The global DC motor market is experiencing robust growth, driven by rising demand for energy-efficient motion control solutions across industries such as automotive, industrial automation, and consumer electronics. According to Mordor Intelligence, the DC motor market is projected to grow at a CAGR of over 4.5% from 2023 to 2028, fueled by advancements in motor control technologies and increasing adoption of electric vehicles and robotics. A critical component of this evolution is precision speed control, which enhances performance, efficiency, and operational lifespan of DC motors. As automation and smart manufacturing continue to scale, the need for reliable speed control systems has intensified, positioning specialized manufacturers at the forefront of innovation. Based on market presence, technological capabilities, and product performance, the following eight companies have emerged as leading manufacturers in the field of DC motor speed control.

Top 8 Speed Control Of Dc Motor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Oriental Motor U.S.A. Corp.

Domain Est. 1997

Website: orientalmotor.com

Key Highlights: Designed to make sizing a motor for your application faster and easier, these new sizing forms calculate the necessary torque, speed, stopping accuracy, and ……

#2 DC Motors with innovative winding technology

Domain Est. 1997

Website: faulhaber.com

Key Highlights: Advantages of our DC-motors. No cogging. Smooth position and speed control. High efficiency. Low Noise. High Torque. What is a DC motor? DC is an acronym for ……

#3 Minarik Drives

Domain Est. 2002

Website: minarikdrives.com

Key Highlights: Minarik Drives specializes in DC Driver products and other motor control products that serve a number of markets, including industrial, commercial, vehicle, ……

#4 Micro Motors

Domain Est. 1996

Website: portescap.com

Key Highlights: Precision feedback for accurate speed, position, and directional control. Controllers. Smart, compact electronics for seamless motor integration and optimized ……

#5 AC, DC and BLDC Motor Controls / Digital Potentiometers

Domain Est. 1997

Website: dartcontrols.com

Key Highlights: DC motor controls, AC variable frequency controls, and other speed controllers for electric motors including digital speed potentiometers and encoders….

#6 DC Controls

Domain Est. 1997

Website: bodine-electric.com

Key Highlights: Bodine PMDC speed controls convert AC line power to the required DC output that is required to drive PMDC motors and geared motors….

#7 High-Quality DC Motors

Domain Est. 2001

Website: ddmotorsystems.com

Key Highlights: Wide Range of high speed & torque heavy duty DC Motors & Controllers – 12v dc motors, 24v dc motors, 48v dc motors, 96 volt dc motors, and 144v dc motors….

#8 KB Controls

Domain Est. 2005

Website: kb-controls.com

Key Highlights: AC SOLID STATE FAN CONTROL. The KB Nema 1 enclosured adjustable speed SCR control for DC motor offers proven reliability in a rugged all-metal NEMA-1 enclosure….

Expert Sourcing Insights for Speed Control Of Dc Motor

H2: Market Trends in Speed Control of DC Motors for 2026

The global market for speed control of DC motors is poised for significant transformation by 2026, driven by advancements in automation, energy efficiency demands, and the integration of smart technologies across industrial and consumer applications. This analysis outlines the key trends shaping the speed control of DC motors in 2026 under the H2 framework, focusing on technological innovation, sectoral adoption, regional dynamics, and sustainability.

1. Advancements in Control Technologies

By 2026, pulse-width modulation (PWM) and field-oriented control (FOC) techniques are expected to dominate the DC motor speed control landscape. The integration of microcontrollers and digital signal processors (DSPs) is enabling more precise, responsive, and energy-efficient motor control. Additionally, the rise of intelligent control algorithms powered by embedded artificial intelligence (AI) and machine learning (ML) allows adaptive speed regulation based on real-time load conditions, enhancing performance in robotics, electric vehicles (EVs), and industrial automation.

2. Growth in Electric Vehicle and Mobility Applications

The surge in electric two-wheelers, e-bikes, and small EVs is a major driver for efficient DC motor speed controllers. In 2026, compact and high-efficiency speed control systems will be in high demand to support regenerative braking, variable torque output, and extended battery life. The automotive sector will continue to adopt brushless DC (BLDC) motors with advanced electronic speed controllers (ESCs), pushing innovation in thermal management and power density.

3. Industrial Automation and Smart Manufacturing

Industry 4.0 initiatives are accelerating the adoption of automated guided vehicles (AGVs), conveyor systems, and CNC machines—all reliant on precise DC motor speed control. By 2026, these systems will increasingly incorporate IoT-enabled motor controllers that allow remote monitoring, predictive maintenance, and integration with centralized manufacturing execution systems (MES), improving operational efficiency and reducing downtime.

4. Renewable Energy and Green Technology Integration

Speed control systems for DC motors are gaining traction in solar tracking systems, wind turbines (auxiliary systems), and energy storage solutions. In 2026, demand will grow for controllers that optimize energy use in off-grid and hybrid renewable setups. The emphasis on reducing carbon footprints is encouraging the replacement of traditional mechanical systems with electronically controlled DC drives, which offer better energy management.

