The global fastener market, driven by robust demand from construction, automotive, and manufacturing sectors, is experiencing steady growth, with the stainless steel segment gaining traction due to its superior corrosion resistance and durability. According to Mordor Intelligence, the global fasteners market was valued at USD 109.3 billion in 2023 and is projected to grow at a CAGR of over 5.2% through 2029. A key contributor to this expansion is the rising adoption of specialized fastening solutions, including stainless steel nails for nail guns, particularly in high-moisture and outdoor applications. The construction industry’s shift toward sustainable and long-lasting materials further amplifies demand, with stainless steel nails offering optimal performance in decking, framing, and roofing. As manufacturers seek reliable, high-performance components, the need for precision-engineered stainless steel nails compatible with leading nail gun systems has become critical. In this competitive landscape, nine standout products have emerged, combining material integrity, consistent sizing, and corrosion resistance to meet the rigorous demands of industrial and professional use.

Top 9 Stainless Steel Nails For Nail Gun Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Litnaglis

Domain Est. 2001

Website: litnaglis.com

Key Highlights: As Europe’s leading nail manufacturer, we’ve been producing high-quality steel nails for over 24 years, serving the Baltic States, Europe, and global markets….

#2 Nails

Domain Est. 1993

#3 Stainless Steel Nails for Powered Nailers

Domain Est. 1994

Website: mcmaster.com

Key Highlights: Choose from our selection of stainless steel nails for powered nailers in a wide range of styles and sizes. Same and Next Day Delivery….

#4 Collated Nails and Staples

Domain Est. 1995

Website: strongtie.com

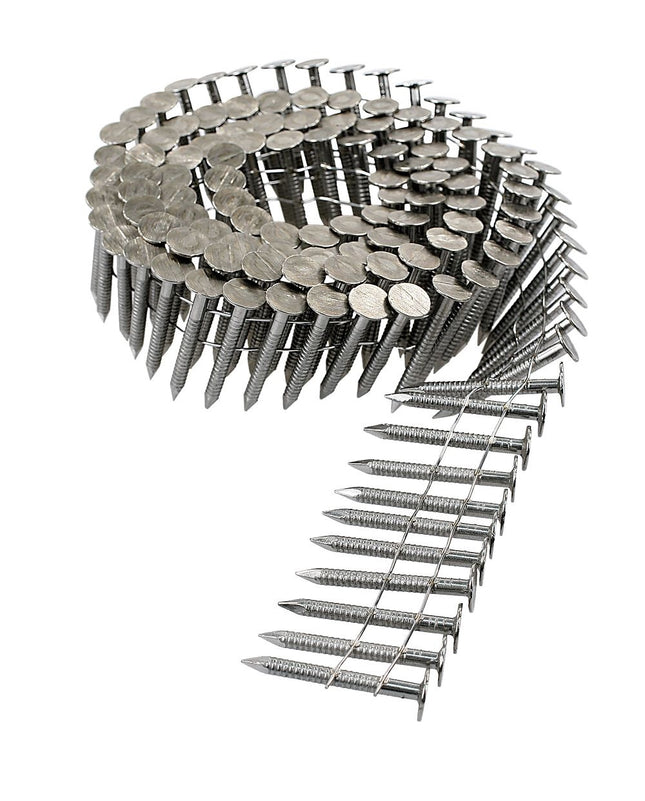

Key Highlights: These stainless steel nails feature full round head and 33° collation angle. Check for tool compatibility. 0° Inserted Plastic Coil ……

#5 Maze Nails Company

Domain Est. 1995

Website: mazenails.com

Key Highlights: Maze Nails have been trusted by professionals for more than a century. Our top quality hot dip galvanizing process delivers superior corrosion resistance….

#6 Shop Stainless Steel Nails, Staples, Screws Online

Domain Est. 2003

Website: fastenerusa.com

Key Highlights: At FastenerUSA, we offer six different gauge sizes of stainless steel finish nails for whatever application you need….

