The global demand for welded and fabricated metal products, including chicken wire, has surged in recent years, driven by growth in agriculture, construction, and DIY sectors. According to Grand View Research, the global wire mesh market was valued at USD 50.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing infrastructure development, rising demand for perimeter security, and the expansion of poultry farming worldwide. As one of the most commonly used variants, square chicken wire—known for its uniform grid pattern and durability—has seen steady demand across residential and commercial applications. With market competition intensifying, identifying reliable manufacturers that balance quality, scalability, and innovation has become crucial for distributors and project planners alike. Based on production capacity, export reach, product range, and customer reviews, here are seven leading square chicken wire manufacturers shaping the industry landscape today.

Top 7 Square Chicken Wire Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wire Mesh Manufacturers

Domain Est. 2001

Website: wire-cloth.net

Key Highlights: Hexagon (Chicken Wire), Square, and Rectangle Meshes: Used where visibility and airflow are needed but access must be controlled (e.g., protective screens ……

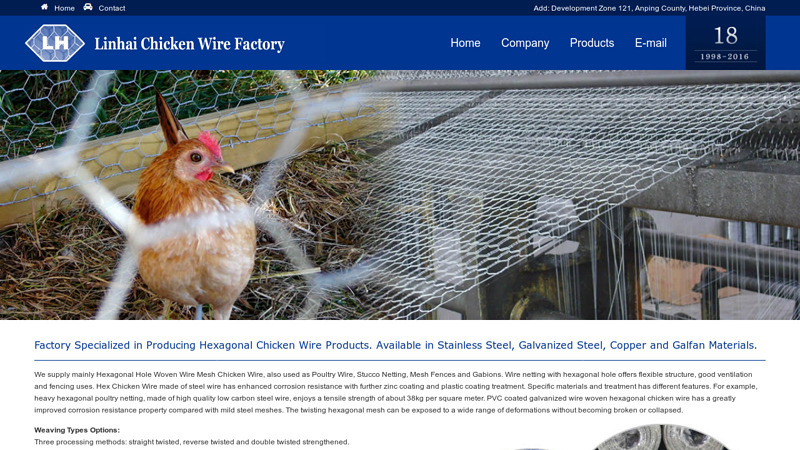

#2 Galvanized Hexagonal Chicken Wire for Poultry Netting and …

Domain Est. 2013

Website: chickenwiremesh.com

Key Highlights: Factory Specialized in Producing Hexagonal Chicken Wire Products. Available in Stainless Steel, Galvanized Steel, Copper and Galfan Materials….

#3 Manufacturer of Wire Mesh & Chicken Wire Mesh by National Wire …

Domain Est. 2023

Website: nationalwirespune.com

Key Highlights: National Wire Products – Manufacturer of Wire Mesh, Chicken Wire Mesh … Square Wire Mesh · Rs 110 / sq ft. Thickness: 22 Gauge (0.73 mm); Opening Size ……

#4 Wire Cloth Man

Domain Est. 2002

Website: wireclothman.com

Key Highlights: Wire Cloth Man is the source for all things wire mesh –from product inventory to your questions, answered….

#5 Chicken Wire Products for Different Applications

Domain Est. 2011

Website: chicken-wire.org

Key Highlights: Chicken wire is named poultry netting or hexagonal wire used to fence poultry livestock, made of 1/2, 3/4 inch stainless steel, PVC and galvanized wire….

