The global sprags market is experiencing steady growth, driven by increasing demand for precision components in automotive, aerospace, and industrial machinery sectors. According to Grand View Research, the global clutch and transmission market—of which sprags are a critical component—was valued at USD 69.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by advancements in automated transmission systems and the need for high-efficiency mechanical power transmission solutions. As key enablers of overrunning clutch mechanisms, sprags play a vital role in enhancing operational reliability and performance across heavy-duty and high-precision applications. With rising industrial automation and technological innovation in material science, the demand for high-quality sprags continues to climb. In this competitive landscape, a select group of manufacturers have emerged as leaders, combining engineering excellence with scalable production capabilities. Based on market presence, product innovation, and global reach, the following eight companies represent the top sprags manufacturers shaping the future of power transmission systems.

Top 8 Sprags Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sprag Products

Domain Est. 1996

Website: marland.com

Key Highlights: Sprag Products. Roller Products · BC Model Backstops · Cebmag Backstops … Metal Producer · Metal Shredder · Mining & Aggregate · Oil & Gas · Power Generation….

#2 Sprague Air Driven Pumps

Domain Est. 1997

Website: highpressure.com

Key Highlights: Sprague offers a variety of air driven pumps designs, each with specific pressure ranges and design configurations to meet the demands of the high pressure ……

#3 Company History

Domain Est. 1998

Website: formsprag.com

Key Highlights: Formsprag Clutch traces its roots to the Detroit area businesses and innovators who supported the US effort in World War II….

#4 Sprag Clutch

Domain Est. 1998

Website: renoldajax.com

Key Highlights: A Sprag Clutch is a freewheel device having an inner race, and an outer race either of which can be the input or output member….

#5 Sprague: Our Energy Makes the Difference

Domain Est. 1998

Website: spragueenergy.com

Key Highlights: Sprague offers comprehensive energy solutions and material handling services to meet the needs of customers across the Northeast….

#6 Sprag Clutches

Domain Est. 2000

Website: gmnbt.com

Key Highlights: GMN Sprag Clutches, also known as one-way bearings and freewheel clutches, can be used in backstopping, indexing, and overrunning applications….

#7 Sprag Elements BW Units

Domain Est. 2002

Website: crossmorse.com

Key Highlights: Standard sprags are manufactured from 52100 bearing steels. Two basic designs of sprag are available, disengaging types (Diseng.) where the sprag lifts-off from ……

#8 Sprague

Domain Est. 2022

Website: pacificpsc.com

Key Highlights: Sprague Products developed the first air-operated liquid pump in 1947 for aerospace hydrostatic testing. This positive-displacement design became the foundation ……

Expert Sourcing Insights for Sprags

H2 2026 Market Trends for Sprags

While comprehensive data on the sprag clutch market specifically for H2 2026 is inherently forward-looking, analysis based on current trajectories, industry reports, and macroeconomic factors reveals several key trends likely to shape the sector in the second half of 2026:

-

Accelerated Electrification Driving Innovation:

- Focus on E-Mobility: Demand for sprags in electric vehicles (EVs), hybrid systems, and electric powertrains will surge. Sprags are critical in one-way clutches for e-axles, launch clutches, and regenerative braking systems. H2 2026 will see continued R&D focused on sprags designed for higher speeds, reduced friction (improving efficiency), quieter operation, and integration with compact e-drive units.

- Lightweighting & Material Advancements: To support EV efficiency goals, sprag manufacturers will increasingly adopt advanced materials like high-strength, lightweight alloys and potentially composite materials to reduce rotational mass without compromising durability.

-

Growth in Industrial Automation and Robotics:

- Increased Adoption: The global push for automation in manufacturing, logistics (AGVs, AMRs), and warehousing will drive demand for reliable, maintenance-free one-way clutches. Sprags are essential in conveyor systems, indexing mechanisms, and safety brakes within automated equipment.

- Demand for Precision & Reliability: H2 2026 will emphasize sprags with tighter tolerances, higher cycle life, and enhanced reliability for critical automation applications, reducing downtime and maintenance costs.

-

Renewables and Energy Sector Expansion:

- Wind Power: Sprags remain vital components in wind turbine yaw and pitch systems. Continued global investment in wind energy, particularly offshore projects, will sustain demand. Focus will be on sprags with exceptional corrosion resistance and longevity for harsh environments.

- Energy Storage & Grid Stability: Emerging applications in flywheel energy storage systems and grid stabilization mechanisms may present niche but growing opportunities for high-performance sprags.

-

Supply Chain Resilience and Regionalization:

- Geopolitical & Cost Pressures: Ongoing supply chain scrutiny and efforts to reduce dependency on single regions will continue. H2 2026 may see further investment in regional manufacturing (e.g., nearshoring in North America, expanding capacity in Southeast Asia) to mitigate risks and reduce logistics costs.

