The global laser welding market is experiencing robust expansion, driven by rising demand for precision manufacturing in industries such as automotive, electronics, and medical devices. According to a 2023 report by Mordor Intelligence, the market was valued at USD 3.87 billion in 2022 and is projected to grow at a CAGR of 7.4% over the forecast period (2023–2028). Similarly, Grand View Research reports increasing adoption of advanced joining technologies and the integration of automation in production processes as key growth accelerators. As manufacturers prioritize efficiency, minimal heat distortion, and high repeatability, laser welding has emerged as a critical solution in modern industrial applications. This growing demand has fueled innovation and competition among leading players worldwide. Below is a data-driven overview of the top eight laser welding manufacturers shaping the industry landscape through technological advancement, global reach, and strategic investments in R&D.

Top 8 Spawanie Laserowe Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Spawanie laserowe MOST

Website: rywal.com.pl

Key Highlights: We are a producer. We are a producer of high quality welding consumables and abrasive materials at reasonable price. We also own a bandsaws blades welding ……

#2 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions.Missing: spawanie laserowe…

#3 LFW Series

Website: andelaser.com

Key Highlights: Spawanie laserowe · Oznaczanie laserowe i wycinanie laserowe · Oczyszczanie laserowe · Akcesoria laserowe · Laserowe materiały zużywające · Laserowe urządzenie ……

#4 3D laser

Website: treko-laser.pl

Key Highlights: Treko Laser – laserowe cięcie, wycinanie laserowe 3D, gięcie, spawanie blach · Homepage; Technology. 2D cutting · 3D laser · Bending · Welding · Brazing ……

#5 Spawanie laserowe

Website: strumet.pl

Key Highlights: Laser welding is an advanced material joining method that uses a concentrated laser beam as the heat source. Its high precision, speed, and reliability make ……

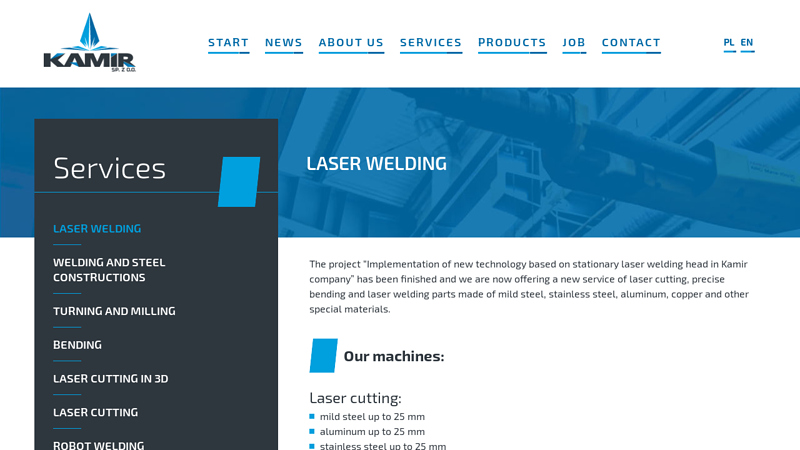

#6 Laser welding

Website: kamir.eu

Key Highlights: Our machines: Laser cutting: mild steel up to 25 mm; aluminum up to 25 mm; stainless steel up to 25 mm; fiber laser; direct mechanical and software connection ……

#7 Profesjonalne lasery do czyszczenia i spawania

Website: ownlaser.com

Key Highlights: Czyszczarki laserowe skutecznie usuwają rdzę, farbę, tlenki bez uszkadzania powierzchni, a spawarki zapewniają mocne i estetyczne połączenia….

