The global spray can market is experiencing steady growth, driven by rising demand across industries such as automotive, construction, personal care, and household products. According to Grand View Research, the global aerosol cans market size was valued at USD 17.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. A key innovation supporting this expansion is the development of spray can containers with removable bottoms—specifically engineered for easier recycling, residue recovery, and improved sustainability compliance. With increasing regulatory pressure and corporate sustainability goals, manufacturers are prioritizing designs that facilitate end-of-life processing. As demand for eco-conscious packaging solutions rises, a select group of manufacturers has emerged as leaders in producing high-quality, removable-bottom spray can containers. These companies combine advanced engineering with scalable production capabilities to meet the evolving needs of brand owners and fillers worldwide.

Top 8 Spray Can Container Removeable Bottom Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Technology

Domain Est. 2000

Website: spraymax.com

Key Highlights: Remove the red head from the cap on the spray can; Place the red button on the bottom of the spray can on the pen. Make sure it is placed straight on the pin….

#2 Frequently Asked Questions on the Container and …

Domain Est. 1997

Website: epa.gov

Key Highlights: This webpage contains answers to questions that the Agency has received from stakeholders on the container and containment labeling requirements….

#3 DTSC Managing Empty Containers Fact Sheet

Domain Est. 1997

Website: dtsc.ca.gov

Key Highlights: The Department of Toxic Substances Control (DTSC) has prepared this fact sheet to provide an overview of general information about the management of empty …Missing: removeable b…

#4 Recycled content products

Domain Est. 1997

Website: ecology.wa.gov

Key Highlights: Description: The bottom part of the container that provides stability and support. Features: These can include structural reinforcements or indentations to ……

#5 Spray Bottles For Sale

Domain Est. 1999

Website: thecarycompany.com

Key Highlights: 30-day returnsPlastic spray bottles come available in 23 oz and 32 oz white (HDPE) and 22 oz clear (PET). — Wholesale & Volume Pricing!…

#6 [PDF] Guidance for Industry: Container Closure Systems for …

Domain Est. 2000

Website: fda.gov

Key Highlights: Inhalation Solution, Suspension, and Spray Drug Products; Chemistry, Manufacturing … Container closure systems for on-site storage have generally been …Missing: removeable bot…