- Focus on Vertical Integration: Key players might pursue greater control over raw materials (specialty steels) and critical sub-components to ensure supply security and quality consistency.

-

Technological Advancements and Smart Components:

- Condition Monitoring Integration: While still emerging, the trend towards predictive maintenance will push some manufacturers to explore integrating basic sensors or designing sprags compatible with external monitoring systems (e.g., vibration, temperature) to detect wear or potential failure.

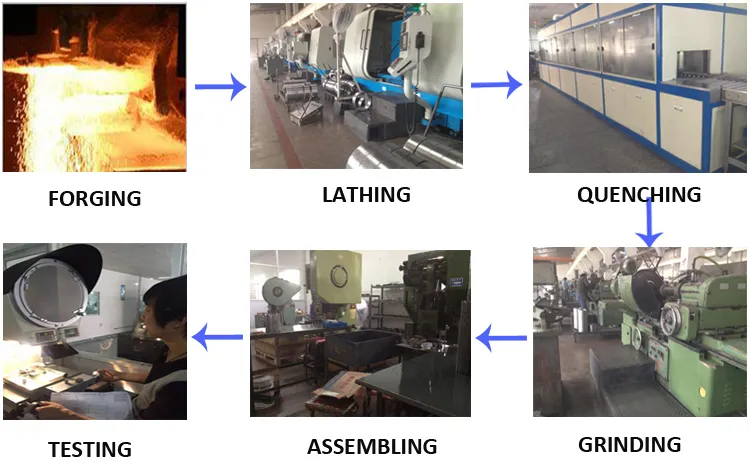

- Advanced Manufacturing: Wider adoption of precision forging, additive manufacturing (for prototypes or complex geometries), and AI-driven quality control will improve performance consistency and potentially reduce costs.

-

Consolidation and Competitive Landscape:

- Market Consolidation: The competitive landscape may see further consolidation as larger players seek to expand market share, gain access to new technologies (especially in e-mobility), and achieve economies of scale.

- Focus on Custom Solutions: Competition will intensify, driving suppliers to offer highly customized sprag solutions tailored to specific customer applications and performance requirements, particularly in high-growth sectors like EVs and automation.

-

Sustainability and Regulatory Compliance:

- Environmental Regulations: Stricter global emissions standards and sustainability goals will indirectly benefit sprags by driving the EV and efficiency markets. Directly, manufacturers will face pressure to reduce the environmental impact of their own production processes (energy use, waste).

- Material Sourcing: Increased focus on ethical and sustainable sourcing of raw materials (e.g., conflict-free minerals) may become a differentiating factor.

Conclusion for H2 2026:

The sprag clutch market in H2 2026 is poised for steady growth, primarily fueled by the unstoppable momentum of electrification (especially in transportation) and industrial automation. Success will hinge on manufacturers’ ability to innovate rapidly—developing lighter, more efficient, and higher-performing sprags for EVs and automation—while simultaneously navigating supply chain complexities and potentially consolidating to strengthen market positions. Sustainability and regionalization will be ongoing strategic considerations. While traditional markets (automotive ICE, general industry) remain important, the future growth vector is clearly aligned with electric and automated systems.

Common Pitfalls Sourcing Sprags (Quality, IP)

Sourcing sprags—precision mechanical components used in clutches and overrunning applications—can be fraught with risks if not managed carefully. Two of the most critical pitfalls involve quality inconsistencies and intellectual property (IP) concerns.

Quality Inconsistencies

One of the primary challenges when sourcing sprags is ensuring consistent quality across batches. Low-cost suppliers, especially those in regions with less stringent manufacturing oversight, may use substandard materials or imprecise machining processes. This can lead to premature wear, inconsistent engagement, or outright failure under load. Dimensional inaccuracies—even in the micrometer range—can compromise the sprag’s function within an assembly. Additionally, inadequate heat treatment can result in reduced hardness and fatigue resistance. Without proper quality control documentation, such as material certifications and geometric inspections, buyers risk integrating unreliable components into critical systems.

Intellectual Property (IP) Risks

Sourcing sprags from unauthorized or third-party manufacturers raises significant IP concerns. Many high-performance sprags are patented or protected under trade secret laws, particularly those designed for aerospace, automotive, or industrial applications. Purchasing counterfeit or reverse-engineered components not only violates IP rights but also exposes the buyer to legal liability and reputational damage. Moreover, unauthorized copies often lack the performance validation and reliability testing of genuine parts, increasing the risk of system failure. To mitigate this, buyers should verify supplier authenticity, demand traceability documentation, and prioritize OEM or licensed manufacturers.

Logistics & Compliance Guide for Sprags

Sprags—also known as anti-rotation devices or one-way bearings—are critical components in many mechanical and industrial systems. Ensuring their safe, legal, and efficient transportation and use requires strict adherence to logistics and compliance protocols. This guide outlines key considerations for handling, shipping, storing, and complying with regulations related to sprags.