#8 Spawanie laserowe

Website: metalkonstrukcje.pl

Key Highlights: Spawanie laserowe · Spawanie MAG / TIG · spawanie stali czarnej · spawanie stali nierdzewnej · spawanie aluminium · spawanie na szczelność. PRZĘSŁA OGRODZENIOWE ……

Expert Sourcing Insights for Spawanie Laserowe

Market Trends for Laser Welding in 2026

By 2026, the laser welding (Spawanie Laserowe) market is expected to experience substantial growth, driven by advancements in manufacturing technologies, rising demand for precision engineering, and the expansion of key end-use industries. Several macroeconomic and technological factors are shaping the evolution of this sector globally, with Europe—particularly Poland—emerging as a growing hub for industrial laser applications.

1. Increased Adoption in Automotive and EV Manufacturing

The automotive industry remains the largest consumer of laser welding technologies. With the global shift toward electric vehicles (EVs), demand for high-precision, high-speed, and energy-efficient joining methods is surging. Laser welding offers superior seam quality, minimal heat distortion, and automation compatibility—critical for battery pack assembly, lightweight body structures, and electric motor components. By 2026, EV production expansion in Central and Eastern Europe is expected to significantly boost laser welding adoption in countries like Poland.

2. Integration of AI and Smart Manufacturing

Industry 4.0 trends are transforming laser welding systems. In 2026, smart welding cells integrated with artificial intelligence (AI), real-time monitoring, and predictive maintenance are becoming standard. These systems optimize weld quality, reduce scrap rates, and enhance process traceability—offering competitive advantages to manufacturers embracing digitalization. Polish industrial firms are increasingly investing in such solutions to align with EU manufacturing standards.

3. Growth in Renewable Energy and Aerospace Sectors

Beyond automotive, the renewable energy sector—especially wind turbine and solar panel manufacturing—requires durable, high-integrity welds. Laser welding enables reliable joining of dissimilar and high-strength materials used in turbine blades and power electronics. Similarly, aerospace and defense industries are adopting laser welding for turbine engines and lightweight airframes. These high-value applications are fueling demand for advanced laser systems in 2026.

4. Advancements in Laser Technology

The market is witnessing a shift from traditional CO₂ and Nd:YAG lasers to fiber and disk lasers, which offer higher efficiency, better beam quality, and lower operating costs. Hybrid laser-arc welding and remote laser welding systems are gaining traction for their ability to combine speed and depth. Polish manufacturers and research institutions are actively collaborating with European laser technology providers to localize these innovations.

5. Regional Market Expansion in Central Europe

Poland’s manufacturing sector is undergoing modernization, supported by EU funding and foreign direct investment. As a result, domestic demand for laser welding equipment is rising across industries such as metal fabrication, medical devices, and white goods. By 2026, Poland is expected to become a regional center for laser processing services, with increasing local production of laser-welded components.

6. Sustainability and Regulatory Drivers

Environmental regulations are pushing manufacturers to reduce energy consumption and emissions. Laser welding, with its precision and reduced material waste, aligns with green manufacturing goals. Additionally, EU directives on industrial emissions and product lifecycle management are encouraging the use of cleaner, automated processes like laser welding.

Conclusion

By 2026, the laser welding market will be defined by technological convergence, automation, and sustainability. For Poland and other Central European nations, this presents a strategic opportunity to strengthen industrial competitiveness through advanced joining technologies. Continued investment in R&D, workforce training, and digital integration will be critical to capitalizing on these trends.

Common Pitfalls When Sourcing Spawanie Laserowe (Laser Welding) – Quality and Intellectual Property (IP) Risks

Sourcing laser welding services, particularly from external suppliers or new markets, presents significant opportunities for efficiency and precision. However, companies often encounter critical challenges related to quality consistency and intellectual property protection. Failure to address these pitfalls can result in defective products, production delays, legal disputes, and loss of competitive advantage.

Quality-Related Pitfalls

Inconsistent Weld Quality Due to Process Variability

Laser welding is highly sensitive to parameters such as power density, beam alignment, shielding gas, and material preparation. Suppliers may lack standardized operating procedures or adequate process control, leading to inconsistent weld penetration, porosity, or spatter. Without proper documentation and process validation (e.g., via welding procedure specifications – WPS), repeatable quality cannot be assured.

