The global spring hook clip market is experiencing steady growth, driven by increasing demand across industrial, automotive, and consumer goods sectors. According to Grand View Research, the global fasteners market—under which spring hook clips fall—was valued at USD 97.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by rising infrastructure development, manufacturing activities, and automotive production, particularly in Asia-Pacific and North America. As demand for reliable, versatile fastening solutions grows, manufacturers of spring hook clips are scaling innovation in materials, durability, and precision engineering. In this evolving landscape, identifying leading suppliers becomes critical for procurement teams seeking quality, scalability, and cost-efficiency. Based on production capacity, geographic reach, product range, and industry reputation, the following nine manufacturers have emerged as key players in the spring hook clip market.

Top 9 Spring Hook Clip Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

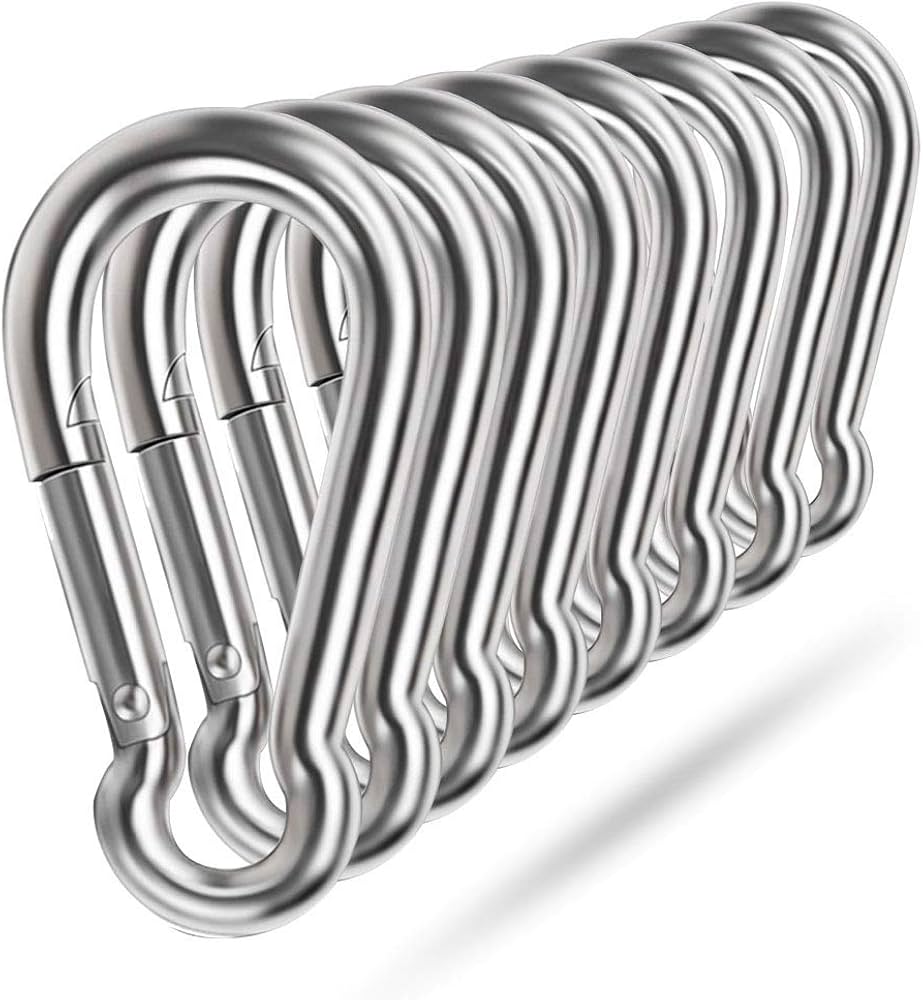

#1 Spring Hooks Made of Steel Metal and Stainles Steel

Domain Est. 2008

Website: usalanyards.com

Key Highlights: Free deliveryWe are a factory-direct wholesaler and manufacturer of heavy-duty, high quality spring hooks. Our spring hooks are available in 4 colors….

#2 Spring Snap Clip Supplies

Domain Est. 2021

Website: murphylift.com

Key Highlights: In stock Free deliveryMurphy Industrial Products, Inc.: A wholesale spring snap hooks supplier located in Houston, TX supplies varieties of spring snap clips with same-day shipping…

#3 Swivel Clip Factory Highly Durable Safety Versatility Custom

Domain Est. 2023

Website: johoty.com

Key Highlights: Best Swivel Clip, China Manufacturer. Swivel Clip is very reliable and beautiful, often made of stainless steel and zinc alloy, with high strength….