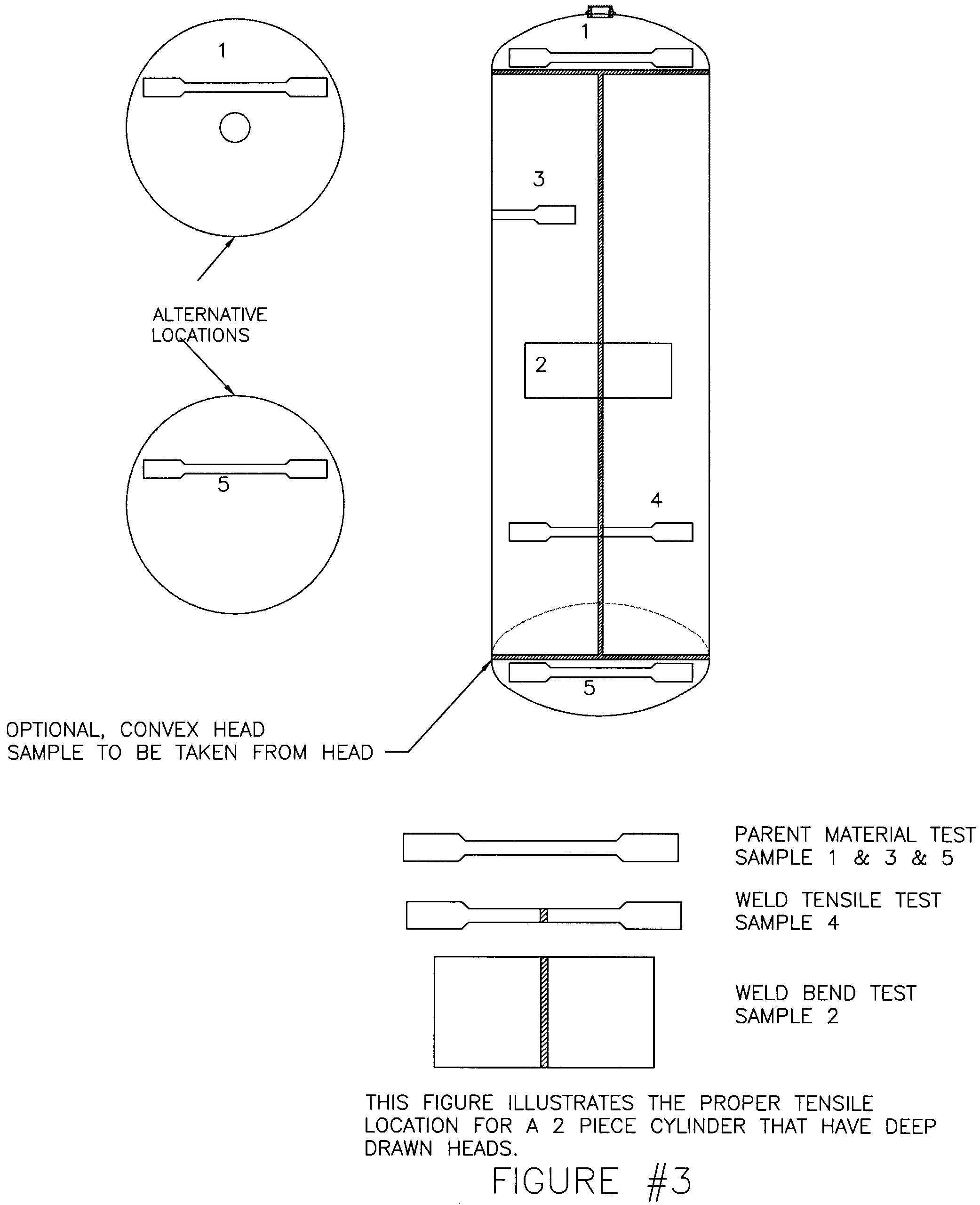

#7 49 CFR Part 178

Domain Est. 2012

Website: ecfr.gov

Key Highlights: This part prescribes the manufacturing and testing specifications for packaging and containers used for the transportation of hazardous materials in commerce….

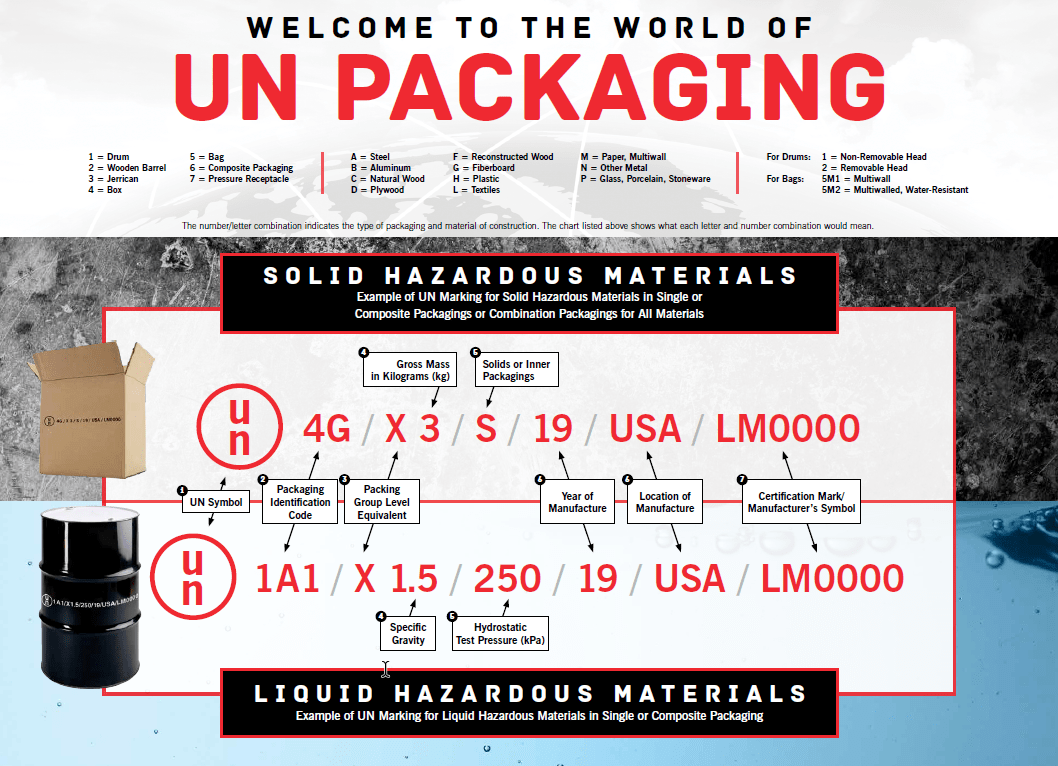

#8 UN Markings Guide

Domain Est. 1995

Website: labelmaster.com

Key Highlights: Easily read and understand UN Markings with this guide from Labelmaster, your resource for UN certified packaging, hazmat shipping resources, and more….

