The global automotive diagnostic equipment market is experiencing robust growth, driven by increasing vehicle production, rising demand for preventive maintenance, and the proliferation of advanced onboard electronics. According to Grand View Research, the global automotive diagnostic tools market size was valued at USD 13.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. As critical components of ignition system diagnostics, sparkplug testers play an essential role in ensuring engine efficiency and reliability. This expanding demand has led to a surge in manufacturers specializing in high-precision, reliable sparkplug testing solutions. Based on market presence, technological innovation, product range, and customer feedback, we’ve identified the top 9 sparkplug tester manufacturers shaping the industry landscape today.

Top 9 Sparkplug Tester Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 OEM Tools & Equipment

Domain Est. 2000 | Founded: 1996

Website: ipatools.com

Key Highlights: Free delivery Free 30-day returnsIPA is an Original Equipment Manufacturer (OEM) specializing in the development of innovative, professional tools and equipment since 1996….

#2 NGK Spark Plugs

Domain Est. 1997

Website: ngksparkplugs.com

Key Highlights: NGK Spark Plugs (U.S.A.), Inc. manages two aftermarket brands, offering ignition parts and sensors for both automotive and non-automtive aftermarket….

#3 Find Your Plugs

Domain Est. 2000

Website: am.denso.com

Key Highlights: Some spark plugs on this catalogue and website are manufacturer’s genuine parts and reference only. Those cannot be sold directly from DENSO. Please contact ……

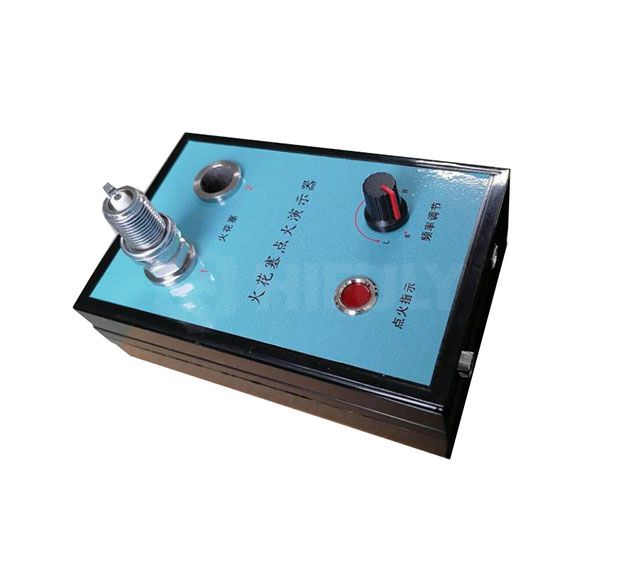

#4 Spark Tester Supplier, Manufacturer China

Domain Est. 2020

Website: hifulyignitionsystem.com

Key Highlights: Spark Tester Supplier, Manufacturer China. If you have interested in our products, pls feel free to contact us….

#5 MSD Ignition

Domain Est. 1995

Website: msdignition.com

Key Highlights: MSD was the first company to develop and offer the multiple sparking, capacitive discharge ignition for engines. The line of MSD 6-Series Ignitions are the most ……

#6 Spark Checkers

Domain Est. 2000

Website: stevensinstrument.com

Key Highlights: Highest quality, versatile open-gap spark checker for 1 to 8 cylinders. This “sparky” can be separated into two 4-wire halves by loosening two wing nuts….

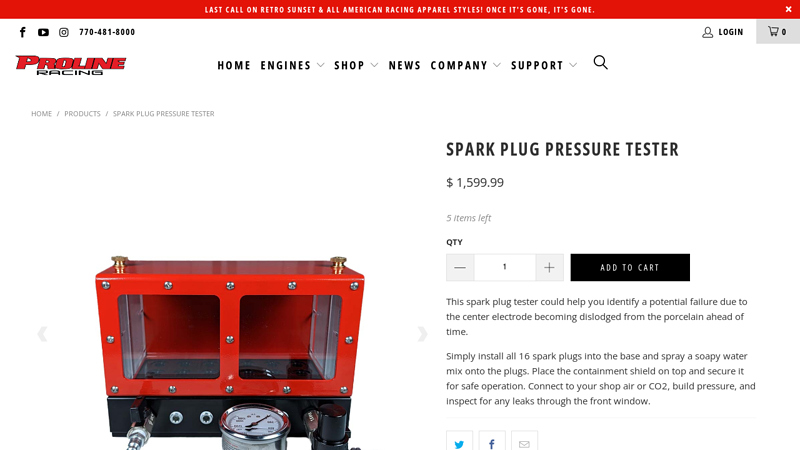

#7 SPARK PLUG PRESSURE TESTER

Domain Est. 2009

#8 DUOYI Spark Plug Tester Dual Holes Spark Tester Working …

Domain Est. 2022

Website: duoyitool.com

Key Highlights: In stock Free deliveryDual Hole Car Spark Plug Tester Detector have two testing holes, you can test two spark plugs meanwhile and and if you suspect any spark plug works improperly…

#9 Spark Plugs

Website: beruparts.eu

Key Highlights: BERU offers an excellent quality range of spark plugs. Expect your engine to achieve great performance in terms of power, fuel consumption and emissions….

