The global lock washer market is experiencing steady growth, driven by increasing demand across automotive, construction, industrial machinery, and infrastructure sectors. According to Mordor Intelligence, the lock washer market was valued at approximately USD 1.8 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. This expansion is fueled by rising industrialization, stricter safety regulations requiring secure fastening solutions, and growing investments in equipment maintenance and reliability. Split lock washers, in particular, remain a critical component for preventing loosening due to vibration and thermal expansion, making them indispensable in high-stress applications. As demand surges, a select group of manufacturers has risen to prominence through innovation, quality control, and global supply chain reach. Based on production scale, geographic footprint, material engineering, and industry certifications, the following ten companies represent the leading split lock washer manufacturers shaping the market today.

Top 10 Split Lock Washer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Split Lock Washers

Domain Est. 1999

Website: fastcoinc.com

Key Highlights: We supply split lock washers in multiple styles with various materials and finish options. Understanding the characteristics of each ……

#2 Lock Washer Manufacturers

Domain Est. 2003

Website: kdfasteners.com

Key Highlights: Our split lock washers come in a variety of materials. It includes low carbon steel, through-hardened steel, various grades of stainless steel, silicon bronze, ……

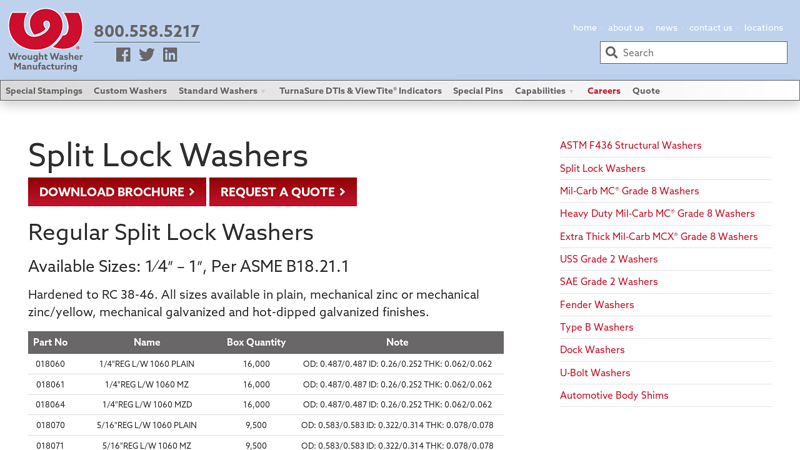

#3 Split Lock Washers

Domain Est. 1996

Website: wroughtwasher.com

Key Highlights: Regular Split Lock Washers Available Sizes: 1⁄4′′ – 1′′, Per ASME B18.21.1 Hardened to RC 38-46. All sizes available in plain, mechanical zinc or mechanical ……

#4 Split Lock Washers

Domain Est. 1996

Website: olander.com

Key Highlights: Find split lock washers from Olander in an array of materials, finishes, sizes, and other configurations. Also referred to as helical spring lock washers or ……

#5 Lock Washer

Domain Est. 1996

Website: minerallac.com

Key Highlights: Provides a hardened bearing surface, creating more uniform torque control and load distribution. Material, Steel. Finish, Zinc Plated. Thickness, 0.094″….

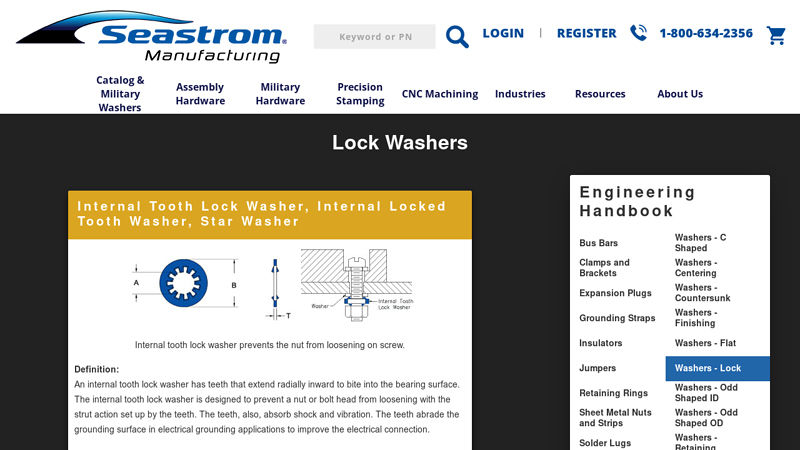

#6 Lock Washers

Domain Est. 1997

Website: seastrom-mfg.com

Key Highlights: The split in the helical lock washer provides the resistance to the rotation of the screw when the tension in the assembly is reduced. Helical Lock Washers are ……

#7 Regular Helical Spring Split Lock Washers

Domain Est. 1997

Website: wclco.com

Key Highlights: The tension generated by the deflection of the Regular helical spring split lock washer meets the needs of most commercial applications….

