The global spray foam insulation market is experiencing robust growth, driven by increasing demand for energy-efficient building solutions and stringent regulations surrounding carbon emissions. According to Grand View Research, the global spray foam insulation market size was valued at USD 2.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. This surge is fueled by rising construction activities, advancements in insulation technologies, and growing awareness of long-term cost savings associated with improved thermal performance. As the demand for do-it-yourself (DIY) and contractor-grade spray foam kits continues to climb, a competitive landscape of manufacturers has emerged, offering diverse formulations, yield capacities, and application-specific solutions. This report identifies the top 10 spray foam kit manufacturers shaping the industry through innovation, product reliability, and market reach.

Top 10 Sprayfoam Kits Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wholesale Spray Foam Insulation Suppliers

Domain Est. 2011

Website: idi-insulation.com

Key Highlights: IDI: Insulation Distributors Inc. is Americas wholesale spray foam insulation supplier. We offer next day delivery, trainings, expertise and more….

#2 Froth

Domain Est. 1987

Website: dupont.com

Key Highlights: Froth-Pak Insulation Spray Foam is a Class A Fire Rated two-component, quick-cure polyurethane foam that fills cavities, penetrations and cracks….

#3 Spray Foam & Insulation Products

Domain Est. 1995

Website: dap.com

Key Highlights: DAP spray foam can eliminate air leaks and drafts, seal gaps and cracks and insulate against the elements to make homes comfortable, quiet, cozy and more ……

#4 Spray Polyurethane Foam Alliance

Domain Est. 1997

Website: sprayfoam.org

Key Highlights: Elevate your business with Spray Polyurethane Foam Alliance: The leading trade association for the Spray Foam Industry. Access official technical resources, ……

#5 Spray Foam Insulation Equipment

Domain Est. 1999

Website: masterpkg.com

Key Highlights: Master Pack is a premier National supplier of spray foam insulation equipment throughout the USA and Internationally….

#6

Domain Est. 2000

Website: handifoam.com

Key Highlights: Now available: HandiFoam E84 A superior application experience with unmatched sprayability, seamless coverage, and durable performance. · LEADERS IN INNOVATIVE, ……

#7 Tiger Foam

Domain Est. 2005

Website: tigerfoam.com

Key Highlights: Tiger Foam is a proven leader in providing spray foam kits, supplies and accessories to homeowners and contractors alike….