#4 Spring Snap Hooks

Domain Est. 1997

Website: ronstan.com

Key Highlights: Free delivery over $75 30-day returnsSpring Snap Hooks – Commodity Grade Stainless Steel Hardware – Industrial Products – Products | Ronstan Sailboat Hardware USA….

#5 Snap Hooks

Domain Est. 1997

Website: spep.com

Key Highlights: SPEP offers heavy duty snap hooks for OEMs, distributors & other professionals. Browse our catalog & custom order your spring loaded clips today….

#6 Spring Links

Domain Est. 1995

Website: peerlesschain.com

Key Highlights: Hooks, Links, Snaps, Clips. HOOKS, LINKS, SNAPS, CLIPS. Explore How to Buy · G43 Clevis Grab Hook. G43 Clevis Grab Hook. Available finishes: zinc plated or self ……

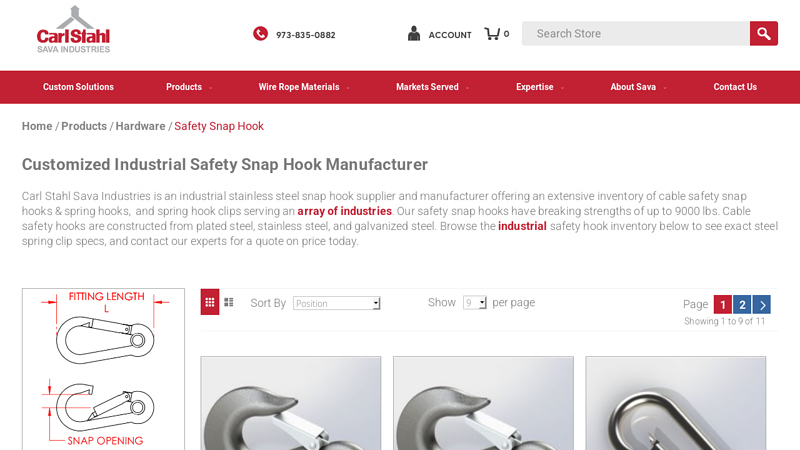

#7 Safety Snap Hooks – Breaking Strengths Up To 9000 lbs.

Domain Est. 1997

Website: savacable.com

Key Highlights: Our safety snap hooks have breaking strengths of up to 9000 lbs. Cable safety hooks are constructed from plated steel, stainless steel, and galvanized steel….

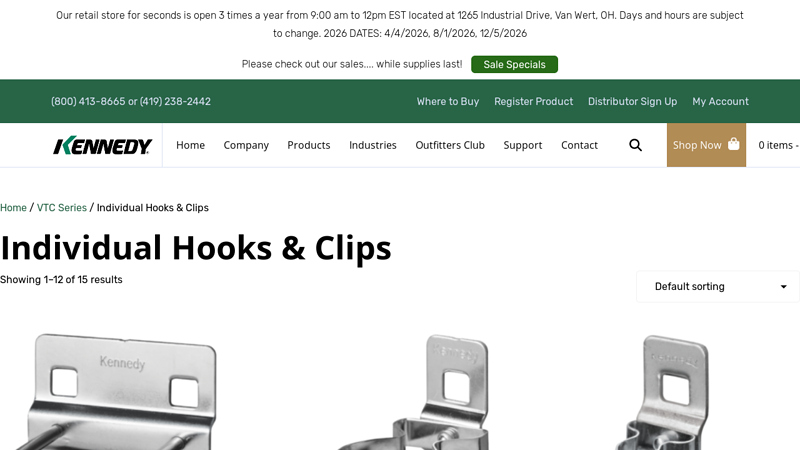

#8 Individual Hooks & Clips Archives

Domain Est. 2013

Website: buykennedy.com

Key Highlights: Individual Hooks & Clips ; 1 3/8″ W Toolboard Plier Hook · 99831 · 45.60 ; 1″ Diam. Toolboard Spring Clip · 99836 · 35.93 ; 1/2″ Diam. Toolboard Spring Clip · 99833 ……

#9 Spring Hooks

Domain Est. 2018

Website: baronhardware.com

Key Highlights: Spring load interlocking snaps. Ideal for small boat, water skiing, mooring, motor safety line, etc. 700. 2450S-4, 3/8, 4 ……

