The global laser cleaning equipment market is experiencing robust growth, driven by increasing demand for eco-friendly and precision-based industrial cleaning solutions. According to Grand View Research, the market was valued at USD 850 million in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 18.6% from 2023 to 2030. This surge is largely attributed to the rising adoption of laser technology in automotive, aerospace, and heritage conservation applications, where non-abrasive stain and corrosion removal is critical. As industries shift away from chemical-based cleaning methods, laser descaling and surface treatment have emerged as sustainable alternatives, bolstering investments in advanced stain removal laser systems. Mordor Intelligence further supports this trajectory, noting that technological advancements and growing awareness of operational efficiency are accelerating market penetration across North America, Europe, and Asia-Pacific. Against this backdrop, a select group of manufacturers has risen to the forefront, combining precision engineering, scalable output, and innovative beam delivery systems to dominate the stain removal segment. The following nine companies represent the vanguard of this transformation, shaping the future of industrial surface restoration through laser-driven solutions.

Top 9 Stain Removal Laser Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Custom Wood Stain Removal Laser Factory, Manufacturer

Website: jgzoe.com

Key Highlights: As a reliable manufacturer, Shenzhen Sub-lattice Optical Technology Co., Ltd. offers advanced Wood Stain Removal Lasers designed for ODM factories to ……

#2 The Power of Laser Stain Removal for Surface Restoration

Website: umw.top

Key Highlights: Laser stain removal using focused laser light, this technology offers a precise, non-invasive way to cut stains without harming the surface….

#3 Candela Medical

Website: candelamedical.com

Key Highlights: Candela Medical is a leader in medical aesthetic and cosmetic lasers, a respected US-based manufacturer of other energy-based equipment such as intense ……

#4 Laser Wood Cleaning & Restoration

Website: advancedlaserrestoration.com

Key Highlights: Advanced Laser Restoration offers eco-friendly laser wood cleaning for cabinets, floors, beams, and decks. Remove paint, stain, mold, soot, ……

#5 BK

Website: baikeopto.com

Key Highlights: In stockLaser cleaning system is stable with little maintenance; High cleaning efficiency, save time. Applications: Remove surface resin, paint, oil stains, dirt ……

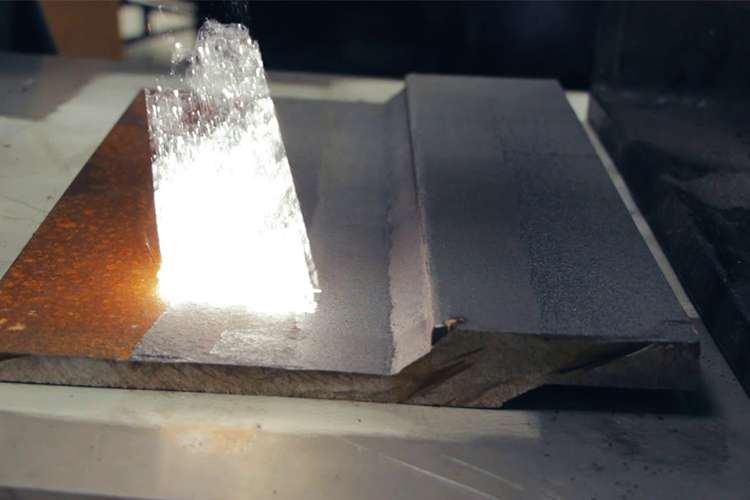

#6 Laser Paint Removal from Metals with Laser Cleaning

Website: laserax.com

Key Highlights: Laser paint removal is an environmentally friendly process used to remove paint layers from metal surfaces without damaging the substrate….

#7 300W JPT Mopa Pulse Laser Cleaning Machine For Oil Stain …

Website: mrj-lasermark.com

Key Highlights: The machine is perfect for a wide range of cleaning tasks, including removing oil stains, cleaning pipeline oil, removing thick paint and rust, and eliminating ……

#8 xeo

Website: cutera.com

Key Highlights: A customizable, multi-application laser- and light-based platform designed to treat the widest range of today’s most common nonsurgical aesthetic concerns….

