The global stainless steel fan market is experiencing robust growth, driven by increasing demand across industrial, commercial, and HVAC sectors. According to Grand View Research, the global industrial fan market size was valued at USD 28.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030, with stainless steel variants gaining preference due to their corrosion resistance, durability, and performance in harsh environments. Similarly, Mordor Intelligence projects steady expansion in the fan market, citing rising infrastructure development and stricter ventilation standards in manufacturing and wastewater treatment facilities as key growth catalysts. As industries prioritize longevity and efficiency, stainless steel fans have become a go-to solution. In this evolving landscape, a select group of manufacturers have emerged as leaders, combining engineering excellence with scalable production. Here are the top 9 stainless steel fan manufacturers shaping the market today.

Top 9 Stainless Steel Fan Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Twin City Fan & Blower

Domain Est. 1997

Website: tcf.com

Key Highlights: Twin City Fan & Blower is an industry-leading designer and manufacturer of high-quality custom, semi-custom and standard fans ranging from heavy-duty industrial ……

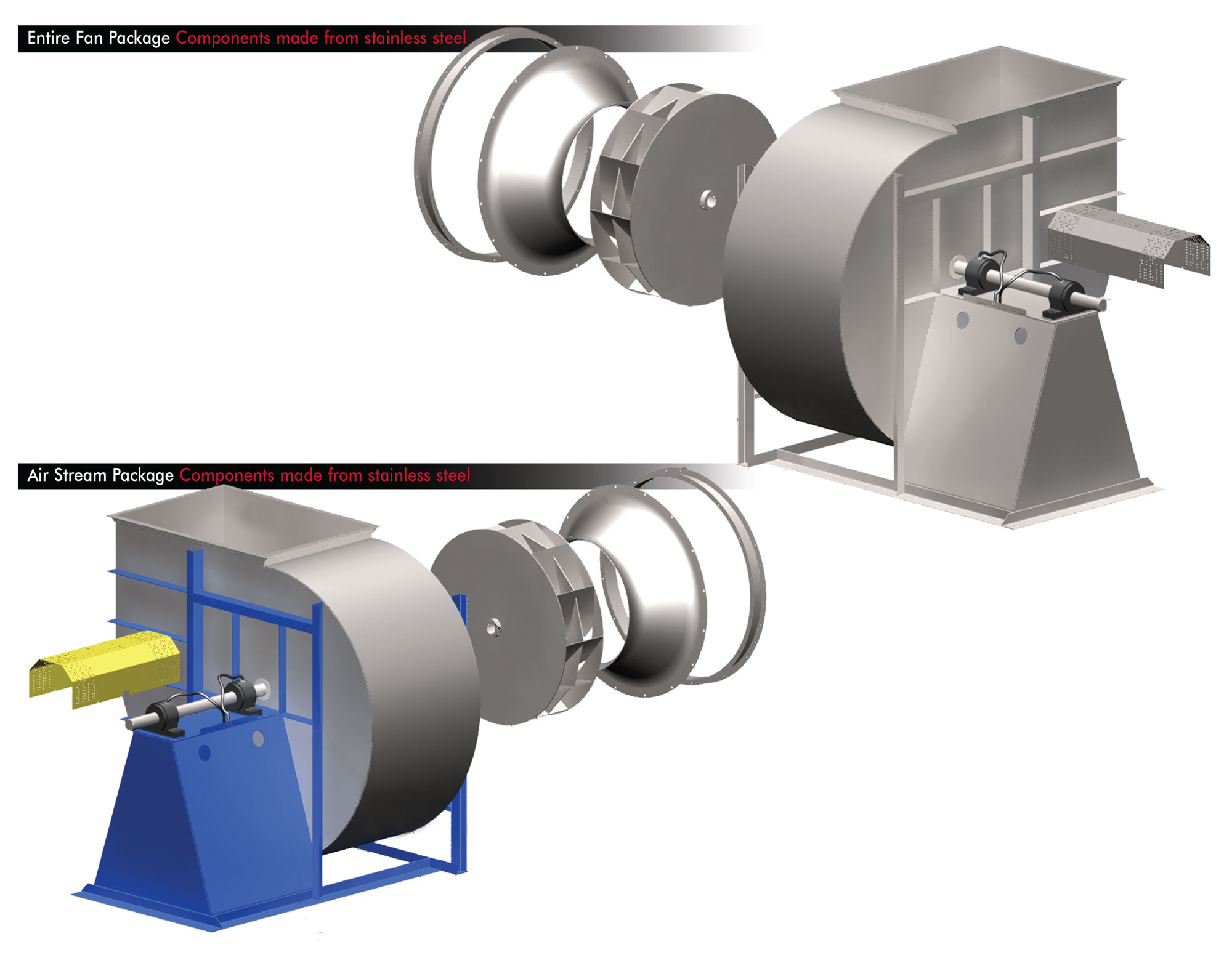

#2 Stainless Steel Fans and Blowers

Domain Est. 2002

Website: indairtech.com

Key Highlights: Industrial Air Technology, Corp. Stainless Steel Fan packages are designed for non-sanitary requirements where corrosion resistance is desired….

