The global demand for decorative and functional building materials has fueled rapid growth in the stained acrylic glass market, with applications spanning architectural design, interior decoration, and retail displays. According to Grand View Research, the global acrylic sheet market was valued at USD 10.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, driven by increasing demand for lightweight, shatter-resistant alternatives to traditional glass. This surge is further amplified by trends in sustainable construction and design innovation, positioning stained acrylic glass as a preferred material for both aesthetic appeal and practical performance. As the market expands, manufacturers are differentiating themselves through advanced coloring techniques, UV resistance, and customization capabilities. In this evolving landscape, a select group of producers have emerged as industry leaders, setting benchmarks in quality, scalability, and design versatility. The following insights highlight the top nine stained acrylic glass manufacturers shaping the future of this dynamic segment.

Top 9 Stained Acrylic Glass Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Stained Glass

Domain Est. 2013

Website: cavalliniglass.com

Key Highlights: Over 900 stained glass types in our powerful search engine. Chosen for quality and affordability used by our craftsmen for personal and commercial projects ……

#2 PPG

Domain Est. 1990

Website: ppg.com

Key Highlights: We protect and beautify the world. Our Paints & Stains. Explore our international portfolio of brands. Here are just a few….

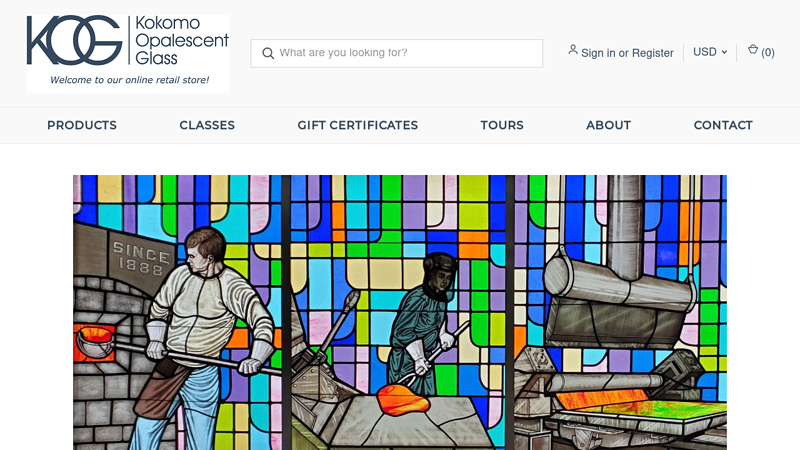

#3 Kokomo Opalescent Glass

Domain Est. 1996

Website: kog.com

Key Highlights: Welcome to the official Kokomo Opalescent Glass website, we have been proudly manufacturing the world’s finest art glass products since 1888….

#4 About Delphi Stained Glass

Domain Est. 1997

Website: delphiglass.com

Key Highlights: Delphi Glass was the first company to make art glass accessible to everyone. Founded on the belief that creativity should be fun and rewarding, its simple ……

#5 Acrylic Sheet

Domain Est. 1997

Website: professionalplastics.com

Key Highlights: Rating 4.0 (1) · 3-day returnsAcrylic Sheet – Stained Glass – These decorative high-gloss acrylic sheets come in dozens of designer colors and styles for applications ranging f…

#6 History of Stained Glass

Domain Est. 1997

Website: stainedglass.org

Key Highlights: Introduction. Stained glass possesses an aura of mystery and romance. It is the interplay between light and color that sparks the imagination….

#7 Bullseye Glass

Domain Est. 2003 | Founded: 1974

Website: bullseyeglass.com

Key Highlights: Colored glass handcast in Portland, OR, since 1974 for fusing, stained glass, mosaic, and more….

#8 How to Make Stained Glass with Acrylic

Domain Est. 2013

Website: xtool.com

Key Highlights: Making stained glass with acrylic is cost effective (in this case approximately $25 in materials), extremely light weight, and time efficient….

#9 Stained Glass

Domain Est. 2019

Website: smokeyhilldesigns.com

Key Highlights: 3–4 day delivery · 30-day returnsPatternPly® Smoke and Mirrors Acrylic · Acrylic Sheets · Glitter Acrylic · Non-Glitter Acrylic · Diode Friendly Acrylic · Wood, MDF, Veneers & Bla…

Expert Sourcing Insights for Stained Acrylic Glass

H2: 2026 Market Trends for Stained Acrylic Glass

The global market for stained acrylic glass is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements, and sustainability demands. Unlike traditional stained glass, stained acrylic glass offers enhanced durability, lighter weight, and greater design flexibility, making it increasingly popular across architectural, interior design, and artistic applications. Key trends shaping the 2026 landscape include:

1. Rising Demand in Architectural and Interior Design

Stained acrylic glass is gaining traction in residential and commercial construction due to its versatility in creating decorative partitions, windows, and facades. Designers are leveraging digital printing and laser-cutting technologies to produce intricate stained effects with precision, enabling custom aesthetics without the fragility of glass. The trend toward biophilic and ambient lighting design further boosts adoption, as translucent acrylic panels enhance natural light diffusion while adding color and visual interest.

