The global aluminum framing market is experiencing robust growth, driven by rising demand across construction, solar energy, and industrial sectors. According to Grand View Research, the global aluminum extrusion market size was valued at USD 63.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. A key contributor to this trend is the increasing preference for lightweight, corrosion-resistant, and recyclable materials—qualities inherent in square aluminum frames. Additionally, Mordor Intelligence forecasts the aluminum profile market to grow at a CAGR of over 4.5% during the 2023–2028 period, with particular momentum in North America and Asia-Pacific due to infrastructure development and renewable energy investments. As demand surges, manufacturers specializing in precision-engineered square aluminum frames are scaling production and innovation to meet evolving industry standards. Below, we profile the top 9 manufacturers leading this transformation through quality, scalability, and technological integration.

Top 9 Square Aluminum Frame Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Element Designs

Domain Est. 2002

Website: element-designs.com

Key Highlights: Element Designs is the leading manufacturer of custom aluminum frame and glass cabinet doors in North America. Other custom manufactured products include ……

#2 SAF

Domain Est. 1992

Website: saf.com

Key Highlights: SAF is the leader in metals fabrication, finishing, and distribution around the world. Learn more about how we can turn your ideas into reality….

#3 U.S. Aluminum Systems

Domain Est. 1995

Website: crlaurence.com

Key Highlights: U.S. Aluminum® architectural aluminum products, including glass doors, windows & storefront systems, make it easy to design durable commercial buildings….

#4 Agam

Domain Est. 1996

Website: agam.com

Key Highlights: We engineer & manufacture custom structures for trade shows & events, commercial interiors & retail with industry-leading turnaround times….

#5 80/20 Aluminum Extrusions

Domain Est. 1997

Website: 8020.net

Key Highlights: Custom aluminum framing from 80/20 lets you design your own machine guarding and enclosures. Learn More…

#6

Domain Est. 2000

Website: tslots.com

Key Highlights: TSLOTS is the top choice for structural extrusion and so much more! You can literally have a CAD model drawn, price quoted, pieces cut, assembled, and shipped ……

#7 Aluminum Profiles

Domain Est. 2000

Website: boschrexroth.com

Key Highlights: Modular by design, rugged by nature, and built to move with you – Bosch Rexroth’s aluminum profile system provides everything to build anything….

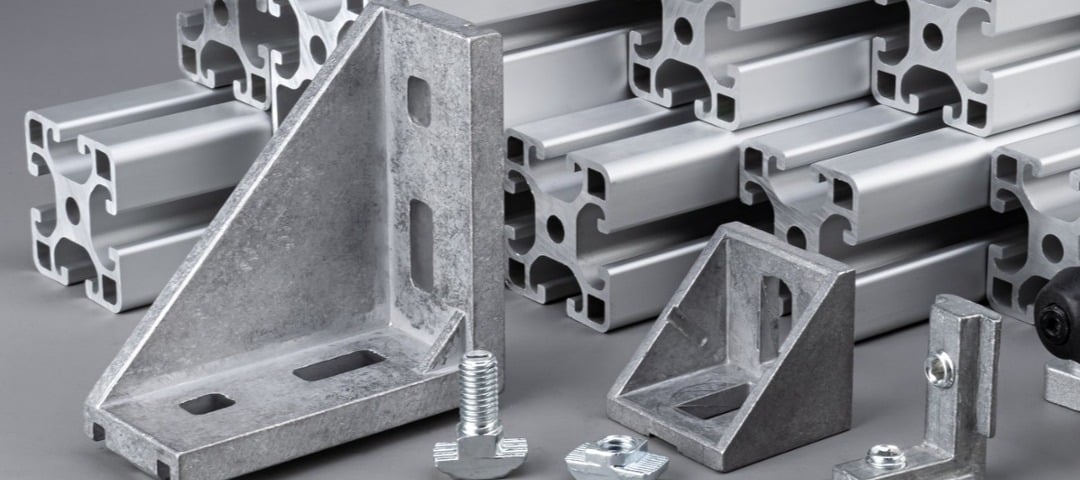

#8 Parco T-Slotted Aluminum Extrusions

Domain Est. 2004

Website: parco-inc.com

Key Highlights: 1000’s of aluminum extrusions, t-slot parts & accessories. Free customization. 100% compatibility. Satisfaction guaranteed. Shop online now….