#3 Aerovent

Domain Est. 1996

Website: aerovent.com

Key Highlights: We offer a wide choice of construction materials and accessories for specialty applications including composite, stainless steel, aluminum, hot-dip galvanized ……

#4 Stainless Steel & Galvanized Fans

Domain Est. 1997

Website: pattersonfan.com

Key Highlights: Patterson Fan provides state of the art stainless steel & galvanized fans washdown-duty fans for all types of harsh industrial environments….

#5 Cincinnati Fan

Domain Est. 1998

Website: cincinnatifan.com

Key Highlights: Product Specialization. Cast aluminum, fabricated steel, aluminum and stainless steel industrial fans between 1/4 and 600 horsepower, including custom fans….

#6 Greenheck

Domain Est. 1995

Website: greenheck.com

Key Highlights: Greenheck is the leading supplier of air movement, air control and air conditioning equipment. Delivering reliable air comfort, safety and energy ……

#7 AJ Manufacturing

Domain Est. 1996

Website: ajmfg.com

Key Highlights: AJ Manufacturing produces some of the world’s best commercial stainless steel HVAC products, specifically designed for sterile environments….

#8 Loren Cook Company: Air Moving Experts

Domain Est. 1996

Website: lorencook.com

Key Highlights: Make fast fan selections and export schedules in seconds with our brand new selection software: CookSelect.Missing: stainless steel…

#9 All

Domain Est. 1999

Website: continentalfan.com

Key Highlights: Continental Fan’s customized all-stainless steel tubeaxial fan is the perfect ventilation solution for the challenge of a laboratory….

Expert Sourcing Insights for Stainless Steel Fan

H2: Projected Market Trends for Stainless Steel Fans in 2026

The market for stainless steel fans in 2026 is expected to be shaped by a confluence of global economic, technological, and regulatory forces, driving growth in specific sectors while demanding innovation and adaptation from manufacturers. Key trends include:

-

Sustained Growth Driven by Industrial & Infrastructure Expansion:

- Industrial Processes: Demand will remain robust in sectors like chemical processing, food & beverage, pharmaceuticals, and wastewater treatment, where corrosion resistance, hygiene, and durability are non-negotiable. Asia-Pacific’s continued industrialization, particularly in China, India, and Southeast Asia, will be a major growth engine.

- Infrastructure Projects: Increased global investment in water & wastewater treatment plants, power generation (including renewables and nuclear), and large-scale HVAC systems for commercial and public buildings will drive demand for reliable, long-life ventilation equipment like stainless steel fans.

- Focus on Efficiency: While stainless steel itself isn’t the most thermally conductive, the systems incorporating these fans will face pressure to improve energy efficiency. This drives demand for fans integrated with EC motors and smart controls, even in corrosive environments.

-

Heightened Focus on Sustainability & Circular Economy:

- Material Recyclability: Stainless steel’s inherent high recyclability (>90% globally) will become a significant selling point as ESG (Environmental, Social, Governance) criteria and regulations tighten. Manufacturers will emphasize the long lifespan and end-of-life recyclability of their products.

- Reduced Environmental Impact: Demand will grow for fans designed for lower energy consumption (e.g., optimized blade designs, EC motors) and reduced noise pollution, aligning with broader sustainability goals and stricter noise regulations in urban and industrial zones.

- Supply Chain Transparency: Expect increased scrutiny on the sourcing of raw materials (nickel, chromium, molybdenum) and manufacturing processes, pushing suppliers towards greater transparency and responsible sourcing certifications.

-

Rise of Smart & Connected Fan Systems:

- IIoT Integration: Stainless steel fans, particularly in critical industrial applications, will increasingly incorporate sensors (vibration, temperature, pressure) and connectivity (IIoT – Industrial Internet of Things). This enables predictive maintenance, remote monitoring, performance optimization, and reduced downtime.

- Demand for Analytics: The value will shift beyond the physical fan to the data and insights it provides. Manufacturers offering integrated monitoring platforms and analytics services will gain a competitive edge.

- Integration with Building Management Systems (BMS): Seamless integration of stainless steel HVAC fans into smart building networks will be essential for optimizing overall building energy use and environmental conditions.

-

Technological Innovation & Material Optimization:

- Advanced Alloys: Development and use of more cost-effective, high-performance stainless steel grades (e.g., lean duplex, new ferritic grades) offering better corrosion resistance or strength-to-weight ratios will continue, potentially expanding applications.

