The global spring manufacturing market continues to expand, driven by increasing demand across automotive, industrial machinery, and consumer electronics sectors. According to a 2023 report by Mordor Intelligence, the global spring market was valued at USD 27.8 billion and is projected to grow at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2028. This growth is mirrored in specialized segments such as hinge springs, where precision, durability, and miniaturization are critical. As the demand for high-performance hinges rises—particularly in appliances, medical devices, and smart electronics—the need for reliable spring suppliers has never been greater. Leveraging market data, production capacity, and engineering expertise, the following list highlights the top 10 manufacturers excelling in spring solutions for hinge applications, combining innovation with scalable manufacturing to meet evolving industry standards.

Top 10 Spring For Hinge Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

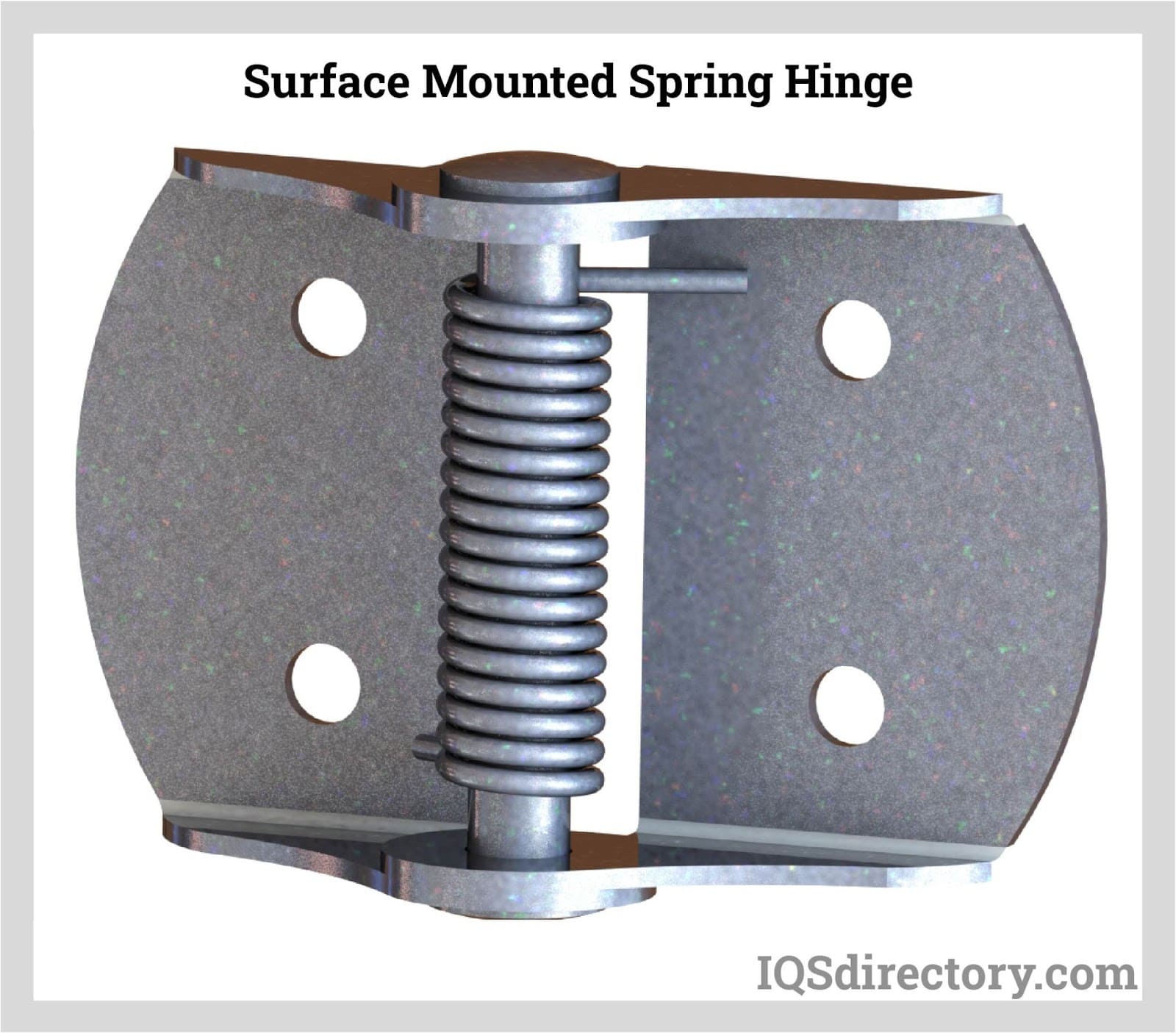

#1 Spring Hinges for Industrial Doors & Cabinets

Domain Est. 1995

Website: guden.com

Key Highlights: Find or customize spring hinges for industrial doors, cabinets and enclosures. High-quality spring hinges for controlled closing and hands-free access….