Expert Sourcing Insights for Spray Can Container Removeable Bottom

H2: 2026 Market Trends for Spray Can Containers with Removable Bottoms

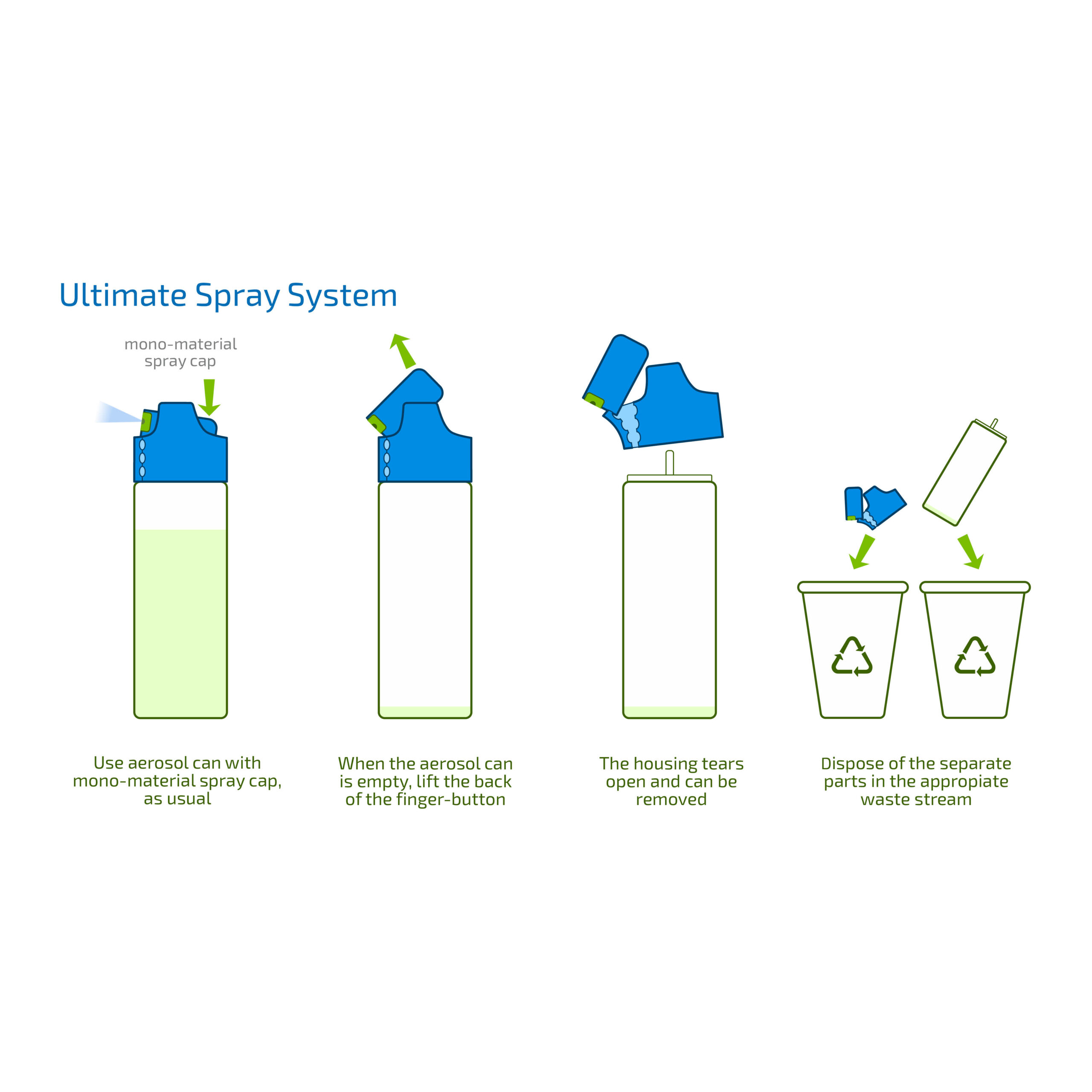

The global market for spray can containers with removable bottoms is poised for notable transformation by 2026, driven by sustainability mandates, evolving packaging innovations, and growing demand across industrial, consumer, and specialty applications. These containers—characterized by their detachable base that facilitates easier recycling, refilling, or residue extraction—are gaining traction as brands and regulators prioritize circular economy principles.