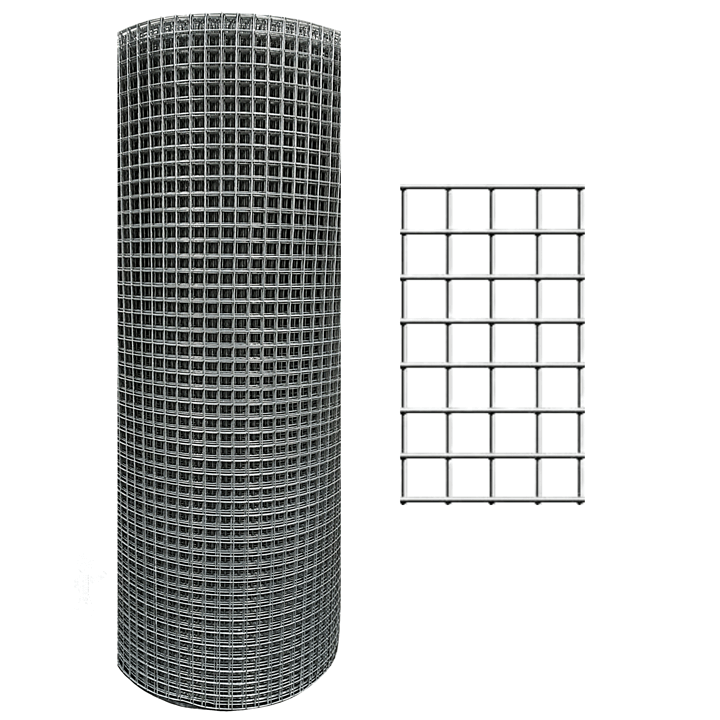

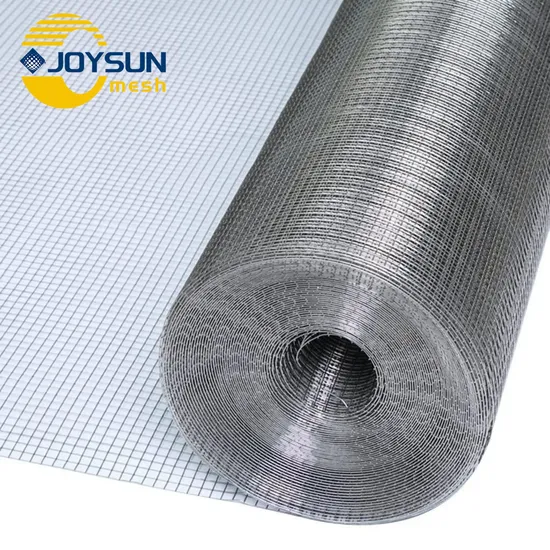

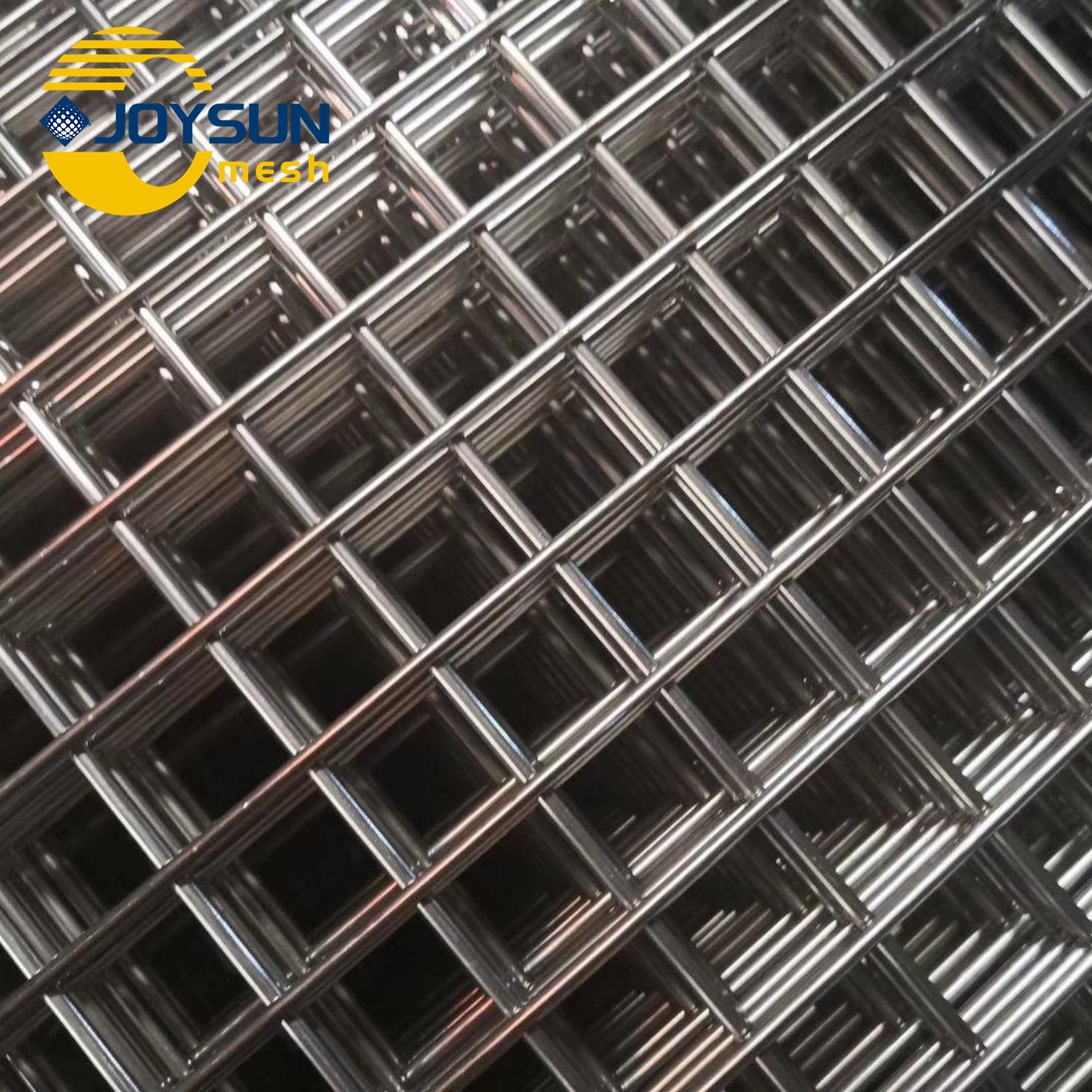

#6 Export Square Chicken Wire Mesh

Domain Est. 2024

Website: sunshinemesh.com

Key Highlights: Galvanized square hole shaped wire mesh ; Material: Galvanized iron wire, stainless wire ; Color: silver ; Wire gauge:, 0.2MM-1.2MM ; Surface treatment: Hot dipped ……

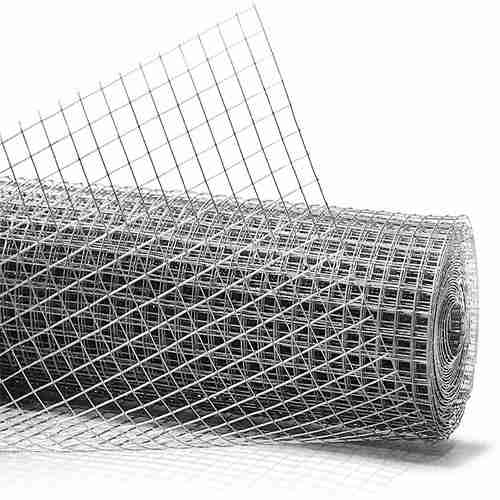

#7 CHICKEN WIRE

Website: tigermetal.ph

Key Highlights: Our Chicken Wire Mesh offers a world of possibilities for agricultural, gardening, and DIY projects, making it an essential asset for your endeavors….