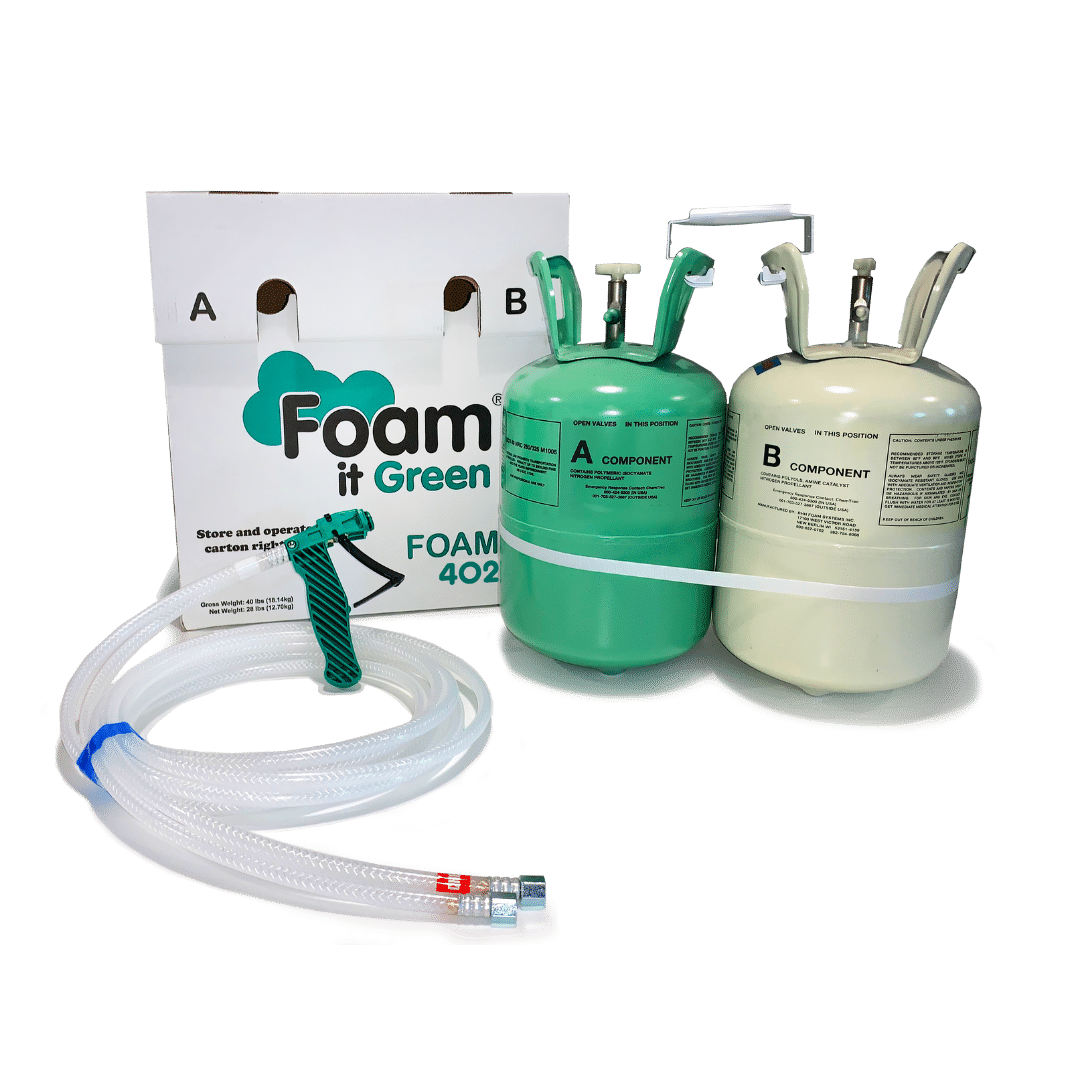

#8 Foam It Green

Domain Est. 2007

Website: foamitgreen.com

Key Highlights: America’s best residential spray foam insulation kits. Shop Spray Foam Kits. Lower prices and bulk discounts on our best selling kits….

#9 KrakenBond Official Store

Domain Est. 2021

Website: krakenbond.net

Key Highlights: Shop Kraken Bond’s official store for spray foam insulation, sealants, adhesives, glues, spray cleaners, lubricants – trusted by professionals & DIY…

#10 SPRAYMAN Official Store

Domain Est. 2022

Expert Sourcing Insights for Sprayfoam Kits

H2: 2026 Market Trends for Spray Foam Kits

The global market for spray foam kits is projected to experience robust growth by 2026, driven by increasing demand for energy-efficient building solutions, stricter environmental regulations, and advancements in insulation technology. Key trends shaping the market include:

-

Rising Demand for Energy Efficiency

With growing awareness of climate change and rising energy costs, homeowners and contractors are prioritizing high-performance insulation. Spray foam kits offer superior thermal resistance (R-value per inch) compared to traditional materials like fiberglass, making them a preferred choice for both new construction and retrofitting projects. -

Expansion in Residential and DIY Segments

The do-it-yourself (DIY) market is a major growth catalyst. Pre-measured, easy-to-use spray foam kits are becoming increasingly popular among homeowners for sealing gaps, insulating attics, and improving HVAC efficiency. Manufacturers are responding with user-friendly kits that require minimal equipment and training. -

Technological Advancements and Product Innovation

By 2026, manufacturers are expected to introduce low-global-warming-potential (GWP) blowing agents and bio-based formulations to meet sustainability goals. Improved two-component systems with faster cure times, reduced waste, and enhanced safety profiles are also gaining traction. -

Regulatory Support and Green Building Standards

Government initiatives promoting energy-efficient buildings—such as the U.S. Inflation Reduction Act, EU Energy Performance of Buildings Directive (EPBD), and various green building certifications (e.g., LEED, Passive House)—are incentivizing the use of spray foam insulation, further boosting market adoption. -

Geographic Growth Opportunities

North America remains the largest market due to stringent building codes and high construction activity. However, the Asia-Pacific region is expected to witness the highest growth rate, fueled by rapid urbanization, industrial expansion, and increasing focus on sustainable infrastructure. -

Supply Chain and Raw Material Challenges

Despite positive trends, the market faces headwinds from fluctuating petrochemical prices and supply chain constraints. Companies are investing in localized production and alternative raw materials to mitigate risks.

In summary, the 2026 outlook for spray foam kits is highly favorable, with innovation, regulatory support, and consumer demand converging to drive market expansion across residential, commercial, and industrial sectors.

Common Pitfalls When Sourcing Spray Foam Kits: Quality and Intellectual Property (IP) Concerns

When sourcing spray foam insulation kits, especially for DIY or small-scale applications, buyers often encounter significant challenges related to product quality and intellectual property (IP) infringement. Being aware of these pitfalls is critical to ensuring performance, safety, and legal compliance.

Poor Product Quality and Inconsistent Performance

One of the most frequent issues is encountering spray foam kits that fail to deliver consistent or reliable results. Low-quality kits may use inferior chemical formulations that result in:

- Incomplete curing: Foam remains tacky or soft, leading to poor adhesion and structural integrity.