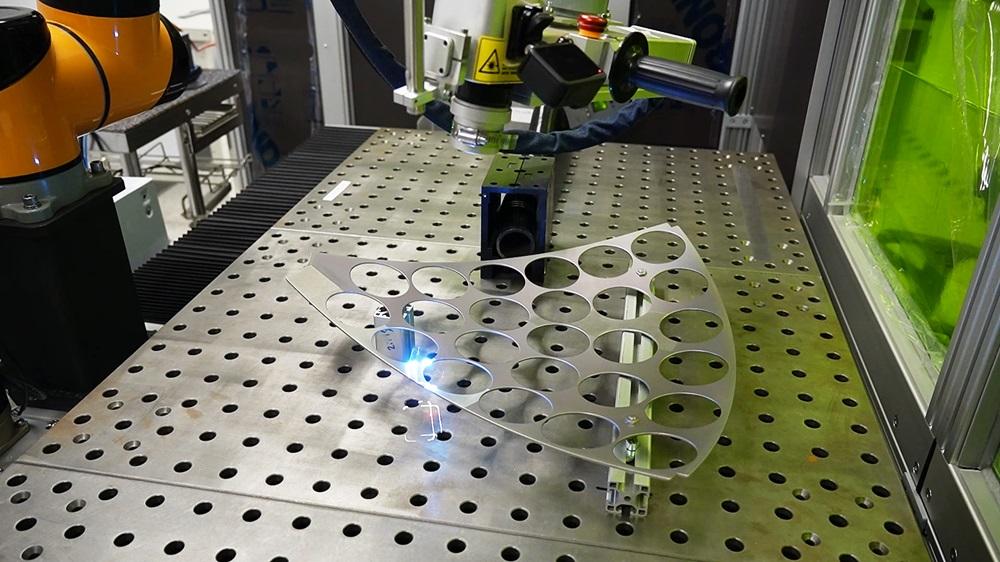

#9 Laser Stain Removal Machine

Website: dwcnclaser.com

Key Highlights: These machines use cutting-edge laser technology to efficiently remove stains, making them an indispensable tool for a wide range of industries….

Expert Sourcing Insights for Stain Removal Laser

H2: Market Trends for Stain Removal Laser Technology in 2026

By 2026, the stain removal laser market is poised for significant transformation, driven by advancements in laser technology, rising consumer demand for non-invasive cleaning solutions, and growing sustainability concerns across multiple industries. This analysis explores key market trends shaping the adoption and development of stain removal lasers in 2026.

1. Expansion in Consumer and Commercial Applications

Stain removal lasers are transitioning from niche industrial tools to mainstream solutions in both consumer and commercial sectors. In the textile and fashion industry, brands are adopting laser technology for eco-friendly garment finishing and stain removal, reducing reliance on water and chemical treatments. Concurrently, home appliance manufacturers are exploring integration of compact laser modules into high-end washing machines and dry cleaning systems, signaling a shift toward smart, precision-based home care.

2. Sustainability and Regulatory Support

Environmental regulations are increasingly favoring technologies that minimize water consumption and chemical waste. Laser-based stain removal systems produce no wastewater and require no solvents, aligning with global sustainability goals. In 2026, government incentives and green certifications are expected to accelerate adoption, particularly in Europe and North America, where circular economy frameworks are influencing industrial practices.

3. Technological Advancements

Innovations in pulsed laser diodes, AI-driven targeting systems, and real-time spectral analysis are enhancing the precision and efficiency of stain removal lasers. By 2026, smart lasers equipped with machine learning algorithms can identify fabric types and stain compositions automatically, optimizing energy use and preventing material damage. These advancements are reducing operational costs and broadening the range of applicable materials—from delicate silks to heavy-duty upholstery.

