The global stainless steel market is witnessing robust expansion, driven by increasing demand from industries such as chemical processing, marine engineering, pharmaceuticals, and oil & gas—sectors where corrosion-resistant materials like Stainless Steel 316 are critical. According to Mordor Intelligence, the global stainless steel market was valued at USD 137.4 billion in 2023 and is projected to reach USD 186.2 billion by 2029, growing at a CAGR of 5.2% during the forecast period. A key driver behind this growth is the rising preference for austenitic grades such as SS 316, which offers superior durability and a density of approximately 8.0 g/cm³, making it ideal for high-stress and corrosive environments. With Asia-Pacific accounting for over 60% of global stainless steel production—led by China, Japan, and South Korea—the competition among high-density SS 316 manufacturers has intensified. As quality, consistency, and technical specifications become decisive factors in procurement decisions, identifying the top-performing manufacturers with reliable density control and rigorous quality assurance has become essential for supply chain efficiency and performance optimization.

Top 8 Stainless 316 Density Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 AISI 316L

Domain Est. 2007

Website: stahlportal.com

Key Highlights: Material grade 1.4435, also called 316L stainless steel, is described as a non-magnetic steel. The Delta ferrite content is max. 0.5%. It can be used in …Missing: density manufa…

#2 [PDF] Stainless steel 316L (1.4404)

Domain Est. 1996

Website: renishaw.com

Key Highlights: Stainless steel 316L alloy (DIN/W.Nr 1.4404) is an austenitic stainless steel which comprises of iron alloyed with chromium of mass fraction up to 18%, nickel ……

#3 316 / 316L Stainless Steel

Domain Est. 1997

Website: smithmetal.com

Key Highlights: Type 316 is an austenitic stainless steel with added molybdenum which gives the alloy improved corrosion resistance….

#4 Stainless Steel, 316

Domain Est. 1997

#5 Stainless Steel

Domain Est. 1999

Website: azom.com

Key Highlights: Grade 316 is the standard molybdenum-bearing grade, second in importance to 304 amongst the austenitic stainless steels….

#6 316 Stainless Steel Properties

Domain Est. 2015

Website: metalscut4u.com

Key Highlights: 316 stainless steel is an austenitic stainless steel alloy containing significant amounts of chromium, nickel, and molybdenum….

#7 316L Stainless Steel 3D Printing and Applications

Domain Est. 2016

Website: 3deo.co

Key Highlights: 316L stainless steel is a weldable material that is extremely corrosion resistant, which makes it ideal for applications that will experience harsh ……

#8 Stainless Steel 316L

Domain Est. 2017

Website: thyssenkrupp-materials.co.uk

Key Highlights: This data sheet applies to stainless steel 316L / 1.4404 hot and cold-rolled sheets/plates and strip, semi-finished products, rods, rolled wire and profiles….