2. Growth in Sustainable and Eco-Friendly Materials

Environmental concerns are pushing manufacturers to develop recyclable and low-carbon acrylic alternatives. By 2026, an increasing number of suppliers are expected to offer bio-based or recycled-content acrylic sheets that maintain the optical clarity and color vibrancy of traditional materials. Certifications such as Cradle to Cradle and EPDs (Environmental Product Declarations) will become key differentiators in green building projects pursuing LEED or BREEAM standards.

3. Expansion in Artistic and Niche Applications

Beyond architecture, stained acrylic glass is finding new markets in art installations, retail displays, and luxury furnishings. Artists and designers appreciate its workability—allowing for layering, carving, and embedding of materials—which enables innovative expressions previously unachievable with glass. The DIY and maker movement also fuels demand for user-friendly stained acrylic kits, especially in home décor and craft sectors.

4. Technological Integration and Smart Surfaces

By 2026, integration with smart technologies will emerge as a key trend. Some manufacturers are experimenting with stained acrylic panels embedded with LED lighting, photovoltaic elements, or responsive coatings that change opacity or color with environmental stimuli. These “smart stained panels” are expected to appeal to high-end residential and hospitality sectors seeking immersive experiences.

5. Regional Market Shifts and Manufacturing Innovations

Asia-Pacific, particularly China and India, is anticipated to be a high-growth region due to rapid urbanization and rising disposable income. Meanwhile, North America and Europe will focus on premium, custom-designed solutions for retrofit and restoration projects. Advancements in digital printing and robotic cutting will reduce production costs and lead times, making stained acrylic glass more accessible to mid-market segments.

6. Competitive Landscape and Brand Differentiation

As the market expands, competition will intensify among material suppliers and fabricators. Brands that offer comprehensive design support, augmented reality (AR) visualization tools, and rapid prototyping services will gain a strategic edge. Partnerships with architects and interior designers will be crucial for market penetration.

In conclusion, the stained acrylic glass market in 2026 will be defined by innovation, sustainability, and customization. Its ability to merge aesthetic appeal with functional performance positions it as a material of choice for forward-thinking design applications across multiple industries.

Common Pitfalls When Sourcing Stained Acrylic Glass (Quality, IP)

Sourcing stained acrylic glass—often used in architectural features, signage, displays, and interior design—requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these can lead to performance issues, legal risks, and reputational damage. Below are the most common pitfalls to avoid.

Poor Material Quality and Inconsistent Staining

One of the biggest challenges when sourcing stained acrylic glass is ensuring consistent, high-quality material. Lower-tier suppliers may use substandard acrylic sheets or inconsistent staining processes, leading to:

- Color variation across batches, making large installations look patchy or unprofessional.

- Poor UV resistance, causing the stain to fade or yellow over time, especially in outdoor or sun-exposed applications.

- Surface imperfections such as streaks, bubbles, or uneven opacity due to improper staining techniques or low-grade dyes.

- Reduced durability, including susceptibility to scratching, cracking, or warping under stress or temperature changes.

To mitigate this, always request physical samples, verify the manufacturer’s quality control processes, and prioritize suppliers who use cell-cast acrylic over extruded, which offers better clarity and consistency.

Inadequate Light Transmission and Optical Clarity

Stained acrylic is often chosen for its aesthetic and light-diffusing properties. However, poorly manufactured products may suffer from:

- Reduced light transmission, making the material appear dull or muddy.

- Hazing or cloudiness, especially with dark or complex stains, which compromises the visual impact.

Ensure that technical specifications include light transmission percentages and that samples are tested under real-world lighting conditions before bulk ordering.

Ignoring Intellectual Property (IP) Rights

Using stained acrylic with custom patterns, textures, or designs can inadvertently infringe on intellectual property if proper due diligence is not performed. Common IP pitfalls include:

- Unauthorized use of proprietary designs: Some suppliers offer “designer” patterns or textures that may be protected by copyright, trademark, or design patents. Using them without a license can lead to legal action.

- Lack of documentation: Suppliers may not provide proof of design ownership or licensing, leaving the buyer liable.

- Counterfeit or copied products: Especially when sourcing from overseas, designs may be reverse-engineered or replicated without authorization.

Always verify that the supplier has the legal right to distribute the stained acrylic design and request written confirmation of IP clearance. For custom designs, ensure contracts clearly assign or license IP rights to your organization.

