The global stainless steel pipe flanges market is experiencing robust growth, driven by rising demand across industries such as oil & gas, chemical processing, power generation, and water treatment. According to a 2023 report by Grand View Research, the global industrial flanges market size was valued at USD 8.6 billion and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, fueled by infrastructure development and increasing industrialization. Similarly, Mordor Intelligence projects steady growth in stainless steel flange demand, particularly in emerging economies, citing advancements in pipeline infrastructure and stringent regulatory standards that favor corrosion-resistant materials. With North America, Europe, and Asia Pacific leading in both production and consumption, the competitive landscape is marked by a mix of established players and regional manufacturers focused on quality, material innovation, and compliance with international standards such as ASME, ANSI, and DIN. In this evolving market, identifying top-tier manufacturers capable of delivering high-performance stainless steel pipe flanges is critical for ensuring reliability and efficiency in critical piping systems.

Top 10 Stainless Steel Pipe Flanges Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pipe Flange

Domain Est. 1998

Website: apiint.com

Key Highlights: We manufacture standard and custom steel flanges to meet the highest quality standards, including AWWA and ANSI specifications….

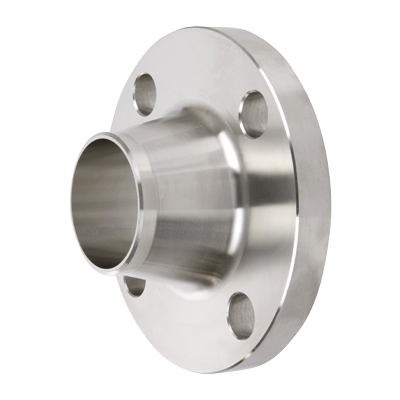

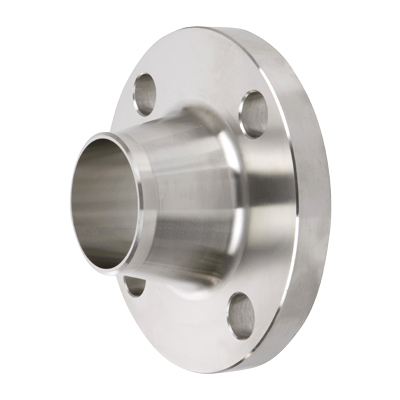

#2 Stainless steel flange

Domain Est. 2008

Website: cnpipefitting.com

Key Highlights: C&N Industrial is a leading pipe ,flange and fitting manufacturer. these products can be with epoxy and 3HDPE coating and lining….

#3 Carbon, Steel, & Alloy Pipe Flanges

Domain Est. 1996

Website: coastalflange.com

Key Highlights: We’re an ISO 9001:2015 certified quality management system that’s specialized In large diameter steel pipe flanges, carbon, stainless and alloys….

#4 Texas Flange

Domain Est. 1997

Website: texasflange.com

Key Highlights: We provide ANSI, API, and AWWA pipe flanges in carbon steel, stainless steel, alloys, and chrome steel. Styles we offer include weld neck, slip on, blind ……

#5 Cangzhou Haoguan Pipe Fittings Flanges Manufacturing Co.,Ltd

Domain Est. 2018

Website: hgffgroup.com

Key Highlights: HGFF is a manufacturer of butt weld pipe fittings and flanges which has more 20 years’ experience, also a stockiest of carbon steel pipes….

#6 BFN Forgings

Domain Est. 2020

Website: bfnf.in

Key Highlights: BFN Forgings Pvt. Ltd is a well-known stainless steel SS flange manufacturer and suppliers in India. Contact us to get high quality SS flanges according to ……

#7 Stainless Steel Pipe Flange Supplier

Domain Est. 1996

Website: usmetals.com

Key Highlights: US Metals is a Premier Worldwide Supplier for All Your Stainless Steel Flanges A182 / SA182 Needs. Our Chrome Alloy Flange inventory is unsurpassed….

