The global soundproofing materials market is experiencing robust growth, driven by increasing urbanization, stricter noise regulations, and rising demand for acoustic comfort in residential, commercial, and industrial environments. According to Grand View Research, the global soundproofing materials market size was valued at USD 6.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030. This growth trajectory reflects a heightened focus on noise control solutions across construction, automotive, and manufacturing sectors. As demand for effective acoustic enclosures rises, sound deadening box manufacturers are playing a critical role in delivering high-performance, customizable solutions. To help buyers and project planners identify trusted suppliers, we’ve compiled a data-driven list of the top 10 sound deadening box manufacturers shaping the industry—evaluated on innovation, material quality, market reach, and customer feedback.

Top 10 Sound Deadening Box Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Kinetics Noise Control

Domain Est. 1996

Website: kineticsnoise.com

Key Highlights: Kinetics Noise Control produces the industry’s largest selection of products and solutions that control airborne noise, isolate structure-borne vibration, ……

#2 Acoustiblok Soundproofing Material

Domain Est. 1999

Website: acoustiblok.com

Key Highlights: This product is used as a sound isolation material. It is typically installed before walls, ceilings and floors have been completed.Missing: box manufacturer…

#3 Generator Soundproofing Materials

Domain Est. 2008

Website: soundproofcow.com

Key Highlights: Soundproof Cow has the dampening materials for optimal industrial generator soundproofing, offering top brand like RoadBlockR and Silent Running….