Expert Sourcing Insights for Sparkplug Tester

H2: Market Trends for Spark Plug Testers in 2026

By 2026, the global spark plug tester market is expected to experience moderate but steady growth, shaped by a complex interplay of automotive evolution, technological advancements, and regional economic factors. While the long-term shift toward electrification poses a structural challenge, near-term demand and niche opportunities will sustain market relevance. Key trends include:

-

Stagnant Growth Amidst ICE Decline: The primary driver of spark plug tester demand remains internal combustion engine (ICE) vehicles. As global EV adoption accelerates, the rate of new ICE vehicle production will slow, leading to a gradual decline in the new equipment segment for spark plug testers. However, the massive existing global fleet of ICE vehicles (estimated to remain dominant in service for decades) ensures continued demand for diagnostic and maintenance tools. The market will shift focus from new vehicle manufacturing support to the aftermarket and repair sector.

-

Dominance of the Aftermarket & DIY Segments: The largest growth potential lies in the automotive aftermarket. Independent repair shops, mobile mechanics, and DIY enthusiasts maintaining older ICE vehicles will be the primary customers. Demand will be driven by:

- Aging Vehicle Fleets: Especially in developing economies and regions with slower EV adoption, older vehicles require more frequent ignition system diagnostics.

- Cost-Effectiveness: Spark plug testers remain a relatively inexpensive and essential tool for efficient diagnosis compared to broader scan tools.

- DIY Culture: Online platforms and accessible information fuel consumer confidence in performing basic diagnostics, boosting demand for affordable, user-friendly testers.

-

Technological Evolution & Integration: Basic manual testers will persist, but innovation will focus on:

- Enhanced Diagnostics: Testers incorporating multimeter functions, waveform analysis (simulating basic oscilloscope capabilities), or Bluetooth connectivity to smartphone apps for data logging and guided troubleshooting will gain traction. This adds value beyond simple spark detection.

- Compatibility: Testers designed to handle a wider range of plug types (including modern fine-wire and iridium plugs requiring higher voltages) and ignition systems (COP, coil-on-plug) will be preferred.

- Durability & Safety: Features like improved insulation, robust probes, and clear safety warnings will remain critical selling points.

-

Regional Divergence:

- Developed Markets (North America, Western Europe): Growth will be slowest, potentially flat or slightly negative, driven almost entirely by the aging ICE fleet and professional repair shops. Premium, multi-functional testers may find a niche.

- Developing Markets (Asia-Pacific, Latin America, Africa): These regions will be the primary growth engines. Rapid vehicle ownership growth, predominantly ICE-based, combined with large aftermarket repair networks and cost sensitivity, will drive demand for affordable, reliable testers. China and India, in particular, represent significant markets.

-

Impact of Electrification: While pure BEVs don’t use spark plugs, the rise of mild hybrids (MHEV) and range-extender hybrids ensures that ICEs (and thus spark plugs) remain relevant in a portion of the new vehicle mix through 2026 and beyond. However, the overall trend is clear: the total addressable market for spark plug testers is on a long-term downward trajectory.

-

Consolidation & Competitive Landscape: The market is fragmented with numerous manufacturers (especially in Asia). Expect potential consolidation as larger automotive tool companies acquire niche players or focus on bundling testers with other diagnostic kits. Competition will center on price, reliability, feature integration, and distribution reach in key aftermarket regions.

In summary for 2026: The spark plug tester market will be characterized by resilience driven by the vast legacy ICE fleet and strong aftermarket demand, particularly in developing economies, rather than growth from new vehicle production. Innovation will focus on adding diagnostic value and integration to compete with multi-function tools. While the long-term outlook is constrained by electrification, 2026 will still see a viable and necessary market centered on vehicle maintenance and repair.

Common Pitfalls When Sourcing a Spark Plug Tester (Quality and IP Rating)

When sourcing a spark plug tester—especially for industrial, automotive, or maintenance applications—overlooking key quality aspects and Ingress Protection (IP) ratings can lead to unreliable performance, safety hazards, and premature equipment failure. Below are common pitfalls to avoid:

Poor Build Quality and Inaccurate Diagnostics

One of the most frequent issues is selecting a spark plug tester made from substandard materials or with imprecise calibration. Low-quality testers may deliver inconsistent spark simulations, leading to false diagnostics. This can result in unnecessary part replacements or undetected engine problems. Always verify that the tester is constructed with durable, heat-resistant materials and complies with relevant industry standards (e.g., ISO, SAE).

Inadequate IP Rating for Operating Environment

The Ingress Protection (IP) rating indicates the level of protection against dust and moisture. A common mistake is choosing a tester with an insufficient IP rating for its intended environment. For example:

- Indoor workshop use may only require IP54 (protected against dust and water splashes).

- Outdoor or high-humidity environments demand at least IP65 or higher (dust-tight and protected against water jets).

Using a low-IP tester in harsh conditions can result in internal component corrosion, electrical shorts, and safety risks.