1. Sustainability as a Primary Growth Driver

By 2026, environmental regulations are expected to tighten across North America, Europe, and parts of Asia-Pacific, pushing manufacturers to adopt eco-friendly packaging solutions. Spray cans with removable bottoms enable more efficient separation of metal (typically aluminum or steel) from residual product and plastic components, significantly improving recyclability. The European Union’s Packaging and Packaging Waste Regulation (PPWR) and similar initiatives in Canada and Japan are anticipated to mandate design-for-recycling standards, favoring innovations like the removable bottom.

2. Expansion in Refillable and Reusable Models

Consumer demand for refillable products—especially in household cleaners, personal care, and automotive care—is projected to rise. Removable bottom designs allow for thorough cleaning and safe refilling, supporting closed-loop systems. Major CPG (Consumer Packaged Goods) companies are expected to pilot or scale refill programs using such containers, particularly in premium and eco-conscious product lines.

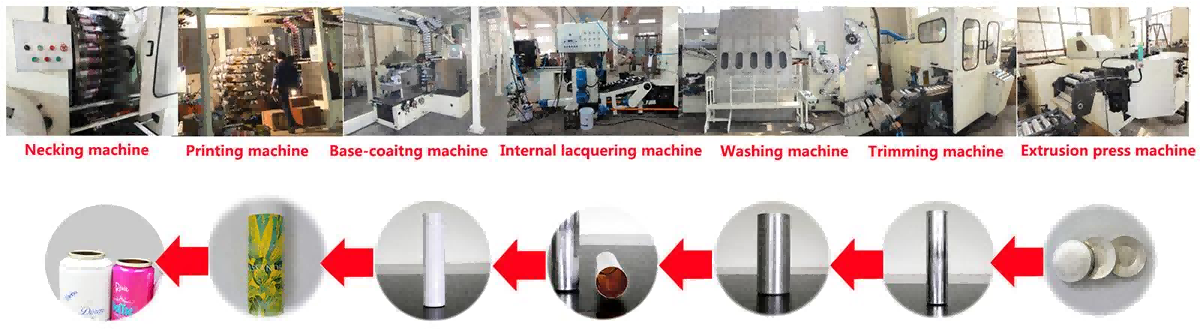

3. Technological Advancements in Manufacturing

Innovations in can manufacturing, such as precision welding and modular base attachment techniques, are reducing production costs and enhancing structural integrity. By 2026, automation and smart tooling are likely to make removable-bottom cans more cost-competitive with traditional one-piece aerosol cans, enabling broader adoption.

4. Growth in Niche and Industrial Applications

Beyond consumer goods, sectors like construction (spray adhesives, foams), automotive (lubricants, touch-up paints), and food service (cooking sprays) are exploring removable-bottom cans for maintenance, recycling compliance, or waste reduction. These applications benefit from easier disposal of hazardous or viscous residues.

5. Challenges and Supply Chain Considerations

Despite their advantages, removable-bottom spray cans face hurdles related to leakage risks, pressure resistance, and compatibility with existing filling lines. By 2026, industry standards and testing protocols are expected to evolve to address safety and performance concerns. Additionally, supply chain integration—particularly with recycling facilities—will be critical for realizing environmental benefits.

6. Regional Market Dynamics

Europe is expected to lead adoption due to stringent environmental policies, followed by North America and select Asia-Pacific markets (e.g., Japan and South Korea). Emerging economies may adopt the technology more slowly due to infrastructure and cost constraints, but pilot projects supported by global brands could accelerate uptake.

Conclusion

By 2026, spray can containers with removable bottoms are projected to transition from a niche innovation to a mainstream sustainable packaging solution. Success will depend on collaboration among manufacturers, recyclers, regulators, and brands to ensure technical reliability, economic viability, and environmental impact. As circular economy goals take center stage, the removable-bottom spray can is likely to become a benchmark for next-generation aerosol packaging.

Common Pitfalls Sourcing Spray Can Containers with Removable Bottoms (Quality, IP)

Sourcing spray can containers with removable bottoms—especially when quality and intellectual property (IP) are critical—can present several challenges. Businesses must navigate technical, legal, and supply chain risks to ensure reliable, compliant, and innovative products. Below are some of the most common pitfalls to avoid.

