The global knife sharpener market is experiencing steady growth, driven by increasing demand for kitchen maintenance tools and rising consumer preference for high-quality cutlery. According to Grand View Research, the global kitchen tools market—which includes knife sharpeners—was valued at USD 12.4 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A key segment within this space is stainless steel knife sharpeners, favored for their durability, corrosion resistance, and precision performance. As consumer awareness around kitchen hygiene and cutting efficiency grows, manufacturers are investing in advanced sharpening technologies and ergonomic designs. Fueled by both household and commercial demand, particularly from professional kitchens and culinary enthusiasts, the market for stainless steel knife sharpeners continues to expand. Based on production capability, innovation, global reach, and customer reviews, the following list highlights the top 10 stainless steel knife sharpener manufacturers shaping the industry in 2024.

Top 10 Stainless Steel Knife Sharpener Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

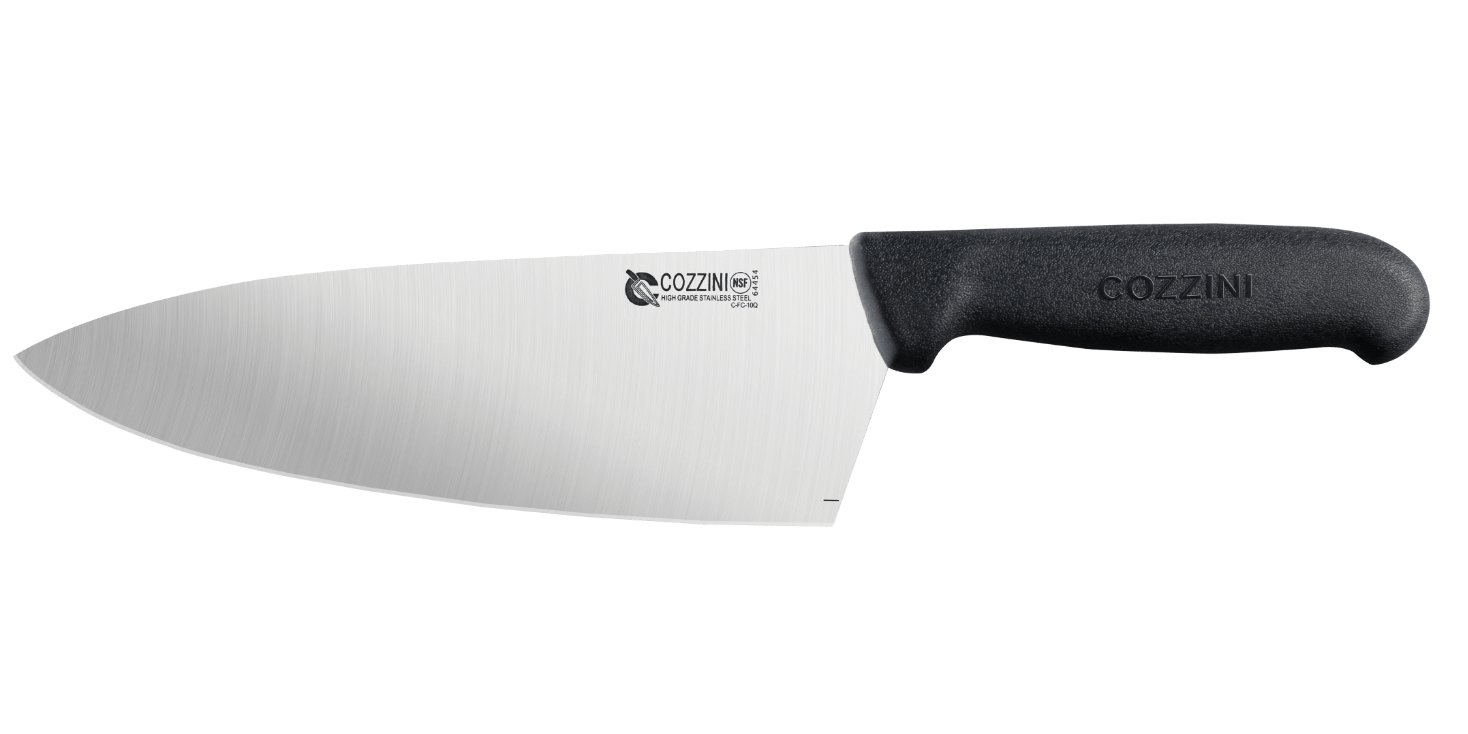

#1 Cozzini Bros

Domain Est. 2004

Website: cozzinibros.com

Key Highlights: Cozzini Bros is the only company with an exclusive, in-house-engineered sharpening process. Our Hydra technology, developed by our own engineers,…

#2 Lansky Knife Sharpeners

Domain Est. 1996

Website: lansky.com

Key Highlights: Lansky Sharpeners will sharpen anything from knives to gardening tools. Our selection of top-quality sharpening tools ensures precision and longevity….