#2 Reell

Domain Est. 1995

Website: reell.com

Key Highlights: Reell provides solutions to transmit torque, control angular position, and protect delicate components from excessive force….

#3 Hinge Outlet

Domain Est. 2004

Website: hingeoutlet.com

Key Highlights: Hinge Outlet, Inc. offers a wide range of spring hinges, residential door hinges, ball bearing hinges, and more. Find out more about our products today….

#4 Spring Hinge Suppliers

Domain Est. 2015

Website: hingemanufacturers.org

Key Highlights: See Spring Hinge manufacturers and suppliers through this site, many of whom are offering hinges of all styles, including marine hinges, from materials….

#5 Bommer Industries

Domain Est. 1996

Website: bommer.com

Key Highlights: Bommer has ceased manufacturing operations. We no longer have any inventory available! For contract butt hinges OR single acting spring hinges ( ……

#6 McKinney Hinge

Domain Est. 1997

Website: mckinneyhinge.com

Key Highlights: McKinney Products Company is an ASSA ABLOY product line that manufactures & designs high quality architectural hinges for commercial use….

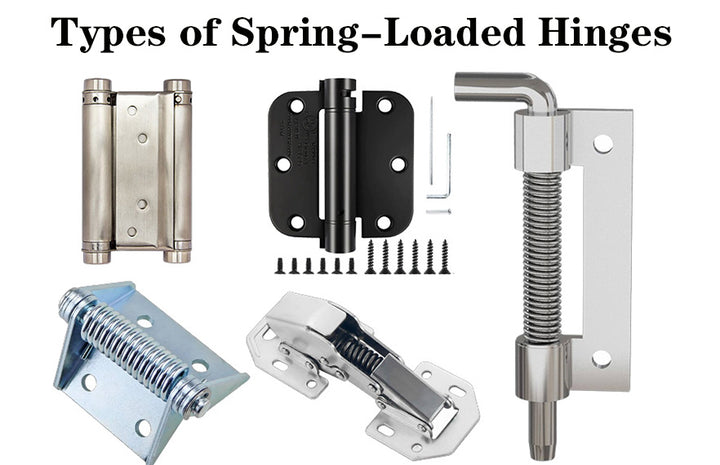

#7 Spring Loaded Hinges

Domain Est. 1999

Website: monroeengineering.com

Key Highlights: Monroe manufactures custom spring loaded hinges. Spring Loaded Hinges can be configured for various tensions and to hold the hinge in the open or the closed ……

#8 SIMONSWERK

Domain Est. 2000

Website: us.simonswerk.com

Key Highlights: Discover premium hinge systems by SIMONSWERK: solutions for timber, glass, PVC-u, aluminium and steel doors. 135 + years of German craftsmanship, ……

