The global acoustic insulation market is experiencing robust growth, driven by rising urbanization, increasing construction activities, and growing consumer demand for noise reduction in residential and commercial spaces. According to Grand View Research, the global acoustic insulation materials market size was valued at USD 15.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This surge is further amplified by stricter building regulations and a heightened focus on indoor environmental quality. As one of the most accessible and cost-effective solutions for reducing impact sound and enhancing floor comfort, soundproof carpet padding has become a key component in modern flooring systems. With the flooring underlayment segment gaining traction—especially in noise-sensitive environments like apartments, home theaters, and offices—the demand for high-performance acoustic padding is on the rise. In this expanding landscape, manufacturers are innovating with denser foams, recycled materials, and composite technologies to deliver superior sound transmission class (STC) and impact insulation class (IIC) ratings. Based on performance metrics, material innovation, market presence, and customer reviews, here are the top 10 soundproof carpet padding manufacturers leading the charge in this growing industry.

Top 10 Soundproof Carpet Padding Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sound Seal

Domain Est. 1996 | Founded: 1978

Website: soundseal.com

Key Highlights: Sound Seal is a leading manufacturer of industrial & architectural acoustic sound control products. Controlling noise in every environment since 1978….

#2 Carpenter Co.

Domain Est. 1993

Website: carpenter.com

Key Highlights: Carpenter Co. is the world’s largest vertically integrated manufacturer of polyurethane foams, and serves a diversified global marketplace with polyurethane ……

#3 Milliken Flooring

Domain Est. 1994

Website: milliken.com

Key Highlights: WellBAC® cushion backing reduces muscle fatigue by up to 24%, absorbs sound, manages moisture, and handles heavy traffic while looking great and extending ……

#4 Dura Undercushions: High

Domain Est. 1998

Website: duracushion.com

Key Highlights: Discover Dura Undercushions’ premium flooring underlayment and carpet padding designed for superior soundproofing in residential and commercial spaces….

#5 Carpet Padding

Domain Est. 1998

Website: georgiacarpet.com

Key Highlights: 5–11 day deliveryFelt: Felt pads are a more adaptable solution that additionally provides improved soundproofing and temperature control. For choosing a carpet pad: 1….

#6 dB Series Carpet Pad

Domain Est. 2005

Website: proflex.us

Key Highlights: Enhance your carpeted environment with dB Series Carpet Cushion. Achieve optimal sound control with our high-performance carpet cushion solutions….

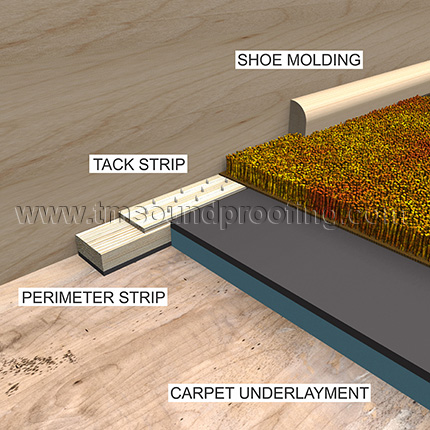

#7 Sound Proofing Carpet Underlayment

Domain Est. 2008

Website: tmsoundproofing.com

Key Highlights: In stock Rating 3.0 (4) Features: Easy to use and install; Low cost solution for both noise transmission and privacy issues. No need for additional carpet pad; Firm yet comfortab…

#8 Flooring Underlayments

Domain Est. 2008

#9 Soundproof Rug Pads

Domain Est. 2012

Website: rugpadusa.com

Key Highlights: Free delivery · Free 60-day returnsLife can get noisy sometimes. Help cut down on everyday thumps and thuds with our soundproof rug pads. Rug shape: Rectangle. Rug size: Length in…

#10 Soundproofing Carpet

Domain Est. 2019

Website: soundisoco.com

Key Highlights: Our products for soundproofing carpeted floors will provide significant reduction in footstep noise and block loud noises from above and below….

Expert Sourcing Insights for Soundproof Carpet Padding

2026 Market Trends for Soundproof Carpet Padding

The global market for soundproof carpet padding is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements, and increasing urbanization. As noise pollution becomes a growing concern in residential, commercial, and multi-family housing sectors, demand for high-performance acoustic solutions continues to rise. This analysis explores key trends shaping the soundproof carpet padding market in 2026.