#9 Extruded Aluminum Framing & T

Domain Est. 2009

Website: mknorthamerica.com

Key Highlights: Versatile, durable, and easy to use, mk North America’s extruded aluminum framing and t-slot extrusions provide the foundation for creating custom solutions….

Expert Sourcing Insights for Square Aluminum Frame

H2: 2026 Market Trends for Square Aluminum Frames

The global market for square aluminum frames is poised for robust growth and significant transformation by 2026, driven by converging trends across sustainability, technology, and shifting consumer and industrial demands. Here’s a detailed analysis of the key trends shaping the market:

1. Sustainability and Green Building as Primary Growth Drivers

- Net-Zero Commitments: Increasing global regulations (e.g., EU Green Deal, U.S. Inflation Reduction Act) are pushing construction and manufacturing sectors toward low-carbon materials. Aluminum’s high recyclability (up to 75% of all aluminum ever produced is still in use) positions square aluminum frames as a preferred choice.

- Circular Economy Integration: Manufacturers are investing in closed-loop recycling systems, reducing reliance on primary aluminum and lowering carbon footprints. By 2026, recycled-content aluminum frames will dominate premium segments.

- LEED & BREEAM Certification Demand: Square aluminum frames are increasingly specified in commercial and residential projects seeking green building certifications due to their durability, energy efficiency (when thermally broken), and sustainable sourcing.

2. Smart Integration and IoT-Enabled Frames

- Modular Smart Infrastructure: Square aluminum frames are evolving into structural platforms for IoT devices. By 2026, expect widespread adoption in smart buildings and cities, where frames integrate sensors, lighting, HVAC controls, and solar panels.

- Prefabrication and BIM Compatibility: The precision of aluminum extrusion makes square frames ideal for modular construction. Integration with Building Information Modeling (BIM) will streamline design-to-manufacture workflows, reducing waste and construction timelines.

3. Lightweighting in Transportation and Mobility

- EV and Lightweight Vehicle Design: The automotive and transportation sectors are prioritizing weight reduction to extend EV range. Square aluminum frames are being used in battery enclosures, chassis components, and interior structures.

- Urban Air Mobility (UAM): Emerging eVTOL (electric vertical takeoff and landing) aircraft rely on lightweight, high-strength materials. Aluminum square frames offer optimal strength-to-weight ratios for structural frameworks.

4. Expansion in Renewable Energy Infrastructure

- Solar Mounting Systems: Square aluminum frames are the standard in solar panel racking due to corrosion resistance, ease of assembly, and durability. The global solar boom will significantly drive demand through 2026.

- Energy Storage Enclosures: Modular battery storage units increasingly use aluminum frames for thermal management, protection, and scalability.

5. Regional Market Shifts and Supply Chain Resilience

- Nearshoring and Regional Hubs: Geopolitical tensions and supply chain disruptions are pushing manufacturers to regionalize production. North America and Europe are investing in domestic aluminum extrusion capacity, reducing reliance on Asia.

- Emerging Markets Growth: Rapid urbanization in Southeast Asia, India, and Africa is fueling demand for modern construction materials, including prefabricated aluminum framing systems.

6. Design Innovation and Aesthetic Flexibility

- Customization and Finishes: Advances in powder coating, anodizing, and digital printing allow for high-end aesthetic customization. Square frames will be used in premium architectural facades, retail interiors, and furniture.

- Minimalist and Industrial Design Trends: The clean lines of square aluminum align with contemporary design preferences in residential, commercial, and tech spaces.

7. Technological Advancements in Manufacturing

- Digital Twin and AI-Optimized Extrusion: AI-driven process control will enhance precision and reduce material waste in aluminum extrusion plants.