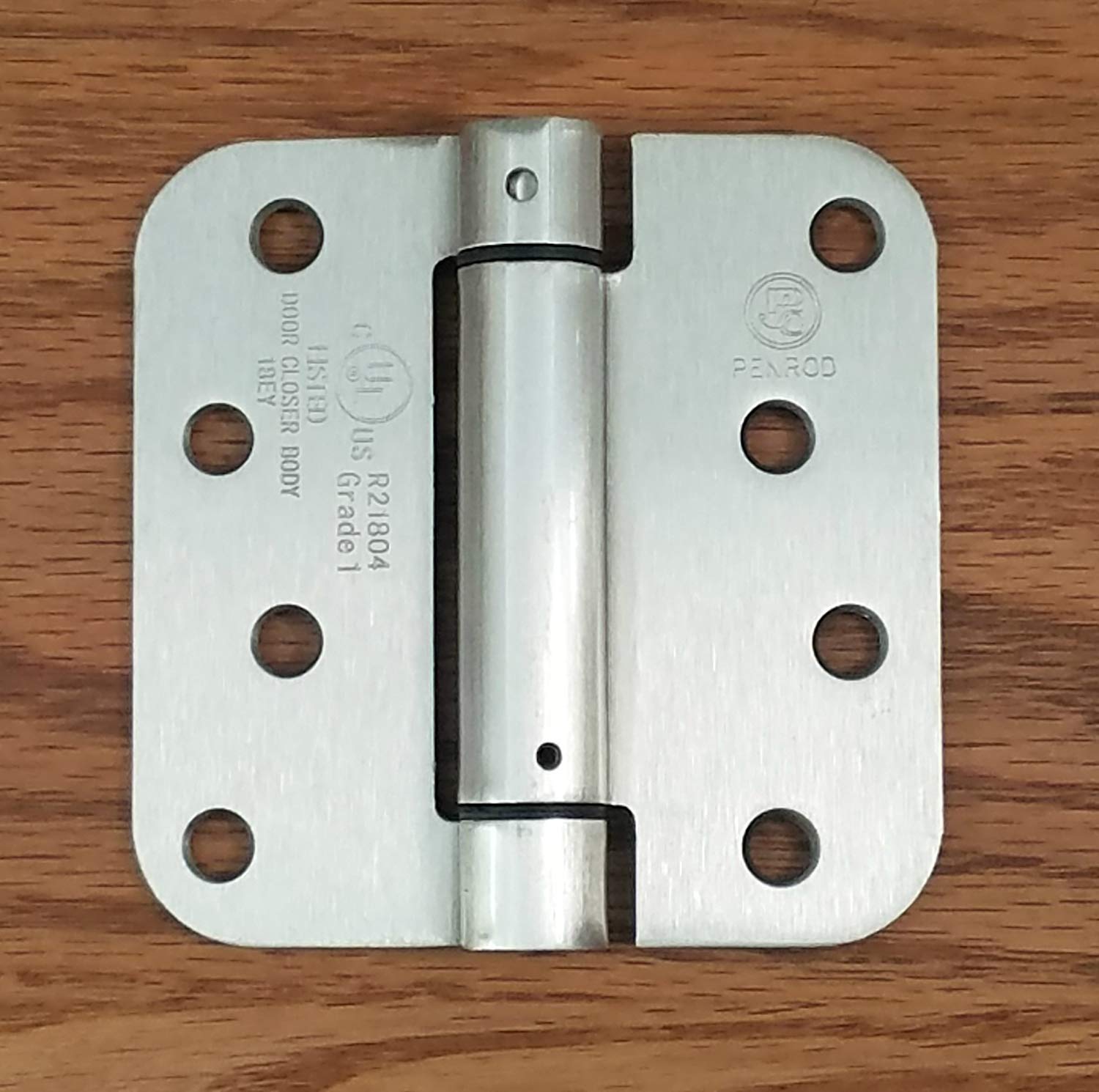

#9 Penrod

Domain Est. 2017

Website: hardwarebypenrod.com

Key Highlights: Penrod supplies high-quality door hardware—hinges, weather stripping, sweeps, barn door hardware, and PVC mouldings—with 35+ years of trusted expertise….

#10 Spring Hinge Series

Domain Est. 1996

Website: bestaccess.com

Key Highlights: Our spring hinges are ideal for wood and metal doors, medium to heavy weight doors and low to medium frequency usage applications….

Expert Sourcing Insights for Spring For Hinge

2026 Market Trends for Spring For Hinge

1. Hyper-Personalization Through AI Dominates User Experience

By 2026, Spring For Hinge will leverage advanced AI to deliver deeply personalized matchmaking and content curation. Machine learning algorithms will analyze not only explicit user preferences but also behavioral patterns—such as response timing, photo engagement, and conversation tone—to predict compatibility with higher accuracy. Expect dynamic profile optimization, where the app suggests real-time tweaks to bios and photos based on performance data. AI-driven “date idea” suggestions tailored to mutual interests and local events will become a core feature, enhancing user engagement and conversion.

2. Emphasis on Intentional Dating and Long-Term Outcomes

The market will continue shifting away from casual swiping toward platforms that promote meaningful connections. Spring For Hinge will double down on its “designed to be deleted” ethos, introducing verified milestone tracking (e.g., first date, three-month anniversary) and success story features. By 2026, user trust will hinge on transparency—expect more verified profiles, digital identity checks, and integration with wellness apps to promote emotional readiness for relationships. Brands that demonstrate real-world relationship outcomes will gain a competitive edge.