#7 Stainless Steel Nails at Nail Gun Depot

Domain Est. 2004

Website: nailgundepot.com

Key Highlights: 30-day returnsChoose between 304 and 316 grade stainless steel nail gun nails. These stainless steel nails are ideal for use in coastal construction, where rust resistant ……

#8 Spotnails

Domain Est. 2007

Website: spotnails.biz

Key Highlights: 304/316 Stainless Steel · 20-22 Degree Plastic Strip Nails · 34 Degree Joist Hanger Nails · Coil Roofing Nails .090 Coil Nails · 15GA DA Angle Brads · 15GA FN ……

#9 Nails

Website: prebena.shop

Key Highlights: The PREBENA product range offers a wide variety of nails – round-head nails, half-head nails, corrugated nails, anchor nails, fastening nails, roofing felt ……

Expert Sourcing Insights for Stainless Steel Nails For Nail Gun

H2: Projected Market Trends for Stainless Steel Nails for Nail Guns in 2026

The global market for stainless steel nails for nail guns is expected to experience steady growth by 2026, driven by increasing demand in construction, infrastructure development, and industrial applications. Key trends shaping the market include rising construction activities in emerging economies, a shift toward corrosion-resistant fasteners in coastal and high-moisture environments, and growing emphasis on durable, low-maintenance building materials.

One of the primary drivers is the construction sector’s increasing preference for stainless steel over traditional carbon steel nails. Stainless steel offers superior resistance to rust and corrosion, making it ideal for exterior applications, marine environments, and structures exposed to harsh weather. As sustainability and building longevity gain priority, builders and contractors are more likely to invest in premium fasteners that extend the service life of structures.

Advancements in nail gun technology are also supporting demand. Modern pneumatic and cordless nail guns are being optimized to handle harder materials like stainless steel, improving efficiency and reducing tool wear. This compatibility is encouraging wider adoption across residential, commercial, and industrial construction.

Regionally, Asia-Pacific is expected to lead market growth due to rapid urbanization, government infrastructure initiatives, and expanding industrial zones in countries like India, Vietnam, and Indonesia. North America and Europe will maintain strong demand, particularly in renovation projects and green building certifications that favor corrosion-resistant materials.

Additionally, supply chain optimization and localized manufacturing are emerging trends. Producers are investing in regional production facilities to reduce lead times and mitigate raw material price volatility, especially given fluctuating nickel and chromium costs that affect stainless steel pricing.

In summary, the 2026 market for stainless steel nails for nail guns will be shaped by technological advancements, sustainability demands, and geographic expansion. Manufacturers who focus on product durability, compatibility with modern tools, and cost-effective supply chains are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Stainless Steel Nails for Nail Guns (Quality and Intellectual Property)

Sourcing stainless steel nails for nail guns may seem straightforward, but several pitfalls can compromise project quality, cost-efficiency, and legal compliance—particularly concerning material quality and intellectual property (IP) rights. Being aware of these issues helps procurement professionals, contractors, and manufacturers avoid costly mistakes.

Quality-Related Pitfalls

1. Misrepresentation of Stainless Steel Grade

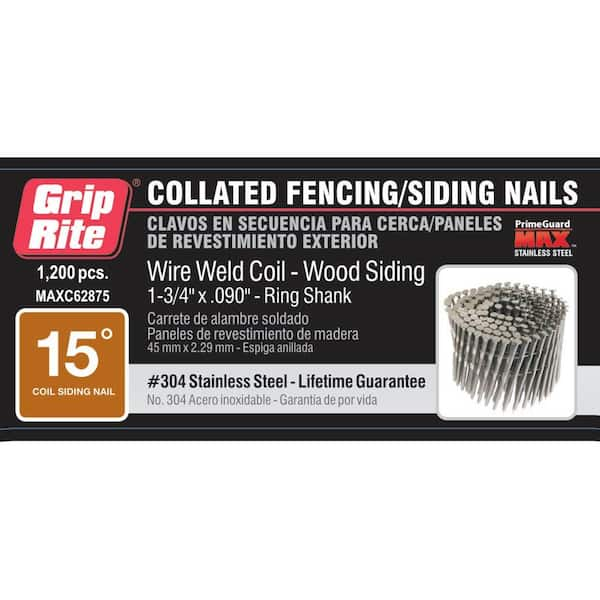

Suppliers may claim that nails are made from high-grade stainless steel (e.g., 304 or 316), but deliver lower-quality or even non-stainless alternatives. Grade 316 offers superior corrosion resistance, especially in marine or high-moisture environments, while inferior grades or counterfeit materials can lead to premature rusting and structural failure.