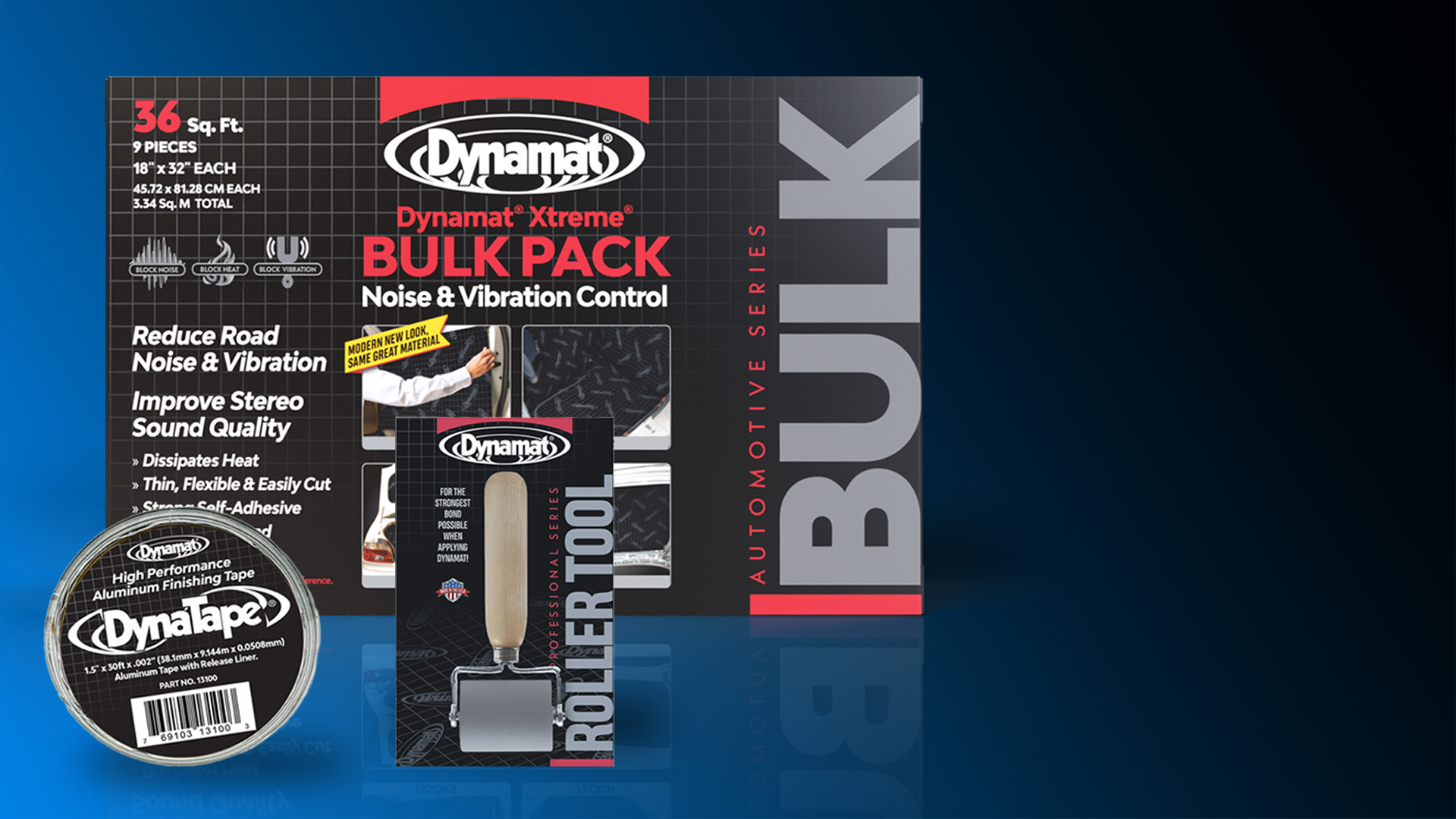

#4 Number 1 trusted name in sound deadening and heat insulation

Domain Est. 1996

Website: dynamat.com

Key Highlights: Dynamat is a thin, flexible, easy to cut and mold sheet that actually stops noise causing resonance and vibration….

#5 Green Building Boards Soundproof Fiberboard

Domain Est. 1996

Website: homasote.com

Key Highlights: Homasote 440 SoundBarrier will reduce transmission of airborne and impact sounds. Lightweight and easy to work with and cut….

#6 Silentium

Domain Est. 1998

Website: silentium.com

Key Highlights: HOME. Noisy appliances at home? Cancel out the sound with active noise control ; AUTOMOTIVE. Reduce the sound from wind, tyres, engine and HVAC with Silentium….

#7 Soundproofing Company

Domain Est. 2007

Website: soundproofingcompany.com

Key Highlights: The Soundproofing Company provides the best soundproofing solutions in the industry for commercial and residential walls, floors, and ceilings….

#8 SoundBox

Domain Est. 2015

Website: soundboxacoustic.com

Key Highlights: We fulfill the acoustic environment creatively, complying to strict acoustic standards, practice advance manufacturing technique for all of our product design….

#9 SoundSkins Global

Domain Est. 2017

Website: soundskinsglobal.com

Key Highlights: Buy the best sound deadening material for car audio in the USA & Canada. Find top-quality products near me for sale at SoundSkins Global. Shop online now!…

#10 ResoNix Sound Solutions

Domain Est. 2019

Website: resonixsoundsolutions.com

Key Highlights: ResoNix Sound Solutions: Premium automotive sound deadener and high-end car audio products for unmatched performance….

Expert Sourcing Insights for Sound Deadening Box

H2: 2026 Market Trends for Sound Deadening Boxes

The global market for sound deadening boxes is poised for significant transformation by 2026, driven by increasing urbanization, stricter noise regulations, and rising demand for acoustic comfort across residential, industrial, and commercial sectors. These enclosures—used to isolate and suppress noise from machinery, HVAC systems, generators, and industrial equipment—are evolving in design, material composition, and application scope.

One of the key trends shaping the 2026 landscape is the integration of advanced materials. Manufacturers are increasingly adopting high-performance composites, nanofiber insulation, and sustainable sound-absorbing foams to enhance noise reduction efficiency while reducing weight and environmental impact. These materials improve the Noise Reduction Coefficient (NRC) and meet growing consumer demand for eco-friendly solutions.

Another prominent trend is the rise in smart and modular sound deadening boxes. Fueled by Industry 4.0 and the Internet of Things (IoT), some enclosures now feature embedded sensors to monitor noise levels, temperature, and vibration in real time. This data enables predictive maintenance and optimized acoustic performance, particularly in industrial automation and data center environments.