3. Integration of Augmented Reality (AR) and Immersive Experiences

Spring For Hinge will experiment with AR-powered profile enhancements, allowing users to share 3D snapshots or virtual “mini-tours” of favorite spots. Virtual dating spaces—such as co-watched movies or AR-enabled games—will bridge the gap between online interaction and real-life chemistry. These immersive tools will be especially valuable in early 2026 as hybrid social models persist, helping users build rapport before meeting in person.

4. Niche Community Expansion and Inclusivity

To capture underserved demographics, Spring For Hinge will launch interest-based micro-communities (e.g., “Outdoor Enthusiasts,” “Creative Professionals,” “Parents Dating Again”). These sub-networks foster deeper connections by aligning users around shared lifestyles. Additionally, inclusivity features—such as expanded gender/identity options, accessibility tools, and culturally sensitive matching algorithms—will be standard by 2026, reflecting broader societal expectations and regulatory trends.

5. Monetization Shifts Toward Value-Added Services

While subscription models remain, Spring For Hinge will expand into premium services such as AI-powered dating coaching, personalized compatibility reports, and curated match events. Partnerships with lifestyle brands (e.g., date spot discounts, travel experiences) will create new revenue streams. Users will increasingly pay for time-saving, high-trust features that accelerate the path to meaningful relationships.

6. Data Privacy and Ethical AI as Competitive Differentiators

With heightened global scrutiny on data usage, Spring For Hinge will prioritize transparent data policies and on-device processing to protect user privacy. The ethical use of AI—avoiding bias in matching and ensuring equitable visibility—will be a key brand message. By 2026, users will favor platforms that offer clear control over personal data, making privacy a core component of brand trust and market positioning.

Common Pitfalls Sourcing Springs for Hinges (Quality, IP)

When sourcing springs for hinge applications—whether in consumer electronics, industrial equipment, or automotive systems—organizations often face recurring challenges that impact performance, durability, and compliance. Two critical areas of concern are quality inconsistencies and intellectual property (IP) risks. Below are common pitfalls in these domains and how to avoid them.

Quality-Related Pitfalls

1. Inadequate Material Specifications

Many suppliers use substandard materials to cut costs, leading to premature spring failure. For example, using non-stainless or improperly tempered steel in high-cycle or corrosive environments results in fatigue, rust, or loss of tension.

Mitigation: Define exact material grades (e.g., ASTM A313 for stainless steel springs), hardness (HRC), and corrosion resistance (e.g., salt spray test requirements) in procurement specifications.

2. Poor Dimensional Consistency

Springs with inconsistent free length, wire diameter, or coil count produce uneven torque, causing hinge mechanisms to feel loose, stiff, or unstable.

Mitigation: Require statistical process control (SPC) data and implement incoming inspection protocols with calibrated measurement tools (e.g., optical comparators or CMMs).

3. Inadequate Fatigue Testing

Suppliers may provide springs that pass initial load testing but fail under repeated cycling. Hinges in laptops or automotive doors may undergo tens of thousands of cycles—springs must be tested accordingly.

Mitigation: Mandate lifecycle testing (e.g., 20,000+ cycles under load) with documented results. Use accelerated life testing where feasible.

4. Lack of Traceability and Certifications

Without proper batch traceability or material certifications (e.g., mill test reports), it becomes difficult to investigate field failures or comply with industry standards.

Mitigation: Require full documentation package with each shipment, including traceable batch numbers, RoHS/REACH compliance, and material test reports.

Intellectual Property (IP)-Related Pitfalls

1. Unintentional Design Infringement

Sourcing off-the-shelf or custom springs without vetting existing patents can lead to infringement claims. For example, a unique dual-torsion spring design used in a patented hinge mechanism may be protected.

Mitigation: Conduct a freedom-to-operate (FTO) analysis before finalizing designs. Engage IP counsel to review key hinge spring configurations.

2. Supplier Reuse of Custom Designs

When a supplier develops or manufactures a custom spring for your application, they may later sell the same design to competitors, diluting your product’s uniqueness.

Mitigation: Include explicit IP ownership clauses in contracts stating that all custom designs, tooling, and specifications are the buyer’s exclusive property. Use non-disclosure agreements (NDAs) and non-compete terms.

