The global cutlery market is experiencing steady growth, driven by rising disposable incomes, expanding foodservice industries, and increasing consumer preference for high-quality kitchenware. According to Grand View Research, the global cutlery market was valued at USD 23.4 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. A critical yet often overlooked component of premium cutlery is the spoon handle—where design, ergonomics, and material quality converge to influence both functionality and aesthetic appeal. As demand for durable, hygienic, and innovative spoon designs rises across commercial and residential sectors, manufacturers specializing in spoon handles are playing an increasingly vital role in the supply chain. From stainless steel to eco-friendly composite materials, these top seven spoon handle manufacturers are leading the way in precision engineering, scalability, and compliance with international quality standards—positioning themselves at the forefront of a growing, global industry.

Top 7 Spoon Handle Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

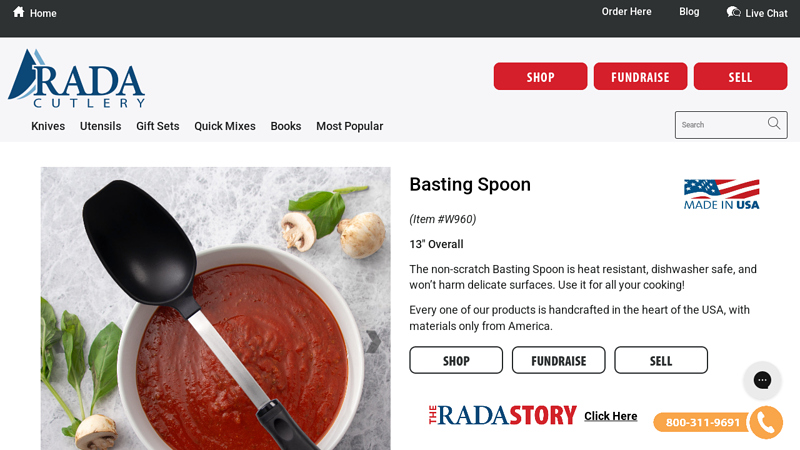

#1 Basting Spoon

Domain Est. 1997

Website: products.radacutlery.com

Key Highlights: (Item #W960). 13″ Overall. The non-scratch Basting Spoon is heat resistant, dishwasher safe, and won’t harm delicate surfaces. Use it for all your cooking!…

#2 Tramontina Tradicional 3

Domain Est. 1997

Website: global.tramontina.com

Key Highlights: Free delivery over $99 30-day returnsThe spoons have natural wood handles with aluminum rivets, which bring the charm and elegance that your luncheon or dinner deserve! Technical i…

#3 Spoons

Domain Est. 1997

Website: jbprince.com

Key Highlights: 4-day deliveryJB Prince offers a wide range of high-quality spoons for culinary professionals and enthusiasts. Elevate your cooking game with our premium cooking utensils ……

#4 Wooden Handle Spoon 9″

Domain Est. 1998

Website: korin.com

Key Highlights: This serving spoon features a dark wood handle for beautiful presentation. Suitable for home and restaurant use, this shallow ladle is durable and economical….

#5 Spoon

Domain Est. 2003

Website: manital.com

Key Highlights: This handle draws inspiration from the oval shape of a spoon and explores different aspects including the value of fullness and emptiness….

#6 SPANK SPOON Bar The Killer Quality and Killer Price Bar TGC

Domain Est. 2007

Website: spank-ind.com

Key Highlights: In stock 90-day returnsWant to upgrade your bar with one that doesn’t cost an arm and a leg? Then the SPOON Bar is ideal for you. Premium quality All-Mountain bar with a great ……

#7 Standard Stainless Steel Basting Spoons with Grip N Serv Handles

Domain Est. 2017

Website: vollrathfoodservice.com

Key Highlights: The Grip N’ Serve handles are heat-resistant up to 230°F. You’ll want a hardworking lineup of solid perforated, slotted and three-sided spoons. Durable ……

Expert Sourcing Insights for Spoon Handle

H2: 2026 Market Trends for Spoon Handle

As of 2026, the market for spoon handles—particularly within the broader cutlery, kitchenware, and foodservice industries—reflects evolving consumer preferences, sustainability mandates, and innovations in materials and design. Key trends shaping the spoon handle segment include:

