The global stainless steel market is experiencing robust expansion, driven by increasing demand across industries such as construction, automotive, and consumer goods. According to Grand View Research, the global stainless steel market size was valued at USD 138.6 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. China, as the world’s largest producer and consumer of stainless steel, plays a pivotal role in this growth—accounting for over 50% of global production in recent years, as reported by Mordor Intelligence. With an extensive industrial base, technological advancements, and strong government support for manufacturing, Chinese stainless steel manufacturers have emerged as key suppliers on the international stage. This dominance, combined with rising export volumes and continuous capacity expansion, positions China at the forefront of the global supply chain—making it essential to identify the leading companies shaping the industry’s future.

Top 10 Stainless China Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Shanghai Metal Corporation

Domain Est. 2001

Website: shanghaimetal.com

Key Highlights: Shanghai Metal Corporation (SMC) is one of the largest china’s manufacturer and supplier. From the acquisition of raw materials, packaging and exportation, ……

#2 China Stainless Steel Sheet, Welded Tube Manufacturer

Domain Est. 2012

Website: jiangsusteel.com

Key Highlights: Jiangsu Steel Group is the leading manufacturer of Stainless steel sheet, Round Bar, angle bar, flat bar, welded tube, Stainless steel pipe in china….

#3 Jiangsu Wujin Stainless Steel Pipe Group Co., Ltd.

Domain Est. 2012

Website: en.wjss.com.cn

Key Highlights: As a high-tech enterprise, Wujin Stainless engages in R&D, manufacturing and sales of stainless steel and nickel alloy seamless pipe, welded pipe, ……

#4 YC INOX

Domain Est. 2012

Website: ycinox.com

Key Highlights: YC INOX is the leading stainless steel manufacturer in Taiwan. We offer a variety of products such including stainless steel pipes, tubes, sheets, plates, ……

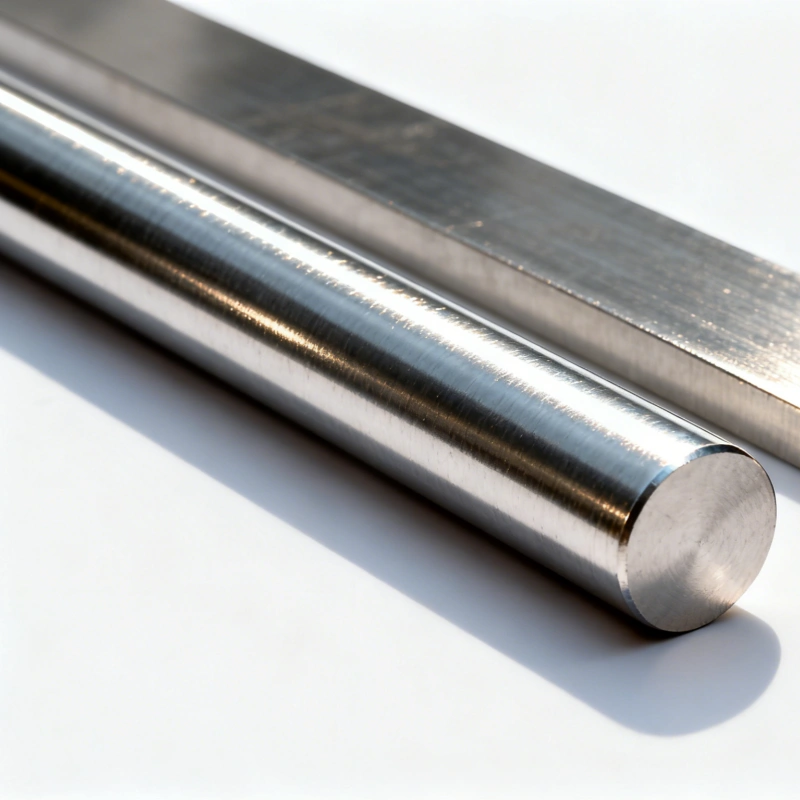

#5 Fushun Special / Professional Manufacturer of Special Steel

Domain Est. 2015

Website: fushunspecialsteel.com

Key Highlights: Fushun Special Steel is the one and only China company who exports tool steel and special alloys to more than 52 different countries, more than 5400 grades ……

#6 About Us

Domain Est. 2015 | Founded: 1991

Website: solidflask.com

Key Highlights: Official sponsor of China golf team-SOLIDWARE was established in 1991. Over the past 30 years, we have been specialized in the stainless steel insulation ware….

#7 Zhejiang Kingstone Housewares Co., Ltd.