#3 Professional Knives, Shears and Sharpeners

Domain Est. 1997

Website: global.tramontina.com

Key Highlights: Free delivery over $99 30-day returns…

#4 Knife sharpener

Domain Est. 1997

Website: cristel.com

Key Highlights: In stock Rating 4.8 (4) It will allow you to both sharpen (collect the wire) and sharpen your knife. Characteristics. Dishwasher-friendly….

#5 Pull Through Knife Sharpeners & Steels

Domain Est. 1997

Website: zwilling.com

Key Highlights: Free delivery over $79Buy knife sharpeners from the ZWILLING online shop. With the right knife care you can enjoy your kitchen knives for a long time….

#6 Victorinox Knife Sharpener in Red

Domain Est. 1998

Website: victorinox.com

Key Highlights: Crafted in high-carbon stainless steel, it makes effortless work of sharpening extra-large blades. Keep your culinary knife game on point for the long haul….

#7 Knife sharpener with two stages green

Domain Est. 2000

#8 Work Sharp

Domain Est. 2006

Website: worksharptools.com

Key Highlights: Free delivery over $100 Free 30-day returns…

#9 Knife Sharpening Stones

Domain Est. 2012

#10 Knife Maintenance

Domain Est. 2014

Expert Sourcing Insights for Stainless Steel Knife Sharpener

H2: 2026 Market Trends for Stainless Steel Knife Sharpeners

The global market for stainless steel knife sharpeners in 2026 is poised for steady growth, driven by evolving consumer behaviors, technological advancements, and heightened focus on kitchen efficiency and sustainability. Key trends shaping the industry include:

1. Rising Demand for Home Cooking and Culinary Enthusiasm:

Post-pandemic, home cooking remains a dominant trend, with consumers investing in quality kitchen tools. As more people explore gourmet cooking and maintain professional-grade knives at home, the need for effective, durable sharpening solutions like stainless steel sharpeners increases. This trend is amplified by the popularity of cooking shows and social media culinary content, encouraging skill development and tool maintenance.

2. Preference for Durable, Sustainable Kitchenware:

Consumers are increasingly prioritizing sustainability and longevity in their purchases. Stainless steel knife sharpeners—known for their durability, recyclability, and resistance to corrosion—align with eco-conscious values. This positions them favorably against plastic-based or disposable sharpening alternatives, supporting long-term market appeal.

3. Integration of Multi-Functional and Ergonomic Designs:

In 2026, product innovation focuses on multi-stage sharpening systems (e.g., coarse, fine, honing) integrated into compact, user-friendly stainless steel units. Ergonomic designs with non-slip bases and intuitive alignment guides enhance safety and ease of use, appealing to both novice and experienced users. These features differentiate premium products in a competitive market.

4. Growth in E-Commerce and Direct-to-Consumer Sales:

Online retail continues to dominate kitchenware sales, enabling brands to reach global audiences. Detailed product videos, customer reviews, and subscription models (e.g., replacement stone kits) enhance consumer confidence and drive repeat purchases. Brands leveraging digital marketing and influencer partnerships gain significant visibility.

5. Expansion in Emerging Markets:

Urbanization and rising disposable incomes in regions like Asia-Pacific and Latin America are fueling demand for modern kitchen tools. As middle-class households adopt Western cooking practices, the adoption of knife sharpeners—particularly durable stainless steel models—is expected to grow rapidly in these regions.

6. Competitive Pressure and Brand Differentiation:

With increasing market entrants, differentiation through design, warranty, and brand trust becomes critical. Established brands emphasize craftsmanship and heritage, while newer players focus on innovation and affordability. Certifications (e.g., food-grade stainless steel, BPA-free components) add credibility and influence purchasing decisions.

In summary, the 2026 stainless steel knife sharpener market will be characterized by innovation, sustainability, and consumer empowerment. Brands that combine functional design with transparent, eco-friendly practices are best positioned to capture market share in this evolving landscape.

Common Pitfalls When Sourcing Stainless Steel Knife Sharpeners (Quality & IP)

Sourcing stainless steel knife sharpeners, especially from international suppliers, involves navigating several potential pitfalls related to product quality and intellectual property (IP). Being aware of these risks can help ensure a reliable and legally compliant supply chain.

