to safety and environmental standards.

Material Specifications and Classification

Stainless steel slides are typically manufactured from grades such as 304 or 316, chosen for their strength and resistance to rust. For logistics and customs purposes, they are classified under the Harmonized System (HS) Code 7326.20 – “Other articles of stainless steel, of iron or steel.” Accurate classification ensures correct duty assessment and compliance with international trade regulations.

Packaging and Handling Requirements

To prevent surface damage and corrosion during transit:

– Use protective wrapping (e.g., plastic film or foam padding) on all surfaces.

– Secure components on wooden pallets with strapping or stretch wrap.

– Label packages with handling instructions: “Fragile,” “This Side Up,” and “Protect from Moisture.”

– For large or custom slides, use crated packaging with internal bracing.

Transportation Considerations

- Domestic Shipping: Use flatbed or enclosed trucks depending on size and environmental exposure risk.

- International Shipping: Sea freight is cost-effective; ensure containers are dry and secured to prevent shifting. Air freight is suitable for time-sensitive or small-batch deliveries.

- Weight and Dimensions: Confirm that slide components comply with carrier limits for weight, length, and load capacity. Oversized loads may require special permits.

Import/Export Compliance

- Documentation: Prepare commercial invoice, packing list, bill of lading/airway bill, and certificate of origin.

- Duty and Tariffs: Verify applicable tariffs based on destination country and HS code classification.

- Regulatory Approvals: Ensure compliance with destination country standards (e.g., CE marking for EU, ASTM F1487 for playground equipment in the U.S.).

- Sanctions and Embargoes: Confirm that destination countries are not under trade restrictions.

Safety and Environmental Regulations

- REACH (EU): Confirm that materials comply with substance restrictions under Regulation (EC) No 1907/2006.

- RoHS (EU): Although primarily for electronics, applicable if slides include electronic components (e.g., lighting).

- OSHA & ANSI (U.S.): Slides intended for public use must meet safety standards for structural integrity, fall zones, and accessibility (e.g., ADA compliance).

Quality Assurance and Certification

- Provide mill test certificates (e.g., EN 10204 3.1) confirming stainless steel composition and mechanical properties.

- Include third-party inspection reports if required by the customer or jurisdiction.

- Maintain records of quality control checks, welding certifications, and surface finish verification.

Installation and End-Use Compliance

- Supply installation manuals with torque specifications, anchoring requirements, and safety clearances.

- Ensure final installation complies with local building codes and playground safety standards.

- Recommend periodic maintenance checks for corrosion, structural integrity, and wear.

Conclusion

Successful logistics and compliance for stainless steel slides require attention to material classification, protective packaging, regulatory documentation, and adherence to international safety standards. Proactive planning minimizes delays, ensures product integrity, and supports legal and safe deployment in the target market.

In conclusion, sourcing stainless steel slides requires careful consideration of material quality, supplier reliability, compliance with industry standards, and cost-effectiveness. Stainless steel offers excellent durability, corrosion resistance, and low maintenance, making it ideal for applications in demanding environments such as marine, food processing, and outdoor recreational equipment. Evaluating potential suppliers based on their certifications, production capabilities, and track record ensures consistent product quality and timely delivery. Additionally, factoring in long-term value—rather than just initial cost—can lead to more sustainable and efficient procurement decisions. By establishing strong partnerships with reputable suppliers and maintaining clear specifications, organizations can secure high-performance stainless steel slides that meet both technical requirements and project timelines.