#8 Lock Washer Supplier

Domain Est. 2002

Website: apf.com

Key Highlights: We manufacture and globally source lock washers for use in high-vibration fastening environments, with a wide range of materials and coatings available….

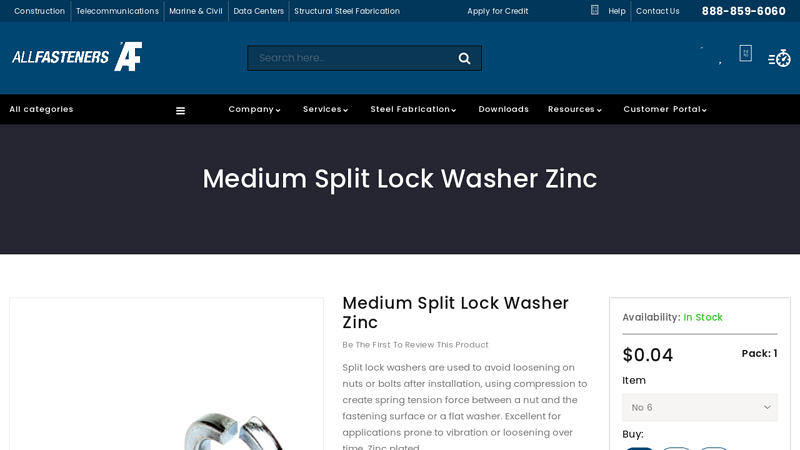

#9 Medium Split Lock Washer Zinc

Domain Est. 2002

Website: allfasteners.com

Key Highlights: Split lock washers are used to avoid loosening on nuts or bolts after installation, using compression to create spring tension force….

#10 Lock Washers

Domain Est. 2002

Website: nickel-systems.com

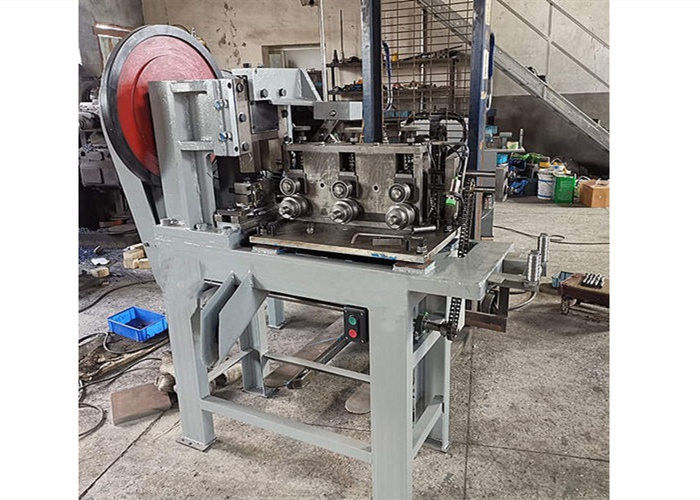

Key Highlights: Split lock washers are made mostly from coils of wire. Lock washers made from coil are subject to high-volume production runs. Steel and stainless steel ……

Expert Sourcing Insights for Split Lock Washer

H2: 2026 Market Trends for Split Lock Washers

The global split lock washer market is anticipated to experience moderate yet steady growth by 2026, driven by sustained demand across key industrial and manufacturing sectors despite evolving fastening technologies. Several macroeconomic, technological, and regional factors are shaping the market landscape.

-

Steady Industrial Demand

Split lock washers remain essential in applications requiring reliable vibration resistance and load distribution, particularly in automotive, construction, heavy machinery, and aerospace industries. As global infrastructure projects rebound post-pandemic and manufacturing activity stabilizes, demand for cost-effective and proven fastening solutions like split lock washers is expected to remain resilient. -

Shift Toward High-Performance Materials

A notable trend is the increasing adoption of corrosion-resistant and high-strength materials such as stainless steel, silicon manganese steel, and coated carbon steel. Manufacturers are focusing on enhancing product durability to meet stringent environmental and safety standards, especially in automotive and outdoor equipment sectors. -

