The global stainless steel channel market is experiencing steady growth, driven by rising demand across construction, infrastructure, and industrial manufacturing sectors. According to Grand View Research, the global stainless steel market was valued at USD 157.9 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030, fueled by increasing urbanization and infrastructure development—particularly in Asia Pacific and the Middle East. Similarly, Mordor Intelligence projects a CAGR of over 5.4% for the stainless steel market during the forecast period of 2024–2029, underpinned by growing applications in transportation, energy, and architectural structures where stainless channels are critical for their strength, corrosion resistance, and durability. As demand for high-performance structural components intensifies, identifying leading stainless channel manufacturers becomes crucial for supply chain reliability and product quality. The following analysis highlights the top nine manufacturers shaping this evolving landscape through innovation, scale, and global reach.

Top 9 Stainless Channel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Gibson Stainless & Specialty Inc.

Domain Est. 2002 | Founded: 1995

Website: gibsonstainless.com

Key Highlights: Founded in 1995, Gibson Stainless is a family-owned and operated company that focuses exclusively on manufacturing the highest quality stainless steel ……

#2 Hot Rolled & 304 Stainless Steel Channels

Domain Est. 1996

Website: onealsteel.com

Key Highlights: We stock hot rolled, aluminum, and stainless steel channel for a variety of applications. Shop channel or request a quote for your next project now!…

#3 Channels

Domain Est. 1999

Website: pennstainless.com

Key Highlights: Penn Stainless Products supplies stainless channels in 304/304L and 316/316L. Larger channels in excess of 24′′ can be manufactured utilizing laser fusion ……

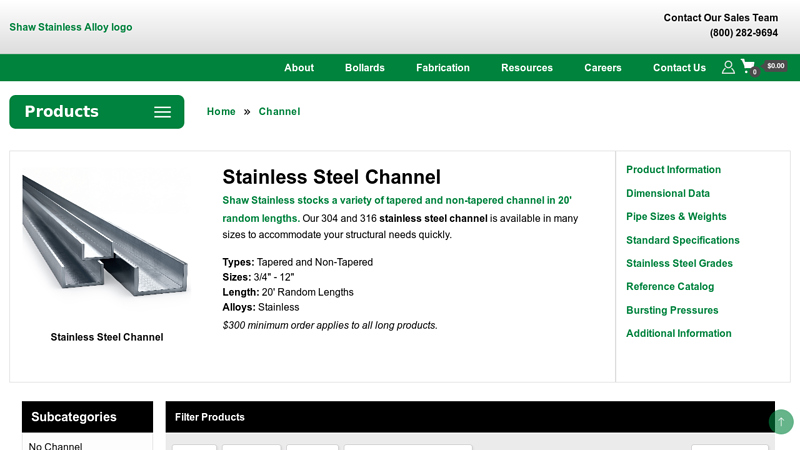

#4 Stainless Steel Channel

Domain Est. 1999

Website: stainlessandalloy.com

Key Highlights: Our 304 and 316 stainless steel channel is available in many sizes to accommodate your structural needs quickly. Types: Tapered and Non-Tapered Sizes: 3/4″ – 12 ……

#5 North American Stainless

Domain Est. 1999 | Founded: 1990

Website: northamericanstainless.com

Key Highlights: North American Stainless is part of the Acerinox Group. Founded in 1990, North American Stainless (NAS) has undertaken several phases of expansion to become ……

#6 of stainless steels

Domain Est. 2000

Website: worldstainless.org

Key Highlights: worldstainless.org is the most comprehensive site for anyone interested in stainless steels. You will find documentation on the properties, ……

#7 304 & 316 Steel Structural Channels

Domain Est. 2001

Website: stainlesstubular.com

Key Highlights: We offer 304/304L and 316/316L stainless channels in standard size ranges, both mill finish and polished….

#8 Stainless steel channels

Domain Est. 2005

Website: stainless-structurals.com

Key Highlights: We produce and distribute hot rolled and laser fused stainless steel channels throughout the world in both imperial and metric sizes….