Poor Material and Construction Quality

Low-grade materials or substandard manufacturing processes can lead to structural weaknesses, leaks, or failure during pressurization. Removable bottom designs add complexity, increasing the risk of seal failure or inconsistent can integrity. Sourcing from suppliers without proven quality control systems (e.g., ISO certifications) often results in batch inconsistencies, product recalls, or safety hazards.

Inadequate Pressure and Leak Testing

Spray cans must withstand internal pressure over time and across temperature variations. Some suppliers skip rigorous pressure cycling or drop tests, especially for novel designs like removable bottoms. Without proper performance validation, these containers may fail in real-world conditions, leading to customer dissatisfaction or regulatory non-compliance.

Lack of Intellectual Property Protection

Using or replicating a removable bottom mechanism that is patented elsewhere can expose your business to IP infringement claims. Many innovative can designs (e.g., easy-disassembly or refillable systems) are protected by patents. Sourcing without conducting a Freedom-to-Operate (FTO) analysis risks costly litigation or forced redesigns.

Copying Proprietary Designs

Some suppliers may offer “compatible” or “generic” versions of patented removable bottom systems. These are often knock-offs of established proprietary designs. While initially cheaper, they pose legal risks and may compromise performance or brand reputation. Due diligence on supplier origins and design provenance is essential.

Insufficient Regulatory Compliance

Aerosol containers are subject to transportation (e.g., UN/DOT regulations), safety (e.g., FDA for food-contact materials), and environmental standards (e.g., VOC emissions). Removable bottom designs may not meet drop-test or hermetic seal requirements unless specifically engineered and certified. Non-compliant cans can be blocked from distribution or recalled.

Supply Chain Instability and Scalability Issues

Suppliers offering removable bottom cans may lack the tooling, capacity, or long-term commitment to scale production. Relying on a single or niche supplier increases risk of delays, price volatility, or discontinuation. Without qualified backup manufacturers, production can halt unexpectedly.

Poor Documentation and Traceability

Lack of detailed technical specifications, material certifications, or batch traceability makes quality assurance difficult. This is especially critical if a product issue arises and a root cause analysis or recall is needed. Reputable suppliers provide full documentation to support compliance and quality control.

Overlooking End-of-Life and Sustainability Claims

Some removable bottom designs are marketed as “eco-friendly” or “refillable,” but without proper lifecycle analysis or recyclability validation, such claims may be misleading. Sourcing based on unsubstantiated sustainability benefits can lead to greenwashing accusations and damage brand credibility.

To avoid these pitfalls, conduct thorough supplier audits, engage IP counsel early, demand third-party testing data, and ensure contracts include quality warranties and IP indemnification clauses.

Logistics & Compliance Guide for Spray Can Containers with Removable Bottoms

Product Overview and Key Features

Spray can containers with removable bottoms are specialized packaging solutions designed for easy disposal, recycling, or refilling. The removable bottom feature allows safe depressurization and separation of components, enhancing environmental compliance and logistics efficiency. These containers are commonly used for aerosol products in industrial, automotive, household, and cosmetic sectors. Key features include: tamper-evident seals, pressure-rated construction, and compatibility with standard filling and dispensing equipment.

Regulatory and Safety Compliance

Spray can containers are subject to stringent international and national regulations due to their pressurized nature. Compliance must be maintained across design, labeling, transportation, and disposal. Key regulatory frameworks include:

- UN Recommendations on the Transport of Dangerous Goods (UN Model Regulations): Aerosols are classified as Division 2.1 (Flammable Gas) or Class 2, depending on contents. Containers must pass performance tests (e.g., pressure, leakage, drop tests) and may require UN certification.

- DOT (U.S. Department of Transportation) 49 CFR: Governs domestic transport of hazardous materials in the U.S. Aerosol cans must comply with packaging, labeling, and shipping documentation requirements. Removable bottom designs must not compromise structural integrity during transit.

- ADR/RID/ADN (Europe): For road, rail, and inland waterway transport in Europe. Similar to DOT, with additional requirements for packaging compatibility and pressure resistance.

- CLP Regulation (EU): Requires proper classification, labeling, and safety data sheet (SDS) communication based on hazardous properties of the contents.

