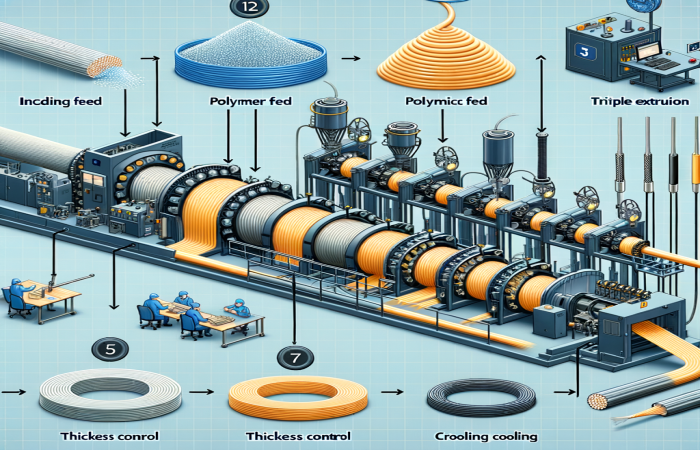

The global market for automotive and electrical wiring, including specialized products like SPt2 wires, is experiencing steady growth driven by rising demand in automotive, home appliance, and industrial sectors. According to a 2023 report by Mordor Intelligence, the global automotive wiring harness market—which heavily relies on SPt2 and similar wire types—was valued at USD 44.5 billion in 2022 and is projected to grow at a CAGR of over 6.8% from 2023 to 2028. This expansion is fueled by increased vehicle production, the proliferation of electronic components in modern automobiles, and advances in electric vehicle (EV) technology requiring reliable, durable wiring solutions. SPt2 wires, known for their twin-conductor, parallel configuration and resistance to abrasion and moisture, have become a standard in low-voltage power applications. As demand surges, manufacturers capable of delivering high-quality, compliant SPt2 wiring at scale are gaining strategic importance. Based on capacity, certifications, innovation, and global reach, the following seven companies stand out as leading SPt2 wire manufacturers shaping the industry’s future.

Top 7 Spt2 Wire Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SPT

Domain Est. 1994

Website: southwire.com

Key Highlights: Southwire’s Lamp Cord is manufactured with two bare annealed flexible stranded copper conductors and premium-grade two or three conductors laid parallel….

#2 93

Domain Est. 1996

Website: satco.com

Key Highlights: Lamp And Lighting Bulk Wire; 18/2 SPT-2 105C; 250 Foot/Spool; White. Products Specs. Products Specs. General. Company, SATCO. Status, Active. Wire Color, White….