- Additive Manufacturing (3D Printing): While not mainstream for large fans yet, 3D printing will enable rapid prototyping of complex impeller designs and potentially the production of custom, low-volume components with optimized geometries for specific performance needs.

- Coatings & Hybrid Designs: Exploration of complementary protective coatings or hybrid designs (e.g., stainless steel housing with composite blades for specific applications) may offer performance or cost advantages in niche markets.

-

Geopolitical & Supply Chain Dynamics:

- Raw Material Volatility: Prices for key alloying elements (especially nickel) will remain susceptible to geopolitical tensions, mining output fluctuations, and demand from the electric vehicle battery sector (nickel). This necessitates robust supply chain management and potential hedging strategies.

- Regional Manufacturing Shifts: Companies may further diversify manufacturing locations beyond traditional hubs to mitigate trade risks (tariffs, sanctions) and reduce logistics costs, potentially boosting regional production capacity in key growth markets.

- Local Content Requirements: Infrastructure projects and government initiatives may increasingly favor suppliers with local manufacturing or significant local content, influencing investment decisions.

Conclusion for 2026:

The stainless steel fan market in 2026 will be characterized by steady growth driven by essential industrial and infrastructure needs, amplified by a strong undercurrent of digitalization and sustainability. Success will depend on manufacturers’ ability to:

* Leverage the inherent durability and recyclability of stainless steel as sustainability assets.

* Integrate smart technologies for predictive maintenance and performance optimization.

* Innovate with materials and designs to improve efficiency and reduce total cost of ownership.

* Navigate complex global supply chains and raw material markets.

* Adapt to regional regulatory and market-specific requirements.

While facing cost competition from alternative materials in less demanding environments, stainless steel fans will solidify their position as the premium, long-term solution in critical applications where reliability, hygiene, and corrosion resistance are paramount.

Common Pitfalls When Sourcing Stainless Steel Fans (Quality and IP Rating)

Sourcing stainless steel fans requires careful attention to both material quality and Ingress Protection (IP) ratings to ensure durability and performance in demanding environments. Overlooking key factors can lead to premature failure, safety hazards, and increased lifecycle costs. Below are common pitfalls to avoid:

1. Assuming All “Stainless Steel” is Equal

One of the most frequent mistakes is assuming that any stainless steel fan offers the same corrosion resistance. Different grades (e.g., 304 vs. 316) vary significantly in performance.

- Pitfall: Selecting a fan made from low-grade stainless steel (like 304) for marine or chemical environments where chloride exposure is high.

- Consequence: Pitting corrosion, rust formation, and shortened lifespan.

- Solution: Specify the correct grade—opt for 316 stainless steel in high-corrosion environments due to its molybdenum content, which enhances resistance to chlorides and acids.

2. Ignoring Material Certification and Traceability

Without proper documentation, it’s difficult to verify the authenticity of the stainless steel used.

- Pitfall: Accepting fans without mill test certificates (MTCs) or material test reports (MTRs).

- Consequence: Risk of receiving counterfeit or substandard materials that don’t meet claimed specifications.

- Solution: Require full traceability and certification for all stainless steel components, especially for critical applications in food, pharmaceutical, or offshore industries.

3. Overlooking Build Quality and Welding Standards

Even with high-grade stainless steel, poor fabrication can compromise performance.

- Pitfall: Fans with inconsistent or poorly finished welds, leading to crevices where moisture and contaminants can accumulate.

- Consequence: Corrosion initiation at weld points, reduced hygiene (in clean environments), and structural weakness.

- Solution: Insist on TIG (GTAW) welding, which provides cleaner, more precise welds, and verify surface passivation and electropolishing where required.

4. Misunderstanding IP Ratings and Their Application

IP ratings (e.g., IP55, IP68) indicate protection against solids and liquids, but incorrect interpretation can lead to inadequate protection.

- Pitfall: Assuming a higher IP number always means better performance, without considering the specific environment (e.g., selecting IP65 instead of IP66 in high-pressure washdown areas).

- Consequence: Water ingress, motor failure, and electrical hazards.

- Solution: Match the IP rating precisely to the operating environment—e.g., IP66 or higher for outdoor or washdown applications where high-pressure water jets are used.

5. Compromising on Motor and Electrical Component Protection

The fan casing may be stainless, but if motors or electrical enclosures lack proper IP protection, the entire unit is vulnerable.

- Pitfall: Focusing only on the fan housing while neglecting the motor housing’s IP rating.

- Consequence: Moisture ingress into the motor, leading to short circuits and failure.

- Solution: Ensure the entire assembly, including motor, terminal box, and cabling, meets the required IP rating. Look for fully sealed motors with appropriate insulation.

6. Failing to Consider Long-Term Maintenance and Cleanability

Poor design can make cleaning difficult and accelerate wear.

