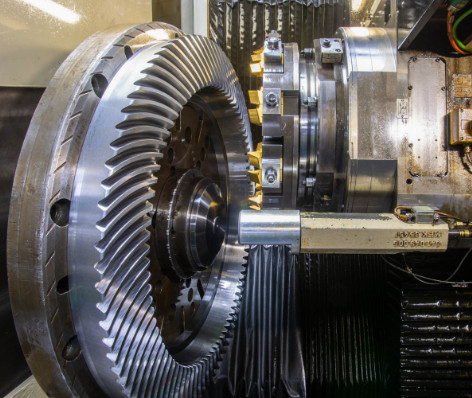

The global spiral bevel gears market is experiencing robust growth, driven by increasing demand from automotive, aerospace, and industrial machinery sectors. According to a report by Mordor Intelligence, the bevel gear market was valued at USD 4.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of over 5.2% from 2024 to 2029. This expansion is fueled by the rising need for precision power transmission components in electric vehicles, wind turbines, and advanced manufacturing equipment. Spiral bevel gears, known for their high load capacity, smooth operation, and efficiency in right-angle torque transmission, are becoming increasingly critical in high-performance applications. As industries prioritize energy efficiency and mechanical reliability, leading manufacturers are investing in advanced machining technologies and material innovations to meet evolving specifications. In this competitive landscape, a select group of global players stand out for their technological expertise, production scale, and market reach—making them key contributors to the ongoing evolution of power transmission systems.

Top 7 Spiral Bevel Gears Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Spiral Bevel Gears

Domain Est. 1997

Website: cbgear.com

Key Highlights: Spiral Bevel Gears. Spiral and Straight Bevel Gears. C-B Gear has recently enhanced its spiral bevel gear manufacturing process by implementing CNC technology….

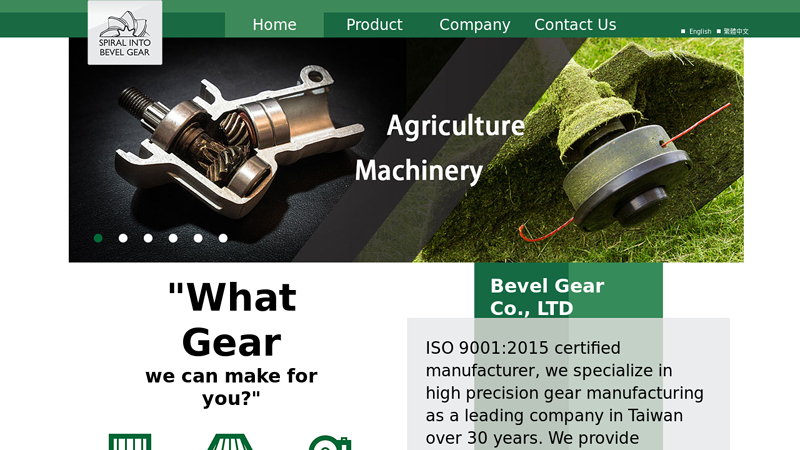

#2 Bevel Gear Co., LTD

Domain Est. 2013

Website: bevelgeartw.com

Key Highlights: High precision gear manufacturer more than 30 years and specialized in spiral bevel gears, bevel gear, hypoid gear, worm gear, helical gears….