#3 SPT-2 Lamp Cord

Domain Est. 1997

Website: awcwire.com

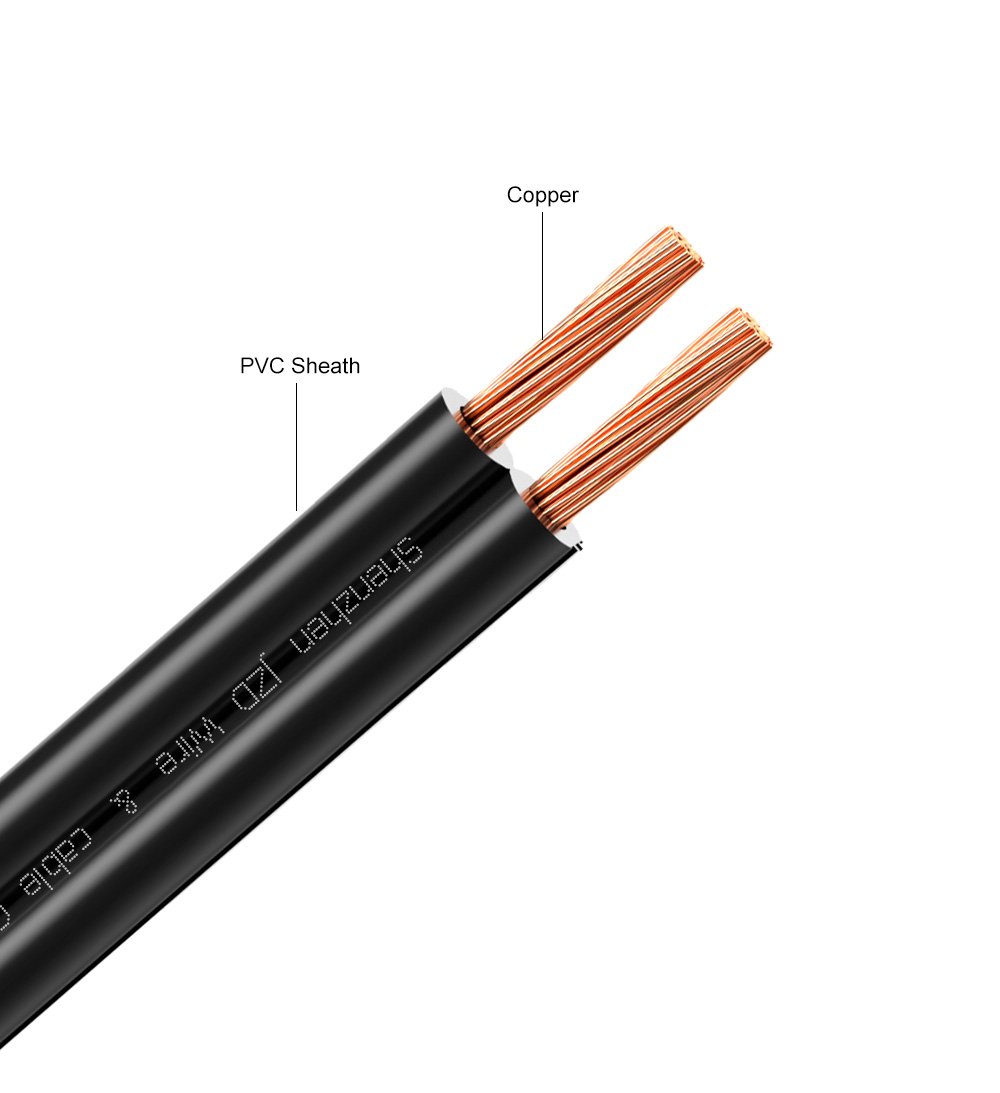

Key Highlights: Our SPT-2 Lamp Cord is commonly used in household appliances. It features two stranded copper conductors and PVC insulation….

#4 18/2 SPT

Domain Est. 1997

#5 18/2 SPT

Domain Est. 1999

Website: americord.com

Key Highlights: In stock Rating 4.8 (50) High-temp 18/2 SPT-2 black flat thermoplastic bulk cable rated 300V 10A. Great for lamps, small devices, and safe residential electrical applications….

#6 Shop Christmas Light Wire

Domain Est. 2001

Website: 1000bulbs.com

Key Highlights: Free delivery over $599.99 · 30-day returns…

#7 Plain Wire SPT-2

Domain Est. 2004

Expert Sourcing Insights for Spt2 Wire

H2: Market Trends for SPT2 Wire in 2026

As the global demand for safe, efficient, and versatile electrical wiring solutions continues to evolve, SPT2 wire—a standard type of parallel cord used extensively in light-duty electrical applications—is expected to experience notable shifts in market dynamics by 2026. Driven by advancements in technology, regulatory changes, and shifting consumer preferences, the SPT2 wire market is poised for moderate growth, particularly in specific industry sectors. Below is an analysis of key trends shaping the SPT2 wire market in 2026.

-

Growth in Consumer Electronics and Home Appliances

SPT2 wire remains a staple in low-voltage household appliances such as lamps, fans, coffee makers, and decorative lighting. By 2026, the continued expansion of smart home ecosystems and energy-efficient appliances is expected to sustain demand for reliable power cords. As consumers upgrade to newer, more efficient models, the replacement and repair market for SPT2 wire will benefit, especially in North America and Europe. -

Regulatory and Safety Standards Influence

Regulatory bodies such as UL (Underwriters Laboratories) and the National Electrical Code (NEC) continue to emphasize fire safety and electrical efficiency. SPT2 wire, rated for 300 volts and typically used in 16–18 AWG configurations, complies with many safety standards for indoor use. By 2026, stricter energy codes and increased scrutiny on cord safety (especially in children’s products and holiday lighting) may lead to higher demand for certified SPT2 variants that meet enhanced flammability and durability requirements. -

Sustainability and Material Innovation

Environmental concerns are driving innovation in wire insulation materials. Traditional PVC insulation used in SPT2 wire is under scrutiny due to its environmental impact during production and disposal. By 2026, manufacturers are increasingly adopting low-smoke zero-halogen (LSZH) or recyclable thermoplastic alternatives. This shift supports sustainability goals and appeals to eco-conscious consumers and B2B clients in the retail and manufacturing sectors. -

E-Commerce and DIY Market Expansion

The DIY (Do-It-Yourself) movement, combined with the rise of e-commerce platforms like Amazon, Home Depot, and specialized electrical suppliers, has made SPT2 wire more accessible to end users. In 2026, online retail is expected to account for a significant share of SPT2 wire sales, especially for replacement cords, custom-length cuts, and color-matched wiring in home décor applications. -