Expert Sourcing Insights for Spring Hook Clip

2026 Market Trends for Spring Hook Clip

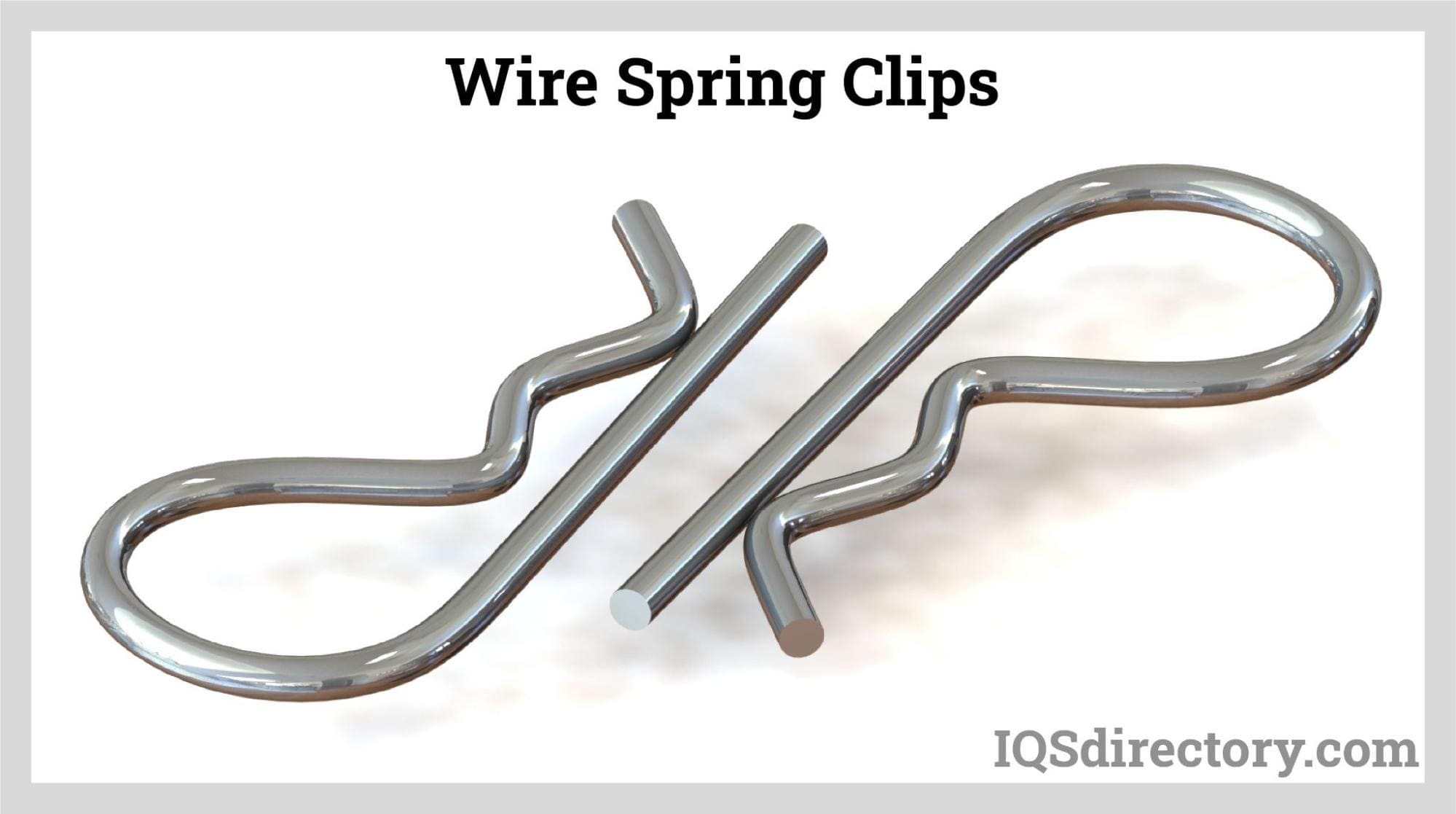

The global market for spring hook clips—mechanical fasteners designed for quick attachment and detachment using a spring-loaded mechanism—is poised for notable evolution by 2026. Driven by advancements in manufacturing, shifting end-user demands, and sustainability imperatives, several key trends are expected to shape the industry landscape.

Rising Demand from Automotive and Electronics Sectors

The automotive industry’s continued shift toward lightweight materials and modular assembly will boost demand for reliable, reusable fastening solutions like spring hook clips. In electric vehicles (EVs), these components are increasingly used in battery enclosures and interior paneling due to their vibration resistance and ease of maintenance. Similarly, in consumer electronics, compact and durable spring hook clips are being adopted in device casings and internal component securing, reflecting trends toward slimmer designs and serviceability.