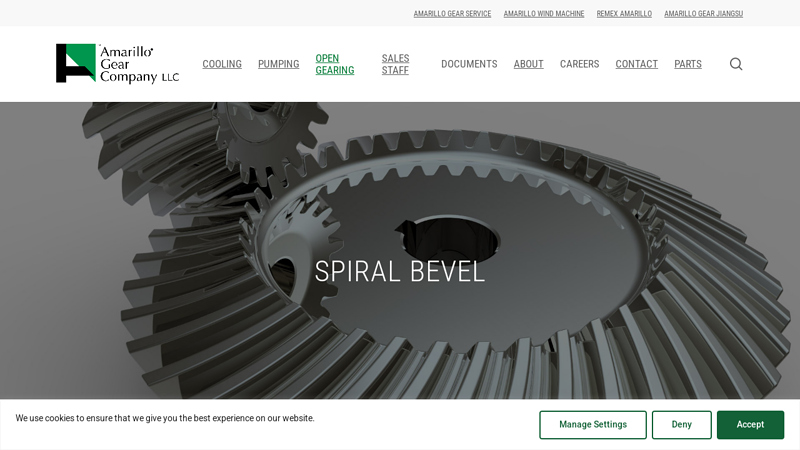

#3 Spiral Bevel

Domain Est. 1996

Website: amarillogear.com

Key Highlights: Amarillo Gear manufactures one of the largest selections of spiral bevel gears in the industry for your power transmission requirements….

#4 Custom Bevel Gears and Spiral Bevel Gears

Domain Est. 1996

Website: circlegear.com

Key Highlights: Explore our custom line of bevel and spiral bevel gears, we work with materials including aluminum, ductile iron, and stainless steel. Learn more!…

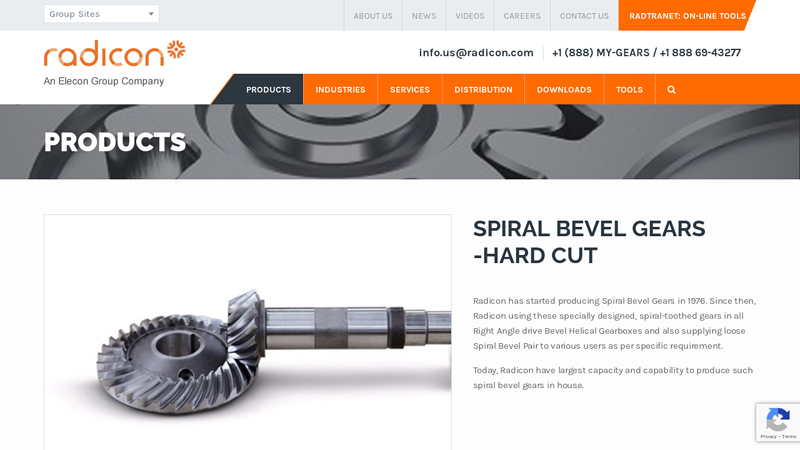

#5 Spiral Bevel Gears

Domain Est. 1997

Website: us.radicon.com

Key Highlights: Spiral Bevel gears have the advantage over straight bevel gears in terms of smooth running, low noise level, and increase power transmission capacity….

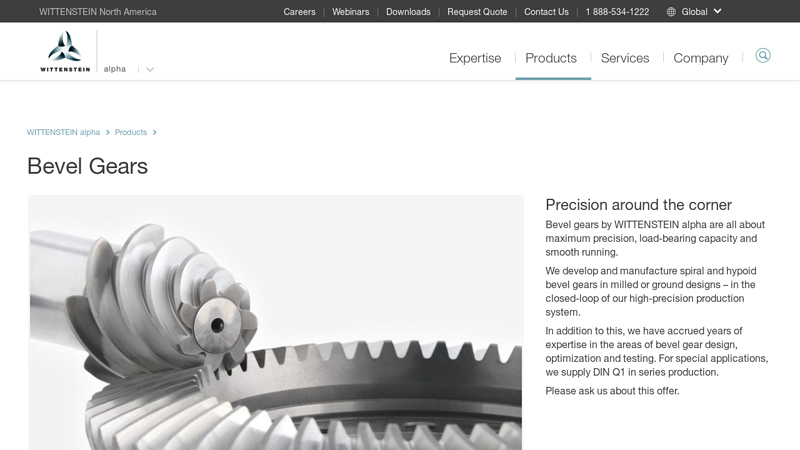

#6 Bevel Gears

Domain Est. 2007

Website: alpha.wittenstein-us.com

Key Highlights: We develop and manufacture spiral and hypoid bevel gears in milled or ground designs – in the closed-loop of our high-precision production system. In ……

#7 Spiral Bevels

Domain Est. 2009

Website: sovereigngears.com

Key Highlights: Spiral bevel gears are primarily used as vehicle differentials; helping to assist the drive shaft and making vehicle wheels turn 90 degrees….

