The global fastener market, valued at USD 95.2 billion in 2022, is projected to grow at a CAGR of 5.8% through 2030, driven by rising demand in automotive, construction, and industrial manufacturing sectors (Grand View Research, 2023). Within this expansive market, stainless steel pan head screws represent a critical product segment due to their corrosion resistance, mechanical strength, and versatility across assembly applications. With industries increasingly prioritizing durability and performance under extreme conditions, manufacturers specializing in precision-engineered stainless pan head screws are gaining strategic importance. This growing demand, coupled with regional shifts in manufacturing and tightening quality standards, has intensified competition among key players. As the market evolves, identifying the top manufacturers becomes essential for procurement teams and supply chain leaders aiming to balance cost, compliance, and reliability. Based on production scale, global reach, product innovation, and adherence to ISO and ASTM standards, the following ten companies stand out as leaders in the stainless pan head screw segment.

Top 10 Stainless Pan Head Screws Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Stainless Steel Screws & Fastener Manufacturers

Domain Est. 1997

Website: intercorpusa.com

Key Highlights: Intercorp is a trusted stainless steel fastener manufacturer that offers 410 Stainless Steel fasteners, as well as 300 Series Stainless Steel fasteners….

#2 Pan Head Machine Screws

Domain Est. 1999

Website: fastcoinc.com

Key Highlights: Our pan head machine screws are available in stainless steel and steel with zinc coating for applications requiring various levels of corrosion resistance….

#3 3″ Stainless Steel Phillips Pan Head Screws

Domain Est. 2000

Website: yostmfg.com

Key Highlights: In stock 30-day returnsThese 3″ long stainless steel screws have a Phillips pan head and a #10 shank. Quantity: 100 per box…

#4 Midwest Fastener

Domain Est. 2000

Website: fastenerconnection.com

Key Highlights: Midwest Fastener is a fastener supplier and fastener manufacturer offering construction fasteners, drywall screws, and much, much more….

#5 Marine Screw — Pan Head

Domain Est. 1995

Website: strongtie.com

Key Highlights: This pan-head screw is designed to fasten securely in fiberglass, plywood and wood-substitute materials in applications exposed to harsh marine or ……

#6 Wholesale Stainless Steel Products

Domain Est. 1998

Website: starstainless.com

Key Highlights: Star Stainless is a wholesale distributor specializing in Stainless Steel products. For over 70 years our STAR Service, Off-the-Shelf Inventory Programs and ……

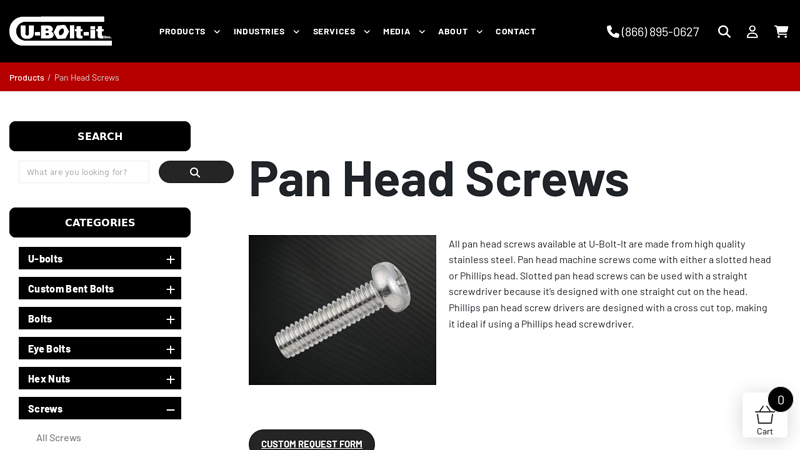

#7 Pan Head Screws

Domain Est. 1999

Website: uboltit.com

Key Highlights: All pan head screws available at U-Bolt-It are made from high quality stainless steel. Pan head machine screws come with either a slotted head or Phillips head….

#8 Pan Head

Domain Est. 1999

#9 Pan Head Screws

Domain Est. 2004

Website: distributioninternational.com

Key Highlights: 30-day returnsPan head screws are a common head type of non-countersunk screw head used to secure and fasten insulation. They have wide heads, a flat bearing surface….