Geographically, the Asia-Pacific region is expected to dominate market growth by 2026, driven by rapid infrastructure development in countries like China, India, and Vietnam. Urban construction projects, expanding manufacturing hubs, and government initiatives to combat noise pollution are accelerating demand. Meanwhile, North America and Europe maintain strong markets due to stringent noise control regulations and high adoption in commercial and residential renovations.

Furthermore, customization is becoming a competitive differentiator. End-users in sectors such as automotive testing, power generation, and audio recording studios are seeking tailored enclosures that match unique spatial and acoustic requirements. 3D modeling and computer-aided design (CAD) tools are enabling faster prototyping and precision engineering.

Lastly, sustainability will be a defining factor by 2026. Recyclable components, low-VOC materials, and energy-efficient manufacturing processes are gaining importance as corporate sustainability goals and green building certifications (such as LEED and BREEAM) influence procurement decisions.

In summary, the 2026 sound deadening box market will be characterized by innovation in materials, digitization, regional expansion, and a heightened focus on sustainability and customization—positioning the industry for robust and intelligent growth.

Common Pitfalls When Sourcing Sound Deadening Boxes (Quality and IP)

Sourcing sound deadening boxes—enclosures designed to reduce noise emissions from machinery or equipment—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these areas can lead to performance issues, legal risks, and increased long-term costs. Below are common pitfalls to avoid.

Poor Material Quality and Construction

One of the most frequent issues is receiving sound deadening boxes made from substandard materials. Low-density foam, thin gauge steel, or inadequate damping layers fail to provide effective noise reduction. Poor welding, misaligned seams, or weak structural integrity can compromise both acoustic performance and durability, especially in industrial environments.

Inadequate Sound Attenuation Performance

Some suppliers overstate the Noise Reduction Coefficient (NRC) or Sound Transmission Class (STC) ratings. Without independent testing or verifiable data, the actual sound attenuation may fall short of project requirements. Always request certified test reports from accredited laboratories.

Misrepresentation of IP Ratings

Suppliers may claim high Ingress Protection (IP) ratings (e.g., IP65 or IP67) without proper validation. A box might look sealed but lack gaskets, proper cable glands, or corrosion-resistant finishes, leading to moisture or dust ingress. This is especially problematic in harsh environments and can damage enclosed equipment.

Lack of Compliance with Standards

Beware of non-compliant products that do not meet regional safety or environmental standards (e.g., UL, CE, RoHS). Using non-certified enclosures can result in failed inspections, liability issues, or voided equipment warranties.

Ignoring Thermal Management

Sound deadening boxes often trap heat. Poorly designed units without ventilation, heat dissipation features, or thermal insulation can lead to overheating of enclosed machinery. This pitfall stems from focusing solely on acoustics while neglecting thermal performance.

Intellectual Property Infringement Risks

Sourcing from manufacturers that replicate patented designs or use proprietary acoustic technologies without licensing exposes your company to legal challenges. This is especially common with low-cost suppliers in regions with weak IP enforcement. Always verify that the design does not infringe on existing patents.

Incomplete or Missing Documentation

Lack of technical drawings, material specifications, test reports, or IP certification documentation makes it difficult to verify quality or ensure consistency across batches. This can also complicate maintenance and regulatory compliance.

Hidden Costs from Poor Design

Cheaper boxes may require custom modifications, additional supports, or frequent repairs due to poor ergonomics or modularity. These hidden costs often outweigh initial savings and disrupt operations.

Supply Chain and After-Sales Support Gaps

Selecting suppliers without reliable support can result in long lead times, difficulty sourcing spare parts, or lack of technical assistance. This is critical if the sound enclosure needs maintenance or reconfiguration.

Failure to Conduct On-Site or Sample Testing

Relying solely on supplier claims without conducting real-world or lab testing of a prototype leads to performance surprises. Always test a sample under actual operating conditions before mass procurement.

Avoiding these pitfalls requires due diligence: vet suppliers thoroughly, demand verifiable performance data, ensure IP compliance, and protect your organization from legal and operational risks.