Insufficient Material and Surface Preparation Oversight

The success of laser welding depends heavily on precise joint fit-up and surface cleanliness. Suppliers may overlook critical preparation steps, such as deburring, degreasing, or maintaining tight tolerances, resulting in weak or defective welds. Poor handling of reflective or thermally conductive materials (e.g., aluminum, copper) further increases the risk of process instability.

Lack of In-Process and Post-Weld Quality Control

Many suppliers rely solely on visual inspection rather than implementing non-destructive testing (NDT) methods like ultrasonic testing, X-ray, or automated optical inspection. Without real-time monitoring systems (e.g., weld seam tracking or plasma monitoring), defects may go undetected until final assembly, leading to costly rework or field failures.

Inadequate Equipment Calibration and Maintenance

Laser welding equipment requires regular calibration and maintenance to ensure beam quality and power consistency. Suppliers with outdated or poorly maintained systems may deliver substandard results. Additionally, a lack of traceability in equipment logs makes it difficult to correlate quality issues with specific machines or maintenance cycles.

Unqualified or Undertrained Personnel

Even with advanced machinery, operator expertise is crucial. Suppliers may employ technicians without proper certification (e.g., according to ISO 14731 or national standards) or sufficient experience in laser-specific challenges. This increases the risk of incorrect parameter selection and poor troubleshooting.

Intellectual Property (IP)-Related Pitfalls

Exposure of Sensitive Design and Process Information

Laser welding often involves proprietary joint designs, fixture setups, or parameter recipes. Sharing detailed technical drawings or process instructions with suppliers without robust confidentiality agreements can expose core IP. In some jurisdictions, enforcement of such agreements may be weak or inconsistent.

Lack of Clear IP Ownership Clauses in Contracts

Vendor contracts may fail to explicitly state who owns improvements, adaptations, or derivative works developed during the welding process. This ambiguity can lead to disputes if the supplier claims rights to a new method or if the client wishes to transfer the process to another vendor.

Risk of Technology Replication or Diversion

In regions with lax IP enforcement, there is a heightened risk that suppliers may replicate the client’s components or processes for unauthorized third parties. This is particularly concerning when high-precision laser systems are used to produce complex, patented assemblies.

Inadequate Cybersecurity and Data Protection Measures

Digital data exchange, including CAD files and machine programming (e.g., CNC or robot paths), may be vulnerable to cyber theft. Suppliers with poor IT security protocols could inadvertently or deliberately leak sensitive manufacturing data, compromising competitive advantage.

Failure to Audit Supplier Compliance

Without regular audits—both technical and legal—companies cannot verify that suppliers adhere to agreed-upon quality standards or IP protections. A lack of oversight may result in unnoticed deviations or unauthorized use of proprietary information.

Mitigation Strategies

To avoid these pitfalls, sourcing organizations should:

– Conduct thorough due diligence on supplier certifications (e.g., ISO 3834, EN 15085, or IATF 16949).

– Require documented welding procedure qualifications (WPQR) and material traceability.

– Implement comprehensive NDAs and IP clauses in supplier contracts.

– Perform on-site audits to assess equipment, training, and data security practices.

– Limit the release of sensitive information on a need-to-know basis.

– Use secure data-sharing platforms and watermark proprietary documents.

By proactively addressing quality and IP risks, companies can leverage the benefits of laser welding while safeguarding their products and innovations.

Logistics & Compliance Guide for Spawanie Laserowe (Laser Welding)

Understanding Spawanie Laserowe in the Supply Chain

Spawanie Laserowe, or laser welding, is a high-precision joining process widely used in manufacturing industries such as automotive, aerospace, medical devices, and electronics. When integrating laser welding into production or outsourcing it, logistics and compliance considerations are critical to ensure safety, quality, and regulatory adherence throughout the supply chain.