#10 Self

Domain Est. 2005

Website: allpointsfasteners.com

Key Highlights: We have stainless steel self-drilling pan head screws in a variety of sizes. Check out our large variety of pan head screws online!…

Expert Sourcing Insights for Stainless Pan Head Screws

H2: Projected 2026 Market Trends for Stainless Steel Pan Head Screws

The global market for stainless steel pan head screws is expected to experience steady growth by 2026, driven by rising demand across key industrial and commercial sectors. Several strategic trends are shaping this trajectory:

-

Increased Demand from Construction and Infrastructure

The construction industry, especially in emerging economies, continues to prioritize durable and corrosion-resistant fasteners. Stainless steel pan head screws are favored for outdoor applications, architectural fittings, and marine environments due to their resistance to rust and extreme weather. Government investments in infrastructure development in regions like Asia-Pacific and the Middle East are expected to boost demand. -

Growth in Renewable Energy and Industrial Automation

The renewable energy sector—particularly solar panel installation and wind turbine assembly—relies heavily on corrosion-resistant fasteners. Stainless steel pan head screws are integral in these applications, contributing to long-term reliability. Additionally, the expansion of automated manufacturing systems requires precision-engineered components, further increasing demand for standardized, high-quality screws. -

Sustainability and Material Efficiency

Environmental regulations and corporate sustainability goals are encouraging manufacturers to adopt recyclable and long-lasting materials. Stainless steel is 100% recyclable and offers extended service life, reducing the need for replacements. This aligns with green building certifications and eco-conscious procurement policies, reinforcing market growth. -

Regional Market Shifts and Supply Chain Localization

While China remains a dominant producer, regional manufacturing hubs in India, Vietnam, and Eastern Europe are gaining prominence due to cost efficiency and supply chain diversification efforts. Companies are increasingly localizing production to mitigate geopolitical risks and reduce lead times, impacting import/export dynamics for pan head screws. -

Technological Advancements and Customization

Innovations in coating technologies, thread design, and anti-seizing treatments are enhancing the performance of stainless steel pan head screws. Market players are offering customized solutions for niche applications in aerospace, medical devices, and high-performance automotive systems, creating new revenue streams. -

Price Volatility and Raw Material Challenges

Fluctuations in the prices of nickel and chromium—key components of stainless steel—may impact production costs. However, advancements in material substitution and process optimization are helping manufacturers maintain margins without compromising quality.

In conclusion, the 2026 market for stainless steel pan head screws is set for moderate but consistent expansion, supported by infrastructure development, sustainability trends, and technological innovation. Companies that invest in product differentiation, supply chain resilience, and regional market penetration are likely to gain a competitive edge.

Common Pitfalls When Sourcing Stainless Pan Head Screws (Quality, IP)

Sourcing stainless pan head screws may seem straightforward, but several pitfalls can compromise product quality, performance, and compliance—especially when Intellectual Property (IP) and material integrity are concerns. Being aware of these issues helps ensure reliable procurement and protects your business from legal and operational risks.

Poor Material Quality and Misrepresentation

One of the most frequent issues is the misrepresentation of stainless steel grades. Suppliers may claim screws are made from high-grade materials like A2 (304) or A4 (316) stainless steel, but deliver lower-quality or counterfeit alternatives. Substandard alloys corrode more easily, lack required tensile strength, and fail in demanding environments. Always request material test reports (MTRs) and verify certifications such as ISO 3506 to confirm composition and mechanical properties.

Inconsistent Manufacturing Tolerances

Low-cost manufacturers, particularly in regions with less stringent quality control, often produce screws with inconsistent thread dimensions, head shape, or drive type. These variances can lead to assembly issues, reduced clamping force, or incompatibility with automated equipment. Specify tight tolerances and conduct regular product audits or third-party inspections to maintain consistency.

Lack of Traceability and Certification

Reputable suppliers provide full traceability, including batch numbers and compliance documentation. Without this, it becomes difficult to address quality failures or recall defective batches. Ensure your supplier adheres to international standards (e.g., ISO, ASTM) and can supply documentation for every shipment.

Intellectual Property (IP) Infringement Risks

When sourcing screws with proprietary drive systems (e.g., Torx with tamper-resistant variants, Spanner, or specialized security drives), there’s a risk of IP infringement. Many patented drive designs are protected, and unauthorized production or distribution can expose your company to legal action. Always verify that your supplier is licensed to manufacture patented drive types and avoid designs clearly mimicking protected technologies.

Counterfeit or Grey Market Products

Third-party sellers or unauthorized distributors may offer “genuine” branded screws at reduced prices, but these are often counterfeits. These products may look identical but fail under stress or environmental exposure. Source directly from authorized distributors or manufacturers to avoid grey market risks.