Rising Urbanization and Demand for Noise Reduction

With urban populations expanding rapidly, especially in emerging economies, the need for noise mitigation in densely populated areas has intensified. Apartments, condominiums, and mixed-use developments are increasingly incorporating soundproofing materials to improve occupant comfort. Soundproof carpet padding plays a critical role in reducing impact noise—such as footsteps—between floors. Regulatory standards for sound transmission (e.g., IIC and STC ratings) in building codes are becoming stricter, further accelerating adoption across new constructions and renovations.

Growth in Multi-Family and Rental Housing

The surge in multi-family housing and short-term rental platforms like Airbnb has amplified the need for cost-effective noise control. Property managers and landlords are investing in soundproof carpet padding to enhance tenant satisfaction, reduce noise complaints, and increase property value. In 2026, this segment is expected to be one of the primary drivers of market growth, particularly in metropolitan areas across North America, Europe, and parts of Asia-Pacific.

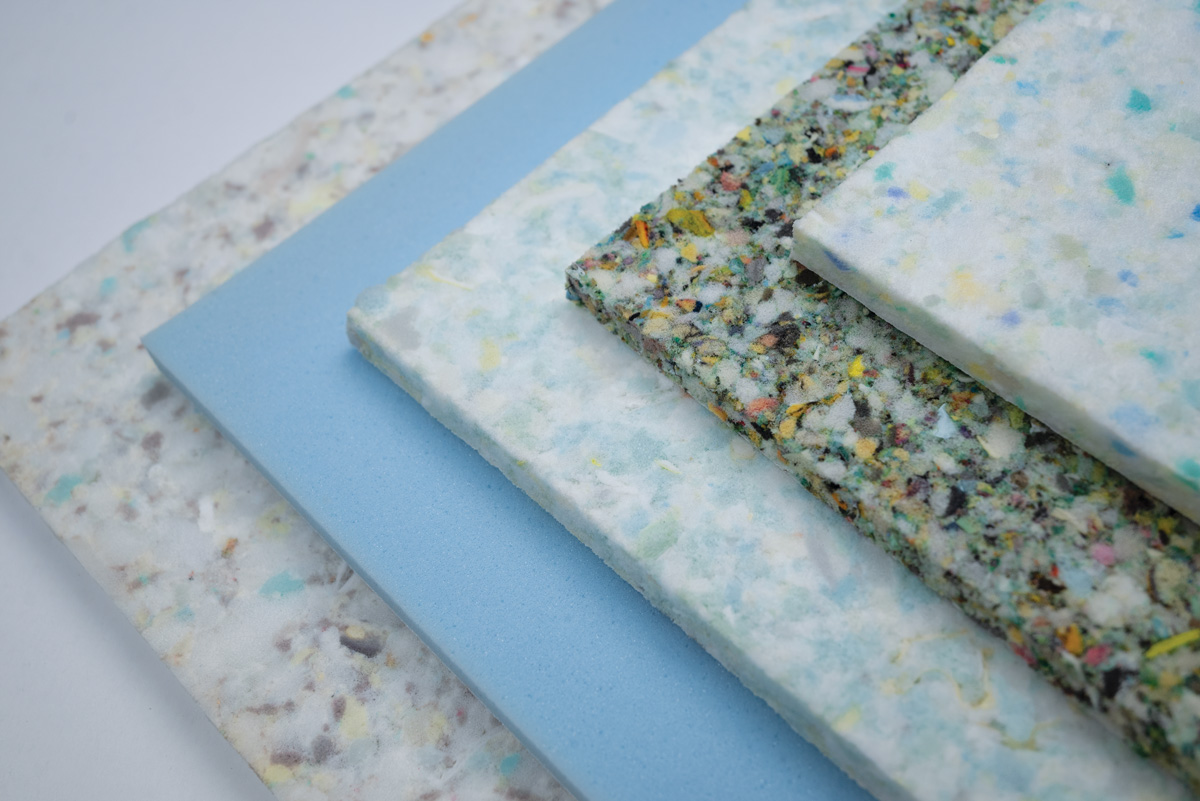

Technological Innovation in Materials

Manufacturers are responding to market demands by developing advanced soundproof carpet padding using high-density foams, recycled rubber, and composite materials engineered for superior sound absorption. Innovations such as viscoelastic polymers and underlayment with integrated vapor barriers are enhancing both acoustic and moisture resistance performance. Additionally, smart underlayments with embedded sensors for monitoring floor conditions are beginning to emerge, signaling a move toward intelligent flooring systems.