Domain Est. 2020

Website: ks-housewares.com

Key Highlights: Kingstone now manufactures knives, tableware, outdoor tools, kitchenware, protective masks, robotic polishing equipment and full-automatic mask production ……

#8 Yongshang Special Materials

Domain Est. 1999

Website: china-stainless.com

Key Highlights: It is a specialized, refined, characteristic and innovative little giant enterprise integrating the production and sales of pipe fittings and steel pipes….

#9 Jiangsu Xinyuanxing Metal Products Co.,Ltd

Domain Est. 2021

Website: stainlessmetalsheet.com

Key Highlights: China quality Stainless Steel Sheet Coil and Stainless Steel Pipes suppliers Jiangsu Xinyuanxing Metal Products Co.,Ltd, We are committed to providing high ……

#10 Baoxin Steel

Domain Est. 2022

Website: baoxinsteel.com

Key Highlights: Baoxin Steel is your reliable stainless steel metal supplier. We source our material from approved steel factories worldwide and offer a range of stock forms, ……

Expert Sourcing Insights for Stainless China

H2 2026 Market Trends for Stainless Steel in China

As the global industrial landscape evolves and China continues to assert its dominance in the stainless steel sector, the second half of 2026 (H2 2026) is expected to reflect a confluence of economic, technological, and regulatory developments shaping the Chinese stainless steel market. Below is a detailed analysis of key trends anticipated during this period:

1. Domestic Demand Recovery Amid Infrastructure and Green Energy Push

By H2 2026, China’s domestic demand for stainless steel is projected to show moderate growth, driven primarily by government-led infrastructure projects and the expansion of green energy technologies. The Chinese government’s continued emphasis on “dual carbon” goals (carbon peak by 2030, carbon neutrality by 2060) is accelerating investments in renewable energy infrastructure — including solar panel frames, wind turbine components, and hydrogen storage systems — all of which rely heavily on corrosion-resistant stainless steel.

- Construction and Urban Development: Rebound in real estate activity, particularly in high-end residential and commercial projects, is expected to support demand for architectural stainless steel (e.g., elevators, facades, and handrails).

- Transportation Sector: Increased production of electric vehicles (EVs) and high-speed rail projects will drive demand for specialized stainless grades used in battery enclosures and lightweight structures.

2. Export Dynamics Under Global Trade Pressures

China remains the world’s largest exporter of stainless steel, but H2 2026 will likely see continued trade friction and anti-dumping measures from key markets such as the EU, the U.S., and Southeast Asia.

- Trade Diversification: Chinese producers are increasingly redirecting exports to emerging markets in Africa, the Middle East, and Latin America to mitigate protectionist policies in traditional markets.

- Downstream Integration: More Chinese stainless steel companies are establishing overseas processing hubs (e.g., in Indonesia and Vietnam) to bypass tariffs and serve regional demand directly.

3. Raw Material Volatility and Supply Chain Adjustments

Chromium, nickel, and molybdenum prices remain volatile due to geopolitical tensions (e.g., Russia-Ukraine, Indonesia’s export policies) and supply chain constraints.

- Nickel Market Stabilization: By H2 2026, the market for nickel — especially high-purity Class I nickel used in premium stainless grades — is expected to stabilize somewhat due to increased production from Indonesia and new refining capacity in China.

- Ferrous Scrap Utilization: Chinese mills are increasing the use of recycled stainless scrap to reduce reliance on primary raw materials and lower carbon emissions, supported by national circular economy policies.

4. Technological Advancements and Product Innovation

Chinese steelmakers are investing heavily in R&D to produce higher-value stainless steel products, such as duplex and super-austenitic grades, for use in chemical processing, marine, and pharmaceutical industries.

- Digitalization and Smart Manufacturing: Adoption of AI-driven quality control, predictive maintenance, and energy optimization systems is improving yield rates and reducing production costs in major mills.

- Green Steel Initiatives: Several leading producers (e.g., Tsingshan, Baowu) are piloting hydrogen-based reduction and electric arc furnace (EAF) technologies to reduce CO₂ emissions, aligning with national decarbonization mandates.

5. Regulatory and Environmental Pressures

Environmental regulations are tightening across China, with the Ministry of Ecology and Environment enforcing stricter emissions standards for steel production.

- Capacity Optimization: The government continues to phase out outdated blast furnaces and promote consolidation among mid-tier producers, leading to a more concentrated and efficient industry structure.