Inadequate Surface Finish and Corrosion Resistance

Even with proper alloy composition, poor surface finishing—such as improper passivation or inadequate cleaning—can reduce corrosion resistance. This is especially critical for A4 (316) screws used in marine or chemical environments. Confirm that screws undergo proper passivation per ASTM A967 and request salt spray test results when needed.

Conclusion

To avoid these pitfalls, conduct thorough due diligence on suppliers, demand verifiable certifications, and consider engaging independent inspectors for high-volume orders. Protecting against substandard quality and IP violations ensures long-term reliability and legal compliance in your supply chain.

Logistics & Compliance Guide for Stainless Pan Head Screws

This guide outlines key logistics considerations and compliance requirements for the procurement, transportation, storage, and use of stainless pan head screws in industrial and commercial applications.

Material and Product Specifications

Stainless pan head screws must adhere to recognized material standards such as ASTM A320 (for low-temperature applications), ASTM A193 (for high-temperature service), or ISO 3506 (corrosion-resistant stainless steel fasteners). Common grades include A2 (AISI 304) and A4 (AISI 316), with A4 recommended for marine or corrosive environments. Each shipment should include material certification (e.g., mill test certificate) confirming compliance with specified standards.

Packaging and Labeling Requirements

Screws must be packaged to prevent damage, corrosion, and contamination during transit. Use anti-static or moisture-resistant packaging where applicable. Each package must be clearly labeled with:

– Product description (e.g., “Stainless Steel Pan Head Screw, M6x20mm, A4-70”)

– Quantity

– Batch or lot number

– Material grade and standard

– Manufacturer or supplier name

– Date of manufacture

– Handling symbols (e.g., “Fragile,” “Keep Dry”)

Transportation and Handling

Use clean, dry transport vehicles protected from weather and contaminants. Avoid mixing with carbon steel or other metals to prevent galvanic corrosion. Handle packages with care to avoid deformation. Maintain separation from chemicals, acids, and salts during storage and transit.

Storage Conditions

Store stainless pan head screws in a dry, climate-controlled environment with relative humidity below 60%. Keep materials off the floor using pallets or shelves. Prevent direct contact with concrete, which can leach chlorides. Segregate different grades and sizes to avoid mix-ups and cross-contamination.

Regulatory Compliance

Ensure compliance with regional and international regulations, including:

– REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals – confirm no restricted substances in packaging or coatings.

– RoHS (EU): Restriction of Hazardous Substances – applicable if screws are used in electrical/electronic assemblies.

– UKCA/CE Marking: Required for screws sold in the UK/EU when part of a construction product or machinery.

– Customs and Import Regulations: Provide accurate HS codes (e.g., 7318.15 for stainless steel screws) and country of origin documentation.

Traceability and Documentation

Maintain full traceability from supplier to end use. Retain documentation including:

– Purchase orders

– Certificates of Conformance (CoC)

– Material Test Reports (MTRs)

– Batch/lot tracking records

– Inspection reports

This enables audit readiness and supports quality control or recall procedures if necessary.

Quality Inspection and Acceptance

Conduct incoming inspections to verify:

– Dimensions (per ISO 1580 or ANSI B18.6.3)

– Thread accuracy

– Surface finish and absence of defects

– Magnetic response (for verifying austenitic grades)

– Quantity and labeling accuracy

Use calibrated gauges and follow ANSI/ASQ Z1.4 or ISO 2859-1 sampling plans.

Environmental and Safety Considerations

Dispose of packaging materials in accordance with local waste regulations. While stainless steel is inert, manufacturing residues may require special handling. Provide Safety Data Sheets (SDS) if coatings or lubricants are applied. Ensure worker safety during handling with appropriate PPE to prevent injury from sharp edges.

In conclusion, sourcing stainless steel pan head screws requires careful consideration of factors such as material grade (typically 304 or 316 stainless steel for corrosion resistance), screw dimensions (diameter, length, and drive type), compliance with industry standards (e.g., ISO, DIN, or ANSI), and the reliability of the supplier. Ensuring the right combination of durability, strength, and environmental resistance is essential for optimal performance in applications ranging from construction and automotive to marine and outdoor equipment. By evaluating supplier reputation, cost-efficiency, lead times, and certification, businesses can secure high-quality fasteners that meet both technical specifications and project timelines. Proper sourcing not only enhances product reliability but also contributes to long-term cost savings and operational efficiency.