Expert Sourcing Insights for Square Chicken Wire

H2: Market Trends for Square Chicken Wire in 2026

By 2026, the global market for square chicken wire (a type of welded or woven wire mesh primarily used for poultry enclosures, fencing, and various agricultural and industrial applications) is expected to experience steady but evolving trends shaped by sustainability, technological advancements, and shifting consumer demands. Key developments include:

1. Growth Driven by Sustainable Agriculture and Backyard Poultry Movement:

The rising popularity of backyard chicken keeping, particularly in North America and Europe, continues to fuel demand for reliable, humane enclosures. Square chicken wire—known for its strength and uniform openings—remains a preferred choice among hobbyists and small-scale farmers. This trend is amplified by increased consumer interest in organic, locally sourced eggs and meat, supporting a broader shift toward sustainable and self-sufficient lifestyles.

2. Emphasis on Durability and Corrosion Resistance:

Market demand is shifting toward galvanized and PVC-coated square chicken wire to enhance longevity and resistance to rust, especially in humid or coastal environments. Manufacturers are investing in improved coating technologies to extend product lifespan, reducing replacement frequency and appealing to environmentally conscious buyers seeking low-maintenance solutions.

3. Expansion in Alternative Applications:

Beyond poultry farming, square chicken wire is gaining traction in landscaping, DIY projects, and architectural design (e.g., decorative screens, trellises, and fencing). The structured geometry of square mesh offers aesthetic and functional advantages over hexagonal wire, driving innovation in non-agricultural sectors and broadening the product’s market reach.

4. Regional Market Divergence:

In emerging economies (e.g., Southeast Asia, Africa), demand is rising due to expanding poultry industries and government initiatives promoting food security. Conversely, in mature markets like the U.S. and Western Europe, growth is more moderate but stable, supported by replacement cycles and niche applications. Supply chain localization is also increasing to reduce costs and carbon footprints.

5. Competitive Pricing and E-Commerce Growth:

The market remains price-sensitive, with competition intensifying among manufacturers and distributors. Online retail platforms are becoming dominant sales channels, offering consumers greater access to product specifications, customer reviews, and competitive pricing—driving transparency and convenience.

6. Environmental and Regulatory Pressures:

Regulations around animal welfare and material sourcing are becoming more stringent. Producers are responding by adopting eco-friendly production methods, recyclable materials, and certifications to meet compliance and appeal to green-minded customers.

Conclusion:

By 2026, the square chicken wire market will be characterized by resilient demand anchored in agricultural and lifestyle trends, innovation in material quality, and diversification into new applications. Success will depend on manufacturers’ ability to balance cost-efficiency with sustainability, durability, and responsiveness to regional market dynamics.

Common Pitfalls When Sourcing Square Chicken Wire (Quality, IP)

Sourcing square chicken wire may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to subpar performance, safety risks, and legal complications. Here are common pitfalls to avoid:

Poor Material Quality and Corrosion Resistance

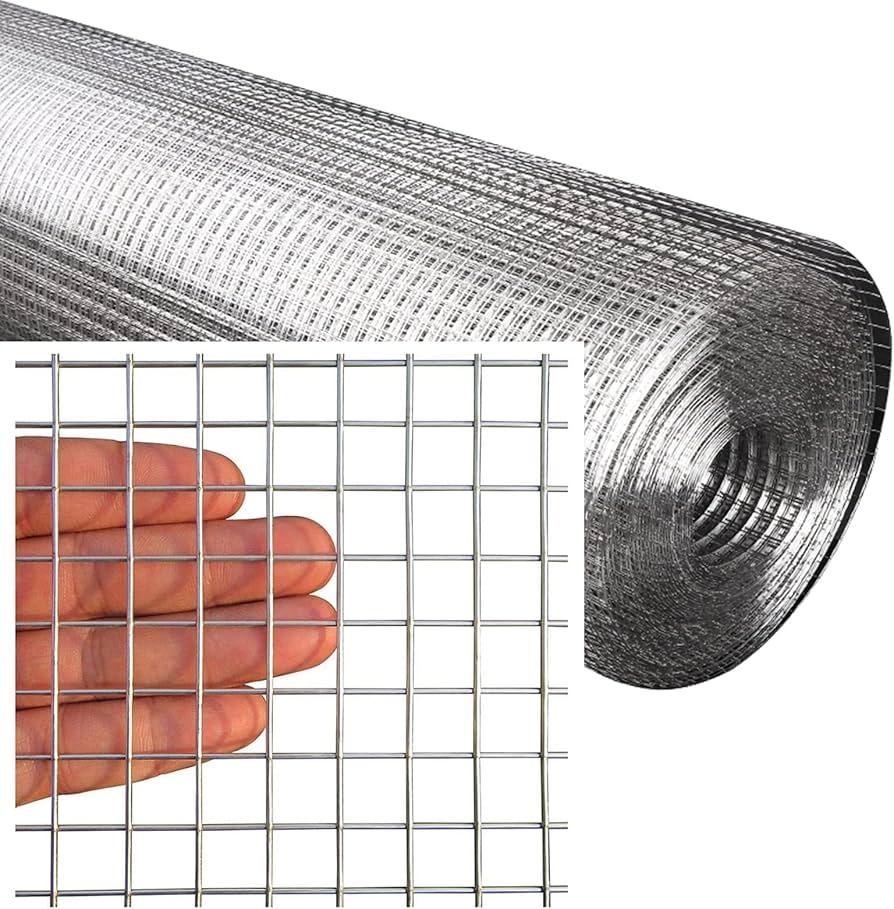

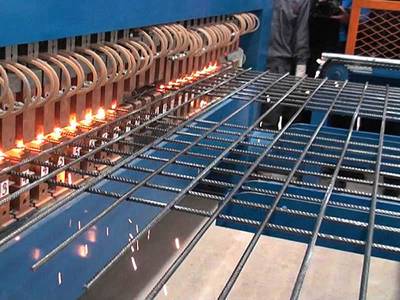

Many suppliers offer chicken wire made from low-grade steel or insufficiently galvanized wire. This leads to premature rusting and structural failure, especially in outdoor or humid environments. Always verify the wire gauge (typically 19–22 gauge for durability) and confirm the type of galvanization—hot-dip galvanized provides far superior corrosion resistance compared to electro-galvanized alternatives.

Inaccurate Mesh and Dimensional Tolerances

“Square” chicken wire should have uniform, consistent openings. Low-quality products often feature irregular mesh sizes or distorted shapes due to poor manufacturing. This compromises functionality—whether for animal enclosures, gardening, or crafts—and can create safety hazards. Request samples and inspect dimensional accuracy before bulk ordering.

Misrepresentation of Specifications

Some suppliers mislabel wire gauge, mesh size, or coating thickness to appear competitive. This lack of transparency affects both performance and longevity. Insist on certified material test reports (MTRs) and clear technical specifications to ensure you’re getting what’s advertised.

Ignoring Intellectual Property (IP) in Design or Branding

If your product or packaging incorporates unique designs, logos, or patented wire-weaving techniques, failing to secure proper IP protection—such as trademarks or design patents—can leave you vulnerable to copycats. Conversely, ensure your sourcing doesn’t infringe on existing patents, especially if using specialized machinery or proprietary patterns.

Sourcing from Unverified Suppliers

Dealing with uncertified or unvetted manufacturers, particularly in international markets, increases the risk of receiving counterfeit or non-compliant goods. Conduct supplier audits, request third-party certifications (e.g., ISO), and use secure payment terms to mitigate risk.

Overlooking Packaging and Handling Damage

Poor packaging can result in kinked or tangled wire rolls, increasing labor costs and waste during installation. Confirm that suppliers use robust packaging methods designed to maintain product integrity during shipping and storage.

By addressing these pitfalls proactively, businesses can ensure they source reliable, high-quality square chicken wire while protecting their brand and avoiding legal exposure.