- Carbon Trading Influence: The expansion of China’s national carbon market to include more steel producers will increase operational costs for high-emission facilities, incentivizing low-carbon innovation.

6. Price Trends and Market Sentiment

Stainless steel prices in H2 2026 are expected to remain range-bound, influenced by fluctuating raw material costs and seasonal demand cycles.

- 300-Series Dominance: Austenitic 304 and 316 grades will continue to dominate, but demand for 200-series (manganese-based) stainless is growing in cost-sensitive applications, particularly in household appliances and consumer goods.

- Inventory Management: Producers are adopting just-in-time inventory models and forward pricing agreements to manage volatility and improve cash flow.

Conclusion

H2 2026 will be a pivotal period for China’s stainless steel industry, characterized by structural transformation, green transition, and strategic adaptation to global market dynamics. While challenges such as trade barriers and raw material volatility persist, the sector is poised for long-term resilience through innovation, sustainability initiatives, and diversification. Companies that invest in high-end products, digital transformation, and low-carbon technologies are likely to gain a competitive edge in the evolving landscape.

Common Pitfalls Sourcing Stainless China: Quality and Intellectual Property Risks

Sourcing stainless steel tableware (“Stainless China”) from China offers cost advantages but comes with significant risks, particularly concerning product quality and intellectual property (IP) protection. Being aware of these common pitfalls is essential for mitigating potential losses and reputational damage.

Quality Inconsistencies and Substandard Materials

One of the most frequent issues is inconsistent product quality. Suppliers may use substandard grades of stainless steel (e.g., non-food-grade 201 instead of 304/18-8), leading to corrosion, rusting, or leaching of harmful metals. Variations in thickness, poor welding, rough edges, and inconsistent finishing are also common. Without stringent quality control and third-party inspections, buyers risk receiving goods that fail to meet safety standards or customer expectations.

Misrepresentation of Material Specifications

Suppliers may falsely advertise products as “18/10” or “304-grade” stainless steel when they are not. This mislabeling can mislead buyers about the product’s durability and safety. Verification through material certifications (e.g., Mill Test Certificates) and independent lab testing is crucial but often overlooked, especially by inexperienced importers.

Lack of Compliance with International Safety Standards

Stainless steel products intended for food contact must comply with regulations such as FDA (USA), LFGB (Germany), or EU food safety directives. Some Chinese manufacturers may not be fully aware of or adhere to these standards. Products may contain excessive levels of nickel, chromium, or other substances, posing health risks and leading to customs rejections or recalls.

Intellectual Property Infringement

Sourcing from China carries a high risk of IP violation, especially when dealing with branded or patented designs. Suppliers may replicate copyrighted patterns, logos, or patented product features without authorization. Even if the buyer is unaware, importing such goods can result in legal action, seizure of shipments, and damage to brand reputation. Conducting thorough due diligence and securing written assurances of IP compliance is essential.

Weak Contractual Protections and Enforcement Challenges

Many sourcing agreements lack robust clauses on quality, IP rights, and remedies for non-compliance. Enforcing contracts in China can be difficult and costly due to legal and jurisdictional complexities. Without clear terms and dispute resolution mechanisms, buyers may struggle to obtain refunds, replacements, or compensation for damages.

Supply Chain Opacity and Hidden Subcontracting

Some suppliers outsource production to unapproved subcontractors to cut costs, resulting in uncontrolled quality and increased IP risks. This lack of transparency makes it difficult to trace the origin of materials and ensure compliance with agreed-upon standards.

Inadequate Quality Control Processes

Relying solely on supplier self-inspection is risky. Without on-site audits, pre-shipment inspections (PSI), or third-party quality checks, defects may go undetected until products reach the end customer. Implementing a structured quality assurance process is critical to avoid large-scale rejections or returns.

Conclusion

To avoid these pitfalls, importers should conduct thorough supplier vetting, require material certifications, perform independent testing, include strong IP and quality clauses in contracts, and invest in regular audits and inspections. Partnering with reputable sourcing agents or legal experts familiar with Chinese manufacturing practices can also significantly reduce risks.

Logistics & Compliance Guide for Stainless China

Overview

Stainless China refers to stainless steel products manufactured in China, which are widely exported globally for use in construction, automotive, food processing, and industrial applications. Ensuring efficient logistics and adherence to international compliance standards is critical for timely delivery, cost optimization, and regulatory acceptance in target markets.

Export Documentation Requirements

All stainless steel shipments from China require accurate and complete documentation to clear customs and comply with trade regulations. Key documents include:

– Commercial Invoice: Must detail product description, quantity, value, and Incoterms.