5. Miniaturization and Cost Reduction

Ongoing improvements in semiconductor technology, including wide-bandgap materials like silicon carbide (SiC) and gallium nitride (GaN), are enabling smaller, more efficient motor drivers. By 2026, these advancements will lead to lower production costs and wider accessibility, especially in consumer electronics, drones, and home automation devices.

6. Regional Market Dynamics

Asia-Pacific, particularly China, India, and South Korea, will remain the largest market for DC motor speed control systems due to robust manufacturing, EV production, and government support for smart infrastructure. North America and Europe will focus on high-precision and energy-efficient solutions driven by strict environmental regulations and advanced R&D ecosystems.

7. Sustainability and Regulatory Compliance

Energy efficiency standards, such as those from the International Electrotechnical Commission (IEC) and ENERGY STAR, are pushing manufacturers to develop compliant speed control solutions. By 2026, eco-design directives will mandate longer product lifecycles, recyclability of components, and reduced electromagnetic interference (EMI), influencing control circuit design and materials used.

Conclusion

In 2026, the speed control of DC motors will be characterized by smarter, smaller, and more sustainable technologies. The convergence of digitalization, green energy, and automation will define the market, with innovation focused on improving precision, reducing energy consumption, and enabling seamless integration into connected systems. Companies investing in R&D for intelligent motor control solutions are expected to lead the market in this evolving landscape.

Common Pitfalls in Sourcing Speed Control of DC Motor (Quality, IP)

When sourcing speed control solutions for DC motors, especially in industrial or commercial applications, several critical pitfalls related to quality and intellectual property (IP) can compromise performance, compliance, and long-term reliability. Understanding these challenges is essential to ensure optimal functionality and legal safety.

Poor Quality Components and Design

One of the most frequent issues in sourcing DC motor speed controllers is the use of substandard components. Low-cost suppliers may utilize inferior transistors, capacitors, or PCB materials that degrade quickly under thermal or electrical stress. This leads to inconsistent speed regulation, premature failure, and potential safety hazards.

Additionally, inadequate thermal management design—such as missing heat sinks or poor airflow—can cause overheating, especially in high-duty-cycle applications. Controllers not rated for the specified motor load or voltage may also result in erratic motor behavior or damage to the motor itself.

Lack of IP Protection and Risk of Infringement

Sourcing from manufacturers without clear intellectual property rights exposes buyers to legal risks. Many low-cost speed controllers, particularly from unverified suppliers, may incorporate patented technologies (e.g., PWM algorithms, feedback control logic) without licensing. Using such products could lead to IP infringement claims, especially in regulated markets like the EU or North America.

Moreover, counterfeit or cloned control units often lack proper firmware documentation or source code ownership, making it difficult to customize, troubleshoot, or ensure compliance with industry standards.

Inadequate IP (Ingress Protection) Rating

The term “IP” refers not only to intellectual property but also to Ingress Protection—critical in determining a motor controller’s resistance to dust and moisture. A common oversight is selecting a speed controller with an insufficient IP rating for the operating environment.

For example, using an IP20-rated controller in outdoor or washdown environments can result in corrosion, short circuits, or complete failure. Buyers must ensure the IP rating (e.g., IP65, IP67) matches the environmental conditions, particularly in automotive, marine, or food processing applications.

Missing Certifications and Compliance

Many low-tier suppliers fail to provide essential certifications such as CE, UL, or RoHS compliance. Lack of these certifications indicates potential non-compliance with safety, electromagnetic compatibility (EMC), and environmental standards. This can result in failed audits, product recalls, or operational hazards.

Poor Documentation and Support

Low-quality or unverified suppliers often provide incomplete technical documentation, making integration, maintenance, and troubleshooting difficult. Missing datasheets, unclear pinouts, or absent firmware details can significantly delay projects and increase development costs.

Conclusion

To avoid these pitfalls, buyers should prioritize reputable suppliers with verifiable quality standards, proper IP rights, and environmental certifications. Conducting due diligence—such as requesting samples, reviewing compliance documents, and verifying IP ownership—can prevent costly failures and legal complications down the line.

Logistics & Compliance Guide for Speed Control of DC Motor

Product Overview and Classification

Speed control systems for DC motors are electronic devices or circuits designed to regulate the rotational speed of direct current (DC) motors. These systems may include pulse width modulation (PWM) controllers, variable voltage drives, or microcontroller-based solutions. They are commonly used in industrial automation, robotics, electric vehicles, and consumer appliances. Proper classification under international trade codes (e.g., HS Code 8543.70 for electrical apparatus for machine control) is essential for import/export compliance.

Regulatory Compliance Requirements

Speed control units for DC motors must comply with relevant electrical and safety standards depending on the target market. Key regulations include:

– CE Marking (European Union): Compliance with the Low Voltage Directive (2014/35/EU) and Electromagnetic Compatibility (EMC) Directive (2014/30/EU).