#8 Shaw Stainless, Steel Pipe & Tube Supplier

Domain Est. 1999

Website: stainlessandalloy.com

Key Highlights: We stock an extensive inventory of stainless steel flanges. We also specialize in sanitary tubing, sanitary valves, and a full product line of stainless steel ……

#9 Stainless Steel Flanges (ANSI)

Domain Est. 1999

Website: buyfittingsonline.com

Key Highlights: Free delivery over $99 60-day returnsDiscover durable and affordable ANSI stainless steel flanges. Buy 304 & 316 pipe flanges available in various styles and classes….

#10 Stainless Steel Pipe Flanges

Domain Est. 2001

Website: stainlesstubular.com

Key Highlights: Stainless Tubular Products – Your trusted pipe flanges supplier for high-quality stainless steel pipe flanges. Find the perfect fit for your project….

Expert Sourcing Insights for Stainless Steel Pipe Flanges

H2: Projected Market Trends for Stainless Steel Pipe Flanges in 2026

The global market for stainless steel pipe flanges is poised for steady growth by 2026, driven by expanding industrial infrastructure, increasing demand for corrosion-resistant materials, and the push toward sustainable and durable engineering solutions. Several key trends are expected to shape the market landscape in the coming years.

-

Rising Demand from Key End-Use Industries

Industries such as oil & gas, chemical processing, power generation (including renewables), water treatment, and pharmaceuticals continue to be major consumers of stainless steel flanges. By 2026, increased investments in LNG (liquefied natural gas) infrastructure and offshore drilling projects, particularly in Asia-Pacific and the Middle East, are projected to boost demand. Additionally, the global shift toward clean energy will stimulate growth in nuclear and solar thermal power plants, which rely heavily on high-performance piping systems. -

Growth in Asia-Pacific Region

The Asia-Pacific region is expected to dominate the stainless steel flange market by 2026, with China, India, and Southeast Asian countries leading in industrial expansion and urbanization. Government initiatives promoting infrastructure development, including pipeline networks and smart cities, will further accelerate demand. Local manufacturing capacities are also improving, reducing dependency on imports and fostering regional supply chain resilience. -

Technological Advancements and Material Innovation

Manufacturers are increasingly adopting advanced production techniques such as precision forging, automated machining, and digital quality control systems to enhance product consistency and reduce lead times. There is also growing interest in high-grade stainless steel alloys (e.g., duplex, super austenitic, and 6% Mo grades) that offer superior resistance to chloride stress corrosion and high-temperature environments—crucial for harsh operating conditions in desalination and offshore applications. -

Sustainability and Regulatory Pressures

Environmental regulations and industry standards are becoming more stringent, particularly in Europe and North America. Compliance with ISO, ASME, and PED (Pressure Equipment Directive) standards is now a baseline requirement. Furthermore, the emphasis on reducing carbon footprints is encouraging the use of recycled stainless steel and energy-efficient manufacturing practices, influencing procurement decisions across sectors. -

Supply Chain Resilience and Localization

Post-pandemic and geopolitical disruptions have prompted companies to reevaluate supply chain dependencies. By 2026, there will be a stronger trend toward localized sourcing and nearshoring, especially in North America and Europe, to mitigate risks and ensure timely delivery. This shift may benefit domestic manufacturers and drive investments in regional production facilities. -

Digital Integration and Industry 4.0

Smart manufacturing technologies—including IoT-enabled monitoring, predictive maintenance, and digital twins—are being integrated into flange production and quality assurance processes. These technologies enhance traceability, reduce waste, and improve customization capabilities, meeting the growing demand for engineered-to-order (ETO) flange solutions.

In conclusion, the stainless steel pipe flange market in 2026 will be characterized by robust growth, technological innovation, and a strategic shift toward sustainability and supply chain agility. Companies that invest in advanced materials, digital capabilities, and regional manufacturing are likely to gain a competitive edge in this evolving market.

Common Pitfalls When Sourcing Stainless Steel Pipe Flanges (Quality, IP)

Sourcing stainless steel pipe flanges requires careful attention to quality standards, material specifications, and international compliance. Overlooking key aspects can lead to performance failures, safety hazards, and costly replacements. Below are common pitfalls related to quality and international procurement (IP):

Inadequate Material Certification and Traceability

One of the most frequent issues is receiving flanges without proper material test reports (MTRs) or with falsified documentation. Buyers may assume the flanges are made from genuine stainless steel (e.g., 304/316), but substandard or counterfeit materials are sometimes supplied. Ensure suppliers provide full traceability, including heat numbers and mill certifications compliant with ASTM, ASME, or EN standards.