-

Sustainable and Eco-Friendly Materials

Environmental consciousness continues to drive demand for biodegradable, compostable, or recyclable spoon handles. Materials such as bamboo, wheat straw, birch wood, and plant-based bioplastics dominate the market, especially in the single-use and disposable cutlery space. Regulatory pressure in regions like the EU and North America has accelerated the shift away from traditional plastic handles. -

Ergonomic and Inclusive Design

There is growing demand for spoon handles designed with ergonomics in mind, catering to aging populations, individuals with disabilities, or those seeking comfort in daily use. Anti-slip textures, angled grips, and lightweight yet durable materials are increasingly incorporated into both household and medical-grade utensils. -

Customization and Branding

In the foodservice and hospitality sectors, branded spoon handles—especially for premium desserts, coffee stirrers, or promotional events—are gaining traction. Digital printing and laser engraving technologies enable cost-effective personalization, supporting marketing initiatives and consumer engagement. -

Integration with Smart Kitchen Trends

Though still emerging, some high-end spoon handle designs are incorporating smart features, such as temperature-sensitive materials that change color or embedded NFC chips for product authentication and traceability—particularly in baby feeding or medical nutrition products. -

Rise of Reusable and Multi-Functional Designs

Consumers are favoring reusable spoon handles that pair with detachable heads or serve dual purposes (e.g., spoon-knife combos or compact, travel-friendly designs). These align with the zero-waste movement and appeal to outdoor enthusiasts and urban professionals alike. -

Regional Market Diversification

In emerging markets, affordability and durability remain primary concerns, driving demand for stainless steel and robust polymer handles. Meanwhile, Western markets prioritize aesthetics and sustainability, fueling innovation in minimalist, designer handles made from recycled materials. -

Supply Chain Resilience and Local Sourcing

Post-pandemic and geopolitical disruptions have prompted manufacturers to localize production. Spoon handle producers are increasingly sourcing raw materials regionally and investing in automation to reduce dependency on global supply chains.

In summary, the 2026 spoon handle market is characterized by a convergence of sustainability, functionality, and personalization. Companies that innovate in material science, inclusive design, and circular economy models are best positioned to capture market share in this evolving landscape.

Common Pitfalls When Sourcing Spoon Handles (Quality and Intellectual Property)

Sourcing spoon handles—whether for replacement parts, retail resale, or integration into larger products—can present several challenges, particularly concerning quality consistency and intellectual property (IP) risks. Overlooking these aspects can lead to product failures, legal disputes, and reputational damage. Below are key pitfalls to avoid:

Quality Inconsistencies

One of the most frequent issues in sourcing spoon handles is variability in material quality and manufacturing standards. Suppliers, especially those from regions with less stringent oversight, may use substandard materials such as low-grade stainless steel, recycled plastics, or alloys prone to corrosion or breakage. This can result in handles that bend, crack, or degrade after minimal use. Additionally, surface finishes may be uneven, leading to rough edges or poor ergonomics. Always verify material specifications and request physical samples before placing bulk orders.

Lack of Compliance with Safety Standards

Spoons and their components often come into contact with food and are subject to food safety regulations such as FDA (U.S.) or EC 1935/2004 (EU). Sourcing handles made from non-compliant materials—like plastics containing BPA or metals with excessive lead content—can lead to product recalls or legal liability. Ensure suppliers provide certifications and conduct independent testing where necessary.

Inadequate Durability and Functional Testing

Many sourced spoon handles fail under stress due to poor design or insufficient structural integrity. For example, handles may detach from the spoon bowl during use or fail under thermal stress (e.g., during dishwashing). Conduct real-world usage tests, including drop tests, thermal cycling, and dishwasher resistance, to validate performance before scaling production.

Intellectual Property Infringement

A significant but often overlooked risk is inadvertently sourcing spoon handles that mimic patented or trademarked designs. Some suppliers may copy popular ergonomic shapes, decorative elements, or integrated features (e.g., measurement markings or collapsible mechanisms) protected by IP laws. Purchasing such items—even unknowingly—can expose your business to infringement claims. Always vet designs against patent databases and ensure suppliers warrant that products do not infringe on existing IP.

Supplier Misrepresentation and Counterfeit Goods

Some suppliers, particularly on online marketplaces, may falsely claim material composition (e.g., “18/10 stainless steel”) or origin. Counterfeit or misrepresented goods may look identical but perform poorly. Build relationships with verified suppliers, conduct factory audits, and use third-party inspection services to mitigate this risk.