– FCC Part 15 (USA): Required for digital control circuits to limit electromagnetic interference.

– RoHS (Restriction of Hazardous Substances): Prohibits the use of lead, mercury, cadmium, and other hazardous materials in electronic components.

– REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals applies to materials used in manufacturing.

– UL/CSA Certification (North America): Recommended for safety assurance in commercial and industrial applications.

Import and Export Documentation

To legally transport speed control systems across borders, the following documentation is typically required:

– Commercial Invoice detailing product description, value, and country of origin

– Packing List specifying quantity, weight, and packaging type

– Bill of Lading or Air Waybill

– Certificate of Conformity (CoC) verifying compliance with destination country standards

– HS Code classification for customs clearance

– Export License (if applicable, based on destination or technology controls)

Packaging and Handling Instructions

Proper packaging ensures safe transit and prevents damage to sensitive electronic components:

– Use anti-static bags or foam-lined boxes for individual units

– Clearly label packages with handling symbols (e.g., “Fragile,” “Do Not Stack”)

– Include moisture barrier bags if shipping to high-humidity environments

– Secure all wiring terminals and connectors to prevent loosening during transport

– Avoid exposure to extreme temperatures or direct sunlight during storage and transit

Transportation and Shipping Considerations

- Choose carriers experienced in handling electronic equipment

- Opt for air freight for time-sensitive or high-value shipments; sea freight for bulk orders

- Ensure compliance with IATA regulations if shipping lithium batteries (if integrated)

- Declare the shipment as “Electronic Control Equipment” to avoid customs delays

- Use trackable and insured shipping methods to monitor delivery and mitigate loss

Environmental and Disposal Compliance

End-of-life disposal of DC motor speed controllers must follow environmental guidelines:

– Classify as Waste Electrical and Electronic Equipment (WEEE) in the EU

– Partner with certified e-waste recyclers for proper dismantling and material recovery

– Avoid landfill disposal due to presence of circuit boards and electronic components

– Maintain records of disposal for audit and regulatory purposes

Quality Assurance and Traceability

Maintain rigorous quality control to meet compliance standards:

– Implement ISO 9001-compliant manufacturing and testing procedures

– Keep batch records and component traceability for recall readiness

– Conduct routine testing for electrical safety, thermal performance, and EMC

– Provide user manuals with safety warnings, installation guidance, and compliance labels

Training and Technical Support

Ensure end-users and logistics personnel are informed:

– Offer installation and operational training where applicable

– Provide multilingual technical documentation and compliance certificates

– Establish a support channel for troubleshooting and regulatory inquiries

– Update compliance status promptly in case of regulatory changes

Summary and Best Practices

To ensure smooth logistics and full compliance when shipping or using DC motor speed control systems: verify regulatory requirements early, maintain accurate documentation, use protective packaging, and partner with certified suppliers and recyclers. Proactive compliance reduces delays, avoids penalties, and supports sustainable operations.

Conclusion:

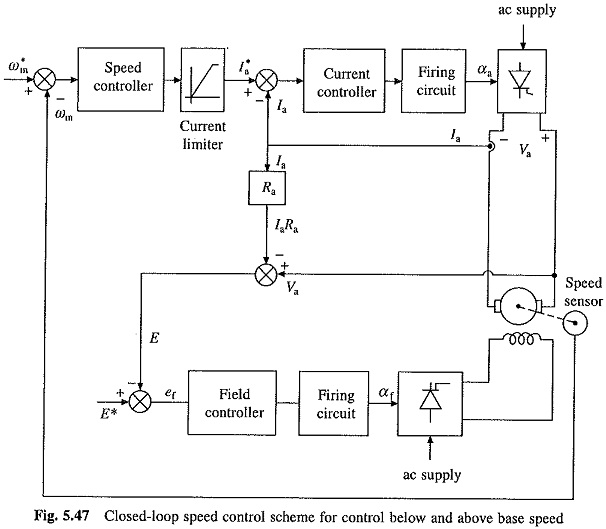

Speed control of a DC motor is a critical aspect in various industrial, automotive, and consumer applications where precise and efficient motor performance is required. Through various sourcing methods—such as using PWM (Pulse Width Modulation), variable voltage supplies, and electronic controllers like thyristor-based drives or microcontroller-based systems—accurate and reliable speed regulation can be achieved. Each method offers distinct advantages in terms of efficiency, cost, complexity, and response time.

Among these, PWM has emerged as one of the most effective and widely adopted techniques due to its high efficiency, minimal power loss, and excellent control resolution. Additionally, integration with digital control systems such as microcontrollers and feedback mechanisms (e.g., using encoders or tachometers) enables closed-loop control, further enhancing accuracy and stability under varying load conditions.

In summary, proper selection of the sourcing and control method depends on the specific application requirements, including desired precision, power efficiency, cost constraints, and dynamic response. With advancements in power electronics and control technologies, modern DC motor speed control systems continue to improve in performance, reliability, and energy efficiency, making them indispensable in today’s automated and smart systems.