The global soundproofing materials market is experiencing robust growth, driven by rising urbanization, increasing infrastructure development, and stricter noise pollution regulations. According to Grand View Research, the global acoustic panels market size was valued at USD 3.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.7% from 2023 to 2030. This growth is further amplified by expanding construction activities in commercial, industrial, and outdoor spaces requiring noise mitigation solutions. As demand for effective soundproof outdoor panels rises—particularly in densely populated areas and near transportation hubs—manufacturers are innovating with advanced materials and scalable designs. In this evolving landscape, selecting the right supplier is critical. Based on market presence, product innovation, customer reviews, and technical performance, we’ve identified the top 10 soundproof outdoor panel manufacturers leading the industry in quality and acoustic efficiency.

Top 10 Soundproof Outdoor Panels Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sound Seal

Domain Est. 1996 | Founded: 1978

Website: soundseal.com

Key Highlights: Sound Seal is a leading manufacturer of industrial & architectural acoustic sound control products. Controlling noise in every environment since 1978….

#2 Kinetics Noise Control

Domain Est. 1996

Website: kineticsnoise.com

Key Highlights: Kinetics NOISEBLOCK PW275 is a lightweight noise barrier wall, panel system engineered for acoustic and structural performance. Manufactured with durable ……

#3 Noise Barriers

Domain Est. 1999

Website: noisebarriers.com

Key Highlights: With over 40 years’ experience in sound control engineering and installation, we develop and manufacture unique designs to meet your specific site or project ……

#4

Domain Est. 1999 | Founded: 1977

Website: acoustiguard.com

Key Highlights: AcoustiGuard-Wilrep Ltd. has been a leading manufacturer and supplier of Soundproofing and Vibration Isolation products since 1977….

#5 Acoustical Solutions

Domain Est. 1996

Website: acousticalsolutions.com

Key Highlights: Acoustical Solutions supplies acoustic panels, soundproofing, sound blocking and noise control solutions for use in all applications….

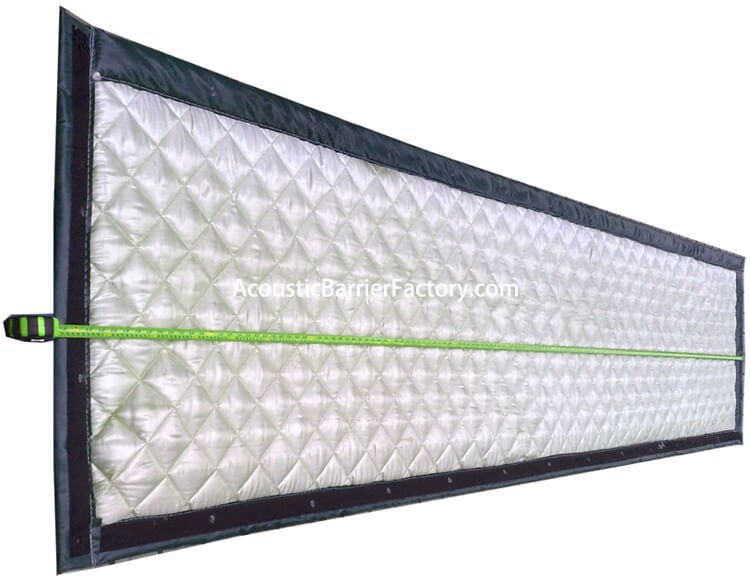

#6 Outdoor Sound Absorbing Panels

Domain Est. 1997

Website: soundfighter.com

Key Highlights: Our outdoor sound absorbing panels provide a great solution in reflective structures. Our sound attenuation panels will reduced noise levels….

#7 Acoustical Surfaces

Domain Est. 1998

Website: acousticalsurfaces.com

Key Highlights: Acoustical Surfaces offers panels, tiles, doors, windows, and other acoustical materials. Browse our website and call us for a soundproofing solution….

#8 Acoustimac

Domain Est. 2006

Website: acoustimac.com

Key Highlights: Buy Acoustic Panels and Acoustic Insulation & Accessories at Acoustimac.com. Call 888-827-1266 or Shop online. Speak with an Acoustic Expert today!…

#9 Soundproof Cow

Domain Est. 2008

Website: soundproofcow.com

Key Highlights: Soundproof Cow is the leading online provider of soundproof & sound absorbing materials. We offer acoustic & soundproofing supplies for any space….