- Pitfall: Selecting fans with complex geometries, crevices, or non-smooth surfaces that trap debris and moisture.

- Consequence: Increased maintenance costs, hygiene risks in food or medical settings, and accelerated corrosion.

- Solution: Choose fans with smooth, continuous surfaces, minimal joints, and CIP (Clean-in-Place) compatibility where needed.

7. Prioritizing Low Cost Over Total Cost of Ownership

Cheaper fans may seem economical upfront but often lead to higher long-term costs.

- Pitfall: Selecting the lowest bidder without evaluating durability, warranty, and expected service life.

- Consequence: Frequent replacements, downtime, and higher operational costs.

- Solution: Evaluate total cost of ownership, including expected lifespan, maintenance needs, and energy efficiency.

By addressing these common pitfalls, buyers can ensure they source stainless steel fans that deliver reliable, long-term performance in challenging environments. Always partner with reputable suppliers who provide full technical documentation and support.

Logistics & Compliance Guide for Stainless Steel Fan

Product Classification and Documentation

Ensure accurate classification of the stainless steel fan under the appropriate Harmonized System (HS) code, typically falling under Chapter 84 (Nuclear Reactors, Boilers, Machinery), specifically headings such as 8414 (Air Pumps, Vacuum Pumps, Air or Gas Compressors, and Fans). Confirm the exact 8–10 digit code based on design, power source, and application (e.g., industrial, ventilation, HVAC). Maintain complete technical documentation including product specifications, material composition (e.g., AISI 304 or 316 stainless steel), performance data, and user manuals for customs clearance.

Export and Import Regulations

Comply with export control regulations of the country of origin, such as the Export Administration Regulations (EAR) in the U.S. or equivalent frameworks elsewhere. Verify if the fan contains any dual-use technology or exceeds performance thresholds requiring export licenses. On the import side, ensure adherence to the destination country’s standards for mechanical equipment, including conformity assessments, labeling requirements (e.g., CE marking in the EU, UKCA in the UK), and any local certification (e.g., CCC in China, PSE in Japan).

Packaging and Handling Requirements

Package the stainless steel fan securely to prevent mechanical damage and corrosion during transit. Use moisture-resistant materials and consider vapor corrosion inhibitors (VCI) if shipping to humid climates or over long durations. Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include product identification, HS code, country of origin, and safety warnings. Use durable, recyclable materials compliant with international packaging regulations (e.g., ISPM 15 for wooden pallets).

Transportation and Shipping

Choose appropriate transportation mode (air, sea, or land) based on delivery timelines, cost, and destination. For sea freight, ensure compliance with the International Maritime Dangerous Goods (IMDG) Code if batteries or hazardous components are included—though typical stainless steel fans are non-hazardous. Secure cargo properly in containers to avoid shifting. For air transport, adhere to IATA regulations, especially regarding lithium batteries if integrated controls are present.

Customs Clearance and Duties

Prepare a complete customs package including commercial invoice, packing list, bill of lading/air waybill, certificate of origin, and any required permits or test reports. Accurately declare the value of goods for duty calculation; undervaluation may lead to delays or penalties. Leverage free trade agreements (e.g., USMCA, RCEP) if applicable to reduce or eliminate import duties. Maintain records for at least five years for audit purposes.

Environmental and Safety Compliance

Ensure the product meets environmental directives such as the EU’s RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals). Confirm that manufacturing processes and materials do not contain restricted substances. Comply with energy efficiency standards if applicable (e.g., Ecodesign Directive 2009/125/EC for fans in the EU). Include disposal and recycling information in product documentation.

After-Sales and Warranty Logistics

Establish a reverse logistics process for returns, repairs, or warranty claims. Clearly define responsibilities for shipping costs, customs duties on returned goods, and repair turnaround times. Provide multilingual support documentation and ensure spare parts availability in key markets to maintain compliance with consumer protection laws.

Regulatory Monitoring and Updates

Assign responsibility for monitoring changes in international trade policies, sanctions, and technical standards. Subscribe to regulatory update services and conduct periodic compliance audits. Maintain open communication with freight forwarders, customs brokers, and local distributors to ensure ongoing adherence to evolving logistics and compliance requirements.

In conclusion, sourcing stainless steel fans requires a comprehensive evaluation of material quality, supplier reliability, performance specifications, and long-term cost efficiency. Stainless steel offers superior corrosion resistance, durability, and hygiene, making it ideal for demanding environments such as food processing, marine, chemical, and pharmaceutical industries. When selecting a supplier, it is essential to verify certifications, conduct quality audits, and assess compliance with international standards such as ASTM, ISO, or CE. Additionally, considering factors like energy efficiency, customization options, and after-sales support ensures optimal performance and longevity of the fan system. A strategic sourcing approach—balancing cost, quality, and reliability—will ultimately lead to a successful procurement decision and improved operational efficiency.