The global sous vide cooking market has experienced significant growth, driven by rising consumer demand for precision cooking and consistency in both commercial and residential kitchens. According to a 2023 report by Mordor Intelligence, the global sous vide equipment market is projected to grow at a CAGR of 7.2% from 2023 to 2028, fueled by advancements in smart kitchen technology and increased adoption in professional culinary settings. Similarly, Grand View Research estimates that the broader precision cooking devices market, which includes thermal immersion circulators, will expand at a CAGR of over 7.5% through 2030, underpinned by growing awareness of sous vide’s benefits in food safety, texture control, and flavor retention. As demand surges, manufacturers are competing on innovation, durability, connectivity, and price positioning. In this evolving landscape, eight key players have emerged as leading sous vide thermal immersion circulator manufacturers, combining engineering excellence with market reach to shape the future of precision cooking.

Top 8 Sous Vide Thermal Immersion Circulator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SoftcookerXP Thermal Immersion Circulator

Domain Est. 1999

Website: eurodib.com

Key Highlights: Thermal immersion circulator is a low-temperature sous-vide cooking instrument that maximizes the preservation of nutrients in food and enhances flavor….

#2 Machines and accessories for sous

Domain Est. 2000

Website: besservacuum.com

Key Highlights: Professional thermal immersion circulators for sous-vide cooking, designed to deal with large volumes of work ensuring consistency and accuracy in the results….

#3 SousVide Supreme

Domain Est. 2009

Website: sousvidesupreme.com

Key Highlights: SousVide Supreme is a trusted culinary brand for sous vide cooking, for both home cooks and culinary professionals, offering a full range of affordable water ……

#4 WiFi Sous Vide Cooker ISV

Domain Est. 2010

Website: inkbird.com

Key Highlights: In stock Rating 5.0 (20) INKBIRD WiFi Sous Vide Cooker ISV-100W provides convenience and safety for sous vide cooking, with WiFi control via its app for real-time updates….

#5 Sous Vide Thermal Circulators

Domain Est. 2011

#6 Swid Premium SOUS VIDE professional immersion circulator

Domain Est. 2012

Website: sousvideconsulting.com

Key Highlights: Commercial Immersion Circulator for SOUS VIDE – The SWID Premium 2400W is design for intensive use up to 58 L. High quality MADE in GERMANY….

#7 Sous Vide Immersion Circulators

Domain Est. 2017

Website: vollrathfoodservice.com

Key Highlights: The Vollrath® sous vide immersion circulators work efficiently to ensure consistent, repeatable results. These compact units cook unattended, saving you……

#8 Sous Vide Immersion Circulator

Domain Est. 2017

Expert Sourcing Insights for Sous Vide Thermal Immersion Circulator

2026 Market Trends for Sous Vide Thermal Immersion Circulator

The global market for sous vide thermal immersion circulators is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements, and increased adoption across both home and commercial kitchens. This analysis explores key trends expected to shape the industry in the coming years.

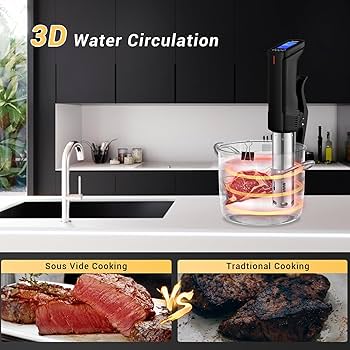

Rising Demand for Precision Cooking

Consumers are increasingly prioritizing culinary precision and consistency, particularly as interest in gourmet and restaurant-quality meals at home continues to grow. Sous vide thermal immersion circulators—devices that maintain precise water temperatures for vacuum-sealed food—align perfectly with this trend. By 2026, demand is expected to rise as more home cooks embrace precision cooking techniques popularized by celebrity chefs and online culinary content.

Technological Integration and Smart Features

A major trend shaping the 2026 market is the integration of smart technology. Leading manufacturers are incorporating Wi-Fi and Bluetooth connectivity, mobile app control, and voice assistant compatibility (such as Alexa and Google Assistant) into their immersion circulators. These enhancements allow users to monitor and adjust cooking parameters remotely, receive recipe suggestions, and integrate sous vide into broader smart kitchen ecosystems.

Expansion in the Home Kitchen Segment

Once considered niche appliances, sous vide immersion circulators are becoming mainstream in home kitchens. The declining cost of entry-level models, coupled with greater awareness through social media and cooking influencers, is accelerating adoption. By 2026, market analysts project that over 15% of urban households in developed markets will own a sous vide device, driven by ease of use and consistent results.

Growth in Commercial and Foodservice Applications

Beyond residential use, commercial kitchens—including fine dining restaurants, meal kit providers, and cloud kitchens—are increasingly adopting sous vide technology for efficiency and scalability. The ability to cook large volumes of food with minimal labor and waste makes immersion circulators attractive for foodservice operations. This trend is expected to drive a compound annual growth rate (CAGR) of approximately 8.3% in the commercial segment through 2026.