Expert Sourcing Insights for Stainless 316 Density

H2: Projected 2026 Market Trends for Stainless Steel 316 Density

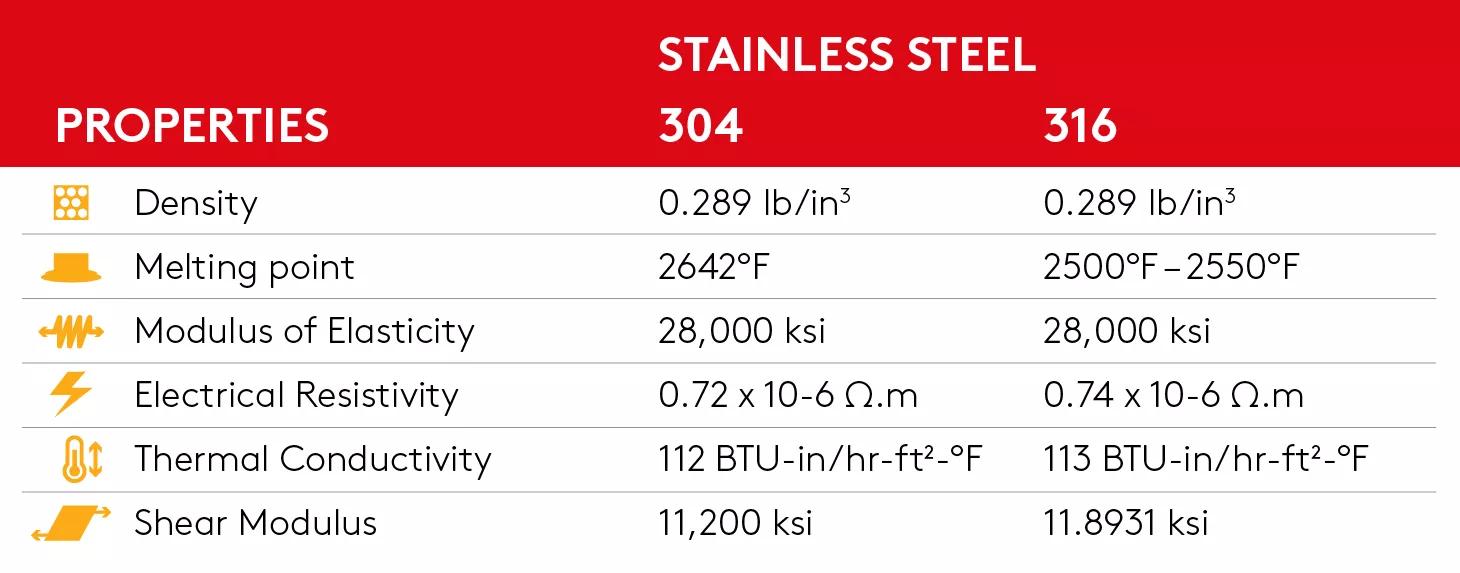

In 2026, market trends for Stainless Steel 316—particularly concerning its density—will be influenced by advancements in material science, shifts in industrial demand, and evolving manufacturing standards. While the physical density of Stainless Steel 316 remains a constant at approximately 8.0 g/cm³, market dynamics will center around how this property impacts performance, cost-efficiency, and application suitability across key industries.

-

Increased Demand in High-Performance Sectors

The consistent density of 316 stainless steel (8.0 g/cm³) contributes to its structural integrity and corrosion resistance, making it ideal for marine, chemical processing, pharmaceutical, and aerospace applications. By 2026, growing investments in offshore energy infrastructure and desalination plants—especially in Asia-Pacific and the Middle East—are expected to drive demand. The material’s predictable density supports precise engineering calculations, enhancing reliability in critical systems. -

Material Optimization and Lightweight Alternatives

Despite its advantages, the relatively high density of 316 stainless steel compared to newer alloys (e.g., duplex stainless steels or titanium) may prompt innovation. Manufacturers are increasingly exploring hybrid materials or optimized fabrication techniques (such as additive manufacturing) to reduce weight while maintaining corrosion resistance. This could lead to a shift in market preference toward lower-density alternatives in weight-sensitive applications, potentially tempering demand growth for standard 316 in certain high-tech sectors. -

Sustainability and Recycling Influence

The circular economy trend will impact the 316 stainless steel market through increased recycling rates. Recycled 316 retains its original density and mechanical properties, making it highly desirable for sustainable construction and green energy projects. By 2026, regulatory pressures and ESG (Environmental, Social, and Governance) standards are expected to favor materials with high recyclability, supporting steady demand for 316 despite its density. -

Geopolitical and Supply Chain Factors

Fluctuations in raw material prices—particularly nickel and molybdenum, key components of 316 stainless steel—will affect production costs. Regions with stable access to these inputs (e.g., Indonesia, Russia, and Canada) may gain competitive advantage. While density itself doesn’t change, cost-driven decisions may influence whether engineers select 316 over lower-density or lower-cost alternatives like 304 stainless steel or aluminum alloys. -

Technological Integration and Quality Control

Advancements in real-time material monitoring and AI-driven quality assurance systems will allow manufacturers to ensure consistency in density and composition. This precision bolsters trust in 316 stainless steel for mission-critical applications, reinforcing its market position despite competition.

Conclusion:

By 2026, the market for Stainless Steel 316 will not see changes in its fundamental density, but the value derived from this property will be increasingly scrutinized through the lenses of performance, sustainability, and cost. While its high density remains a key factor in durability and reliability, market trends will favor innovations that either leverage or mitigate this characteristic depending on application needs. Overall, demand is projected to grow moderately, sustained by industrial modernization and environmental regulations, particularly in emerging economies.

Common Pitfalls When Sourcing Stainless Steel 316: Density and Quality (Including Intellectual Property)

When sourcing Stainless Steel 316, overlooking key factors related to density, material quality, and intellectual property (IP) can lead to significant project risks, cost overruns, or performance failures. Below are common pitfalls to avoid:

Underestimating the Importance of Certified Density and Material Composition

While the theoretical density of Stainless Steel 316 is approximately 8.0 g/cm³, assuming this value without verification can be misleading. Variations in alloying elements (e.g., molybdenum, nickel, chromium content), microstructure, and manufacturing methods (e.g., hot vs. cold working) can cause slight deviations in actual density. Sourcing material without certified mill test reports (MTRs) or chemical composition analysis may result in receiving substandard or counterfeit steel. This is particularly critical in precision applications such as aerospace, medical devices, or high-pressure systems where material consistency directly impacts performance.

