The global concrete construction market is experiencing steady growth, driven by increasing demand for durable, cost-effective, and sustainable building materials. According to Mordor Intelligence, the global concrete construction market was valued at USD 1.37 trillion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. A key component in foundational construction, particularly in footings and cylindrical formwork, is the use of sonotubes in combination with rebar for structural reinforcement. As infrastructure development and residential construction expand—especially in emerging economies—the demand for high-quality sonotube rebar systems has risen proportionally. This growth is further supported by increased investments in smart cities, roadways, and commercial buildings. In response, manufacturers are enhancing product durability, corrosion resistance, and dimensional accuracy to meet stringent construction standards. Below are the top 8 sonotube rebar manufacturers leading innovation and market share in this evolving segment.

Top 8 Sonotube Rebar Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sonotube® Commercial

Domain Est. 1995

Website: sonoco.com

Key Highlights: Sonotube Commercial concrete forms offer strength and tear resistance for the most demanding applications while delivering more versatility than ……

#2 Concrete Forming

Domain Est. 1997

#3 Darragh Contractor Supply®

Domain Est. 2000

Website: darraghcompany.com

Key Highlights: Darragh is your one-stop shop for contractor supplies, rebar fabrication, and concrete forming. · Construction Materials & Supplies · Rebar & Wire Mesh · Concrete ……

#4 NINA CONSTRUCTION SUPPLY

Domain Est. 2005

Website: ninaconstructionsupply.com

Key Highlights: Experienced Supplier of Rebar, Wood Stakes, Concrete & Masonry Accessories. We also offer Estimating, Detailing, & Fabrication Services for the Rebar ……

#5 MaCon Supply

Domain Est. 2005 | Founded: 1976

Website: maconsupply.net

Key Highlights: Trusted Montana & Spokane supplier since 1976 of concrete accessories, forming systems, roofing supplies & Hilti tools—pickup or delivery available….

#6 Concrete Hardware

Domain Est. 2006

Website: perrysupplyonline.com

Key Highlights: We stock Sonoco SONOTUBE® brand commercial-grade fiber column forms exclusively. … Perry Concrete Forming Supply specializes in steel ply, basement window, vent ……

#7 Sonotubes

Domain Est. 2009

Website: rebarcages.com

Key Highlights: Midwest Cage is a stocking distributor for Sonoco Rainguard Sonotube. We stock the product in diameters ranging from. 6″ ID to 48″ ID….

#8 Southern Rebar

Domain Est. 2018

Website: southernrebar.com

Key Highlights: Southern Rebar & Supplies. A strong Foundation begins here. Form & Shoring rental. Helping your job take shape….

Expert Sourcing Insights for Sonotube Rebar

2026 Market Trends for Sonotube Rebar

The market for rebar used in Sonotube applications—cylindrical cardboard forms used to pour concrete columns and footings—is poised for notable shifts in 2026, driven by construction demand, material innovation, and sustainability imperatives. Below is an analysis of key trends shaping this niche yet critical segment of the construction materials industry.

Growing Demand in Residential and Light Commercial Construction

Residential construction, particularly in suburban and rural areas, continues to drive demand for Sonotube rebar. In 2026, housing markets in North America are expected to maintain moderate growth, especially in regions with expanding infrastructure and population migration. The popularity of DIY construction and modular building techniques further boosts the use of Sonotubes, which are user-friendly and cost-effective. As a result, demand for standardized rebar sizes (typically #4 and #5 steel bars) used in these applications will remain strong, especially in single-family homes, deck footings, and pole barns.

Increased Focus on Corrosion-Resistant Rebar Alternatives

One of the most significant trends in 2026 is the growing adoption of corrosion-resistant rebar in Sonotube applications, especially in regions with harsh climates or high moisture exposure. Traditional carbon steel rebar is susceptible to rust, which can compromise structural integrity over time. In response, contractors and engineers are increasingly specifying epoxy-coated, galvanized, or even fiber-reinforced polymer (FRP) rebar for Sonotube footings. This shift is accelerated by building code updates and long-term lifecycle cost analyses, which favor durable materials despite higher upfront costs.