Sustainability and Eco-Friendly Products

Environmental concerns are shaping product development, with a growing preference for sustainable and recyclable materials. By 2026, eco-conscious consumers and green building certifications (e.g., LEED, BREEAM) are pushing manufacturers to adopt bio-based foams, recycled content, and low-VOC emissions in soundproof padding. Companies emphasizing sustainability in their supply chains are gaining a competitive edge, particularly in environmentally regulated regions like Western Europe.

E-Commerce and Direct-to-Consumer Sales

The rise of online home improvement platforms has made soundproof carpet padding more accessible to DIY consumers. Brands are leveraging e-commerce channels to offer detailed product comparisons, noise reduction ratings, and installation guides. In 2026, digital marketing and customer education will be crucial for converting online shoppers, especially as more homeowners undertake acoustic upgrades during remote work and hybrid living trends.

Regional Market Expansion

While North America and Europe remain dominant markets due to stringent building codes and high awareness of acoustic comfort, Asia-Pacific is expected to witness the fastest growth. Countries like China, India, and South Korea are experiencing a construction boom in high-rise residential buildings, creating substantial opportunities for soundproofing solutions. Government initiatives promoting livable urban environments will further support market expansion in these regions.

Conclusion

By 2026, the soundproof carpet padding market will be shaped by urbanization, regulatory changes, technological innovation, and sustainability. Stakeholders—from manufacturers to installers—must adapt to these trends by offering high-performance, eco-friendly, and smart-enabled solutions. As acoustic comfort becomes a standard expectation in modern buildings, the soundproof carpet padding industry is set for sustained and strategic growth.

Common Pitfalls When Sourcing Soundproof Carpet Padding (Quality and Intellectual Property)

Sourcing soundproof carpet padding can be a cost-effective way to improve acoustic performance in residential and commercial spaces. However, buyers often encounter pitfalls related to product quality and intellectual property (IP) issues. Being aware of these challenges helps ensure that the materials meet performance expectations and legal standards.

1. Compromised Material Quality

One of the most frequent issues is receiving padding made from substandard or misrepresented materials. Some suppliers may advertise high-density rubber or recycled foam but deliver lower-density alternatives that offer minimal sound absorption. This can lead to poor noise reduction and customer dissatisfaction.

2. Inaccurate Noise Reduction Ratings

Many manufacturers claim impressive Sound Transmission Class (STC) or Impact Insulation Class (IIC) ratings without third-party testing. Sourcing products based solely on these unverified claims can result in underperforming installations. Always request certified lab test reports before finalizing procurement.

3. Inconsistent Thickness and Density

Variability in padding thickness and density across batches affects both performance and installation. Inconsistent quality often stems from poor manufacturing controls, especially with overseas suppliers. This inconsistency can impact underfoot comfort and sound dampening uniformity.

4. Use of Recycled Materials Without Disclosure

While recycled content is environmentally beneficial, undisclosed use—especially of mixed or contaminated sources—can compromise durability and odor control. Some low-quality recycled foams emit volatile organic compounds (VOCs), affecting indoor air quality.

5. Misrepresentation of Intellectual Property

Some suppliers copy patented designs, such as specialized acoustic foam patterns or composite layer structures, and sell them as generic products. Purchasing such items—even unknowingly—can expose buyers to IP infringement risks, particularly in regulated markets like the U.S. or EU.

6. Lack of Compliance Documentation

Reputable soundproof padding should meet fire safety (e.g., ASTM E648, CAL 117), environmental (e.g., FloorScore, GREENGUARD), and acoustic standards. Suppliers from regions with lax regulations may omit required certifications, creating liability for end users.

7. Hidden Minimum Order Requirements and MOQ Traps

Some suppliers advertise competitive pricing but impose high minimum order quantities (MOQs) or hidden costs for smaller batches. This can lead to overstocking or inflated per-unit costs when customization or small runs are needed.

8. Poor Packaging and Shipping Damage

Soundproof padding is often bulky and sensitive to compression. Inadequate packaging can lead to damaged or compressed rolls upon arrival, reducing effectiveness. Some suppliers cut corners here to save on shipping costs.

9. Limited Technical Support and Product Traceability

When acoustic performance issues arise, lack of technical documentation or traceability makes troubleshooting difficult. Reliable suppliers provide batch numbers, material data sheets, and support for warranty claims.