#9 Stainless Shapes

Domain Est. 2006

Website: stainlessshapes.net

Key Highlights: Stainless Shapes is a supplier of Stainless, Titanium and Nickel Alloys. We offer beams, bars, plates, sheets, tubes and more with proven quality….

Expert Sourcing Insights for Stainless Channel

2026 Market Trends for Stainless Steel Channel: H2 Outlook

As we approach the second half of 2026, the global stainless steel channel market is poised for continued evolution, shaped by macroeconomic forces, technological advancements, and shifting end-user demands. Here’s a comprehensive analysis of the key trends expected to define H2 2026:

1. Steady Demand Growth Driven by Key Sectors:

* Construction & Infrastructure: Sustained investment in commercial buildings, hospitals, transportation hubs (airports, metro systems), and public infrastructure, particularly in emerging economies (Southeast Asia, India, Middle East) and North America’s infrastructure renewal programs, will remain a primary driver. Demand for architectural applications (handrails, facades, structural supports) requiring specific grades (304, 316) will be robust.

* Industrial & Manufacturing: Recovery and expansion in manufacturing, especially in high-tech industries (semiconductors, advanced machinery) and food & beverage processing, will bolster demand for durable, corrosion-resistant structural components. The focus on hygiene and longevity favors stainless steel channels.

* Renewable Energy: The accelerating global transition to renewables continues to be a significant tailwind. Solar power installations (mounting structures) and offshore wind farms (platform components, corrosion resistance) are major consumers, particularly of high-grade austenitic (316/L) and duplex (2205) stainless channels.

* Transportation: While automotive use is more niche (luxury, specialty vehicles), demand in rail (rolling stock interiors, structural elements) and shipbuilding (interiors, specific fittings) remains stable, supported by safety and durability requirements.

2. Supply Chain Stability Improves, but Challenges Linger:

* Normalization: By H2 2026, supply chains are expected to be significantly more stable compared to the volatility seen post-pandemic and during the energy crisis. Logistics bottlenecks should be largely resolved.

* Raw Material Focus: Nickel and Chromium prices will remain critical watchpoints. While likely more stable than previous peaks, geopolitical tensions (especially around key producing regions like Indonesia, South Africa, Russia) and energy costs (especially in Europe) could cause fluctuations impacting final channel pricing. Increased recycling rates may provide some buffer.

* Regionalization & Diversification: Manufacturers and buyers will continue efforts to diversify sourcing and build regional resilience. Nearshoring and friend-shoring trends, particularly in North America and Europe, may lead to increased local production capacity or sourcing from geopolitically stable regions.

3. Sustainability & ESG Imperatives Intensify:

* Circular Economy Focus: Demand for stainless steel channels made with high recycled content will surge as ESG (Environmental, Social, Governance) reporting becomes mandatory in many regions (e.g., EU CSRD). Producers will emphasize their scrap utilization rates and low lifecycle environmental impact.

* Carbon Footprint Transparency: Buyers, especially in construction and large corporates, will demand detailed Environmental Product Declarations (EPDs) for channels. Producers investing in decarbonization (hydrogen-based DRI, renewable energy in mills) will gain a competitive edge. “Green Steel” channels will command a premium.

* Regulatory Pressure: Stricter environmental regulations on emissions and waste management will increase production costs for some players, potentially consolidating the market towards larger, more efficient, and compliant producers.

4. Technological Advancements & Value-Added Services:

* Precision & Efficiency: Adoption of advanced laser cutting, CNC bending, and automated fabrication lines will increase, allowing for tighter tolerances, complex profiles, and faster turnaround times, meeting demands for customized solutions.

* Digital Integration: B2B platforms and digital marketplaces will mature, offering better price transparency, inventory visibility, and streamlined ordering. AI may be used for demand forecasting and supply chain optimization.