Regional Market Dynamics

Asia-Pacific, particularly China and India, continues to dominate production and consumption due to robust industrialization and expanding manufacturing bases. North America and Europe maintain steady demand, supported by aerospace and automotive maintenance, repair, and operations (MRO) activities. However, growth in mature markets is tempered by the gradual adoption of alternative locking mechanisms. -

Competition from Alternative Technologies

Split lock washers face growing competition from toothed lock washers, nylon insert lock nuts, and chemical locking solutions. While split lock washers offer simplicity and low cost, their relatively lower performance in high-vibration environments is prompting some industries to explore advanced alternatives. This trend may limit market expansion but also drives innovation in washer design and material engineering. -

Sustainability and Supply Chain Optimization

Environmental regulations and supply chain resilience are influencing production strategies. Leading manufacturers are investing in lean manufacturing, recycling processes, and localized sourcing to reduce carbon footprint and mitigate geopolitical risks. These factors are expected to improve cost efficiency and supply reliability by 2026. -

Digitalization and E-Commerce Growth

The industrial fasteners distribution landscape is shifting, with B2B e-commerce platforms gaining traction. Increased online procurement is improving market transparency and accessibility, especially for SMEs, thereby expanding the customer base for standardized components like split lock washers.

In conclusion, while the split lock washer market in 2026 is not projected for explosive growth, it remains a vital segment within the broader fasteners industry. Continued innovation, material advancements, and strategic positioning in emerging markets will be key for stakeholders aiming to maintain relevance and profitability.

Common Pitfalls When Sourcing Split Lock Washers (Quality, IP)

Sourcing split lock washers may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to product failure, safety hazards, and legal exposure. Below are critical pitfalls to avoid:

Poor Material Quality and Inadequate Specifications

One of the most frequent issues is receiving split lock washers made from substandard materials. Suppliers may use low-grade carbon steel that lacks proper hardness or corrosion resistance, leading to premature failure under load or in harsh environments. Buyers must ensure washers meet recognized standards (e.g., ISO 7094, DIN 127) and specify material grades (e.g., hardened steel, stainless steel AISI 304/316). Failure to verify chemical composition, tensile strength, and surface finish can compromise joint integrity.

Inconsistent Dimensional Tolerances

Low-cost suppliers often cut corners on precision, resulting in inconsistent outer/inner diameters or uneven split gaps. These variations reduce clamping force efficiency and can cause uneven stress distribution, increasing the risk of loosening in dynamic applications. Always require dimensional certifications and conduct incoming inspections using calibrated gauges.

Inadequate Surface Treatments and Corrosion Protection

Many sourced washers feature insufficient or poorly applied coatings (e.g., zinc plating below required thickness). This leads to rust formation, especially in outdoor or high-moisture environments. Specify coating types and thickness (e.g., ASTM B633 Fe/Zn 8), and request salt spray test reports to validate performance.

Misrepresentation of Intellectual Property and Counterfeit Goods

A significant IP risk arises when suppliers falsely claim compliance with patented designs or registered trademarks. Some manufacturers copy proprietary washer geometries protected under industrial design rights or utility models. Sourcing from unauthorized producers may expose the buyer to infringement claims. Always verify supplier legitimacy, request proof of IP ownership or licensing, and avoid vendors offering “equivalent” versions of patented products without authorization.

Lack of Traceability and Certification

Reputable applications (e.g., aerospace, automotive, medical) require full traceability, including material test reports (MTRs) and compliance certificates. Many suppliers, especially from unverified sources, provide incomplete or forged documentation. Establish supply chain transparency by requiring lot traceability and third-party test reports.

Overlooking Application-Specific Requirements

Not all split lock washers are interchangeable. Using a general-purpose washer in high-vibration or high-temperature environments without proper qualification can lead to failure. Engage engineering teams early to match washer specifications to the operational environment and load conditions.

By addressing these pitfalls proactively—through stringent supplier vetting, clear technical specifications, and IP due diligence—organizations can ensure reliable performance and legal compliance in their fastener sourcing.

Logistics & Compliance Guide for Split Lock Washer

Overview of Split Lock Washer

Split lock washers, also known as helical spring lock washers, are mechanical fastening components designed to prevent loosening due to vibration or thermal expansion. Typically made from hardened steel, stainless steel, or other corrosion-resistant materials, they are widely used across industries such as automotive, construction, aerospace, and manufacturing. Proper logistics handling and compliance with regulatory standards are essential to ensure product integrity, safety, and legal adherence.