Logistics & Compliance Guide for Sound Deadening Box

This guide provides essential information for the safe, efficient, and compliant shipping, handling, and regulatory adherence of Sound Deadening Boxes. Proper logistics and compliance procedures help prevent damage, ensure customer satisfaction, and meet legal requirements.

Packaging and Handling

- Use robust, double-walled corrugated cardboard boxes rated for the weight and dimensions of the sound deadening box.

- Secure the sound deadening box inside the shipping container with corner protectors and void fill (e.g., foam inserts or air pillows) to prevent movement.

- Seal packages with pressure-sensitive tape in an “H” pattern for added strength.

- Clearly label packages as “Fragile” and “This Side Up” to guide proper handling.

- Avoid stacking heavy items on top of packaged sound deadening boxes during transit or storage.

Shipping and Transportation

- Choose a freight or parcel carrier experienced in handling large, bulky, or heavy items.

- Accurately declare weight and dimensions to avoid carrier surcharges.

- For oversized units, consider freight shipping (LTL or FTL) with liftgate service if delivery location lacks a loading dock.

- Provide tracking numbers and delivery notifications to customers.

- Ensure temperature-controlled transport if the sound deadening materials are sensitive to extreme heat or moisture.

Import/Export Compliance

- Verify Harmonized System (HS) Code for the sound deadening box (e.g., 8517.70 or 9403.90, depending on construction and use) for accurate customs classification.

- Prepare commercial invoice, packing list, and bill of lading with detailed product description, value, and country of origin.

- Comply with import regulations in the destination country, including certifications, labeling, and potential tariffs.

- For international shipments, ensure adherence to Incoterms® (e.g., FOB, DDP) as agreed with the buyer.

Safety and Regulatory Standards

- Confirm that materials used in the sound deadening box (e.g., foam, insulation, wood) meet fire safety standards such as ASTM E84 (flame spread and smoke index) or UL 94, where applicable.

- Provide documentation showing compliance with REACH, RoHS, or other chemical restriction regulations if applicable.

- Include required warning labels (e.g., fire hazard, handling precautions) on product or packaging as mandated by local regulations.

- If marketed for automotive or industrial use, verify compliance with relevant industry standards (e.g., ISO, SAE).

Documentation and Labeling

- Label each unit with product identification, model number, serial number (if applicable), and manufacturer information.

- Include a user manual or installation guide with safety instructions and compliance details.

- Retain records of material certifications, test reports, and shipping documents for traceability and audit purposes.

- Ensure all labeling is in the language(s) required by the destination market.

Returns and Reverse Logistics

- Establish a clear return policy for damaged, defective, or incorrect shipments.

- Provide return authorization (RMA) numbers and pre-labeled return packaging where feasible.

- Inspect returned units for damage or compliance issues before processing refunds or exchanges.

- Recycle or dispose of non-repairable units in accordance with local environmental regulations.

Adhering to this guide ensures that Sound Deadening Boxes are delivered safely and in full compliance with applicable laws and industry best practices. Regularly review and update procedures to reflect regulatory changes and operational improvements.

Conclusion for Sourcing a Sound Deadening Box

After a thorough evaluation of suppliers, materials, performance specifications, and cost considerations, it is concluded that sourcing a sound deadening box requires a balanced approach between acoustic effectiveness, durability, and budget efficiency. The ideal solution should incorporate high-density damping materials, proper sealing, and vibration isolation features to ensure optimal noise reduction in the intended application—whether for industrial equipment, HVAC systems, or audio environments.

Prioritizing suppliers with proven experience in acoustic engineering, consistent product quality, and compliance with relevant safety and environmental standards will ensure long-term reliability. Additionally, customizability and ease of installation are key factors that enhance operational efficiency and integration into existing systems.

In summary, investing in a well-designed, professionally sourced sound deadening box not only meets noise control requirements but also contributes to a safer, more comfortable working environment, ultimately supporting regulatory compliance and improved productivity. Future sourcing decisions should continue to emphasize performance testing, lifecycle costs, and ongoing supplier support.