Regional Market Dynamics

North America remains the largest consumer of SPT2 wire due to established electrical codes and high appliance ownership. However, emerging markets in Southeast Asia and Latin America are showing increased demand, driven by urbanization and rising middle-class consumption. Local manufacturing hubs in countries like Vietnam and Mexico are also contributing to regional supply chain resilience, reducing dependency on imports. -

Competition from Alternatives

While SPT2 remains popular, it faces competition from higher-rated wires like SPT3 (for heavier loads) and flat, flexible alternatives used in modern electronics. However, for standard indoor applications under 7 Amps, SPT2 maintains a cost and availability advantage. By 2026, its niche is expected to remain secure, particularly in cost-sensitive and low-power applications.

Conclusion:

By 2026, the SPT2 wire market will continue to be shaped by demand from consumer appliances, evolving safety standards, and sustainability initiatives. While not at the forefront of high-tech electrical innovation, SPT2 wire will maintain steady relevance due to its proven reliability, widespread compatibility, and adaptability to changing market needs. Manufacturers who invest in eco-friendly materials, compliance, and e-commerce distribution will be best positioned to capitalize on these trends.

Common Pitfalls When Sourcing SPT2 Wire (Quality, IP)

When sourcing SPT2 wire—a common type of zip cord used in lamps, small appliances, and holiday lighting—several pitfalls can compromise product safety, performance, and compliance, especially related to quality and intellectual property (IP) concerns. Being aware of these issues is critical for manufacturers, importers, and OEMs.

Substandard Material Quality

One of the most prevalent issues is receiving SPT2 wire that does not meet required electrical and mechanical standards. Inferior copper conductors (such as copper-clad aluminum or reduced gauge) increase resistance, leading to overheating and fire hazards. Additionally, low-grade PVC insulation may crack under stress or temperature changes, exposing live wires and creating safety risks. Always verify compliance with UL 83 and UL 62 standards and request test reports or certifications from suppliers.

Inaccurate or Missing Certifications

Many suppliers, especially those from unverified sources, may falsely claim UL or CSA certification. Counterfeit certification marks are common in low-cost markets. Without valid certifications, products may fail safety inspections or be rejected by retailers and regulatory bodies. Always verify certification authenticity through official databases like UL’s Product iQ.

Gauge Misrepresentation

SPT2 wire is typically available in 16 AWG or 18 AWG. Suppliers may mislabel thinner wire (e.g., 18 AWG as 16 AWG) to cut costs. This can lead to inadequate current-carrying capacity, especially in high-load applications, increasing the risk of overheating. Conduct physical inspections and use micrometers to verify conductor diameter.

Non-Compliant Flame Ratings

Some SPT2 wire variants must meet specific flame resistance standards (e.g., VW-1). Substandard wire may lack proper flame-retardant additives, failing compliance tests. This is especially critical in consumer products where fire safety is paramount. Request flame test documentation and verify against safety standards.

Intellectual Property (IP) Infringement Risks

Sourcing from unauthorized or counterfeit suppliers can expose buyers to IP violations. Reputable brands like WireCare or Belden invest in proprietary formulations and trademarked product lines. Using counterfeit or imitation wire with protected branding—even unknowingly—can lead to legal liability, product seizures, or damage to brand reputation. Ensure suppliers are authorized distributors and avoid suspiciously low pricing that may indicate knock-offs.

Inconsistent Batch Quality

Suppliers, particularly smaller or offshore manufacturers, may lack consistent quality control. This results in variation between production batches—different insulation thickness, color fading, or inconsistent strand count—leading to field failures or rework. Establish quality agreements and conduct incoming inspections to mitigate this risk.

Poor Packaging and Labeling

Mislabeling or missing labeling (e.g., gauge, temperature rating, voltage) can cause incorrect usage in downstream manufacturing. Poor spooling or packaging may also damage the wire during shipping. Ensure labeling meets NEC and UL requirements and inspect packaging integrity upon receipt.

Lack of Traceability and Documentation

Without batch traceability, investigating field failures or conducting recalls becomes nearly impossible. Reputable suppliers provide lot numbers and material certifications. Avoid vendors who cannot supply full documentation, as this increases supply chain risk.

Conclusion

To avoid these pitfalls, work with verified, reputable suppliers, insist on proper certifications, conduct regular audits, and perform incoming quality checks. Prioritizing long-term reliability over short-term cost savings ensures compliance, safety, and protection against IP and quality-related liabilities.