Relying on Unverified Supplier Claims Without Third-Party Certification

A common pitfall is accepting supplier-provided specifications at face value without requesting independent verification or recognized certifications (e.g., ASTM A240, ASME, or ISO 15510). Some suppliers may mislabel 304 as 316 or provide material with insufficient molybdenum content, reducing corrosion resistance. Always require certified test results and consider third-party inspection, especially for large or critical orders. Skipping this step risks receiving non-compliant material that fails in service, leading to safety hazards and reputation damage.

Ignoring Intellectual Property (IP) in Material Specifications and Design

When sourcing components or custom-fabricated parts made from 316 stainless steel, failing to address IP rights can lead to legal complications. For example, using a proprietary design, manufacturing process, or patented alloy variant without proper licensing may expose your organization to infringement claims. Additionally, ensure that technical documentation, CAD models, and material certifications are transferred with proper rights and confidentiality agreements. Never assume that purchased components grant full IP ownership unless explicitly stated in contracts.

Overlooking Traceability and Documentation Requirements

In regulated industries (e.g., pharmaceuticals, food processing, nuclear), full material traceability is essential. Sourcing 316 stainless steel without lot traceability, heat numbers, or proper documentation can result in compliance failures during audits. Ensure suppliers provide complete documentation packages, including MTRs, certificates of conformance (CoC), and, where applicable, material test data (e.g., tensile strength, hardness, corrosion resistance). Lack of traceability may also hinder root cause analysis in the event of component failure.

Failing to Specify Surface Finish and Condition

The density and performance of 316 stainless steel can be indirectly affected by surface condition and finish (e.g., polished, pickled, brushed). An improper finish may lead to increased surface porosity, reduced corrosion resistance, or contamination risks—especially in hygienic or high-purity applications. Always specify required surface finishes (e.g., Ra values, ASTM A480 standards) in procurement documents to avoid receiving material unsuitable for its intended use.

By proactively addressing these pitfalls—verifying density and composition, demanding certifications, protecting IP rights, ensuring traceability, and specifying surface requirements—organizations can mitigate risks and ensure reliable, compliant sourcing of Stainless Steel 316.

H2: Logistics & Compliance Guide for Stainless Steel 316 Density

Understanding and managing the density of Stainless Steel 316 (SS316) is critical for accurate logistics planning, compliance with safety and environmental regulations, and ensuring product quality throughout the supply chain. This guide outlines key considerations for handling SS316 based on its density characteristics.

H2: Density Specifications and Relevance

- Typical Density: Stainless Steel 316 has an average density of 8.0 g/cm³ (8,000 kg/m³ or approximately 0.289 lb/in³). This value can vary slightly (±0.1 g/cm³) depending on exact alloy composition, manufacturing process (cast, forged, rolled), and temperature.

- Why It Matters for Logistics & Compliance:

- Weight Calculations: Accurate density is essential for converting between volume and mass, crucial for shipping cost estimation (freight is often charged by weight), load planning, and avoiding overweight fines.

- Structural Load Limits: Ensures transport vehicles (trucks, ships, aircraft), storage racks, and handling equipment operate within safe weight limits.

- Packaging Design: Influences material strength requirements for crates, pallets, and internal supports to prevent damage during transit.

- Inventory Management: Enables accurate mass-based inventory tracking and reconciliation.

- Regulatory Compliance: Supports accurate Material Safety Data Sheet (MSDS/SDS) reporting, hazardous materials declarations (if applicable), and customs documentation.

H2: Logistics Considerations Based on Density

-

Transportation & Freight:

- Weight Verification: Always calculate the actual weight of SS316 shipments using the formula:

Weight = Volume × Density. Use certified scales for final verification. Assume 8.0 g/cm³ unless precise certified material test reports (MTRs) specify otherwise. - Load Distribution: Account for the high density when loading. Ensure weight is evenly distributed across pallets and within shipping containers/trailers to prevent structural stress and maintain vehicle stability. Use load calculators.

- Mode Selection: High density impacts feasibility and cost. Air freight is often cost-prohibitive for large volumes; ocean or rail freight is typically preferred.