#10 Acoustic Geometry: Acoustic Solutions

Domain Est. 2010

Expert Sourcing Insights for Soundproof Outdoor Panels

2026 Market Trends for Soundproof Outdoor Panels

The global market for soundproof outdoor panels is poised for significant evolution by 2026, driven by urbanization, stricter noise regulations, and a growing demand for outdoor living spaces. Here’s a breakdown of the key trends shaping the industry:

Rising Demand from Urban and Residential Sectors

Rapid urbanization and the proliferation of high-density housing, mixed-use developments, and transportation infrastructure are intensifying noise pollution. This is fueling demand for effective outdoor acoustic solutions in residential complexes, balconies, and private gardens. Homeowners and property developers alike are increasingly investing in soundproof panels to enhance comfort and property value, particularly in densely populated cities.

Stricter Environmental and Building Regulations

Governments and municipalities worldwide are implementing tighter noise control regulations to improve urban livability. By 2026, compliance with local acoustic standards will become a critical factor in construction and renovation projects. This regulatory push will drive adoption of certified soundproof outdoor panels in both public infrastructure (e.g., highways, railways) and private developments.

Innovation in Sustainable and Eco-Friendly Materials

Sustainability will be a major driver in product development. Manufacturers are shifting toward using recycled materials (such as reclaimed wood, recycled plastics, and composite panels) and low-carbon production methods. Biodegradable and recyclable panel options will gain traction, aligning with green building certifications like LEED and BREEAM, appealing to environmentally conscious consumers and developers.

Integration with Smart and Multi-Functional Designs

Future soundproof panels will increasingly incorporate smart technologies and multi-functional features. By 2026, expect to see panels integrated with solar panels, air-purifying coatings, or IoT-enabled noise monitoring systems. Additionally, designs will blend acoustic performance with aesthetics, offering customizable colors, textures, and patterns to complement architectural styles.

Growth in Commercial and Industrial Applications

Beyond residential use, demand is expanding in commercial sectors such as hospitality (outdoor dining areas, resorts), healthcare (healing gardens), and industrial sites (noise barriers near factories or logistics centers). The need to create quieter, more pleasant environments for customers and workers will accelerate adoption in these segments.

Regional Market Expansion

While North America and Europe remain key markets due to mature infrastructure and regulatory frameworks, the Asia-Pacific region will experience the fastest growth. Countries like China, India, and South Korea are investing heavily in urban development and transportation networks, creating substantial opportunities for outdoor acoustic solutions.

Technological Advancements in Acoustic Performance

Advancements in material science—such as meta-materials, porous composites, and hybrid panel systems—will enhance sound absorption and insulation capabilities. These innovations will allow for thinner, lighter panels with superior noise reduction coefficients (NRC), making installation easier and more cost-effective without compromising performance.

In conclusion, the 2026 market for soundproof outdoor panels will be characterized by innovation, sustainability, and regulatory influence. Companies that prioritize eco-friendly materials, smart integration, and high-performance design will be best positioned to capture growing demand across residential, commercial, and infrastructure sectors.

Common Pitfalls When Sourcing Soundproof Outdoor Panels (Quality and IP Considerations)

Sourcing soundproof outdoor panels requires careful evaluation of both acoustic performance and environmental durability. Overlooking key quality and Ingress Protection (IP) factors can lead to premature failure, poor noise reduction, and increased long-term costs. Below are common pitfalls to avoid.

1. Prioritizing Cost Over Quality Materials

One of the most frequent mistakes is selecting panels based solely on price. Low-cost options often use substandard materials—such as thin metal, recycled composites, or insufficient core density—that degrade quickly or offer minimal sound attenuation. High-quality outdoor panels should feature dense acoustic cores (e.g., mineral wool or mass-loaded vinyl) and durable outer cladding (e.g., aluminum or weather-resistant steel).

2. Ignoring Ingress Protection (IP) Ratings

Outdoor panels are exposed to rain, dust, and humidity. Failing to verify appropriate IP ratings (e.g., IP54 or higher) can lead to water ingress, which damages internal components and reduces soundproofing effectiveness. Panels without proper sealing may swell, corrode, or foster mold—compromising both structural integrity and acoustic performance.

3. Overlooking UV and Weather Resistance

Even if a panel has a good IP rating, it may still degrade under prolonged UV exposure or extreme temperatures. Panels made with non-UV-stabilized plastics or low-grade coatings can fade, crack, or delaminate. Always confirm UV resistance through manufacturer specifications or certification (e.g., ASTM G154 compliance).

4. Assuming All “Soundproof” Panels Are Equal

Marketing terms like “soundproof” are often misleading. Many panels only reduce noise marginally (e.g., 10–15 dB) rather than blocking it entirely. Buyers should review tested Sound Transmission Class (STC) or Outdoor-Indoor Transmission Class (OITC) ratings. Panels with STC 30+ and OITC 25+ are typically more effective for outdoor applications.