Handling and Packaging

Proper handling and packaging are essential to maintain the integrity of sprags during transit. Improper packaging can lead to mechanical damage, contamination, or misalignment, affecting performance.

- Use Protective Packaging: Always package sprags in shock-absorbent materials such as foam inserts, bubble wrap, or molded trays to prevent movement and impact damage.

- Prevent Contamination: Keep sprags in sealed, moisture-resistant bags or containers to avoid exposure to dust, moisture, and corrosive elements.

- Label Clearly: Include part numbers, batch/lot numbers, and handling instructions (e.g., “Fragile,” “Do Not Drop”) on all packaging.

- Avoid Magnetization: If sprags contain ferromagnetic materials, store and ship away from strong magnetic fields that could affect performance.

Storage Requirements

Sprags must be stored under controlled conditions to preserve functionality and extend shelf life.

- Environment: Store in a dry, temperature-controlled environment (typically 15–25°C or 59–77°F) with relative humidity below 60% to prevent rust and degradation.

- Orientation: Store sprags in their designated orientation, especially if pre-lubricated or precision-balanced, to avoid internal component shift.

- Shelf Life Monitoring: Adhere to manufacturer-recommended shelf life. For long-term storage, periodic inspection and re-lubrication may be required.

- Inventory Management: Use a first-in, first-out (FIFO) system to minimize the risk of using outdated components.

Transportation and Shipping

Shipping sprags—domestically or internationally—requires compliance with transportation regulations and carrier-specific requirements.

- Domestic Shipments (e.g., within the U.S.):

- Follow carrier guidelines (e.g., UPS, FedEx, USPS) regarding weight, dimensions, and hazardous materials.

-

No special classification is typically required unless lubricants contain restricted substances.

-

International Shipments:

- Comply with IATA (air), IMDG (sea), or ADR (road) regulations if shipping hazardous materials (e.g., certain greases or coatings).

- Prepare accurate commercial invoices, packing lists, and certificates of origin.

- Ensure sprags do not contain restricted substances (e.g., conflict minerals) under laws such as the Dodd-Frank Act.

Regulatory Compliance

Sprags used in regulated industries (e.g., aerospace, defense, medical) must meet specific standards.

- Material Compliance:

- Confirm compliance with REACH (EU), RoHS (electronics), and Proposition 65 (California) regulations regarding hazardous substances.

-

Maintain documentation for substance declarations upon request.

-

Industry Standards:

- Ensure sprags meet relevant standards such as ISO, ANSI, ASME, or SAE based on application.

-

Aerospace sprags may require AS9100 certification and traceability to raw materials.

-

Export Controls:

- Check EAR (Export Administration Regulations) or ITAR (International Traffic in Arms Regulations) if sprags are used in defense or dual-use applications.

- Obtain necessary export licenses before shipping to restricted countries.

Traceability and Documentation

Full traceability is critical for quality assurance and compliance audits.

- Batch Tracking: Maintain records of manufacturing batch, heat treatment, inspection results, and calibration data.

- Certificates: Provide Certificates of Conformance (CoC), Material Test Reports (MTR), and inspection reports when required.

- Digital Records: Use ERP or inventory systems to track movement from production to delivery.

Environmental and Safety Considerations

- Waste Disposal: Dispose of packaging and used sprags in accordance with local environmental regulations. Recycle metal components where possible.

- Worker Safety: Train personnel on safe handling procedures, especially when dealing with heavy or sharp-edged components.

Conclusion

Effective logistics and compliance management for sprags ensures product reliability, regulatory adherence, and customer satisfaction. By following industry best practices in packaging, storage, shipping, and documentation, organizations can mitigate risks and maintain high standards across the supply chain. Always consult manufacturer guidelines and regulatory authorities for application-specific requirements.

Conclusion for Sourcing Sprags:

In conclusion, sourcing sprags requires a strategic approach that balances quality, cost, reliability, and supply chain efficiency. Sprags, as critical components in overrunning clutches and various mechanical systems, demand strict adherence to material specifications, precision engineering, and rigorous quality control. After evaluating multiple suppliers, assessing technical capabilities, production capacity, lead times, and certification standards, it is evident that partnering with suppliers who demonstrate proven expertise in precision bearing components and offer robust quality assurance—such as ISO certification and traceability—is essential.

Furthermore, considering total cost of ownership rather than initial price alone ensures long-term performance and reduced maintenance risks. Developing strong supplier relationships, potentially diversifying sources to mitigate risk, and implementing regular performance reviews will contribute to a resilient and responsive supply chain. Ultimately, a well-executed sourcing strategy for sprags supports improved operational reliability, equipment longevity, and overall system efficiency.