– Packing List: Specifies packaging type, weight, dimensions, and item breakdown.

– Bill of Lading (B/L) or Air Waybill (AWB): Serves as the contract of carriage and title document.

– Certificate of Origin: Often required for tariff determination; can be issued by a chamber of commerce or through a China-issued Form A for GSP-eligible countries.

– Export License: May be required for certain high-grade or dual-use stainless alloys, depending on destination.

Product Classification & HS Codes

Proper Harmonized System (HS) code classification ensures accurate tariffs and regulatory treatment. Common HS codes for stainless steel from China include:

– 7219: Flat-rolled stainless steel, not alloyed.

– 7220: Flat-rolled stainless steel, alloyed.

– 7302: Stainless steel rails and railway track materials.

– 7304: Stainless steel tubes and pipes.

Misclassification can lead to customs delays, fines, or shipment rejection.

Compliance with International Standards

Stainless steel products must meet the technical and safety standards of the importing country:

– United States: Complies with ASTM standards (e.g., ASTM A240 for plate/sheet). Subject to anti-dumping and countervailing duties (AD/CVD) investigations; ensure eligibility for exclusion if applicable.

– European Union: Must meet EN standards (e.g., EN 10088) and may require CE marking for certain construction-related products.

– Canada: Follows CSA standards and may be subject to similar trade remedies as the U.S.

– Australia: Complies with AS/NZS standards.

Third-party testing and mill test certificates (MTCs) in accordance with ISO 10474 are often required.

Anti-Dumping & Trade Remedies

Many countries impose anti-dumping duties on Chinese stainless steel due to pricing concerns:

– Verify current duty rates via official customs databases (e.g., U.S. ITC, EU TARIC).

– Explore use of third countries for transshipment only if rules of origin are strictly followed to avoid circumvention penalties.

– Maintain transparent pricing and transaction records to support legitimate trade claims.

Packaging & Labeling Requirements

- Products must be packaged to prevent corrosion and damage during transit (e.g., waterproof wrapping, wooden crating for coils).

- Labels must include material grade, heat number, dimensions, manufacturer name, and compliance markings as required by destination market.

- Language: Labels and documentation may need translation into the local official language (e.g., Spanish for Mexico, French for Canada).

Shipping & Logistics Options

- Sea Freight: Most common for bulk shipments; use FCL (Full Container Load) or LCL (Less than Container Load) based on volume.

- Incoterms: Clearly define responsibilities using standard terms (e.g., FOB Shanghai, CIF Rotterdam).

- Lead Times: Allow 2–6 weeks for ocean freight depending on destination; include buffer for customs inspection.

- Inland Transport: Coordinate trucking or rail from manufacturing sites (e.g., Guangdong, Zhejiang) to ports like Shanghai, Ningbo, or Shenzhen.

Environmental & Regulatory Compliance

- Comply with China’s export environmental regulations, including restrictions on hazardous substances (RoHS-like standards).

- Adhere to international frameworks such as REACH (EU) for chemical content disclosures.

- Ensure conflict minerals policy compliance if applicable (e.g., chromium, nickel sourcing).

Risk Mitigation Strategies

- Partner with licensed freight forwarders experienced in Chinese steel exports.

- Obtain cargo insurance covering damage, delay, and non-delivery.

- Conduct supplier audits to ensure consistent quality and compliance.

- Monitor changes in trade policies via official sources (e.g., MOFCOM, WTO notifications).

Conclusion

Successfully navigating the logistics and compliance landscape for stainless steel exports from China requires meticulous documentation, adherence to international standards, and proactive management of trade regulations. By aligning with best practices in classification, certification, and shipping, importers and exporters can ensure smooth cross-border transactions and market access.

In conclusion, sourcing stainless steel products from China offers a compelling combination of cost-efficiency, extensive manufacturing capabilities, and access to a wide range of suppliers with varying levels of specialization and capacity. The country’s well-established supply chain, technological advancements, and ability to scale production make it an attractive option for businesses looking to import high-quality stainless steel goods at competitive prices. However, successful sourcing requires due diligence—ensuring supplier credibility, maintaining consistent quality control, understanding compliance standards, and managing logistics effectively. By leveraging strong communication, proper vetting processes, and possibly partnering with local agents or using platforms like Alibaba with verified suppliers, companies can mitigate risks and build reliable, long-term sourcing relationships. Ultimately, when approached strategically, sourcing stainless steel products from China can significantly enhance supply chain efficiency and competitiveness in the global market.