2. Inconsistent Manufacturing Tolerances

Low-cost manufacturers may produce nails with inconsistent shank diameter, head size, or length. These variances can cause feeding jams in nail guns, reduce holding power, or result in uneven finishes—impacting both productivity and safety.

3. Poor Surface Finish and Coating Defects

Even genuine stainless steel nails can suffer from poor surface finishing, such as burrs, rough threads, or inadequate passivation. These flaws reduce corrosion resistance and may interfere with proper nail gun operation.

4. Lack of Certification and Traceability

Many suppliers fail to provide material test reports (MTRs) or mill certifications verifying the stainless steel composition. Without traceability, it’s impossible to confirm compliance with industry standards like ASTM A479 or ISO 3506.

5. Substandard Packaging Leading to Damage

Poor packaging—especially in humid environments—can cause surface contamination or pre-installation corrosion. Reputable suppliers use moisture-resistant packaging to preserve nail integrity.

Intellectual Property (IP) Risks

1. Counterfeit or Knockoff Brand Products

Some suppliers sell imitation versions of patented nail designs or branded fasteners (e.g., Bostitch, Paslode, DeWalt). These counterfeit products not only infringe on IP rights but often underperform due to poor design and material choices.

2. Unauthorized Use of Proprietary Designs

Certain nail configurations (e.g., collation types, head geometry) are protected by patents. Sourcing nails that replicate these designs without licensing exposes buyers to legal liability, especially in commercial or export contexts.

3. Mislabeling and Brand Confusion

Suppliers may use branding or packaging that mimics well-known manufacturers, misleading buyers into believing they are purchasing authentic, IP-protected products. This risks both performance issues and potential trademark infringement.

4. Lack of IP Due Diligence in Supply Chain

Buyers who do not vet suppliers for IP compliance may inadvertently support counterfeit operations. This can damage reputations, lead to shipment seizures, or result in litigation—particularly in regulated markets like the EU or U.S.

Mitigation Strategies

- Require material certifications and conduct third-party testing.

- Audit suppliers and request proof of IP compliance.

- Work with reputable distributors or directly with original manufacturers.

- Verify product specifications against industry standards.

- Include IP indemnification clauses in procurement contracts.

Avoiding these common pitfalls ensures durable, reliable performance of stainless steel nails while protecting your organization from legal and operational risks.

Logistics & Compliance Guide for Stainless Steel Nails for Nail Gun

Product Classification and HS Code

Stainless steel nails for nail guns are typically classified under the Harmonized System (HS) code 7317.00.00, which covers “Nails, tacks, staples, screws, and bolts, of iron or steel.” However, specific subcategories may apply based on composition and size. For stainless steel variants, national tariff schedules might further classify them under subheadings such as 7317.00.50 (for stainless steel nails) depending on the country. Accurate classification is essential for customs clearance and duty assessment.

Packaging and Labeling Requirements

Stainless steel nails must be packaged in moisture-resistant, durable materials (e.g., sealed polypropylene bags inside corrugated cardboard boxes) to prevent corrosion and physical damage during transit. Each package should include clear labeling with:

– Product name and specifications (length, gauge, head type, material grade—e.g., 304 or 316 stainless steel)

– Quantity per unit

– Manufacturer or supplier name and contact information

– Batch or lot number

– Country of origin

– Applicable safety and handling symbols (e.g., “Fragile,” “Keep Dry”)

– Barcodes or SKUs for inventory tracking

Compliance with labeling regulations in target markets (e.g., OSHA in the U.S., CLP in the EU) is mandatory if hazard communication is required.