Logistics & Compliance Guide for Spt2 Wire

This guide outlines key logistics and compliance considerations for handling, shipping, and using SPT-2 (Style 8099) cord wire in accordance with U.S. and international standards.

Product Overview

SPT-2 wire is a two-conductor, parallel jacketed cable commonly used in light-duty extension cords, lamps, and small appliances. It features thermoplastic insulation and a flat profile, rated for 300 volts and typically 105°C. The “SPT” stands for “Service Parallel Thermoplastic,” and the “2” indicates a thicker jacket than SPT-1, offering improved durability and abrasion resistance.

Regulatory Compliance

SPT-2 wire must comply with UL 817 (Standard for Power Supply Cords) and UL 62 (Standard for Flexible Cords and Cables) in the United States. It carries a UL AWM (Appliance Wiring Material) certification (Style 8099) and is often marked with “SPT-2,” “AWM,” “80°C,” and “300V.” Compliance with the National Electrical Code (NEC) Article 400 is required for safe installation. Internationally, equivalent standards include CSA C22.2 No. 44 in Canada and IEC 60227 for general-purpose PVC cables.

Packaging & Labeling Requirements

SPT-2 wire must be packaged to prevent kinking, moisture exposure, and mechanical damage. Spools or reels should be clearly labeled with:

– Wire type (SPT-2 / Style 8099)

– Gauge (e.g., 16 AWG, 18 AWG)

– Voltage and temperature rating (300V, 80°C or 105°C)

– Length

– UL/CSA certification marks

– Manufacturer name and lot number

– RoHS and REACH compliance (where applicable)

Storage Conditions

Store SPT-2 wire in a dry, temperature-controlled environment (10°C to 30°C). Avoid direct sunlight, extreme humidity, and exposure to oils, solvents, or corrosive chemicals. Reels should be stored vertically to prevent deformation and edge damage.

Transportation Guidelines

When shipping SPT-2 wire:

– Use sturdy, moisture-resistant packaging (e.g., corrugated cartons with protective wrapping)

– Secure spools to prevent movement during transit

– Label packages as “Fragile” and “Protect from Moisture”

– Comply with DOT and IATA regulations when shipping hazardous materials (if applicable, e.g., large quantities with flammable packaging)

– Provide appropriate documentation, including packing lists and certificates of compliance

Import & Export Compliance

For international shipments, ensure SPT-2 wire meets destination country regulations. U.S. exports must include UL certification documentation. Importers must verify compliance with local electrical safety standards (e.g., CE in Europe, CCC in China). Maintain records of conformity assessments, test reports, and declarations of performance. Adhere to customs requirements, including proper HS code classification (typically 8544.42 or 8544.49 for insulated wires).

Environmental & Safety Considerations

SPT-2 wire contains PVC, which requires proper disposal or recycling per local environmental regulations. Do not incinerate without emission controls. Handle with standard personal protective equipment (PPE) during cutting or stripping to avoid skin irritation. Ensure end products using SPT-2 wire are designed to prevent overheating and comply with end-use appliance standards.

Quality Assurance & Traceability

Maintain lot traceability for all SPT-2 wire shipments. Conduct periodic audits of supplier compliance with UL and RoHS standards. Retain test reports and certification documents for a minimum of five years. Report non-conformances immediately to regulatory bodies if safety risks are identified.

Conclusion

Proper logistics and compliance management for SPT-2 wire ensures product safety, regulatory adherence, and smooth global distribution. Always verify certifications, follow handling best practices, and maintain accurate documentation throughout the supply chain.

Conclusion for Sourcing SPT-2 Wire:

After thorough evaluation of suppliers, quality standards, cost considerations, and regulatory compliance, sourcing SPT-2 wire requires a balanced approach that prioritizes safety, durability, and value. It is essential to partner with reputable manufacturers or distributors that provide UL-certified or equivalent compliant wire to ensure performance in low-voltage and light-duty electrical applications such as lamps, holiday lighting, and extension cords.

Key factors in successful sourcing include verifying wire gauge (typically 18 AWG to 16 AWG), insulation thickness, temperature rating (commonly 60°C or 105°C), and compliance with local and international standards (e.g., UL 83, CSA Type SPT-2). Additionally, bulk purchasing from suppliers with consistent quality control and reliable lead times can lead to cost savings without compromising safety.

In conclusion, effective sourcing of SPT-2 wire hinges on due diligence in supplier selection, adherence to technical specifications, and ongoing quality assurance to support safe and reliable electrical assemblies.