Sustainability and Energy Efficiency

As sustainability becomes a key purchasing criterion, manufacturers are focusing on energy-efficient designs and durable, recyclable materials. By 2026, eco-conscious consumers will favor brands that emphasize low power consumption and long product lifecycles. Some companies are also exploring modular designs to extend device longevity and reduce electronic waste.

Regional Market Dynamics

North America and Western Europe will remain dominant markets due to high disposable incomes and strong culinary cultures. However, Asia-Pacific is expected to be the fastest-growing region, fueled by rising urbanization, interest in Western cooking methods, and expanding middle-class populations in countries like China, South Korea, and India.

Competitive Landscape and Innovation

The market will see intensified competition among established players (e.g., Anova, Joule, Breville) and emerging brands offering affordable alternatives. Innovation will focus on compact designs, faster heating elements, quieter operation, and improved safety features. Additionally, bundling with vacuum sealers and curated recipe platforms will become common value-added strategies.

Conclusion

By 2026, the sous vide thermal immersion circulator market will be characterized by smart integration, expanded accessibility, and growing adoption across both home and professional sectors. As consumers continue to seek convenience, precision, and culinary exploration, the immersion circulator is set to evolve from a specialty tool into a staple of modern kitchens worldwide.

Common Pitfalls When Sourcing Sous Vide Thermal Immersion Circulators (Quality and IP)

Sourcing sous vide thermal immersion circulators—especially for commercial applications, private labeling, or integration into larger systems—requires careful attention to both product quality and intellectual property (IP) risks. Overlooking these areas can lead to operational failures, legal disputes, reputational damage, and financial losses. Below are key pitfalls to avoid.

1. Prioritizing Low Cost Over Build Quality and Safety

One of the most common mistakes is selecting suppliers based solely on price, especially from manufacturers offering significantly lower costs than established brands. Low-cost units may cut corners in:

- Material Quality: Use of substandard plastics or metals prone to warping, cracking, or corrosion, especially under prolonged high-temperature and humid conditions.

- Heating Element Durability: Cheap heating elements may fail prematurely or provide inconsistent temperature control.

- Waterproofing and IP Rating: Many budget models lack proper ingress protection (e.g., IPX7), increasing the risk of electrical hazards or short circuits during immersion.

- Safety Certifications: Missing essential certifications like UL, CE, ETL, or RoHS can result in non-compliance with regional safety standards and potential liability.

Best Practice: Verify component quality through product teardowns, request safety certification documents, and conduct long-term reliability testing.

2. Inaccurate or Unstable Temperature Control

Precision is critical in sous vide cooking. Poorly calibrated or low-quality PID controllers can result in temperature fluctuations beyond ±0.5°C, leading to undercooked or overcooked food.

- Inadequate Sensors: Low-cost temperature sensors may drift over time or respond slowly.

- Poor Firmware: Lack of robust software for temperature regulation, especially at the extremes of the operating range (e.g., 40°C to 95°C).

Best Practice: Request third-party validation reports or conduct independent testing across various temperature points and water volumes.

3. Overlooking Intellectual Property (IP) Infringement Risks

When sourcing from OEM/ODM manufacturers—particularly in regions with lax IP enforcement—there is a significant risk of inadvertently purchasing or distributing products that infringe on existing patents or designs.

- Design Copying: Many low-cost immersion circulators closely resemble products from brands like Anova, Joule, or PolyScience, potentially violating design patents.

- Technology Patents: Core functionalities such as compact impeller design, wireless connectivity, or app integration may be protected by utility patents.

- Trademark Infringement: Packaging or branding may mimic well-known brands, exposing the buyer to legal liability.

Best Practice: Conduct a freedom-to-operate (FTO) analysis before launch. Require suppliers to warrant that their designs do not infringe third-party IP and include IP indemnification clauses in contracts.

4. Inadequate IP Protection for Custom Designs

If sourcing a custom-designed circulator, failing to secure proper IP ownership can result in losing control over the design.

- Unclear IP Ownership: Many OEM agreements default to shared or supplier-held IP rights unless explicitly negotiated.

- Reverse Engineering Risk: Without patents or trade secrets protection, your design may be replicated and sold to competitors.

Best Practice: Define IP ownership clearly in the contract. File design and utility patents where applicable, and use NDAs throughout development.

5. Poor After-Sales Support and Warranty Infrastructure

Low-cost suppliers may offer limited technical support, spare parts availability, or warranty fulfillment.

- Long Lead Times for Repairs: Can disrupt operations, especially in commercial kitchens or food production environments.

- Lack of Firmware Updates: Critical for security (in smart devices) and performance improvements.

Best Practice: Evaluate supplier support capabilities during due diligence. Require service level agreements (SLAs) for repair turnaround and technical assistance.

6. Misunderstanding Ingress Protection (IP) Ratings

While many immersion circulators claim to be waterproof, not all meet the necessary IP standards for safe operation.