Quality-Related Pitfalls

Inconsistent Material Quality and Composition

Many suppliers may claim their sharpeners are made of “stainless steel” but fail to specify the grade (e.g., 304, 420, 440C). Lower-grade or non-certified stainless steel can lead to premature rusting, dulling, or structural failure. Without proper material verification through mill test certificates or third-party lab testing, buyers risk receiving substandard products that compromise performance and durability.

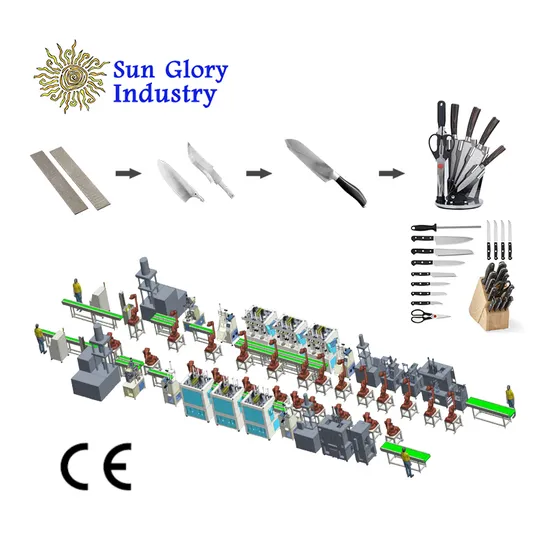

Poor Manufacturing Tolerances and Workmanship

Inaccurate grinding angles, uneven abrasive surfaces, or misaligned components can render a knife sharpener ineffective or even damage blades. Mass-produced units from low-cost manufacturers often lack precision in design and assembly. Without rigorous quality control processes—such as first-article inspection or production-line sampling—defective units may go undetected until they reach end users.

Inadequate or Misleading Performance Claims

Suppliers may exaggerate sharpening efficiency or compatibility (e.g., “works on all knives”) without supporting data. Some sharpeners may perform poorly on harder steels or serrated blades. Lack of standardized performance testing in the supply agreement can make it difficult to enforce quality expectations or return non-conforming goods.

Insufficient Durability and Long-Term Reliability

Many inexpensive sharpeners use weak structural designs or thin housing materials that degrade with regular use. Drop tests, wear resistance assessments, and lifecycle simulations are often skipped during sourcing, leading to high return rates and brand reputation damage after launch.

Intellectual Property (IP)-Related Pitfalls

Risk of Design and Patent Infringement

Popular knife sharpener designs—especially those with unique mechanisms (e.g., guided-angle systems, multi-stage sharpening slots)—may be protected by utility or design patents. Sourcing generic versions that closely mimic patented features can expose the buyer to legal liability, including cease-and-desist orders, customs seizures, or lawsuits, particularly in markets like the U.S. or EU.

Unauthorized Use of Branded or Licensed Technology

Some suppliers may offer sharpeners with features resembling proprietary technologies (e.g., “self-aligning guides” or “diamond-coated rods”) without proper licensing. Using such components without authorization can lead to IP disputes, even if the buyer was unaware of the infringement at the time of sourcing.

Lack of IP Ownership and Clear Documentation

Contracts with OEM/ODM suppliers often fail to specify who owns the design, tooling, or any improvements made during development. Without clear IP assignment clauses, buyers may lose control over tooling, face restrictions on sourcing from alternate suppliers, or be unable to protect their product in key markets.

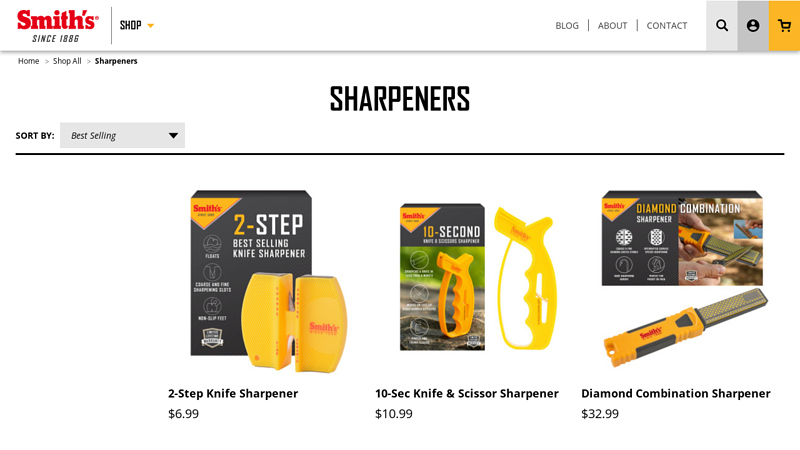

Counterfeit or Grey Market Components

Components such as tungsten carbide rods or diamond abrasives may be counterfeit or sourced from unauthorized distributors. This not only affects performance but can also implicate the buyer in IP violations if branded abrasive materials (e.g., DMT, Smith’s) are used without permission.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Specify stainless steel grades and require material certifications.