* Value-Added Processing: Suppliers offering pre-finished channels (pre-painted, specific surface finishes like 2B, BA, No. 4), pre-cut-to-length, or pre-assembled kits will capture more market share by reducing downstream processing costs for fabricators.

5. Competitive Landscape & Pricing Dynamics:

* Consolidation: The market may see further consolidation among mid-tier producers seeking economies of scale and enhanced capabilities to meet sustainability and technological demands.

* Differentiation: Competition will shift beyond just price. Success will hinge on reliability, technical expertise, sustainability credentials, and the ability to provide integrated solutions and technical support.

* Pricing: Prices are expected to stabilize in H2 2026 compared to previous volatility, but remain underpinned by raw material costs and energy expenses. Premiums will be demanded for high-grade, specialty (duplex, super austenitic), and sustainably produced channels. Price sensitivity may persist in highly competitive segments.

Conclusion for H2 2026:

The stainless steel channel market in the second half of 2026 will be characterized by resilient demand from core sectors like construction and renewables, operating within a more stable but cost-conscious environment. The overarching themes will be sustainability and digitalization. Success will belong to producers and suppliers who can demonstrably deliver low-carbon, recycled-content products through efficient, technologically advanced processes, while offering reliable supply and value-added services. While challenges related to raw materials and energy persist, the market outlook is cautiously optimistic, driven by long-term structural trends favoring durable, sustainable materials like stainless steel.

Common Pitfalls When Sourcing Stainless Steel Channel: Quality and Intellectual Property Risks

Sourcing stainless steel channel can present several challenges, particularly concerning material quality and intellectual property (IP) protection. Being aware of these pitfalls helps ensure you receive reliable, compliant, and legally sound products.

Poor Material Quality and Non-Compliance

One of the most frequent issues is receiving stainless steel channel that fails to meet specified grades or industry standards. Suppliers may misrepresent the alloy (e.g., passing off 201 or 304L as 316), leading to premature corrosion or structural failure. Lack of proper mill test reports (MTRs) or falsified certifications can mask substandard materials. Additionally, dimensional inaccuracies, inconsistent finishes, or poor weld integrity may compromise performance, especially in critical applications.

Counterfeit or Unauthorized Manufacturing

Unauthorized production of branded or patented stainless steel profiles is a growing concern. Some suppliers may replicate proprietary channel designs protected by IP rights, offering counterfeit products at lower prices. Purchasing such items not only violates intellectual property laws but also exposes buyers to legal liability and reputational damage. These knock-offs often lack rigorous quality control, further increasing performance and safety risks.

Inadequate Supply Chain Transparency

Opaque supply chains make it difficult to verify the origin of materials and manufacturing processes. Without traceability, it’s challenging to confirm whether the stainless steel was produced in facilities adhering to environmental, labor, and quality standards. This lack of transparency increases the risk of receiving non-compliant or ethically questionable products.

Insufficient Documentation and Certification

Reliable sourcing requires comprehensive documentation, including material test reports, certificates of conformance (CoC), and compliance with standards such as ASTM, ISO, or EN. Suppliers that provide incomplete, generic, or forged paperwork create uncertainty about material authenticity and suitability for the intended application.

Ignoring IP Rights in Technical Specifications

When providing detailed drawings or custom channel profiles to suppliers—especially overseas manufacturers—there’s a risk of IP theft. Suppliers may duplicate and resell your design without authorization. Without proper non-disclosure agreements (NDAs) or IP clauses in contracts, protecting proprietary designs becomes difficult.

To mitigate these risks, conduct thorough due diligence on suppliers, require verifiable certifications, protect technical designs legally, and consider third-party inspections during production.

Logistics & Compliance Guide for Stainless Channel

This guide outlines the key logistics and compliance considerations for the shipping, handling, and regulatory adherence related to stainless steel channels. Proper management ensures product integrity, regulatory compliance, and supply chain efficiency.