Non-Compliance with International Standards

Flanges sourced from international suppliers may not adhere to required standards such as ASME B16.5, ASME B16.47, or ISO 7005. Differences in regional standards can result in incompatible dimensions, pressure ratings, or face types. Always verify that the flanges meet the specific project’s required standard and are certified accordingly.

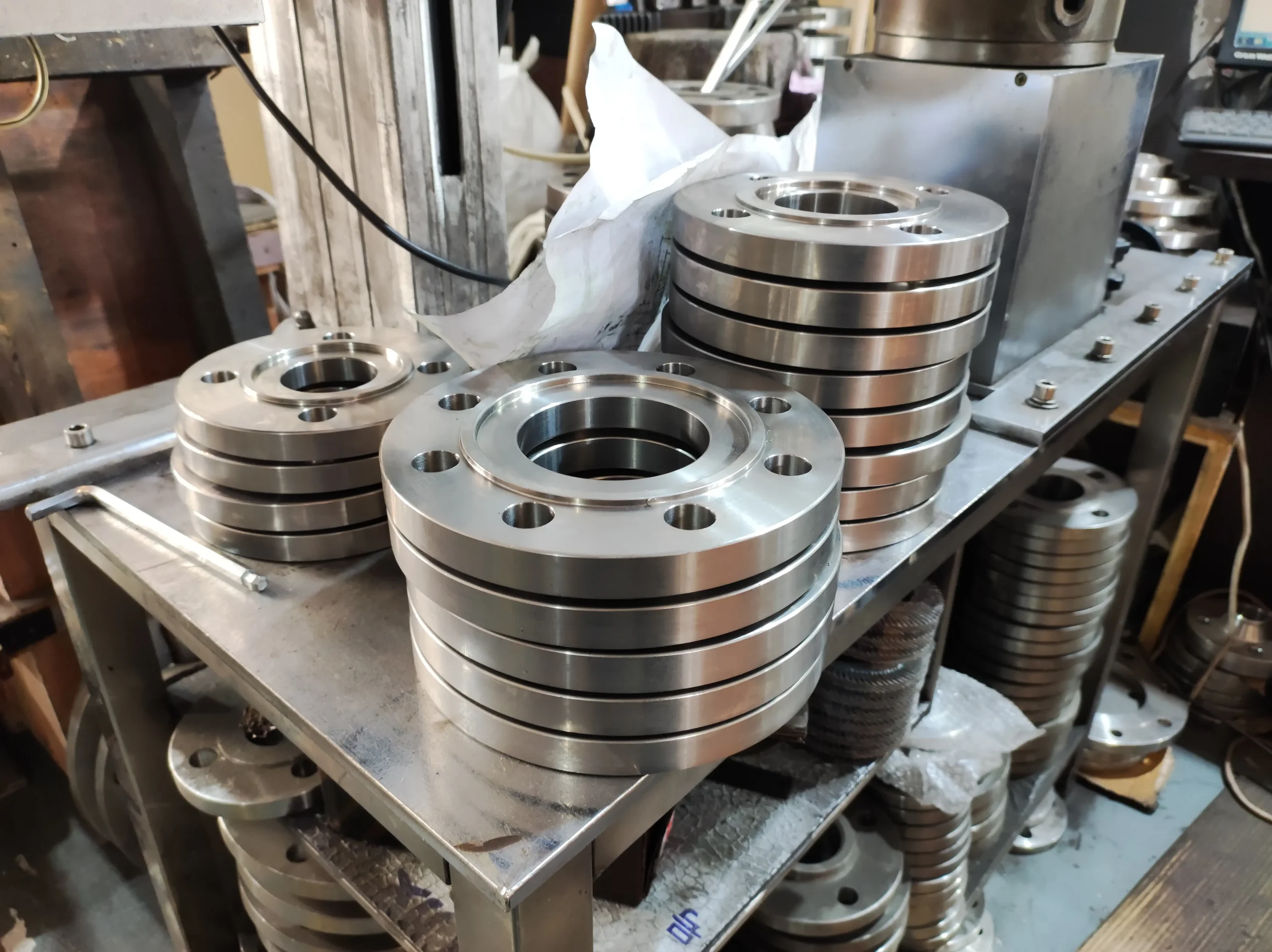

Poor Manufacturing Quality and Workmanship

Low-cost suppliers may cut corners in forging, machining, or surface finishing. Issues like uneven bolt holes, incorrect facing (e.g., RF, FF, RTJ), or inadequate dimensional tolerances can lead to leaks or misalignment. Conduct third-party inspections or pre-shipment quality checks to ensure manufacturing consistency.

Incorrect Grade or Corrosion Resistance

Stainless steel flanges are often chosen for their corrosion resistance, but incorrect alloy selection (e.g., using 304 instead of 316 in chloride-rich environments) can lead to premature failure. Confirm the correct grade for the operating environment and verify through chemical composition testing if necessary.

Lack of Pressure Rating Verification

Flanges must match the system’s pressure-temperature requirements. Sourced flanges may be misrepresented in terms of class ratings (e.g., Class 150, 300, 600). Always validate pressure ratings against applicable standards and ensure they are marked permanently on the flange.

Insufficient Anti-Corrosion Protection During Shipping

International shipping exposes flanges to humidity and salt air, leading to surface rust—even on stainless steel. Inadequate packaging or lack of VCI (Vapor Corrosion Inhibitor) wrapping can compromise integrity. Specify protective packaging requirements in procurement contracts.

Language and Communication Barriers

When sourcing globally, miscommunication about specifications, delivery timelines, or quality expectations can occur. Use clear, standardized technical documentation and consider working with local agents or sourcing partners who understand both technical and linguistic nuances.

Unverified Supplier Credentials

Engaging suppliers without proper vetting increases the risk of receiving subpar products. Avoid suppliers who cannot provide references, facility audits, or certifications like ISO 9001. Utilize supply chain verification platforms or conduct on-site audits when feasible.