4. Growth in Niche Markets

Specialized applications are emerging in restoration, luxury goods, and forensic cleaning. Heritage conservation projects are utilizing low-intensity lasers to restore historical textiles without altering original dyes. In the luxury automotive and aviation sectors, laser cleaning ensures high-standard interior maintenance with minimal wear. These niche markets are driving demand for customizable and portable laser solutions.

5. Competitive Landscape and Market Consolidation

The market is witnessing increased investment from both tech startups and established industrial equipment manufacturers. Strategic partnerships between laser technology firms and textile care companies are common, aiming to co-develop integrated solutions. By 2026, market consolidation is expected, with leading players expanding their portfolios through acquisitions and R&D collaborations.

6. Challenges and Barriers

Despite growth, high initial costs, safety regulations, and the need for trained operators remain barriers to mass adoption. Consumer awareness is still limited, and concerns about material compatibility persist. However, ongoing education campaigns and product standardization are anticipated to mitigate these issues.

Conclusion

In 2026, the stain removal laser market is characterized by technological innovation, sustainability-driven demand, and diversification across industries. With continued investment and regulatory support, laser-based cleaning is on track to become a cornerstone of modern, eco-conscious stain management solutions.

Common Pitfalls Sourcing Stain Removal Lasers: Quality and Intellectual Property Risks

Sourcing stain removal lasers, particularly for industrial, medical, or specialized cleaning applications, involves significant technical and legal complexities. Overlooking key pitfalls related to quality and intellectual property (IP) can lead to project delays, financial losses, safety hazards, or costly litigation. Here are the critical risks to avoid:

Inadequate Quality Control and Performance Verification

- Unverified Performance Claims: Suppliers may exaggerate laser power, wavelength effectiveness, cleaning speed, or safety features. Without independent verification or standardized testing protocols, buyers risk acquiring equipment that fails to meet operational requirements.

- Poor Manufacturing Standards: Lasers sourced from manufacturers lacking rigorous quality management systems (e.g., ISO 9001) may suffer from inconsistent beam quality, unreliable cooling systems, or premature component failure, leading to downtime and increased maintenance costs.

- Lack of Safety Certification: Stain removal lasers must comply with international safety standards (e.g., IEC 60825 for laser safety). Sourcing units without proper certification poses serious safety risks to operators and liability exposure for the buyer.

- Insufficient Documentation: Incomplete or unclear technical documentation (user manuals, maintenance guides, calibration records) hampers proper use, troubleshooting, and regulatory compliance.

Intellectual Property (IP) Infringement and Ownership Issues

- Unauthorized Use of Protected Technology: Sourcing lasers that incorporate patented components, optical designs, or control software without proper licensing exposes the buyer to infringement claims from original patent holders, potentially resulting in injunctions or damages.

- Ambiguous IP Ownership in Custom Solutions: In custom-developed lasers, failure to clearly define IP ownership in contracts may result in disputes over rights to improvements, designs, or derivative works, limiting the buyer’s ability to modify or scale the technology.

- Counterfeit or Knockoff Equipment: Purchasing from unverified suppliers increases the risk of receiving counterfeit lasers that mimic branded products but use substandard parts and may infringe on multiple IP rights, voiding warranties and creating legal exposure.

- Lack of IP Due Diligence: Failing to conduct thorough IP audits or freedom-to-operate (FTO) analyses before procurement can lead to unknowingly acquiring technology that violates existing patents, trademarks, or trade secrets.

To mitigate these risks, buyers should conduct thorough supplier vetting, demand third-party performance testing, ensure compliance with safety standards, perform comprehensive IP due diligence, and establish clear contractual terms regarding quality, warranties, and IP rights.

Logistics & Compliance Guide for Stain Removal Laser

Product Classification and Regulatory Status

The Stain Removal Laser is classified as a Class IV laser device under international laser safety standards (IEC 60825-1). It is intended for professional use in industrial, commercial, or restoration environments for the removal of surface stains on materials such as stone, concrete, metal, and masonry. It is not intended for medical or cosmetic applications. Users must verify local regulations to confirm proper classification and ensure compliance with national laser safety directives.