Lack of Safety Certifications

Many budget spark plug testers lack essential safety certifications such as CE, UL, or RoHS compliance. This increases the risk of electrical hazards, especially when working with high-voltage ignition systems. Always confirm that the product has been independently tested and certified for electrical safety.

Overlooking Voltage Compatibility

Spark plug testers must match the voltage specifications of the engines they are used on. Using a tester rated for lower voltage than required can result in inaccurate readings or equipment damage. Ensure the tester supports the full range of ignition system voltages (typically 10,000–40,000 volts) relevant to your applications.

Ignoring Ergonomics and User Interface

A poorly designed tester—difficult to hold, read, or operate—can lead to user error and inefficiency. Look for models with clear indicators (e.g., LED spark detection), ergonomic grips, and intuitive controls. Digital testers with diagnostic displays offer added value but must be well-sealed to maintain their IP rating.

Conclusion

To avoid these pitfalls, prioritize quality construction, proper IP ratings for the environment, safety certifications, and voltage compatibility when sourcing a spark plug tester. Investing in a reliable, well-rated device ensures accurate diagnostics, operator safety, and long-term durability.

Logistics & Compliance Guide for Sparkplug Tester

Overview

This guide outlines the logistics management and compliance requirements for the Sparkplug Tester, a diagnostic tool used in industrial IoT and manufacturing environments to validate Sparkplug-compliant MQTT messaging. Adherence to these guidelines ensures safe handling, transportation, regulatory compliance, and operational effectiveness.

Packaging & Handling

All Sparkplug Tester units must be shipped in anti-static, foam-lined containers to prevent electrostatic discharge (ESD) damage. Each unit should be individually sealed and labeled with a tamper-evident seal. Handle with ESD-safe procedures in controlled environments (humidity 30–60%, temperature 15–30°C). Avoid exposure to dust, moisture, or extreme temperatures during storage and transit.

Shipping & Transportation

Ship via certified carriers compliant with IATA/IMDG regulations for electronic devices. Use ground or air freight with temperature-controlled options where required. Include a detailed packing list, product safety data, and a declaration of conformity (DoC) in each shipment. For international deliveries, ensure proper HS code classification (e.g., 9030.89 for electronic measuring instruments) and customs documentation.

Regulatory Compliance

The Sparkplug Tester complies with:

– EMC Directive 2014/30/EU – Electromagnetic compatibility

– RoHS 2011/65/EU – Restriction of hazardous substances

– CE Marking – Conforms to European health, safety, and environmental standards

– FCC Part 15, Subpart B – Radio frequency emissions (USA)

– UL/CSA 61010-1 – Safety requirements for electrical test equipment

Ensure all units are labeled with applicable certification marks and include user documentation with compliance statements.

Import/Export Controls

Verify export eligibility under EAR99 (U.S. Export Administration Regulations). No license required for most destinations, but screen end-users against denied party lists (e.g., BIS, OFAC). For shipments to embargoed regions (e.g., Cuba, Iran, North Korea, Syria, Crimea), obtain prior authorization. Maintain records of export transactions for a minimum of five years.

Documentation Requirements

Each shipment must include:

– Commercial invoice

– Packing list

– Certificate of Conformity (CoC)

– Safety Data Sheet (SDS) for battery components (if applicable)

– End-user declaration (for export-controlled destinations)

Warranty & Returns

Warranty period: 24 months from date of purchase. Returns require a Return Material Authorization (RMA) number issued by technical support. Defective units must be repackaged in original packaging and shipped prepaid. Non-warranty returns are subject to a 15% restocking fee.

Environmental & Disposal Compliance

Dispose of end-of-life units per WEEE (Waste Electrical and Electronic Equipment) Directive 2012/19/EU. Recycle through authorized e-waste facilities. Do not landfill. Batteries (if included) must be removed and recycled separately under local battery disposal regulations.

Training & Certification

Personnel handling, shipping, or installing the Sparkplug Tester must complete:

– ESD safety training

– Hazardous materials awareness (for battery-equipped models)

– Export compliance training (for logistics staff)

Keep training records on file for audit purposes.

Audit & Recordkeeping

Maintain logs for:

– Shipment tracking and delivery confirmation

– Compliance certifications (updated annually)

– Export control screenings

– Customer warranty claims and repairs

Records must be retained for a minimum of seven years and made available for internal or regulatory audits upon request.

In conclusion, sourcing a spark plug tester is a crucial step in maintaining and diagnosing internal combustion engines effectively. A reliable spark plug tester ensures accurate assessment of spark plug functionality, helping to identify misfires, weak sparks, or ignition system issues before they lead to larger engine problems. When sourcing the tester, it is important to consider factors such as compatibility with various plug types and engine configurations, build quality, ease of use, safety features, and brand reputation. Whether for professional automotive repair or DIY maintenance, investing in a high-quality spark plug tester from a reputable supplier enhances diagnostic precision, improves vehicle performance, and supports long-term engine reliability. Ultimately, proper sourcing ensures both cost-efficiency and operational effectiveness in engine troubleshooting and maintenance.