Poor Packaging and Logistics Damage

Spoon handles, especially delicate or polished ones, can arrive damaged due to inadequate packaging. This affects both quality and customer satisfaction. Specify packaging requirements upfront and confirm logistics plans to avoid transit-related defects.

By proactively addressing these pitfalls—through due diligence, testing, and legal safeguards—businesses can ensure reliable, compliant, and legally safe sourcing of spoon handles.

Logistics & Compliance Guide for Spoon Handle

This guide outlines the essential logistics and compliance considerations for the manufacturing, packaging, shipping, and sale of spoon handles. Adhering to these standards ensures product safety, regulatory compliance, and efficient supply chain operations.

Product Specifications & Materials

Spoon handles must be manufactured using food-grade materials such as stainless steel (e.g., 18/10 or 18/8), food-safe plastics (e.g., polypropylene), or certified wood compliant with FDA and EU food contact regulations. All materials must be free from BPA, phthalates, and other hazardous substances. Material certifications (e.g., FDA 21 CFR, EU Regulation 1935/2004) must be documented and retained for audit purposes.

Manufacturing & Quality Control

All production facilities must comply with Good Manufacturing Practices (GMP) and, where applicable, ISO 9001 standards. Regular quality audits and in-process inspections are required to verify dimensional accuracy, surface finish, and structural integrity. Batch traceability must be maintained for raw materials and finished goods through serial or lot numbering.

Packaging Requirements

Spoon handles must be packaged in sealed, tamper-evident, and contamination-resistant materials. Packaging should be labeled with product name, material type, manufacturer information, country of origin, batch number, and compliance markings (e.g., “FDA Compliant,” “Dishwasher Safe”). If sold as part of a cutlery set, packaging must meet additional labeling requirements per jurisdiction.

Regulatory Compliance

Products must meet relevant regulatory standards in target markets:

– United States: FDA 21 CFR for food contact materials; CPSC guidelines if marketed for children.

– European Union: EU Regulation 1935/2004 and 10/2011 for plastic materials; CE marking not required unless part of a larger product.

– Other Markets: Local food safety and import regulations (e.g., UK FSA, Health Canada).

Import & Export Documentation

When shipping internationally, ensure proper documentation including commercial invoice, packing list, certificate of origin, and material compliance certificates. Classify spoon handles under the appropriate HS Code (e.g., 8215.99 for stainless steel cutlery parts). Verify tariff rates and import restrictions with local customs authorities.

Labeling & Consumer Information

All labels must be accurate, legible, and in the official language(s) of the destination country. Include care instructions (e.g., hand wash recommended), safety warnings (if applicable), and recycling symbols for packaging. Avoid misleading claims such as “eco-friendly” unless substantiated by recognized certifications.

Transportation & Storage

Handle and store spoon handles in a clean, dry, and pest-free environment. Use protective packaging to prevent scratching or deformation during transit. Follow carrier-specific guidelines for stacking, weight limits, and hazardous material declarations (none required if non-toxic materials used).

Environmental & Sustainability Compliance

Comply with applicable waste and recycling directives (e.g., EU WEEE, Packaging Waste Regulations). Minimize packaging waste and use recyclable or biodegradable materials where possible. Monitor evolving regulations on single-use plastics if plastic handles are used.

Record Keeping & Audits

Maintain records of supplier certifications, quality test results, compliance documentation, and shipment details for a minimum of five years. Conduct annual internal audits and prepare for third-party inspections by regulatory bodies or retailers.

Incident Response & Recalls

Establish a product recall procedure in accordance with FDA, EU Rapid Alert System for Food and Feed (RASFF), or equivalent. Report any safety incidents or non-compliance to relevant authorities promptly and communicate transparently with distributors and consumers.

Conclusion for Sourcing Spoon Handle:

In conclusion, sourcing spoon handles requires a careful balance between material quality, manufacturing capabilities, cost-efficiency, and compliance with safety and sustainability standards. The choice of material—whether stainless steel, wood, silicone, or plastic—should align with the intended use, durability requirements, and brand values. Effective supplier selection, considering factors such as reliability, scalability, and ethical practices, is crucial to ensure consistent quality and timely delivery. Additionally, evaluating customization options, production lead times, and logistical considerations helps optimize the sourcing process. By adopting a strategic and holistic approach, businesses can secure high-quality spoon handles that meet functional needs, customer expectations, and sustainability goals, ultimately contributing to the overall success of the product.