5. Neglecting Structural Durability and Wind Load Resistance

Outdoor panels must withstand wind, vibration, and potential impact. Lightweight or poorly constructed panels may buckle or collapse in high-wind areas. Ensure the product meets structural standards (e.g., EN 1991 or ASCE 7) and includes proper mounting hardware designed for outdoor use.

6. Skipping Third-Party Testing and Certification

Relying solely on manufacturer claims without independent verification is risky. Always request test reports from accredited laboratories for acoustic performance, fire resistance (e.g., ASTM E84), and environmental durability. Certified products provide assurance of consistent quality and compliance.

7. Poor Installation Due to Inadequate Design or Support

Even high-quality panels underperform if not installed correctly. Some suppliers offer panels without full installation guidelines, compatible accessories, or engineering support. This can lead to gaps, flanking paths, or weak seals that drastically reduce noise control. Choose suppliers who provide comprehensive technical documentation and installation training.

8. Failing to Consider Long-Term Maintenance Needs

Some materials require regular maintenance to remain effective outdoors. For example, untreated wood or certain coatings may need resealing every few years. Evaluate total cost of ownership, including upkeep, when comparing options.

Conclusion

Avoiding these common pitfalls ensures that your soundproof outdoor panels deliver lasting noise reduction and withstand environmental challenges. Focus on verified quality, proper IP ratings, and comprehensive performance data to make informed sourcing decisions.

Logistics & Compliance Guide for Soundproof Outdoor Panels

Product Handling and Storage

Handle soundproof outdoor panels with care to prevent physical damage such as cracks, dents, or delamination. Store panels in a dry, covered area off the ground on pallets or skids to avoid moisture absorption and warping. Protect from direct sunlight and extreme temperatures during storage to maintain material integrity. Keep panels vertical when possible to prevent bowing, and cover with breathable protective sheeting if stored outdoors temporarily.

Packaging and Transport

Panels must be securely packaged in weather-resistant materials, typically corrugated cardboard and shrink-wrapped plastic, to prevent moisture ingress during transit. When shipping, ensure loads are properly strapped and braced within transport vehicles to minimize shifting and impact damage. Use edge protectors for stacked panels, and avoid overloading to prevent compression damage. Consider using enclosed trailers or containers to protect against rain, snow, and road debris.

Import/Export Regulations

Verify compliance with destination country regulations before international shipment. Soundproof outdoor panels may be subject to construction material standards, environmental regulations, or noise control certifications. Ensure all export documentation—including commercial invoices, packing lists, and certificates of origin—is accurate and complete. Check for any import duties, tariffs, or restrictions related to composite materials, recycled content, or chemical components (e.g., adhesives or fire retardants).

Environmental and Safety Compliance

Confirm that panels meet relevant environmental standards such as REACH (EU), RoHS, or TSCA (USA) regarding restricted substances. If panels contain recycled materials or bio-based components, provide documentation to support environmental claims. Ensure fire resistance ratings (e.g., ASTM E84, EN 13501-1) are certified and clearly labeled, especially for use in urban or commercial developments. Provide Safety Data Sheets (SDS) for any hazardous components used in manufacturing.

Building Code and Certification Requirements

Panels must comply with local building codes and acoustic performance standards in the installation region. Common certifications include ISO 10140 (acoustic insulation), ASTM C423 (noise reduction coefficient), and local fire safety codes. Verify zoning regulations for outdoor installations, particularly in residential areas or near property lines. Provide third-party test reports and product certifications to contractors, inspectors, or regulatory bodies upon request.

Installation and Site Compliance

Coordinate with installers to ensure panels are transported to site using appropriate equipment (e.g., forklifts, panel lifts). Confirm that installation methods comply with municipal noise abatement ordinances and do not obstruct public pathways or utilities. Follow manufacturer guidelines for fastening, sealing, and expansion gaps to ensure long-term durability and performance. Document compliance with all local environmental, zoning, and safety regulations post-installation.

In conclusion, sourcing soundproof outdoor panels requires careful consideration of several key factors, including material composition, durability, sound absorption and attenuation performance (measured by STC and NRC ratings), aesthetic integration with the environment, ease of installation, and long-term maintenance. When selecting panels, prioritize weather-resistant, UV-stable materials such as recycled composites, aluminum, or specially treated wood and fabrics to ensure longevity in outdoor conditions.

Working with reputable suppliers who provide certified acoustic performance data and offer customization options can greatly enhance the effectiveness and visual appeal of the installation. Additionally, aligning product selection with specific noise sources—such as traffic, construction, or recreational noise—ensures targeted noise reduction.

By investing in high-quality, properly engineered soundproof outdoor panels, businesses, municipalities, and homeowners can create more comfortable, peaceful outdoor environments while complying with local noise regulations. Ultimately, the right sourcing strategy balances acoustic performance, sustainability, and design to deliver long-term value and improved quality of life.