- Shrinkage or cracking: Substandard resins can cause the foam to pull away from surfaces or develop cracks over time, compromising insulation value and air sealing.

- Inaccurate yield: Kits may not produce the advertised volume of foam, leading to project delays and additional costs.

- Off-gassing and odors: Poor-quality chemicals may release harmful volatile organic compounds (VOCs) during and after installation, posing health risks.

These quality shortcomings are often found in off-brand or unbranded kits sold through online marketplaces, where manufacturing standards are less regulated.

Intellectual Property (IP) Infringement and Counterfeit Products

Another major pitfall is the prevalence of IP-infringing spray foam kits that mimic well-known branded systems (e.g., Great Stuff, Froth-Pak, Icynene). These counterfeit or knockoff kits may:

- Copy proprietary formulations: Without proper licensing, manufacturers replicate patented chemical blends, undermining innovation and potentially violating patent laws.

- Use misleading branding: Labels and packaging closely resemble genuine products, deceiving consumers into believing they are purchasing a trusted brand.

- Lack technical support and safety data: Unlike legitimate brands, counterfeit kits often don’t include proper safety data sheets (SDS), installation instructions, or customer support, increasing risk during use.

Purchasing IP-infringing products not only supports illegal activity but also exposes users to untested and potentially hazardous materials.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Purchase spray foam kits directly from authorized distributors or reputable suppliers.

– Verify product authenticity through manufacturer verification tools or batch numbers.

– Check for proper labeling, certifications (e.g., UL, EPA), and inclusion of SDS.

– Be wary of prices that seem too good to be true, as they often indicate substandard or counterfeit goods.

By prioritizing quality and respecting IP, consumers and contractors can ensure safer, more effective, and legally compliant spray foam applications.

Logistics & Compliance Guide for Spray Foam Kits

Product Classification & Regulatory Overview

Spray foam insulation kits are classified as hazardous materials (dangerous goods) for transportation due to their pressurized chemical components and flammability. The two-part components (typically Part A: isocyanate, and Part B: polyol resin blend) are shipped as compressed gases and flammable liquids under international and national regulations. Compliance with transportation, storage, handling, and labeling requirements is essential to ensure safety and avoid legal penalties.

Key regulatory frameworks include:

– UN Recommendations on the Transport of Dangerous Goods (UN Model Regulations)

– IMDG Code (Maritime transport)

– IATA Dangerous Goods Regulations (Air transport)

– 49 CFR (U.S. Department of Transportation – Highway and Rail)

– ADR/RID (European road and rail transport)

– GHS (Globally Harmonized System) for classification and labeling

Spray foam kits typically fall under the following UN numbers:

– UN1057 – Flammable gas, n.o.s. (for cylinders containing propellants like propane/butane)

– UN1208 – Diisocyanates, toxic, flammable (for Part A – isocyanate component)

– UN1866 – Amine solutions, flammable, corrosive, n.o.s. (may apply depending on formulation of Part B)

Packaging & Shipping Requirements

Spray foam kits must be shipped in UN-certified packaging designed to withstand pressure, impact, and temperature fluctuations. The packaging must meet the performance standards of the relevant transport mode (e.g., 49 CFR §178 for U.S., ADR packaging instructions for Europe).

Key packaging specifications:

– Cylinders must be pressure-tested and marked with the UN symbol, country code, serial number, manufacture date, and test pressure.

– Outer packaging (e.g., fiberboard boxes) must be strong enough to prevent damage to cylinders and contain any leaks.

– Kits must be packed to prevent movement during transit to avoid valve damage.

– Inner packaging must include absorbent material if leakage of liquid components is possible.

Temperature considerations:

– Store and transport below 120°F (49°C); exposure to high temperatures can increase internal pressure and risk of rupture.

– Avoid freezing (below 32°F / 0°C), which may affect foam quality and dispensing performance.

– Use temperature-controlled transport if extreme climates are expected.

Labeling and Marking:

– Each package must display:

– Proper shipping name (e.g., “FLAMMABLE GAS, N.O.S., 2.1, UN1057”)

– Hazard class labels (Class 2.1 – Flammable Gas, and/or Class 3 – Flammable Liquid)

– UN number

– Shipper and consignee information

– GHS pictograms (flame, exclamation mark, health hazard) on individual containers

– “Keep Away from Heat” and “Do Not Drop” handling labels

Documentation & Declarations

Accurate documentation is mandatory for all shipments of spray foam kits:

- Shipper’s Declaration for Dangerous Goods (required for air and sea transport)

- Safety Data Sheets (SDS) – Must be provided to customers and carriers, compliant with GHS and local regulations (e.g., OSHA HazCom in the U.S., CLP in EU)

- Transport Emergency Card (TREM Card) – Required in some regions (e.g., ADR) to provide emergency response information

- Commercial Invoice and Packing List – Must clearly indicate hazardous nature of contents

Ensure all documents include:

– Complete technical names of chemicals

– Classification details (hazard class, packing group – typically PG II)

– Total net quantity per package

– Emergency contact information

Storage & Handling Guidelines

Proper storage is critical to maintain product integrity and ensure safety:

- Store in a cool, dry, well-ventilated area away from direct sunlight and heat sources.