Import and Export Regulations

Shipping the Stain Removal Laser across international borders requires adherence to export control laws, including but not limited to the U.S. Export Administration Regulations (EAR) and the International Traffic in Arms Regulations (ITAR), if applicable. The device may require an export license depending on destination country and end-use. Harmonized System (HS) Code 9013.20.00 (laser devices) typically applies. Export documentation must include technical specifications, end-user statements, and laser safety certifications.

Transportation and Handling

The Stain Removal Laser must be transported in its original protective packaging or equivalent shock-resistant container. It should be secured to prevent movement during transit and stored in a dry, temperature-controlled environment (recommended: 5°C to 40°C). Battery-powered units must comply with IATA Dangerous Goods Regulations (DGR) if lithium batteries are installed. Air shipments require proper labeling, including Class 9 Miscellaneous Hazard label for lithium batteries, if applicable.

Customs Clearance Requirements

Customs clearance requires submission of a commercial invoice, packing list, bill of lading/air waybill, and Certificate of Conformity (CE, FCC, or equivalent). For EU imports, compliance with the CE marking directive (including Laser Products Directive and EMC Directive) is mandatory. Importers must also provide evidence of compliance with local laser safety regulations, such as alignment with EN 60825 standards.

Installation and On-Site Compliance

Upon delivery, installations must be performed by trained personnel in accordance with the manufacturer’s guidelines. The operational area must be designated as a controlled laser environment, equipped with appropriate warning signs (e.g., “Laser Radiation — Avoid Eye or Skin Exposure”), interlocks, and beam enclosures where applicable. A Laser Safety Officer (LSO) should be appointed if required by local regulations (e.g., OSHA in the U.S. or HSE in the UK).

Operational Safety and Training

All operators must complete certified laser safety training covering hazard identification, emergency procedures, and proper use of personal protective equipment (PPE), including laser safety goggles with appropriate optical density (OD) for the laser’s wavelength. Standard Operating Procedures (SOPs) must be documented and made available on-site. Regular safety audits and equipment maintenance logs are required to maintain compliance.

Documentation and Recordkeeping

Maintain records of the following for a minimum of five years:

– Equipment calibration and maintenance logs

– Operator training certifications

– Laser safety audits and incident reports

– Export licenses and customs documentation

– CE/FCC/other conformity assessment documentation

Environmental and Disposal Compliance

At end-of-life, the Stain Removal Laser must be disposed of in accordance with local electronic waste (WEEE) regulations. Batteries and optical components may require special handling due to hazardous materials. Recycling must be conducted through authorized e-waste facilities. Users should consult regional environmental agencies for specific disposal protocols.

Contact for Compliance Support

For questions regarding regulatory compliance, shipping documentation, or safety certification, contact the manufacturer’s Compliance Department at [email protected] or +1-800-555-0199. Regional support offices are available in the EU, North America, and Asia-Pacific.

Conclusion: Sourcing a Stain Removal Laser

In conclusion, sourcing a laser-based stain removal system represents a cutting-edge, efficient, and environmentally friendly solution for specialized cleaning applications, particularly in industries such as textile restoration, heritage conservation, and precision manufacturing. The technology offers unparalleled precision, minimal substrate damage, and reduced reliance on chemical solvents, aligning with sustainability goals and strict regulatory standards.

However, successful sourcing requires careful evaluation of several key factors: the laser’s wavelength, power, and pulse duration to match specific stain and material types; compatibility with existing workflows; initial investment and maintenance costs; and the need for trained personnel. Additionally, suppliers must be vetted for reliability, technical support, and after-sales service.

While the upfront costs may be higher compared to traditional cleaning methods, the long-term benefits—such as improved cleaning efficacy, reduced waste, and enhanced material preservation—justify the investment in appropriate applications. As laser technology continues to advance and become more accessible, early adoption positions organizations at the forefront of innovation in sustainable and precision cleaning.

Therefore, sourcing a stain removal laser should be approached strategically, with clear objectives, thorough technical assessment, and partnership with reputable technology providers to ensure optimal performance and return on investment.