10. Counterfeit or Branded Knockoffs

In some markets, especially online platforms, counterfeit versions of well-known branded soundproof padding are sold at lower prices. These copies often lack the original’s performance characteristics and may infringe on trademarks or patents.

To avoid these pitfalls, conduct thorough due diligence: verify certifications, request samples, audit suppliers, and consult legal counsel when dealing with proprietary technologies.

Logistics & Compliance Guide for Soundproof Carpet Padding

Product Classification and HS Code

Soundproof carpet padding is typically classified under Harmonized System (HS) code 5602.90, which covers “Textile materials for technical uses, other.” However, classification may vary based on material composition (e.g., recycled rubber, foam, felt). Confirm the exact HS code with your customs broker to ensure accurate tariff application and compliance with import regulations in the destination country.

Packaging and Labeling Requirements

Ensure all soundproof carpet padding is securely rolled or stacked and wrapped in durable plastic to prevent moisture damage and deformation during transit. Label each package with:

– Product name and description

– Dimensions and weight

– Batch or lot number

– Manufacturer information

– Handling symbols (e.g., “This Side Up,” “Protect from Moisture”)

Comply with local labeling laws, including language requirements (e.g., English in the U.S., French in Quebec).

Transportation and Freight Considerations

Due to bulk and low density, soundproof carpet padding is often classified as a lightweight, high-volume freight item. Use palletized loads for stability and efficient handling. Consider:

– Mode of Transport: Best suited for LTL (Less Than Truckload) or full truckload domestic shipping; ocean freight for international.

– Stackability: Maximize container or trailer space while adhering to weight limits and avoiding compression damage.

– Environmental Protection: Avoid exposure to extreme temperatures and humidity, which can degrade foam or rubber-based padding.

Import and Export Compliance

For international shipments:

– Obtain an Export Control Classification Number (ECCN) if exporting from the U.S.; most padding falls under EAR99 (low regulatory control).

– Prepare a commercial invoice, packing list, and bill of lading/air waybill.

– Verify import duties, taxes, and any anti-dumping or countervailing duties applicable in the destination country.

– Comply with destination country standards (e.g., CE marking in the EU, VOC emission standards).

Environmental and Safety Regulations

Soundproof carpet padding may be subject to environmental and indoor air quality regulations:

– VOC Emissions: Comply with standards such as California’s CA 01350 or GREENGUARD Gold for low-emitting materials.

– Recycled Content Claims: If marketed as eco-friendly, ensure compliance with FTC Green Guides and substantiate claims with documentation.

– REACH & RoHS (EU): Verify absence of restricted substances (e.g., phthalates, heavy metals), especially in synthetic foam products.

Storage and Handling

Store in a dry, well-ventilated area away from direct sunlight to prevent material degradation. Elevate pallets off the floor to avoid moisture absorption. Handle with forklifts or pallet jacks to prevent damage; avoid dragging rolls across surfaces.

Documentation and Traceability

Maintain records of:

– Material Safety Data Sheets (MSDS/SDS), if applicable

– Certifications (e.g., fire resistance, sound transmission class ratings)

– Test reports for acoustic performance (ASTM E492, ASTM E989)

– Proof of origin and compliance with trade agreements (e.g., USMCA)

Ensure lot traceability for quality control and recall readiness.

End-of-Life and Disposal Compliance

Inform customers about proper disposal methods. Rubber and foam padding may not be recyclable in all municipalities. Offer take-back programs or partner with recycling facilities where feasible to support circular economy initiatives.

In conclusion, sourcing soundproof carpet padding requires careful consideration of material type, density, thickness, and installation method to effectively reduce noise transmission. Materials such as rubber, foam, and recycled composites each offer distinct advantages in terms of sound absorption, durability, and environmental impact. Higher density and proper thickness are critical for optimal soundproofing performance, particularly in multi-story buildings or high-traffic areas. Additionally, selecting products with underlayment ratings—such as IIC (Impact Insulation Class) and STC (Sound Transmission Class)—ensures measurable noise reduction. By evaluating supplier reliability, product certifications, cost-efficiency, and sustainability, buyers can make informed decisions that balance acoustic performance with long-term value. Ultimately, investing in high-quality soundproof carpet padding enhances comfort, privacy, and acoustic comfort in residential, commercial, and multi-family environments.