- Additive Manufacturing Integration: 3D-printed aluminum joints and connectors will enable more complex frame assemblies, reducing part count and assembly time.

Conclusion:

By 2026, the square aluminum frame market will be defined by sustainability leadership, smart functionality, and cross-industry versatility. Driven by environmental regulations, digitalization, and the rise of clean technologies, aluminum frames will move beyond structural roles to become intelligent, integrated systems in buildings, transportation, and energy infrastructure. Companies investing in recycling, automation, and design innovation will lead the next phase of growth.

Common Pitfalls Sourcing Square Aluminum Frame (Quality, IP)

When sourcing square aluminum frames—commonly used in industrial enclosures, machinery, and structural applications—buyers often encounter critical challenges related to quality and Intellectual Property (IP). Overlooking these factors can lead to performance issues, compliance risks, and legal exposure. Below are key pitfalls to avoid:

Poor Material Quality and Specifications

One of the most frequent issues is receiving aluminum frames that do not meet specified grades (e.g., 6061-T6 or 6063-T5). Substandard alloys may compromise structural integrity, corrosion resistance, and load-bearing capacity. Suppliers may cut costs by using recycled or off-spec materials, leading to warping, weak welds, or surface defects.

Inconsistent Manufacturing Tolerances

Low-cost manufacturers, especially in less-regulated markets, may fail to adhere to tight dimensional tolerances. This results in frames that do not align properly in assembly, causing delays and increased labor costs. Poor extrusion or machining processes can introduce bowing, twisting, or uneven corner joints.

Inadequate Surface Finish and Coating

Anodizing or powder coating is often applied for durability and aesthetics. However, some suppliers provide thin, uneven, or improperly cured coatings that chip or corrode prematurely. This affects both the product’s lifespan and appearance, especially in outdoor or harsh environments.

Misrepresentation of IP and Design Ownership

Many square aluminum frame systems (e.g., 80/20, Bosch Rexroth) are protected by patents, trademarks, or design rights. Sourcing knock-off or reverse-engineered profiles can expose buyers to intellectual property infringement claims. These copies may look similar but lack engineering validation and compatibility with genuine accessories.

Lack of Certification and Traceability

Reputable applications require material certifications (e.g., mill test reports, RoHS, REACH). Unverified suppliers may not provide documentation, making it impossible to confirm compliance with industry or safety standards. This is especially critical in regulated sectors like medical, aerospace, or transportation.

Hidden Costs from Rework and Downtime

Initial cost savings from low-quality frames are often offset by higher total cost of ownership. Poor-quality frames may require rework, cause assembly line stoppages, or fail in the field—damaging brand reputation and increasing warranty liabilities.

Supply Chain and Communication Risks

Working with overseas suppliers can lead to miscommunication about specs, long lead times, and limited recourse in case of disputes. Language barriers, time zone differences, and lack of on-site quality control increase the risk of receiving non-conforming products.

Conclusion

To mitigate these pitfalls, buyers should conduct thorough supplier vetting, request samples and certifications, and ensure design compliance with IP regulations. Investing in quality and legal diligence upfront protects long-term project success and avoids costly setbacks.

Logistics & Compliance Guide for Square Aluminum Frame

Product Overview

The Square Aluminum Frame is a lightweight, durable structural component commonly used in modular construction, display systems, solar panel mounting, and industrial equipment. Made from extruded aluminum alloy (typically 6063-T5), it features a hollow square cross-section with standardized slot and hole patterns for easy assembly with compatible connectors and accessories.

Packaging Specifications

- Standard Packaging: Frames are bundled in plastic-wrapped or cardboard-sleeved groups, secured on wooden or plastic pallets.

- Labeling: Each bundle includes a label with product code, dimensions (e.g., 40x40mm x 2000mm), alloy type, batch number, and handling instructions (e.g., “Do Not Stack,” “Protect from Moisture”).

- Pallet Dimensions: Standard EUR/ISO pallets (1200x800mm or 1200x1000mm); max stack height: 2.2 meters.