Expert Sourcing Insights for Spiral Bevel Gears

H2: Market Trends in Spiral Bevel Gears for 2026

The global market for spiral bevel gears is poised for significant evolution by 2026, driven by technological advancements, increasing demand from key industries, and the push toward energy efficiency and automation. Below are the key trends shaping the spiral bevel gear market in 2026:

-

Growing Demand from Automotive and Aerospace Sectors

The automotive industry, particularly in electric and hybrid vehicle (EV/HEV) development, is increasingly adopting spiral bevel gears for their high torque transmission and smooth operation in differential systems. In aerospace, these gears are critical in helicopter transmissions and auxiliary power units, where reliability under high stress is essential. As both sectors expand and innovate, demand for high-precision spiral bevel gears is expected to rise steadily through 2026. -

Advancements in Manufacturing Technology

Innovations in gear cutting, such as CNC-controlled bevel gear generators and Six-Axis Free-Form (6X) grinding, are enabling tighter tolerances and improved surface finishes. Additive manufacturing and digital twin technologies are also being integrated into production workflows, reducing lead times and enhancing customization. These advancements support the production of more efficient, lighter, and durable spiral bevel gears, aligning with industry needs for performance optimization. -

Rise of Industry 4.0 and Smart Gear Monitoring

By 2026, the integration of IoT sensors and predictive maintenance systems into gear systems is becoming standard in industrial applications. Spiral bevel gears are increasingly being embedded with condition-monitoring capabilities to detect wear, misalignment, and temperature anomalies in real time. This shift toward smart manufacturing enhances equipment uptime and reduces operational costs, particularly in wind turbines, robotics, and heavy machinery. -

Sustainability and Energy Efficiency Focus

With global emphasis on reducing carbon emissions, industries are prioritizing energy-efficient drivetrain components. Spiral bevel gears, known for their high efficiency in power transmission and reduced noise, are gaining favor in renewable energy applications—especially wind turbines, where reliability and efficiency are critical. Manufacturers are also adopting sustainable materials and heat treatment processes to meet environmental regulations. -

Regional Market Shifts and Supply Chain Optimization

Asia-Pacific, led by China, India, and Japan, is expected to dominate the spiral bevel gear market in 2026 due to rapid industrialization and growth in automotive and manufacturing sectors. Meanwhile, North America and Europe are focusing on high-value, precision-engineered gears for aerospace and defense applications. Supply chains are being reshored or diversified to mitigate geopolitical risks and reduce dependency on single-source suppliers. -

Increased Customization and Application-Specific Designs

End-users across industries are demanding application-specific gear solutions. This trend is driving manufacturers to offer modular designs, custom tooth geometry, and hybrid materials tailored to unique operational environments. The ability to rapidly prototype and iterate designs is becoming a competitive advantage.

In conclusion, the 2026 spiral bevel gear market is characterized by innovation, digitization, and sustainability. As industries demand higher performance and reliability, manufacturers who leverage advanced technologies and adapt to evolving regulatory and environmental standards will lead the market.

Common Pitfalls When Sourcing Spiral Bevel Gears (Quality, IP)

Sourcing high-performance spiral bevel gears requires careful attention to both quality assurance and intellectual property (IP) considerations. Overlooking these aspects can lead to costly failures, legal disputes, and production delays. Below are key pitfalls to avoid:

Poor Quality Control and Material Verification

Many suppliers, especially low-cost manufacturers, may lack rigorous quality control systems. Without proper inspection protocols—such as gear tooth profile measurement, surface finish checks, and material certification—gears may fail prematurely under load. Buyers should insist on documented inspection reports (e.g., CMM results, metallurgical analysis) and adherence to standards like AGMA, DIN, or ISO.