Import/Export Documentation

Standard documentation required for international shipment includes:

– Commercial Invoice (detailing product description, value, currency, terms of sale—e.g., FOB, CIF)

– Packing List (itemizing contents per package, gross/net weights, dimensions)

– Bill of Lading (for sea freight) or Air Waybill (for air freight)

– Certificate of Origin (may be required for preferential duty treatment under trade agreements)

– Material Test Report or Certificate of Compliance (confirming stainless steel grade and mechanical properties)

– Import Declaration (submitted by the importer to customs authorities)

Some countries may require additional documentation, such as an import permit or conformity assessment.

Regulatory and Safety Compliance

Stainless steel nails must comply with relevant regional and international standards:

– United States: Adherence to ASTM F1667 (Standard Specification for Driven Fasteners) and OSHA safety guidelines for workplace use.

– European Union: Compliance with Construction Products Regulation (CPR) if used in construction; CE marking may be required depending on application. Conformity with EN 14592 (Timber structures – Connectors) for structural use.

– Other Markets: Check local standards such as AS/NZS 1379 (Australia/New Zealand) or GB/T standards (China).

Ensure nails are free from hazardous substances under regulations like REACH (EU) and RoHS (if applicable). While fasteners are generally exempt from RoHS, material declarations may still be requested.

Transportation and Handling

- Use palletized shipments with stretch-wrapping to secure boxes and prevent shifting.

- Store and transport in dry, temperature-controlled environments to avoid moisture-induced corrosion.

- Handle with forklifts or pallet jacks; avoid dropping or dragging pallets.

- Follow carrier-specific guidelines for weight limits and stacking.

- For air freight, verify compliance with IATA dangerous goods regulations—stainless steel nails are typically non-hazardous but must be packed to prevent shifting or piercing packaging.

Customs Clearance and Duties

- Accurately declare the HS code, product description, value, and origin.

- Pay attention to anti-dumping or countervailing duties, especially when shipping from regions subject to trade remedies (e.g., certain Asian countries exporting to the U.S. or EU).

- Use a licensed customs broker to facilitate smooth clearance.

- Maintain records of all compliance documents for at least 5–7 years, depending on jurisdiction.

Environmental and Sustainability Considerations

- Stainless steel is recyclable; promote end-of-life recycling in product literature.

- Minimize packaging waste using recyclable or biodegradable materials where possible.

- Comply with environmental regulations such as the EU’s Packaging and Packaging Waste Directive.

Storage and Shelf Life

- Store in a dry, indoor environment with low humidity to prevent oxidation and pitting.

- Keep away from chloride-rich environments (e.g., coastal areas without climate control).

- Shelf life is indefinite if stored properly, though periodic inspection for surface corrosion is recommended.

After-Sales and Warranty Compliance

- Provide technical data sheets and installation guidelines.

- Honor product warranties related to material defects or performance issues.

- Ensure recall readiness in case of non-compliance or safety concerns.

By following this guide, suppliers and importers can ensure efficient logistics and full compliance when distributing stainless steel nails for nail guns across global markets.

In conclusion, sourcing stainless steel nails for use in nail guns requires careful consideration of several key factors to ensure optimal performance, durability, and compatibility. It is essential to select the correct grade of stainless steel—typically 304 or 316—based on the environmental conditions, with 316 being preferred for high-corrosion or marine environments. Nails must match the specifications of the nail gun, including diameter, length, shank type, and collation style (plastic, paper, or wire), to ensure smooth feeding and reliable operation. Sourcing from reputable suppliers who provide consistent quality, certifications, and compliance with industry standards helps prevent job-site failures and ensures long-term structural integrity. Additionally, evaluating total cost—balancing upfront price with longevity and maintenance savings—can lead to more cost-effective outcomes, especially in demanding applications. By prioritizing material quality, tool compatibility, and reliable supply chains, professionals can make informed sourcing decisions that enhance project efficiency and durability.