Inconsistent Marking and Identification

Proper marking—such as material grade, size, standard, and manufacturer—must be permanently stamped on each flange. Inconsistent or missing markings make quality verification and traceability difficult, especially during inspections or audits.

Hidden Costs and Logistics Delays

While initial pricing may appear competitive, international sourcing can incur unforeseen costs such as import duties, customs clearance delays, or non-compliance penalties. Factor in total landed cost and lead times when evaluating suppliers.

Avoiding these pitfalls requires due diligence, clear specifications, and proactive quality control. Partnering with reputable suppliers and employing independent inspection services can significantly reduce risks in sourcing stainless steel pipe flanges globally.

Logistics & Compliance Guide for Stainless Steel Pipe Flanges

This guide outlines key logistics and compliance considerations for the transportation, handling, and regulatory adherence associated with stainless steel pipe flanges in industrial supply chains.

Material Specifications and Standards Compliance

Stainless steel pipe flanges must conform to recognized international and industry standards to ensure compatibility, safety, and performance. Key standards include:

- ASME/ANSI B16.5: Covers pipe flanges and flanged fittings (NPS 1/2 through NPS 24) in various pressure classes.

- ASME B16.47: For larger diameter flanges (NPS 26 through NPS 60).

- DIN 2633–2638: German standards commonly used in European markets.

- EN 1092-1: European standard for flanges, essential for CE-marked products.

- ASTM A182: Standard specification for forged or rolled alloy and stainless steel pipe flanges.

- Material Grade Requirements: Ensure flanges are manufactured from certified grades such as 304/L, 316/L, or other specified alloys, with proper mill test reports (MTRs) provided.

Compliance with these standards is mandatory for certification and acceptance in most jurisdictions.

Packaging and Handling Requirements

Proper packaging and handling are critical to prevent damage and maintain material integrity during transit.

- Protective Coating: Apply anti-rust oil or VCI (Vapor Corrosion Inhibitor) paper to prevent oxidation during storage and shipping.