Logistics & Compliance Guide for Square Chicken Wire

Product Overview

Square chicken wire, also known as poultry netting or hexagonal wire mesh (though typically square in modern variants), is a flexible galvanized steel mesh used primarily for enclosing poultry, garden protection, and light fencing applications. It features evenly spaced square openings and is typically sold in rolls of various widths and lengths. Proper logistics and compliance practices are essential to ensure product integrity, regulatory adherence, and customer satisfaction.

Packaging and Labeling Requirements

Square chicken wire must be packaged to prevent kinking, rust, and mechanical damage during transit. Rolls are typically shrink-wrapped or banded and placed on pallets for stability. Labels must include: product specifications (mesh size, wire gauge, roll dimensions), material type (e.g., galvanized steel), country of origin, manufacturer details, and relevant safety or handling symbols. Ensure compliance with local labeling laws, including language requirements in international markets.

Transportation and Handling

Transport square chicken wire on flatbed or enclosed trucks using secured pallets to prevent shifting. Rolls should be stored horizontally and protected from moisture and extreme weather. Use forklifts or pallet jacks for handling—never drag rolls, as this can cause deformation. Provide edge protection on pallets to avoid damage to the wire mesh during transit. For international shipments, comply with International Safe Transit Association (ISTA) standards for packaging performance.

Storage Conditions

Store square chicken wire in a dry, covered area to prevent corrosion, especially for galvanized or PVC-coated variants. Keep rolls elevated on pallets to avoid ground moisture. Avoid stacking excessive weight on lower pallets to prevent deformation. Maintain organized inventory with first-in, first-out (FIFO) rotation to minimize long-term storage risks.

Regulatory Compliance

Ensure all square chicken wire meets regional and international standards. In the U.S., products should comply with ASTM A641 (Standard Specification for Zinc-Coated (Galvanized) Carbon Steel Wire) and any relevant CPSC guidelines if marketed for consumer use. For EU markets, adhere to EN 10223-3 for steel wire fencing products and fulfill REACH and RoHS directives regarding hazardous substances. Certifications may be required for construction or agricultural applications.

Import and Export Documentation

For cross-border shipments, prepare accurate commercial invoices, packing lists, bills of lading, and certificates of origin. Classify the product under the correct HS Code (e.g., 7314.31 or 7314.39 for steel fencing mesh). Verify import regulations in destination countries, including anti-dumping duties or import licensing. Maintain records for audit purposes in compliance with customs laws.

Environmental and Safety Considerations

Galvanized steel may release zinc oxides when cut or heated—ensure workplace safety protocols include ventilation and protective equipment. Dispose of packaging materials in accordance with local waste regulations. For end-of-life product handling, promote recycling through certified metal recyclers to support sustainability goals.

Quality Assurance and Traceability

Implement a quality control process to inspect raw materials and finished rolls for consistent mesh size, coating integrity, and structural strength. Maintain batch traceability through lot numbering and documentation. Address customer complaints promptly and conduct root cause analysis to prevent recurrence.

Customer Support and Compliance Education

Provide clear installation and safety guidance with each product. Train customer service teams on compliance standards and product specifications to support informed purchasing decisions. Offer access to compliance documentation (e.g., test reports, certifications) upon request.

Continuous Improvement

Regularly review logistics performance, compliance updates, and customer feedback to refine processes. Stay informed on evolving regulations such as changes in zinc coating standards or environmental directives affecting metal products. Collaborate with suppliers and logistics partners to maintain best practices across the supply chain.

In conclusion, sourcing square chicken wire requires careful consideration of factors such as wire gauge, mesh size, material (typically galvanized steel or PVC-coated steel), roll dimensions, and intended application. It is essential to evaluate reputable suppliers who offer consistent quality, competitive pricing, and reliable delivery options. Whether for agricultural fencing, garden protection, or craft projects, selecting the right square chicken wire ensures durability, effectiveness, and long-term value. By comparing product specifications, obtaining samples when possible, and confirming compliance with industry standards, buyers can make informed decisions and establish sustainable sourcing practices.