- Weight: Average unit weight varies by length and thickness; typical 2m frame (40x40x2mm): ~2.1 kg. Total pallet weight must not exceed 1,500 kg for safe handling.

Transportation Requirements

- Mode of Transport: Suitable for road, rail, sea (FCL/LCL), and air freight.

- Securing Loads: Pallets must be stretch-wrapped and strapped to prevent shifting. Use edge protectors to avoid damage during transit.

- Environmental Protection: Protect from rain, snow, and prolonged sun exposure. Avoid contact with corrosive substances.

- Handling: Use forklifts or pallet jacks; never drag bundles. Manual handling requires two personnel for lengths over 3 meters.

Storage Conditions

- Location: Store indoors in a dry, ventilated area. If outdoor storage is unavoidable, cover with waterproof tarpaulins and elevate on wooden pallets.

- Temperature: Stable conditions between -20°C and 50°C. Avoid condensation.

- Stacking: Max 3 layers high on flat, level surfaces. Separate batches to ensure first-in, first-out (FIFO) inventory rotation.

- Compatibility: Keep away from steel or copper materials to prevent galvanic corrosion.

Import/Export Compliance

- HS Code: 7604.21 (Aluminum bars, rods, and profiles, hollow). Confirm with local customs; variations may apply by country.

- Documentation: Commercial invoice, packing list, bill of lading/air waybill, certificate of origin, and material test report (MTR).

- REACH & RoHS: Compliant with EU REACH (SVHC-free) and RoHS directives—contains no restricted heavy metals or hazardous substances.

- TSCA (USA): Complies with Toxic Substances Control Act; aluminum is exempt from significant new use rules.

- Customs Duties: Duty rates vary by destination; verify under local tariff schedules. Free trade agreements (e.g., USMCA, CETA) may apply.

Quality & Certification

- Standards Met:

- ASTM B221 (Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles)

- EN 755-2 (European standard for aluminum and aluminum alloys — Extruded rod/bar, tube and profiles)

- Certifications: Mill Test Certificates (MTC) available upon request (EN 10204 3.1).

- Inspection: Random sampling per AQL Level II (ISO 2859-1) for dimensional accuracy, surface finish, and straightness.

Environmental & Safety Considerations

- Recyclability: 100% recyclable; aluminum recycling saves up to 95% energy compared to primary production.

- Hazardous Components: None. Non-toxic and non-combustible.

- Handling Safety: Wear gloves to prevent cuts from sharp edges. Use eye protection when cutting or machining.

- Waste Disposal: Recycle through certified metal recyclers; do not dispose of in general waste.

Documentation Checklist

Ensure the following are provided with each shipment:

– Packing List (itemized per pallet)

– Commercial Invoice

– Bill of Lading or Air Waybill

– Certificate of Origin

– Material Test Report (if requested)

– Safety Data Sheet (SDS) – available upon request (non-hazardous classification)

Contact & Support

For logistics inquiries, compliance documentation, or product support:

– Logistics Team: [email protected] | +1 (555) 123-4567

– Compliance Officer: [email protected]

– Website: www.yourcompany.com/compliance

Conclusion for Sourcing Square Aluminum Frame:

After a thorough evaluation of potential suppliers, material specifications, cost considerations, and lead times, sourcing square aluminum frames from pre-qualified, reputable manufacturers offers a reliable and cost-effective solution for structural and design applications. Aluminum’s favorable strength-to-weight ratio, corrosion resistance, and recyclability make it an ideal choice for lightweight, durable frameworks in industries such as construction, solar energy, transportation, and industrial equipment.

By partnering with suppliers offering consistent quality (e.g., ISO-certified production), competitive pricing, and customization options (such as varied alloys—6061-T6 or 6063-T5—and surface finishes like anodizing or powder coating), companies can ensure performance and design flexibility. Additionally, consolidating orders with suppliers capable of just-in-time delivery minimizes inventory costs and supports efficient production timelines.

In conclusion, a strategic sourcing approach focused on quality, scalability, and long-term supplier relationships will optimize value, reduce risks, and support sustainable manufacturing goals when procuring square aluminum frames.