Product Specifications and Handling

Stainless steel channels are structural profiles typically made from grades such as 304, 316, or 316L. They are prone to surface damage, corrosion (in contaminated environments), and deformation if improperly stored or handled. Key handling practices include:

- Use padded slings or lifting beams to avoid surface marring during lifting.

- Store channels off the ground on wooden skids to prevent moisture contact.

- Keep in dry, covered areas away from carbon steel to prevent cross-contamination and rust staining.

- Avoid dragging or sliding channels to prevent edge damage.

Packaging and Marking Requirements

Proper packaging ensures protection during transit and meets international shipping standards:

- Bundle channels securely using steel or nylon strapping.

- Apply protective end caps or plastic wrapping to prevent corrosion and physical damage.

- Label each bundle with legible markings including:

- Material grade (e.g., ASTM A276, AISI 304)

- Dimensions (depth, flange width, thickness, length)

- Heat number or batch traceability

- Manufacturer name and logo

- Handling instructions (e.g., “Do Not Drag,” “Protect from Moisture”)

Transportation and Shipping

Transportation methods must align with the size, weight, and destination of the stainless channel orders:

- Use flatbed trucks or enclosed trailers depending on environmental exposure risks.

- Secure loads with chains or straps to prevent shifting during transit.

- For international shipments, comply with IMDG Code (if applicable) and containerization standards.

- Provide Material Safety Data Sheets (MSDS/SDS) even though stainless steel is non-hazardous, as some coatings or treatments may require documentation.

Regulatory and Compliance Standards

Ensure all stainless channels meet relevant international and regional standards:

- ASTM Standards: ASTM A276 (standard specification for stainless steel bars and shapes), ASTM A484 (general requirements for stainless steel).

- ISO Standards: ISO 9001 for quality management systems; ISO 3574 for dimensional tolerances.

- REACH and RoHS: Confirm compliance for shipments into the European Union; stainless steel is generally compliant but verify absence of restricted substances in coatings or treatments.

- Customs Documentation: Provide accurate commercial invoices, packing lists, and certificates of origin. Include HS Code 7222.20 (stainless steel angles, shapes, and sections).

- Country-Specific Requirements: Some countries may require third-party inspections (e.g., SNI in Indonesia, INMETRO in Brazil) or mill test certificates (EN 10204 3.1 or 3.2).

Traceability and Documentation

Maintain full traceability from raw material to delivery:

- Retain mill test reports (MTRs) for each heat/lot.

- Implement a batch tracking system for internal and customer audits.

- Provide certified material test reports upon request, especially for critical applications (e.g., food processing, marine, pharmaceuticals).

Environmental and Safety Compliance

- Follow OSHA and local safety regulations during handling and storage.

- Recycle scrap and packaging materials in accordance with local environmental laws.

- Train personnel on safe lifting practices and use of PPE (gloves, safety glasses, steel-toe boots).

Adhering to this guide ensures that stainless channel logistics operations meet quality, safety, and regulatory requirements across the supply chain.

Conclusion for Sourcing Stainless Steel Channels

After a comprehensive evaluation of suppliers, material specifications, cost structures, and delivery capabilities, sourcing stainless steel channels from a combination of reputable domestic and international suppliers offers a balanced approach in terms of quality, cost-efficiency, and supply chain reliability. Choosing suppliers certified to international standards such as ASTM, ISO, and EN ensures material consistency and performance, particularly in corrosive or high-stress environments.

Stainless steel channels are ideal for applications requiring durability, corrosion resistance, and structural integrity. By prioritizing suppliers with proven track records, sustainable practices, and responsive customer service, organizations can mitigate supply risks and support long-term project success. Additionally, bulk purchasing agreements and strategic inventory planning can further optimize costs and lead times.

In conclusion, a well-structured sourcing strategy—factoring in material grade (e.g., 304, 316), supplier reliability, total landed cost, and compliance—ensures that stainless steel channel procurement aligns with both technical requirements and business objectives. Establishing long-term partnerships with select vendors will enhance supply stability and value over time.