Equipment and Material Logistics

Laser welding requires specialized equipment, including laser sources (e.g., fiber, CO₂), robotic arms, fume extraction systems, and safety enclosures. Transporting and installing this equipment demands careful planning due to its sensitivity and high value. Ensure all components are properly packaged, climate-controlled during transit, and handled by qualified technicians. For raw materials such as metals (stainless steel, aluminum, titanium), precise inventory management and material traceability are essential to maintain weld consistency and meet quality standards.

Safety and Regulatory Compliance

Laser welding operations must comply with international and local safety standards. Key regulations include:

– IEC 60825-1: Safety of laser products – Equipment classification and requirements.

– ANSI Z136.1: Safe use of lasers (U.S. standard).

– Directive 2014/35/EU (Low Voltage Directive) and 2014/30/EU (EMC Directive) for CE-marked equipment in the EU.

Ensure laser workstations are equipped with interlocks, protective enclosures, warning signs, and appropriate personal protective equipment (PPE). Operators must undergo certified training, and risk assessments should be documented.

Environmental and Waste Management

Laser welding produces fumes, spatter, and occasional hazardous waste (e.g., used filters, contaminated consumables). Compliance with environmental regulations such as:

– OSHA (U.S.) and REACH/CLP (EU) for chemical exposure limits.

– Proper filtration systems (e.g., HEPA filters) must be installed and maintained.

– Spent materials must be disposed of via licensed waste handlers, with documentation for audit trails.

Quality Assurance and Documentation

Adherence to quality standards is essential. Common frameworks include:

– ISO 9001: Quality management systems.

– ISO 3834: Quality requirements for fusion welding of metallic materials.

– AS9100 (for aerospace) or ISO 13485 (for medical devices) if applicable.

Maintain comprehensive records including welding parameters, material certifications (e.g., EN 10204 3.1), inspection reports (e.g., NDT results), and operator qualifications.

International Shipping and Import/Export Compliance

When shipping laser-welded components or equipment across borders:

– Comply with ITAR/EAR (U.S.) or EU Dual-Use Regulation (EC) No 428/2009 if components have military or strategic applications.

– Ensure proper classification under the Harmonized System (HS Code) for customs.

– Provide accurate Certificates of Conformity, Material Safety Data Sheets (MSDS), and RoHS/REACH declarations where required.

Supplier and Subcontractor Management

If outsourcing Spawanie Laserowe, vet suppliers for compliance with industry standards and conduct regular audits. Contracts should specify quality requirements, delivery timelines, traceability, and data ownership. Ensure subcontractors follow the same safety and environmental protocols as your organization.

Continuous Improvement and Auditing

Implement regular internal audits and management reviews to monitor compliance and logistics efficiency. Use corrective action systems (e.g., CAPA) to address non-conformities. Stay updated on changes in regulations and technological advancements in laser welding to maintain a competitive and compliant operation.

By following this guide, organizations can ensure safe, efficient, and legally compliant logistics for Spawanie Laserowe processes across global supply chains.

Conclusion for sourcing laser welding (spawanie laserowe):

Sourcing laser welding services offers significant advantages in terms of precision, speed, and quality of welds, making it ideal for high-tech industries such as automotive, aerospace, and medical device manufacturing. When evaluating suppliers, key factors to consider include technical capabilities, equipment quality, certifications, experience in specific materials and applications, and adherence to quality standards (e.g., ISO 3834, EN 15085).

A successful sourcing strategy should balance cost-efficiency with reliability and innovation. Establishing long-term partnerships with experienced and certified providers ensures consistent quality, faster turnaround times, and access to advanced technologies. Additionally, proximity, logistics, and scalability should be taken into account to support just-in-time production and minimize supply chain risks.

In conclusion, strategic sourcing of laser welding services enables companies to enhance product quality, improve production efficiency, and maintain a competitive edge in demanding markets. Continuous evaluation and collaboration with suppliers are essential to adapt to evolving technological and market requirements.