Growth in Industrial Automation and Smart Manufacturing

As factories adopt Industry 4.0 principles, there is increased integration of automated assembly lines. Spring hook clips are well-suited for robotic handling due to their standardized design and tool-less installation. By 2026, manufacturers are expected to focus on producing clips compatible with high-speed automation, driving innovation in material consistency, dimensional precision, and anti-corrosion treatments.

Shift Toward Sustainable and Recyclable Materials

Environmental regulations and corporate sustainability goals are pushing demand for eco-friendly fasteners. By 2026, a growing segment of spring hook clips will be made from recycled metals (e.g., stainless steel, aluminum) or bio-based polymers. Additionally, designs facilitating easy disassembly will gain traction, supporting circular economy models in sectors like electronics and appliances.

Regional Market Expansion in Asia-Pacific

The Asia-Pacific region, particularly China, India, and Southeast Asia, is anticipated to lead market growth due to rapid industrialization, expanding manufacturing bases, and rising domestic consumption. Localized production of spring hook clips will increase to reduce supply chain dependencies and logistics costs, with a focus on cost-effective, high-volume manufacturing techniques.

Technological Innovation and Customization

Advancements in materials science and precision engineering will enable more specialized spring hook clip variants—such as corrosion-resistant, high-temperature, or anti-static versions—for niche applications in aerospace, medical devices, and renewable energy systems. Customization will become a competitive differentiator, with manufacturers offering tailored clip geometries and coatings to meet specific client requirements.

Competitive Landscape and Supply Chain Resilience

The market will likely see consolidation among suppliers, with larger players acquiring niche manufacturers to broaden product portfolios. Simultaneously, supply chain resilience will remain a priority post-pandemic, prompting investment in dual sourcing and digital inventory management systems to mitigate disruptions.

In summary, the 2026 spring hook clip market will be characterized by technological refinement, sustainability integration, and strong regional growth—positioning it as a critical enabler in modern manufacturing and assembly processes across multiple high-growth industries.

Common Pitfalls When Sourcing Spring Hook Clips (Quality, IP)

Sourcing Spring Hook Clips—especially for use in regulated or high-reliability industries—can present several risks related to both quality and intellectual property (IP). Being aware of these pitfalls helps ensure product performance, compliance, and legal safety.

Poor Material Quality and Inconsistent Manufacturing

One of the most frequent issues is sourcing clips made from substandard materials or produced with inconsistent tolerances. Low-grade spring steel or improper heat treatment can lead to premature fatigue, corrosion, or failure under load. Suppliers from regions with lax quality controls may deliver products that visually resemble genuine clips but lack the mechanical properties required for reliable performance.

Risks:

– Reduced fatigue life and structural integrity

– Inconsistent hook tension or retention force

– Corrosion due to inadequate plating or material choice

Best Practice: Require material certifications (e.g., RoHS, REACH, ASTM) and conduct batch testing or third-party inspections.

Lack of Traceability and Documentation

Many low-cost suppliers fail to provide full traceability, including lot numbers, manufacturing dates, or test reports. Without these, it’s difficult to verify compliance or conduct root cause analysis in the event of a failure.

Risks:

– Inability to recall defective batches

– Non-compliance with industry standards (e.g., ISO, AS9100)

– Challenges in auditing supply chain

Best Practice: Insist on full documentation and supplier quality management systems.

Intellectual Property (IP) Infringement

Spring Hook Clips often incorporate patented designs, especially those used in aerospace, medical, or automotive applications. Sourcing generic or “compatible” versions from unauthorized manufacturers can lead to IP violations—even if unintentional.

Risks:

– Legal action from patent holders

– Seizure of goods by customs (especially in IP-sensitive regions like the EU or US)

– Damage to brand reputation and customer trust

Best Practice: Verify the original equipment manufacturer (OEM) design rights and use licensed suppliers or obtain proper IP clearance before production.

Mislabeling or Counterfeit Components

Counterfeit or mislabeled clips may be sold as meeting certain specifications (e.g., MIL-SPEC or DIN standards) without actual compliance. These components often fail under stress or environmental exposure.

Risks:

– System failure in critical applications

– Liability for end-product malfunction

– Regulatory non-compliance

Best Practice: Source from authorized distributors, use forensic testing (e.g., metallurgical analysis), and verify markings and packaging against OEM standards.

Inadequate Testing and Validation

Suppliers may claim compliance with performance standards without conducting proper testing. Without proof of load testing, cycle testing, or environmental resistance, the clips may not perform as expected.