Misunderstanding Fire Safety and Compliance Standards

Stained acrylic may not meet fire safety ratings (e.g., ASTM E84, UL 94) required for commercial or public installations. Some dyes or additives used in staining can reduce flame resistance. Always confirm that the product complies with local building codes and safety standards, particularly for use in schools, hospitals, or transit environments.

Supply Chain and Lead Time Risks

Custom-stained acrylic often involves longer lead times and limited scalability. Relying on a single supplier or region (e.g., Asia) can expose projects to delays due to logistics, quality rejections, or geopolitical factors. Diversify sources and build buffer time into project schedules.

By proactively addressing these pitfalls—focusing on quality verification, IP due diligence, and compliance—buyers can ensure they source stained acrylic glass that meets both aesthetic and legal requirements.

Logistics & Compliance Guide for Stained Acrylic Glass

Product Classification & Regulatory Overview

Stained acrylic glass, also known as colored or tinted acrylic sheet, is a lightweight, shatter-resistant plastic alternative to traditional glass. It falls under polymer-based materials (e.g., polymethyl methacrylate or PMMA) and is typically classified under HS Code 3920.51 (Polymers of methyl methacrylate, sheets, film, foil, etc.). Compliance requirements vary by destination country and intended use (e.g., construction, signage, decorative applications). Key regulatory considerations include chemical composition, flammability, and environmental disposal.

Packaging & Handling Requirements

Due to its susceptibility to scratching and static buildup, stained acrylic glass must be packaged with protective films on both sides. Sheets should be separated with non-abrasive interleaf paper or foam and stored vertically in rigid containers or wooden crates to prevent warping. Edge protectors are recommended to prevent chipping. Avoid exposure to direct sunlight and extreme temperatures during storage and transit. Never stack heavy items on top of acrylic sheets.

Transportation & Shipping Guidelines

Stained acrylic glass can be shipped via air, sea, or ground freight. When shipping internationally, ensure compliance with IATA (air), IMDG (sea), or ADR (road) regulations where applicable. Although acrylic is non-hazardous, proper labeling and documentation are required. Secure loads to prevent shifting; use straps and corner boards for palletized shipments. Temperature-controlled environments are advised in extreme climates to prevent deformation.

Import/Export Documentation

Essential documentation includes:

– Commercial Invoice (detailing product description, value, quantity)

– Packing List (listing dimensions, weight, packaging type per item)

– Bill of Lading or Air Waybill

– Certificate of Origin (required by some countries for tariff determination)

– Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS) – recommended even though acrylic is generally non-hazardous

Check destination-specific requirements—e.g., REACH compliance in the EU, TSCA in the U.S., or INMETRO in Brazil.

Environmental & Safety Compliance

Ensure stained acrylic glass complies with environmental standards such as RoHS (Restriction of Hazardous Substances) if used in electronics or consumer goods. Verify that dyes or pigments used in staining do not contain restricted substances (e.g., heavy metals). Acrylic is recyclable (Plastic #7), but local recycling facilities may have specific handling procedures. Provide disposal guidelines to end-users in line with local waste regulations.

Customs Clearance & Duties

Provide accurate Harmonized System (HS) code classification to avoid delays. Duty rates vary by country—verify with local customs authorities. Some countries impose anti-dumping duties on plastic sheets from certain regions. Ensure proper valuation and declare any applied treatments (e.g., UV coating, anti-static finish), as these may affect tariff classification.

Certification & Labeling Standards

Depending on the application, stained acrylic may need to meet:

– Flame Retardancy: UL 94 ratings or ASTM E84 (for building materials)

– Optical Clarity & Color Fastness: ISO 13666 or ASTM D1003

– Building Codes: Compliance with local construction standards (e.g., IRC, IBC in the U.S.)

Label each shipment with product specifications, manufacturer details, batch number, and safety handling instructions.

Risk Management & Insurance

Insure shipments against breakage, moisture damage, and transit delays. Acrylic sheets are prone to surface damage, so choose carriers with experience handling fragile, high-value materials. Maintain records of inspection reports and shipping condition upon delivery to mitigate liability disputes.

Conclusion for Sourcing Stained Acrylic Glass:

Sourcing stained acrylic glass offers a versatile, durable, and cost-effective alternative to traditional stained glass, making it ideal for a wide range of decorative, architectural, and design applications. Its lightweight nature, impact resistance, and ease of fabrication allow for creative freedom and simplified installation. When sourcing, it is essential to prioritize suppliers who offer high-quality pigmentation, UV resistance, and consistent color matching to ensure longevity and aesthetic integrity. Additionally, considering factors such as customization options, minimum order quantities, and lead times will help align the material with project requirements. By carefully selecting reputable manufacturers and verifying material specifications, designers and builders can confidently incorporate stained acrylic glass into their projects, achieving visually striking results with enhanced practicality and performance.