- EPA and State Regulations (e.g., U.S. RCRA): For end-of-life management. Empty aerosol cans may be exempt from hazardous waste rules if properly emptied (punctured and drained), which is facilitated by removable bottom designs.

Packaging and Labeling Requirements

Proper packaging and labeling are critical for compliance and safe handling:

- Labeling: Must include product name, hazard pictograms, signal words (“Danger” or “Warning”), hazard statements, precautionary statements, supplier information, and net quantity. For transport, UN number (e.g., UN1950 for aerosols), proper shipping name, and class label must be present.

- Child-Resistant Packaging (CRP): Required in certain jurisdictions (e.g., U.S. Poison Prevention Packaging Act) for household products posing ingestion risks.

- Tamper-Evident Features: Mandatory for consumer safety; removal of the bottom should not compromise tamper evidence prior to intended use.

Transportation and Handling Guidelines

Safe logistics operations depend on proper handling and transport practices:

- Packing Instructions: Use UN-certified outer packaging with sufficient cushioning. Individual cans should be separated to prevent contact and damage. For air transport, IATA DGR Packing Instruction 200 applies.

- Segregation: Keep away from heat sources, oxidizers, and incompatible materials. Do not store or transport in temperatures exceeding 50°C (122°F).

- Load Securing: Ensure cargo is immobilized to prevent shifting during transit. Use dunnage and load bars as needed.

- Removable Bottom Considerations: Verify that the removable mechanism is securely closed and does not activate under vibration or pressure changes during shipping.

Storage and Warehouse Compliance

- Storage Conditions: Store in a cool, dry, well-ventilated area away from direct sunlight and ignition sources. Maximum stack height should comply with manufacturer specifications to avoid can deformation.

- Segregation: Segregate full, partially used, and empty cans. Empty cans that have been depressurized and drained may be stored separately for recycling.

- Fire Safety: Ensure fire suppression systems (e.g., sprinklers) are in place. No smoking policies must be enforced.

End-of-Life Management and Recycling

The removable bottom design supports sustainable disposal:

- Depressurization: Use approved can-puncturing devices in well-ventilated areas to safely remove contents and separate metal from residual product.

- Recycling: Steel or aluminum bodies can be recycled if completely emptied. Confirm local recycling program acceptance.

- Hazardous Waste Disposal: If residual contents are hazardous, manage according to local regulations (e.g., RCRA in the U.S.). Maintain records of disposal.

Documentation and Recordkeeping

Maintain up-to-date records to ensure traceability and audit readiness:

- Safety Data Sheets (SDS) for product contents

- UN certification documentation for packaging

- Shipping manifests and hazardous materials declarations

- Waste disposal records and recycling certificates

- Internal compliance checklists and training logs

Training and Personnel Safety

- Train staff on hazard recognition, emergency response (e.g., leaks, fires), and proper handling of pressurized containers.

- Provide PPE (gloves, eye protection) during inspection, repackaging, or disposal operations.

- Conduct regular audits and drills to ensure compliance with safety protocols.

Conclusion

Spray can containers with removable bottoms offer operational and environmental advantages but require strict adherence to logistics and compliance standards. By following this guide, businesses can ensure safe transport, regulatory compliance, and responsible end-of-life management throughout the product lifecycle. Regular review of evolving regulations (e.g., updated GHS or transport codes) is recommended to maintain ongoing compliance.

Conclusion:

After evaluating various sourcing options for spray can containers with removable bottoms, it is evident that specialized manufacturing partners and industrial packaging suppliers offer viable solutions tailored to specific application needs. Key factors such as material durability, ease of cleaning, compatibility with contents, and compliance with safety and environmental standards must guide the selection process. Suppliers from regions with advanced manufacturing capabilities—such as North America, Europe, and parts of Asia—provide a range of customizable options, with some offering innovative designs that enhance functionality and sustainability.

While cost remains an important consideration, long-term value is maximized by prioritizing quality, reliability, and supplier responsiveness. Prototyping and testing with shortlisted vendors are recommended to ensure the removable bottom mechanism functions effectively under real-world conditions. Ultimately, establishing a partnership with a reputable supplier who can support scalability and ongoing technical improvements will ensure a successful implementation of spray can containers with removable bottoms in the intended application.

![[PDF] Guidance for Industry: Container Closure Systems for ...](https://www.sohoinchina.com/wp-content/uploads/2026/01/pdf-guidance-for-industry-container-closure-systems-for-348.jpg)