- Secure Packaging: Use wooden crates, steel strapping, or palletized bundles with edge protectors to prevent mechanical damage.

- Labeling: Clearly label packages with product details (size, grade, standard, heat number), handling instructions (e.g., “Do Not Stack,” “Protect from Moisture”), and safety warnings.

- Lifting Procedures: Use appropriate slings and lifting equipment; avoid direct contact between lifting chains and flange sealing surfaces to prevent galling or deformation.

Transportation and Shipping Logistics

Transportation planning must account for the weight, dimensions, and corrosion sensitivity of stainless steel flanges.

- Mode of Transport: Choose between sea, air, or land freight based on urgency, destination, and cost. Sea freight is common for bulk shipments.

- Containerization: Use dry, ventilated containers to prevent condensation. Desiccants should be included in enclosed shipments.

- Weight Distribution: Ensure even load distribution in containers or trucks to avoid shifting and structural stress.

- Customs Documentation: Provide accurate commercial invoices, packing lists, certificates of origin, and material test reports to expedite customs clearance.

Import/Export Regulations and Documentation

International trade of stainless steel flanges is subject to regulatory oversight and documentation requirements.

- HS Code Classification: Use correct Harmonized System (HS) codes (e.g., 7307.23 or 7307.29 for stainless steel flanges) for customs declarations.

- Export Controls: Verify if flanges are subject to export restrictions (e.g., dual-use items under Wassenaar Arrangement).

- Import Duties and Taxes: Research destination country tariffs, VAT, and anti-dumping duties that may apply.

- Certificates Required: Provide Certificate of Conformity (CoC), CE marking (for EU), or other regional certifications (e.g., GOST for Russia, INMETRO for Brazil) as needed.

Quality Assurance and Traceability

Maintaining traceability and quality control throughout the logistics chain is essential for compliance and accountability.

- Heat Lot Traceability: Each flange or batch should be traceable to its manufacturing heat number and associated MTRs.

- Inspection Reports: Include third-party inspection certificates (e.g., SGS, BV) if required by the buyer or regulation.

- Non-Destructive Testing (NDT): Certify that flanges have undergone required testing (e.g., PMI, hydrotesting, dye penetrant) where applicable.

Environmental and Safety Compliance

Ensure logistics operations adhere to environmental and workplace safety standards.

- Hazardous Materials: Although stainless steel is non-hazardous, protective coatings or cleaning agents may require SDS (Safety Data Sheets).

- Waste Disposal: Recycle packaging materials (wood, steel, plastic) in accordance with local environmental regulations.

- OSHA and Local Safety Standards: Train personnel in safe handling practices to prevent injuries during loading/unloading.

Storage and Inventory Management

Proper storage prevents degradation and ensures flanges remain ready for use.

- Indoor Storage: Store in a dry, covered area away from moisture, chlorides, and direct contact with carbon steel to avoid cross-contamination.

- Racking: Use racks to elevate flanges off the ground; avoid stacking heavy loads on finished surfaces.

- Inventory Controls: Implement a first-in, first-out (FIFO) system and conduct periodic inspections for signs of corrosion or damage.

Adherence to this logistics and compliance guide ensures that stainless steel pipe flanges are delivered safely, meet regulatory requirements, and perform reliably in their intended applications.

In conclusion, sourcing stainless steel pipe flanges requires careful consideration of material grade, manufacturing standards, supplier reliability, and cost-effectiveness. Selecting flanges made from appropriate stainless steel grades—such as 304, 316, or duplex alloys—ensures compatibility with the intended environment, especially in corrosive or high-pressure applications. Compliance with international standards like ASME, ASTM, or ISO guarantees quality and performance reliability. Partnering with reputable suppliers who provide proper certifications, consistent quality control, and traceability is essential to avoid failures and ensure long-term operational safety. Additionally, evaluating total cost—including logistics, lead times, and lifecycle durability—rather than focusing solely on price contributes to more sustainable and efficient procurement. Ultimately, a strategic sourcing approach to stainless steel pipe flanges supports system integrity, reduces maintenance costs, and enhances overall project success.