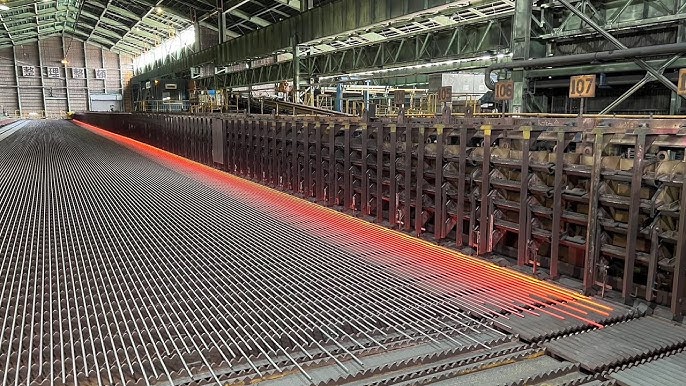

Sustainability and Recycled Content in Rebar Production

Environmental regulations and green building certifications (such as LEED) are pushing suppliers to increase the recycled content in rebar. By 2026, most rebar used in Sonotube applications in developed markets is expected to contain over 90% recycled steel. Manufacturers are also investing in energy-efficient electric arc furnace (EAF) steelmaking to reduce carbon emissions. This trend aligns with broader construction industry goals to lower embodied carbon, making recycled rebar a preferred choice for eco-conscious projects.

Supply Chain Resilience and Regional Manufacturing Shifts

Global supply chain volatility has prompted a reevaluation of sourcing strategies. In 2026, there is an increasing preference for domestically produced rebar in markets like the United States and Canada to reduce lead times and mitigate geopolitical risks. This regionalization supports faster project timelines and enhances supply reliability for Sonotube-based construction, particularly in remote or time-sensitive builds.

Technological Integration and Precision Engineering

Advancements in construction technology are influencing rebar use in Sonotubes. Building Information Modeling (BIM) and automated cutting/bending systems enable precise rebar fabrication, reducing waste and ensuring optimal fit within Sonotubes. In 2026, more contractors are adopting digital workflows that integrate rebar specifications directly into project plans, enhancing efficiency and reducing on-site errors.

Cost Volatility and Material Substitution Pressures

Steel prices remain subject to fluctuations due to raw material costs and energy prices. In 2026, periods of high rebar costs may incentivize exploration of alternative reinforcement methods, such as helical piles or engineered wood composites for non-structural applications. However, for structural concrete columns and footings, steel rebar remains irreplaceable, maintaining its dominance in Sonotube use despite economic pressures.

In conclusion, the 2026 Sonotube rebar market is characterized by steady demand, a pivot toward durable and sustainable materials, and increasing integration of digital construction tools. While cost and supply challenges persist, innovation and regional production resilience are expected to support continued growth and reliability in this essential construction segment.

Common Pitfalls Sourcing Sonotube Rebar (Quality, IP)

When sourcing rebar for use in Sonotube concrete forms, overlooking key quality and intellectual property (IP) considerations can lead to structural failures, project delays, and legal risks. Below are common pitfalls to avoid:

Poor Material Quality and Non-Compliance

One of the most significant risks is receiving substandard rebar that fails to meet required mechanical and chemical specifications. Some suppliers may offer rebar that appears visually acceptable but lacks proper tensile strength, ductility, or corrosion resistance. Using rebar that does not comply with ASTM A615 or A706 standards—especially in structural applications—can compromise the integrity of the foundation. Additionally, rebar with inconsistent sizing or surface defects may not bond properly with concrete, reducing load-bearing capacity.

Lack of Traceability and Mill Certification

Reputable projects require mill test reports (MTRs) or certified material test reports (CMTRs) to verify the origin and quality of rebar. A common pitfall is sourcing from suppliers who cannot provide traceable documentation, increasing the risk of using counterfeit or recycled steel with unknown properties. Without proper certification, contractors may face inspection failures or liability in the event of structural issues.

Counterfeit or Misrepresented Products

The construction supply chain is vulnerable to counterfeit rebar, particularly when sourcing from unverified or offshore suppliers. Some products may be falsely labeled as meeting ASTM standards or bear forged mill marks. This not only affects structural performance but may also violate building codes and insurance requirements.