3. Reverse Engineering by Suppliers

Low-cost suppliers, particularly in regions with weaker IP enforcement, may reverse engineer samples and sell duplicates.

Mitigation: Limit distribution of physical samples; use blinded part numbers and avoid sharing full system schematics. Prefer suppliers in jurisdictions with strong IP protections.

4. Lack of Trade Secret Protection

Proprietary spring geometries, heat-treatment processes, or coating techniques may be disclosed during sourcing discussions and replicated.

Mitigation: Classify sensitive information, control access, and require signed NDAs before technical discussions. Consider patenting critical innovations instead of relying solely on trade secrets.

Conclusion

Sourcing springs for hinges demands careful attention to both technical quality and legal/IP safeguards. By specifying stringent material and performance criteria, enforcing rigorous testing, and protecting intellectual property through contracts and due diligence, companies can avoid costly failures, recalls, and litigation. Partnering with reputable, transparent suppliers and conducting regular audits further strengthens supply chain resilience.

Logistics & Compliance Guide for Spring For Hinge

This guide outlines the essential logistics and compliance considerations for Spring For Hinge, ensuring smooth operations, regulatory adherence, and customer satisfaction. Following these protocols helps maintain brand integrity and minimize risks across the supply chain.

Product Sourcing and Supplier Compliance

Ensure all suppliers adhere to ethical labor practices, environmental standards, and safety regulations. Require compliance documentation such as Certificates of Compliance (CoC), ISO certifications, and social audit reports (e.g., SMETA or BSCI). Conduct periodic supplier audits and maintain up-to-date vendor agreements that include compliance clauses.

Inventory Management and Warehousing

Maintain accurate inventory records through integrated warehouse management systems (WMS). Follow FIFO (First In, First Out) practices to manage product shelf life and reduce obsolescence. Ensure storage facilities meet safety, climate control, and security standards, especially for temperature-sensitive or high-value items.

Order Fulfillment and Shipping

Process orders promptly with accurate picking, packing, and labeling. Use reliable carriers with trackable delivery options and ensure packaging meets durability and sustainability standards. Clearly communicate shipping timelines and tracking information to customers. Implement order validation checks to reduce fulfillment errors.

Customs and International Trade Compliance

For cross-border shipments, prepare accurate commercial invoices, packing lists, and import/export documentation. Classify products using correct HS codes and comply with destination country regulations (e.g., CE marking, FCC, or RoHS). Stay updated on trade restrictions, tariffs, and sanctions affecting shipping routes.

Product Safety and Regulatory Standards

Ensure all products meet relevant safety standards (e.g., CPSIA for children’s products, REACH for chemicals in the EU). Maintain Product Compliance Files including test reports, labeling documentation, and risk assessments. Label products with required warnings, country of origin, and compliance marks.

Environmental and Sustainability Compliance

Adhere to local and international environmental regulations, including waste disposal, recycling, and hazardous material handling. Minimize packaging waste and use recyclable or biodegradable materials where possible. Report sustainability metrics as required by law or corporate policy (e.g., SEC Climate Disclosure rules).

Data Privacy and Customer Information Security

Protect customer data in compliance with privacy laws such as GDPR, CCPA, or other regional regulations. Secure all logistics data exchanges (e.g., shipping addresses, order history) using encryption and access controls. Ensure third-party logistics (3PL) partners sign data processing agreements (DPA).

Returns and Reverse Logistics

Establish a clear returns policy communicated to customers. Process returns efficiently with inspection and restocking or disposal procedures. Comply with “right to repair” or WEEE regulations where applicable. Track return reasons for quality improvement and compliance reporting.

Audits and Continuous Improvement

Conduct regular internal and third-party audits of logistics and compliance processes. Address findings promptly and update policies accordingly. Train staff annually on compliance updates, safety procedures, and ethical standards to maintain operational excellence.