- Keep away from oxidizers, acids, and incompatible materials.

- Store upright and secure to prevent tipping.

- Implement a first-in, first-out (FIFO) inventory system to prevent aging.

- Use explosion-proof lighting and ventilation in storage areas if large quantities are stored.

- Fire extinguishers rated for flammable liquids (Class B) must be readily accessible.

Personal protective equipment (PPE) required during handling:

– Nitrile or neoprene gloves

– Safety goggles or face shield

– Respiratory protection (NIOSH-approved respirator for isocyanates if vapors are present)

– Protective clothing to prevent skin contact

Regulatory Compliance by Region

United States:

– Regulated by DOT (49 CFR), EPA (TSCA), and OSHA (HazCom, PPE standards)

– SDS must comply with OSHA 29 CFR 1910.1200

– Reporting may be required under EPCRA (Emergency Planning and Community Right-to-Know Act) for large quantities

European Union:

– Subject to CLP Regulation (EC No 1272/2008) for classification and labeling

– REACH compliance required for chemical registration

– ADR regulations govern road transport

– Biocidal Products Regulation (BPR) may apply if fungicides or biocides are included in formulation

Canada:

– Transported under TDG (Transportation of Dangerous Goods) Regulations

– WHMIS 2015 compliance for SDS and labeling

– Health Canada oversight for chemical ingredients

Australia:

– Regulated by ADG Code (Australian Dangerous Goods Code)

– Comply with GHS under Work Health and Safety (WHS) Regulations

– NICNAS (now AICIS) for chemical import assessment

Training & Certification

Personnel involved in handling, packing, shipping, or receiving spray foam kits must be trained and certified in accordance with local dangerous goods regulations:

- Initial and recurrent training every 1–3 years (depending on jurisdiction)

- Training must cover:

- Hazard recognition

- Packaging requirements

- Labeling and documentation

- Emergency response procedures

- Use of PPE

- Certification records must be maintained

Carriers must also possess appropriate licenses and dangerous goods handling certifications.

Emergency Response & Incident Management

In the event of a leak, fire, or exposure:

- Leak or Spill:

- Evacuate area, eliminate ignition sources

- Use absorbent materials (e.g., vermiculite, sand) – do NOT use sawdust

- Ventilate area thoroughly

-

Collect spillage in approved container for disposal

-

Fire:

- Evacuate and call emergency services

- Use dry chemical, CO₂, or alcohol-resistant foam extinguishers

- Cool containers with water from a safe distance

-

Isocyanates may release toxic fumes (e.g., hydrogen cyanide) when burned

-

Exposure:

- Inhalation: Move to fresh air, seek medical attention

- Skin contact: Wash with soap and water, remove contaminated clothing

- Eye contact: Flush with water for at least 15 minutes, consult physician

- Ingestion: Rinse mouth, do NOT induce vomiting, seek immediate medical help

Ensure emergency contact numbers and SDS are accessible at all times.

Disposal & Environmental Considerations

- Empty cylinders may still contain residual pressure and hazardous contents—do NOT puncture or incinerate.

- Dispose of waste through licensed hazardous waste handlers.

- Follow local, state, and federal regulations for disposal (e.g., RCRA in the U.S.).

- Empty containers should be rendered unusable and recycled or disposed of according to jurisdictional rules.

Environmental precautions:

– Prevent release into sewers, waterways, or soil

– Use secondary containment in storage areas to capture leaks

Note: Regulations vary by country and are subject to change. Always consult the latest regulatory texts and engage with certified dangerous goods professionals when shipping spray foam kits.

In conclusion, sourcing spray foam kits requires careful consideration of several key factors to ensure optimal performance, safety, and cost-effectiveness. It is essential to evaluate the type of foam—open-cell versus closed-cell—based on insulation needs, climate conditions, and intended application. Pay close attention to the R-value, expansion rate, and curing time, as these directly impact efficiency and ease of use. Quality assurance, including proper certifications and compliance with safety standards, should not be overlooked. Purchasing from reputable suppliers ensures reliable product integrity and access to technical support. Additionally, comparing pricing, kit sizes, and availability of accessories can help maximize value and project success. Whether for DIY projects or professional use, taking the time to research and select the right spray foam kit will lead to better insulation results, energy savings, and long-term satisfaction.