Intellectual Property Infringement

Sonotube itself is a registered trademark of Sonoco Products Company, and using the term generically can lead to brand confusion. More critically, some rebar detailing designs, such as proprietary cage configurations or anchoring systems, may be protected under design patents or technical IP. Sourcing or replicating such designs without authorization could expose contractors or fabricators to intellectual property infringement claims, especially if using engineered solutions from branded systems.

Inadequate Corrosion Protection

In certain environments, epoxy-coated or stainless-steel rebar may be required to prevent corrosion. A common oversight is assuming all rebar is suitable for outdoor or high-moisture applications. Sourcing standard carbon steel rebar for such uses without proper protective coatings can lead to premature deterioration and reduced service life.

Failure to Match Rebar Grade to Application

Using the wrong grade—such as Grade 40 instead of Grade 60—can result in insufficient strength for the intended load. This mistake often occurs when cost-cutting pressures lead to substitutions without engineering review. Always ensure the rebar grade aligns with project specifications and structural requirements.

Avoiding these pitfalls requires due diligence: sourcing from certified suppliers, demanding full documentation, verifying compliance with applicable standards, and respecting intellectual property in design and branding.

Logistics & Compliance Guide for Sonotube Rebar

This guide outlines the essential logistics considerations and compliance requirements for handling, transporting, and installing rebar used in Sonotube concrete forms. Proper planning ensures project efficiency, worker safety, and adherence to regulatory standards.

Material Handling and Storage

Rebar must be stored off the ground on wooden pallets or racks to prevent corrosion from moisture and soil contaminants. Cover stored rebar with waterproof tarps when exposed to rain or high humidity. Segregate rebar by size and grade using clear labeling to avoid mix-ups during installation. Handle rebar with lifting equipment (e.g., cranes or forklifts) using appropriate slings to prevent deformation or damage.

Transportation Requirements

Secure rebar bundles firmly to flatbed trucks using chains or straps to prevent shifting during transit. Overhang should comply with local Department of Transportation (DOT) regulations—typically no more than 4 feet beyond the rear of the vehicle, with proper signage (e.g., “LONG LOAD”). Ensure transport vehicles are rated for the weight of rebar bundles to avoid structural strain or road hazards.

OSHA Safety Compliance

Follow Occupational Safety and Health Administration (OSHA) standards for steel erection and construction work. Workers handling rebar must wear cut-resistant gloves, steel-toed boots, and eye protection. Use rebar caps on vertical protrusions to prevent impalement hazards. Maintain clear walkways around rebar work areas and implement fall protection when working at heights.

Rebar Installation Standards

Install rebar in Sonotubes according to engineered drawings and local building codes (e.g., International Building Code – IBC). Ensure proper lap splices and tie wire connections meet specified development lengths. Maintain required concrete cover (typically 3 inches for footings) using plastic or concrete spacers. Verify vertical alignment and embedment depth before pouring concrete.

Environmental and Regulatory Compliance

Dispose of rebar offcuts and packaging materials in accordance with local waste management regulations. Recycle scrap metal through certified recycling facilities. If working near waterways, follow EPA guidelines to prevent sediment or metal runoff. Obtain necessary permits for construction activities involving concrete and steel reinforcement.

Documentation and Inspections

Maintain records of rebar mill test reports (certifying steel grade and strength), delivery receipts, and inspection checklists. Schedule third-party or municipal inspections prior to concrete pour to verify rebar placement compliance with approved plans. Keep all documentation on-site for audit purposes.

Conclusion: Sourcing Sonotube Rebar

Sourcing rebar for use with Sonotubes is a critical step in ensuring the structural integrity and longevity of concrete foundation elements such as footings, piers, and columns. After evaluating available options, it is clear that selecting the appropriate rebar grade (typically Grade 60), size (commonly #4 or #5 bars), and proper spacing per engineering specifications is essential. Reliable sourcing involves procuring materials from reputable suppliers—such as local steel suppliers, concrete supply companies, or home improvement stores—to ensure compliance with ASTM standards and project requirements.

Additionally, considering factors like transportation, cost-efficiency, corrosion resistance (especially in moist or corrosive environments), and timely delivery helps streamline construction processes. Pre-cut and pre-fabricated rebar cages can offer labor savings and improved installation accuracy when available. Ultimately, careful planning and sourcing of Sonotube rebar contribute to a safe, durable, and code-compliant structure, minimizing risks of failure and ensuring long-term performance.