Conclusion for Sourcing Springs for Hinges:

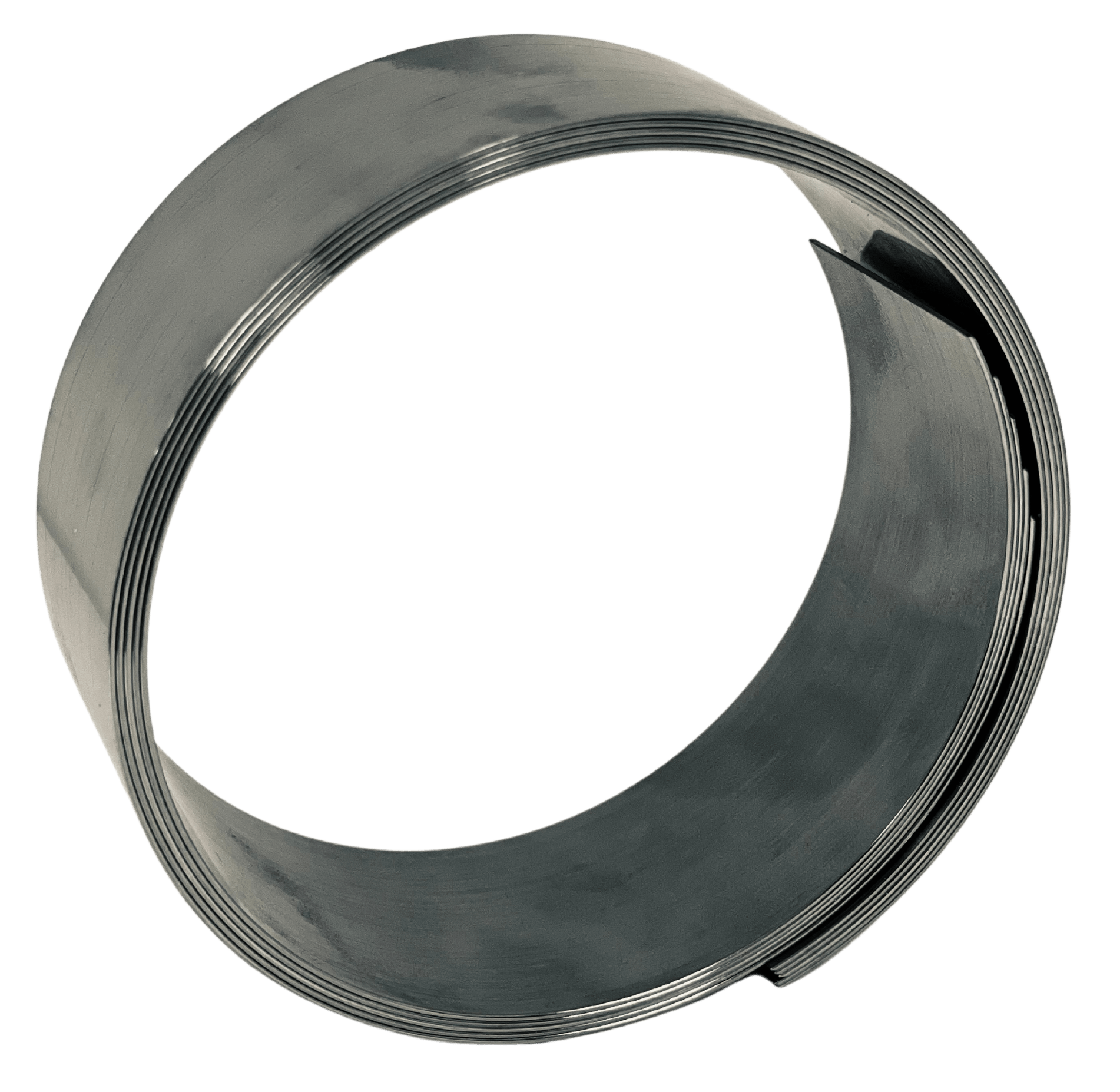

After evaluating various factors such as material type, spring mechanism requirements, load capacity, durability, cost, and supplier reliability, it is evident that sourcing the right spring for a hinge application requires a balanced approach between performance and cost-efficiency. Suitable spring materials such as stainless steel or music wire offer excellent resilience and corrosion resistance, ensuring long-term functionality in diverse operating conditions. Additionally, selecting a reputable supplier who can provide consistent quality, customization options, and timely delivery is crucial to maintaining production efficiency and product reliability.

In conclusion, optimal spring sourcing involves aligning technical specifications with application demands while maintaining supply chain stability. By prioritizing quality, precision, and supplier partnerships, manufacturers can enhance hinge performance, reduce maintenance needs, and improve overall product lifespan.