- Misleading Claims: A unit may be “splash-resistant” but not rated for full submersion (e.g., lacking IPX7).

- Seal Degradation: Poorly designed O-rings or gaskets may degrade over time, leading to water ingress.

Best Practice: Confirm the exact IP rating (e.g., IPX7 indicates protection against immersion up to 1 meter for 30 minutes) and test units under real-world conditions.

Conclusion

Successfully sourcing sous vide thermal immersion circulators requires balancing cost, quality, safety, and legal compliance. Thorough due diligence—covering product testing, certification verification, and IP risk assessment—is essential to avoid costly mistakes and ensure long-term reliability and marketability of the product.

Logistics & Compliance Guide for Sous Vide Thermal Immersion Circulator

Regulatory and Safety Compliance

Ensure all sous vide thermal immersion circulators meet applicable safety and electrical standards prior to distribution or use. Devices must comply with regional and international regulations, including but not limited to:

- Electrical Safety: Conform to IEC 60335-1 (Household and similar electrical appliances – Safety) and region-specific standards such as UL 1083 in the United States or EN 60335-2-13 in the European Union.

- EMC Compliance: Adhere to Electromagnetic Compatibility (EMC) directives (e.g., FCC Part 15 in the U.S., CE marking under EMC Directive 2014/30/EU in the EU) to prevent interference with other electronic devices.

- RoHS and REACH: Comply with Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulations, particularly for devices sold in the EU.

- IP Rating: Verify the device has an appropriate Ingress Protection (IP) rating (e.g., IPX7 for water resistance) to ensure safe operation in wet kitchen environments.

All units must be clearly labeled with certification marks (e.g., CE, UKCA, UL, ETL) and include user documentation in the local language(s) of the destination market.

Packaging and Shipping Requirements

Proper packaging is essential to prevent damage during transit and ensure product integrity. Follow these guidelines:

- Protective Packaging: Use rigid corrugated boxes with internal foam or molded pulp inserts to secure the immersion circulator, power cord, and accessories (e.g., clamp, user manual).

- Environmental Protection: Include moisture-resistant barriers if shipping to humid climates or regions with variable storage conditions.

- Labeling: Clearly mark packages with:

- Product name and model number

- Weight and dimensions

- Fragile and handle-with-care indicators

- Regulatory compliance labels (e.g., CE, UL)

- Barcodes and tracking numbers for inventory management

- Shipping Modes: Use ground or air freight based on delivery timelines. For international shipments, ensure compliance with IATA regulations if lithium components (e.g., in digital displays) are present.

Import and Customs Documentation

For global distribution, prepare accurate documentation to facilitate customs clearance:

- Commercial Invoice: Include product description, HS code (e.g., 8516.79 for electric immersion heaters), unit value, total shipment value, country of origin, and Incoterms (e.g., FOB, DDP).

- Packing List: Detail contents per box, weight, and dimensions.

- Certificates of Conformity: Provide test reports or certificates verifying compliance with local safety and EMC standards.

- Bill of Lading/Air Waybill: Required for freight tracking and proof of shipment.

Verify destination country requirements—for example, PSE certification may be needed for Japan, and INMETRO for Brazil.

Warranty and After-Sales Support

Establish a clear logistics process for handling returns, repairs, and replacements:

- Warranty Period: Typically 1–2 years; clearly state terms in user documentation and on warranty cards.

- Return Authorization (RMA): Implement an RMA system to track defective units and prevent unauthorized returns.

- Service Centers: Partner with authorized service providers in key markets or maintain regional repair hubs to reduce turnaround time.

- Spare Parts Inventory: Maintain stock of common replacement parts (e.g., heating elements, seals, power cords) in strategic warehouses.

Environmental and Disposal Compliance

Ensure end-of-life handling aligns with environmental regulations:

- WEEE Compliance: In the EU, provide take-back options and label products with the crossed-out wheeled bin symbol per the Waste Electrical and Electronic Equipment (WEEE) Directive.

- Recycling Instructions: Include disposal guidelines in user manuals, advising customers to recycle through certified e-waste facilities.

- Battery Handling: If the device contains non-replaceable batteries, ensure compliance with local battery disposal laws.

Adhering to this logistics and compliance framework ensures safe, legal, and efficient distribution of sous vide thermal immersion circulators across global markets.

In conclusion, sourcing a sous vide thermal immersion circulator requires careful consideration of several key factors to ensure optimal performance, reliability, and value. Prioritizing precision in temperature control, build quality, wattage, ease of use, and compatibility with various container sizes will help identify a circulator that meets both culinary demands and operational needs. Additionally, evaluating brand reputation, warranty, customer support, and energy efficiency contributes to a sound investment, whether for professional kitchen use or high-end home cooking. By aligning the selection with specific usage requirements—such as batch cooking, long-duration precision, or portability—and balancing cost against features, buyers can successfully source a high-performing sous vide immersion circulator that enhances consistency, texture, and flavor in cooked dishes while supporting efficient and safe kitchen operations.