– Conduct pre-shipment inspections and performance testing.

– Perform IP clearance searches before finalizing designs.

– Include IP ownership and indemnification clauses in supplier contracts.

– Work with reputable manufacturers with verifiable compliance history.

Proactive due diligence in both quality assurance and IP compliance is essential to a successful and sustainable sourcing strategy.

Logistics & Compliance Guide for Stainless Steel Knife Sharpener

Product Classification and HS Code

The stainless steel knife sharpener is typically classified under the Harmonized System (HS) Code 8205.40.00, which covers “Hand tools (including glass cutters) not elsewhere specified or included.” This classification is crucial for determining import duties, taxes, and regulatory requirements in most countries. Confirm the exact HS code with local customs authorities, as minor variations may exist by region.

Import Regulations and Documentation

Importers must provide a commercial invoice, packing list, bill of lading or airway bill, and certificate of origin. Depending on the destination country, additional documentation such as a conformity assessment or product safety certification may be required. Ensure all documents clearly describe the product as a “stainless steel manual knife sharpener” to avoid customs delays or misclassification.

Product Safety and Compliance Standards

The knife sharpener must comply with relevant consumer safety regulations in the target market. In the European Union, compliance with the General Product Safety Regulation (GPSR) is mandatory. In the United States, adherence to the Consumer Product Safety Improvement Act (CPSIA) and guidelines from the Consumer Product Safety Commission (CPSC) is required. The product should be free of sharp edges (aside from the sharpening mechanism), pose no choking hazards, and carry appropriate safety warnings.

Labeling and Packaging Requirements

All units must feature permanent labeling including the manufacturer name, country of origin, model number, and safety instructions. Packaging should include multilingual safety warnings if sold in multiple regions. In the EU, the CE marking is required to indicate conformity with health, safety, and environmental protection standards. In the U.S., labels must comply with federal labeling laws, including tracking labels for children’s products if applicable.

Restricted Substances and Environmental Compliance

Verify that materials used, especially the stainless steel and any plastic components, comply with restrictions on hazardous substances. In the EU, ensure compliance with REACH and RoHS directives. Avoid the use of lead, cadmium, or phthalates above permitted levels. Consider recyclability of packaging materials to meet environmental standards such as those under the EU Packaging and Packaging Waste Directive.

Shipping and Handling Considerations

Package the knife sharpener in durable, protective materials to prevent damage during transit. Use corrugated cardboard with internal dividers if shipping in bulk. Due to its metallic components, ensure packages are securely sealed to avoid injury during handling. The product is generally non-hazardous and not subject to IATA/IMDG regulations for dangerous goods, but verify with carriers for any internal policies.

Customs Clearance and Duties

Prepare for duty assessment based on the HS code and declared value. Duty rates vary by country—check the latest tariff schedule in the destination market. Use an experienced customs broker to facilitate clearance, especially for first-time shipments. Provide accurate product descriptions and value declarations to avoid penalties or shipment holds.

Post-Import Obligations

Maintain records of compliance documentation, test reports, and import filings for a minimum of five years, as required in many jurisdictions. Monitor for product recalls or regulatory updates related to kitchen tools. Register the product with relevant safety authorities if required, such as the U.S. CPSC’s import surveillance program.

Recommended Best Practices

- Conduct third-party testing for safety and compliance before market entry.

- Work with certified suppliers who provide material declarations.

- Clearly communicate compliance responsibilities across the supply chain.

- Regularly review regulatory updates in all target markets.

Adhering to this guide ensures smooth logistics operations and full compliance with international trade and consumer safety standards for stainless steel knife sharpeners.

In conclusion, sourcing a stainless steel knife sharpener requires careful consideration of quality, durability, cost, and supplier reliability. Stainless steel is a preferred material due to its corrosion resistance, strength, and ability to maintain a precise edge over time. When selecting a supplier, it is essential to evaluate certifications, manufacturing standards, and customer reviews to ensure consistent product performance. Additionally, balancing cost-efficiency with long-term value helps in making a sustainable procurement decision. By partnering with trustworthy manufacturers and conducting thorough due diligence, businesses can secure high-quality stainless steel knife sharpeners that meet both functional requirements and customer expectations.