- Handling Equipment: Ensure forklifts, cranes, and other material handling equipment have sufficient load capacity to safely lift and move SS316 components or stock (e.g., plates, bars, coils).

- Weight Verification: Always calculate the actual weight of SS316 shipments using the formula:

-

Packaging & Storage:

- Robust Packaging: Use strong, high-grade wooden crates, steel-reinforced pallets, or heavy-duty containers designed for dense, high-weight materials. Prevent crushing of packaging or underlying stock.

- Stacking Limits: Strictly adhere to calculated stacking heights based on the density and weight of SS316 items to prevent collapse of storage racks or damage to lower layers. Clearly label maximum stack heights.

- Floor Load Capacity: Verify warehouse floor load capacity (kN/m² or lb/ft²) exceeds the combined weight (calculated via density) of stored SS316 materials and racking.

-

Inventory & Measurement:

- Unit Conversion: Standardize on mass (kg, tons) for inventory tracking rather than volume for SS316 due to its consistent density. Use precise volume measurements (length, width, thickness) and the 8.0 g/cm³ density for conversion if necessary.

- Theft Deterrence: High density and value make SS316 a target. Implement secure storage and inventory controls.

H2: Compliance & Safety Requirements

-

Material Safety Data Sheet (SDS):

- Ensure the SDS for the specific SS316 product lists the correct physical properties, including density. This is mandatory under GHS (Globally Harmonized System) and regulations like OSHA HazCom (US) or CLP (EU).

- SDS Sections 9 (Physical and Chemical Properties) and 14 (Transport Information) are particularly relevant.

-

Transportation Regulations:

- General Cargo: SS316 is generally non-hazardous for transport. Compliance focuses on accurate declaration of weight, proper packaging to prevent shifting/damage, and adherence to carrier weight limits (e.g., FMCSA in the US, ADR in Europe for road).

- Hazardous Materials (Rare): If SS316 contains significant amounts of regulated substances (e.g., certain coatings, contamination), specific hazardous material regulations (IMDG, IATA, ADR) may apply. Density aids in calculating total package weight for classification.

- Customs Declarations: Accurate weight (derived from density and volume) is required for customs valuation and duty calculation. Miscalculations can lead to delays, penalties, or audits.

-

Safety in Handling:

- Manual Handling: The high density means even small SS316 parts can be very heavy. Implement strict manual handling procedures (team lifting, mechanical aids) to prevent musculoskeletal injuries. Conduct risk assessments.

- Falling Object Risk: Secure stored SS316 materials properly. High-density items falling pose significant crush hazards. Use safety netting or containment where appropriate.

- Structural Integrity: Regularly inspect storage racks, pallets, and transport vehicles for signs of stress or damage caused by the sustained high loads from dense SS316 stock.

-

Environmental & Quality:

- Waste Management: While inert, scrap SS316 density is crucial for accurate recycling logistics and reporting. Document recycling weights based on density calculations.

- Quality Control: Verify density indirectly through weight/volume checks as part of incoming inspection to detect potential material substitution (e.g., with lower-density stainless grades like 304, density ~7.93 g/cm³) or significant voids/inclusions in cast parts.

H2: Key Actions for Compliance

- Source Reliable Data: Obtain certified MTRs from suppliers confirming the alloy (316/316L) and relevant physical properties.

- Standardize Calculations: Implement company-wide procedures using 8.0 g/cm³ (with tolerance) for weight estimation unless MTRs specify otherwise.

- Train Personnel: Educate logistics, warehouse, and safety staff on the implications of SS316’s high density for handling, storage, and compliance.

- Document Everything: Maintain records of weight calculations, MTRs, SDS, and handling procedures for audit purposes.

- Verify and Audit: Regularly audit weight calculations, packaging adequacy, storage conditions, and SDS compliance.

In conclusion, the density of stainless steel 316 is typically around 8.0 g/cm³ (or 8,000 kg/m³), which is consistent across most standard references and material specifications. This value is essential for applications involving weight calculations, material selection, and engineering design—particularly in industries such as marine, chemical processing, and medical, where 316 stainless steel is favored for its excellent corrosion resistance and durability. When sourcing this material, verifying density specifications with certified material test reports (MTRs) from reputable suppliers ensures accuracy and compliance with required standards such as ASTM A240 or ASME. Accurate density data supports efficient design, cost estimation, and performance predictability in final applications.

![[PDF] Stainless steel 316L (1.4404)](https://www.sohoinchina.com/wp-content/uploads/2026/01/pdf-stainless-steel-316l-14404-530.jpg)