Inadequate Heat Treatment and Surface Hardness

Improper heat treatment can result in inconsistent hardness, leading to tooth pitting, spalling, or catastrophic gear failure. Some suppliers may cut corners on case depth or tempering processes. Always verify heat treatment specifications and request hardness testing reports to ensure durability and performance.

Tolerances and Precision Misalignment

Spiral bevel gears require high precision in tooth geometry, runout, and mounting dimensions. Sourcing from facilities without advanced CNC gear cutting and grinding equipment increases the risk of tolerance stack-ups and noise/vibration in operation. Confirm the supplier’s capability to meet specified AGMA quality numbers (e.g., AGMA 9 or higher).

Lack of Traceability and Documentation

Reputable suppliers provide full traceability, including material batch numbers, heat treatment records, and inspection data. A lack of documentation not only raises quality concerns but also complicates failure analysis and compliance with industry regulations (e.g., aerospace, defense).

Intellectual Property (IP) Infringement Risks

Sourcing from unauthorized or offshore manufacturers can expose buyers to IP violations. Many spiral bevel gear designs—especially those developed by OEMs or specialized gear houses—are protected by patents or trade secrets. Purchasing counterfeit or reverse-engineered gears may result in legal liability, warranty voidance, and supply chain disruptions.

Use of Unlicensed Manufacturing Drawings or Software

Some suppliers may use proprietary gear design software (e.g., Gleason’s GEMS) or drawings without proper licensing. This not only compromises gear performance but also implicates the buyer in IP misuse. Ensure suppliers are authorized partners or licensees where applicable.

Inadequate Testing and Validation

Avoid suppliers who skip prototype testing or performance validation under simulated operating conditions. Load testing, noise analysis, and endurance testing are essential for mission-critical applications. Lack of test data increases the risk of field failures.

Insufficient Supplier Qualification and Audits

Failing to audit potential suppliers on-site can hide deficiencies in process control, workforce training, and quality management systems (e.g., ISO 9001, AS9100). Conduct regular audits to verify compliance and continuous improvement practices.

By proactively addressing these quality and IP-related pitfalls, buyers can ensure reliable, compliant, and high-performance spiral bevel gear sourcing.

Logistics & Compliance Guide for Spiral Bevel Gears

Proper logistics and compliance management are essential when transporting and handling spiral bevel gears to ensure product integrity, regulatory adherence, and operational efficiency. This guide outlines key considerations for the safe and compliant logistics of spiral bevel gears across domestic and international supply chains.

Packaging & Handling Requirements

Spiral bevel gears are precision-engineered components susceptible to damage from impact, moisture, and contamination. Follow these best practices:

- Protective Packaging: Use rigid, moisture-resistant containers with cushioning materials (e.g., foam inserts, VCI paper) to prevent movement and corrosion during transit.

- Labeling: Clearly label each package with handling instructions (e.g., “Fragile,” “Do Not Stack,” “Keep Dry”) and product identification (part number, heat number, traceability codes).

- Orientation: Package gears in their designated orientation to prevent bearing or tooth surface damage.

- Handling Equipment: Use appropriate lifting devices (e.g., soft-jaw clamps, lifting beams) to avoid surface deformation during loading and unloading.

Transportation & Shipping

Select transportation methods based on gear size, weight, destination, and delivery schedule:

- Domestic Shipments: Use enclosed trucks or containers to protect against environmental exposure. Ensure secure strapping and blocking to prevent shifting.

- International Shipments: Comply with international freight standards (e.g., ISO container specs). Use desiccants and humidity indicators for sea freight to mitigate condensation risks.