Material & Packaging Specifications

Split lock washers must be packaged to prevent corrosion, deformation, and contamination during transit and storage. Standard packaging includes moisture-resistant polyethylene bags, cardboard boxes, or steel/wooden crates for bulk shipments. Desiccants should be used in humid environments. Packaging labels must clearly indicate part number, material grade (e.g., ASTM A193 B7, SS304), quantity, batch/lot number, and manufacturer details. Vacuum sealing or VCI (Vapor Corrosion Inhibitor) packaging is recommended for long-term storage or export to coastal regions.

Transportation & Handling

Shipments should comply with international freight standards (e.g., ISTA, ISO). Use palletized loads secured with strapping or stretch wrap to prevent shifting. Avoid exposure to extreme temperatures, moisture, or corrosive atmospheres during transport. Forklift handling must avoid crushing packaged units. For air freight, ensure compliance with IATA Dangerous Goods Regulations—even non-hazardous metal components may require specific declaration forms. Sea freight shipments should follow IMO IMCO guidelines and utilize protective dunnage to minimize saltwater exposure.

Regulatory Compliance

Split lock washers must meet relevant industry and regional standards. Key compliance requirements include:

– ASTM F436: Standard for hardened washers, including split lock types.

– DIN 127: German standard for slotted spring lock washers.

– ISO 7094: International standard for large series of heavy-duty washers.

– RoHS & REACH: Required for shipments to the EU; ensure materials are free from restricted substances (e.g., lead, cadmium).

– Conflict Minerals Rule (Dodd-Frank Act): Applicable if sourced from the Democratic Republic of Congo or adjoining countries; documentation may be required.

Certifications such as ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) from the manufacturer enhance compliance credibility.

Import/Export Documentation

Accurate documentation is critical for customs clearance. Required documents typically include:

– Commercial Invoice (with HTS/HS code: 7318.22 for spring washers)

– Packing List

– Certificate of Origin

– Material Test Reports (MTRs) or Certificates of Compliance (CoC)

– REACH/RoHS Compliance Declaration (for EU)

– Export License (if applicable, based on destination and material composition)

Ensure Harmonized System (HS) code accuracy to avoid delays or penalties. For shipments to the U.S., compliance with U.S. Customs and Border Protection (CBP) and Bureau of Industry and Security (BIS) regulations is mandatory.

Storage & Inventory Management

Store split lock washers in a dry, temperature-controlled environment (ideally 10–25°C, <60% RH). Use first-in, first-out (FIFO) inventory rotation to prevent long-term storage issues. Segregate different materials (e.g., carbon steel vs. stainless steel) to avoid galvanic corrosion. Implement barcode or RFID tracking for lot traceability, especially in regulated industries like aerospace (AS9100) or medical devices.

Quality Control & Traceability

Each production batch should undergo dimensional inspection, hardness testing, and visual examination per ISO 2859 or ANSI/ASQ Z1.4 sampling standards. Maintain traceability from raw material sourcing to final shipment. Audit suppliers regularly to ensure compliance with specified standards. Non-conforming products must be quarantined and dispositioned per documented procedures.

Environmental & Safety Considerations

Dispose of packaging and rejected components in accordance with local environmental regulations (e.g., EPA in the U.S., WEEE in the EU). Metal shavings or worn washers should be recycled through certified metal reclamation facilities. Provide Safety Data Sheets (SDS) for raw materials used in manufacturing, even if the final product is non-hazardous, to support downstream compliance.

Conclusion

Effective logistics and compliance management for split lock washers ensures reliability, regulatory adherence, and supply chain efficiency. By following standardized packaging, transportation, documentation, and quality practices, businesses can mitigate risks, avoid customs delays, and maintain product performance in critical applications. Regular audits and continuous improvement are recommended to stay aligned with evolving international standards.

Conclusion for Sourcing Split Lock Washer:

After a thorough evaluation of suppliers, material quality, cost, lead times, and compliance standards, sourcing split lock washers from pre-qualified suppliers who adhere to international standards (such as ISO, DIN, or ASME) ensures reliability, performance, and consistency in critical fastening applications. By prioritizing suppliers with proven quality control processes, on-time delivery records, and the capability to scale production as needed, organizations can minimize the risk of mechanical failure due to loosening fasteners. Additionally, establishing long-term partnerships with reliable vendors enhances supply chain stability and supports overall operational efficiency. Therefore, a strategic sourcing approach that balances cost-effectiveness with quality assurance is essential for the successful integration of split lock washers in engineering and manufacturing processes.