Risks:

– Field failures due to unvalidated performance

– Increased warranty claims and returns

– Safety hazards in end-use applications

Best Practice: Require test data (e.g., tensile strength, cycle life) and conduct in-house validation prior to full-scale integration.

By addressing these common pitfalls proactively—through due diligence, supplier vetting, and robust quality controls—companies can ensure reliable, compliant, and legally safe sourcing of Spring Hook Clips.

Logistics & Compliance Guide for Spring Hook Clip

This guide outlines the essential logistics and compliance considerations for handling, transporting, and distributing Spring Hook Clips. Adhering to these standards ensures product integrity, regulatory compliance, and operational efficiency throughout the supply chain.

Product Specifications and Identification

Ensure all Spring Hook Clips are clearly labeled with product codes, material type (e.g., zinc-plated steel, stainless steel), dimensions, and batch/lot numbers. Maintain a detailed product specification sheet that includes weight, packaging configuration, and intended use to support accurate inventory and shipping documentation.

Packaging Requirements

Spring Hook Clips must be packaged to prevent damage, corrosion, and tangling during transit. Use moisture-resistant inner packaging (e.g., anti-corrosion paper or vapor corrosion inhibitors) for metal variants. Outer packaging should be sturdy corrugated cardboard or reusable containers, properly sealed and labeled with handling instructions such as “Fragile” or “Do Not Crush.” Include quantity counts and SKU information on each unit.

Storage Conditions

Store Spring Hook Clips in a dry, temperature-controlled environment to prevent rust and material degradation. Keep inventory off the floor on pallets or shelves and away from direct exposure to humidity or corrosive substances. Implement a first-in, first-out (FIFO) stock rotation system to minimize aging and obsolescence.

Transportation and Handling

Use secure, enclosed transport vehicles to protect packages from weather and contamination. Ensure loads are properly stacked and restrained to avoid shifting. Handle packages with care—avoid dropping or excessive compression. Document carrier compliance with ISO 9001 or equivalent quality management standards where applicable.

Regulatory Compliance

Spring Hook Clips may be subject to international and regional regulations depending on material composition and destination. Confirm compliance with:

- REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals—ensure no restricted substances are present.

- RoHS (EU): Restriction of Hazardous Substances—applicable if clips are used in electrical or electronic equipment.

- CPSIA (USA): Consumer Product Safety Improvement Act—relevant if clips are part of consumer goods.

- ITAR/EAR (USA): Verify if export controls apply, though typically not required for standard hardware.

Maintain up-to-date Declarations of Conformity and Material Safety Data Sheets (MSDS/SDS) for all product variants.

Import/Export Documentation

For cross-border shipments, prepare accurate commercial invoices, packing lists, and certificates of origin. Classify the product under the correct Harmonized System (HS) code—typically 7318.15 for threaded self-tapping screws and similar articles, or 7318.29 for other fasteners. Verify tariff rates and import restrictions in the destination country.

Quality Assurance and Traceability

Implement a traceability system that links each batch of Spring Hook Clips to production records, inspection reports, and shipping data. Conduct regular quality audits of packaging and handling procedures. Address non-conformances promptly with corrective action plans.

Environmental and Sustainability Practices

Prioritize recyclable or reusable packaging materials. Comply with local waste disposal regulations for packaging waste. Where possible, partner with logistics providers that offer carbon-neutral shipping options to support sustainability goals.

Incident Reporting and Recalls

Establish a protocol for reporting logistics-related incidents such as damaged goods, mis Shipments, or compliance failures. In the event of a product recall, ensure rapid communication with distributors and regulatory bodies, supported by full batch traceability.

Conclusion for Sourcing Spring Hook Clip

After a comprehensive evaluation of potential suppliers, material specifications, cost considerations, and quality standards, sourcing spring hook clips from pre-qualified, reliable manufacturers—preferably with ISO certification and a proven track record in metal stamping and spring component production—is strongly recommended. Key factors such as material durability (typically spring steel or stainless steel), consistent dimensional accuracy, corrosion resistance, and competitive pricing have been assessed to ensure optimal performance and longevity in end-use applications.

By partnering with suppliers offering scalable production capacity, stringent quality control measures, and timely delivery, the procurement process can achieve a balance between cost-efficiency and product reliability. Additionally, establishing long-term supplier relationships and conducting periodic audits will support continuous improvement and supply chain resilience.

In conclusion, a strategic sourcing approach focused on quality, reliability, and cost-effectiveness will ensure the successful integration of spring hook clips into the final product, meeting both technical requirements and customer expectations.