- Temperature Control: Avoid extreme temperature fluctuations during transit, especially for gears with sensitive coatings or materials.

- Freight Classification: Classify cargo accurately under NMFC (National Motor Freight Classification) or HS Code systems to avoid delays and billing issues.

Regulatory Compliance

Adherence to international and regional regulations is critical, particularly for cross-border shipments:

- HS Code Classification: Spiral bevel gears typically fall under HS Code 8483.40 (gear boxes and other transmission components). Confirm classification with customs authorities to ensure accurate duty assessment.

- Export Controls: Check for ITAR (International Traffic in Arms Regulations) or EAR (Export Administration Regulations) restrictions if gears are used in defense, aerospace, or high-performance applications.

- RoHS & REACH Compliance: Ensure materials used in gear manufacturing comply with EU directives restricting hazardous substances (RoHS) and chemical safety (REACH).

- Country-Specific Regulations: Verify import requirements in the destination country (e.g., CE marking, conformity assessment, local certification).

Documentation

Accurate documentation ensures smooth customs clearance and traceability:

- Commercial Invoice: Include detailed product description, value, quantity, harmonized code, and Incoterms (e.g., FOB, DDP).

- Packing List: Specify weight, dimensions, number of packages, and internal contents per shipment.

- Certificate of Origin: Required for preferential tariff treatment under trade agreements (e.g., USMCA, EU free trade pacts).

- Material & Test Certificates: Provide mill certificates or inspection reports (e.g., ISO 9001, AS9100) verifying material composition and quality compliance.

- Dangerous Goods Declaration (if applicable): Only required if lubricants or coatings are classified as hazardous.

Customs Clearance & Duties

Facilitate timely customs processing with proactive preparation:

- Pre-Arrival Documentation: Submit electronic data in advance (e.g., ACE in the U.S., Customs Handling of Import Freight in the UK).

- Duty Optimization: Leverage duty drawback programs or bonded warehouses where applicable.

- Customs Brokers: Use licensed brokers familiar with mechanical components to navigate tariff classifications and valuation rules.

Quality & Traceability

Maintain traceability throughout the logistics chain:

- Lot/Batch Tracking: Assign unique identifiers to each batch for full material and process traceability.

- Inspection Upon Receipt: Conduct incoming inspections to verify gear condition and compliance with purchase specifications.

- Non-Conformance Reporting: Establish protocols for reporting and handling damaged or non-compliant shipments.

Environmental & Sustainability Considerations

Adopt eco-friendly logistics practices:

- Recyclable Packaging: Use sustainable materials and minimize packaging waste.

- Carbon Footprint Reduction: Optimize routing and consolidate shipments to lower emissions.

- Compliance with Local Environmental Laws: Adhere to waste disposal and chemical handling regulations at all transit points.

By following this guide, manufacturers, distributors, and logistics providers can ensure the secure, compliant, and efficient movement of spiral bevel gears across global markets.

Conclusion for Sourcing Spiral Bevel Gears

Sourcing spiral bevel gears requires a strategic approach that balances quality, precision, cost, and supplier reliability. These critical components, known for their smooth operation, high load capacity, and efficiency in transmitting power between intersecting shafts, demand strict adherence to engineering specifications and material standards. When selecting a supplier, factors such as manufacturing capabilities (e.g., CNC gear cutting, heat treatment, and grinding), quality certifications (such as ISO 9001), and experience in the relevant industry (automotive, aerospace, industrial machinery, etc.) are essential to ensure long-term performance and durability.

Additionally, considering lead times, customization options, and technical support can significantly impact project timelines and integration success. Establishing strong relationships with reputable manufacturers—whether domestic or international—can provide long-term benefits, including consistent quality, better pricing, and responsive service. Ultimately, a well-informed sourcing strategy for spiral bevel gears contributes to improved mechanical efficiency, reduced maintenance costs, and enhanced reliability of the final application.