The global laser cutting machine market is experiencing robust growth, driven by increasing demand for high-precision fabrication across industries such as automotive, aerospace, and heavy manufacturing. According to Mordor Intelligence, the market was valued at USD 4.78 billion in 2023 and is projected to grow at a CAGR of over 6.5% from 2024 to 2029. This surge is fueled by advancements in fiber laser technology, automation integration, and rising adoption of Industry 4.0 practices. As manufacturers prioritize efficiency, accuracy, and clean cuts in metal processing, solda a laser (laser welding) systems are becoming integral in modern production lines. In this competitive landscape, a select group of manufacturers have emerged as leaders, capturing significant market share through innovation, reliability, and advanced engineering. Below is a data-driven look at the top 10 solda a laser manufacturers shaping the future of industrial manufacturing.

Top 10 Solda A Laser Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Technology & Laser Machines from ALPHA LASER

Website: alphalaser.eu

Key Highlights: As a leading manufacturer of mobile, flexible, and high-performance laser systems for laser welding, laser hardening, powder deposit welding and additive metal ……

#2 Denaliweld

Website: denaliweld.com

Key Highlights: We Specialize in Laser Welding & Cleaning. DenaliWeld INC, is a proud employee-owned fiber laser welding machine manufacturer based in Chicago, USA. Bolstered ……

#3 Solta Medical

Website: solta.com

Key Highlights: Solta Medical is a global leader in the aesthetic industry providing innovative products such as VASERlipo®, VASER® ultrasonic systems, Thermage® radiofrequency ……

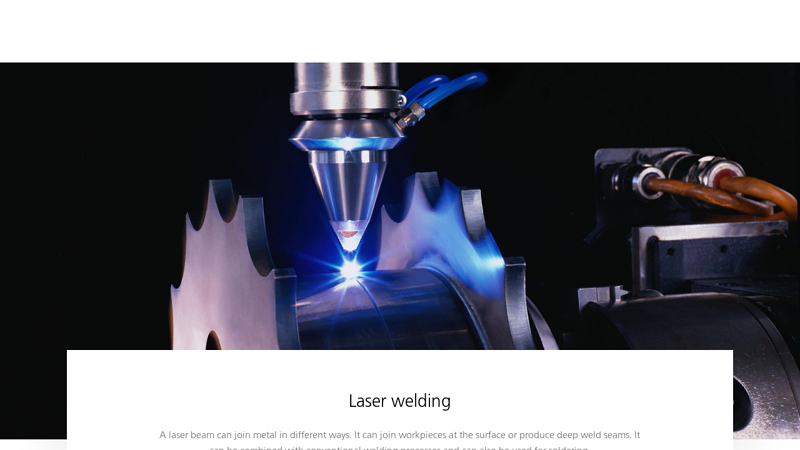

#4 Laser Welding

Website: ipgphotonics.com

Key Highlights: Laser welding is the process of transferring a laser beam’s energy in the form of heat to fuse or join parts. This transferred heat melts the materials to ……

#5 JASIC

Founded: 2005

Website: jasictech.com

Key Highlights: JASIC is a versatile welding solution provider. Founded in 2005, exporting to 80+ countries, stringent quality standards, and innovative technologies….

#6 Orotig: Laser Machinery

Website: orotig.com

Key Highlights: We specialise in engineering and manufacturing laser solutions for welding, engraving, casting and cutting precious and non-precious metals….

#7 Laser welding

Website: trumpf.com

Key Highlights: TRUMPF lasers can create fine weld points of just a millimeter in diameter in an instant, as well as deep-welded seams stretching over several meters….

#8 Portable Laser Welder

Website: fslaser.com

Key Highlights: In stock $1,550 deliveryHandheld laser welding is easy to learn, simple and fast to set up and provides consistent high-quality results across a wide range of materials and ……

#9 Soudronic

Website: soudronic.com

Key Highlights: We provide a complete range of machines and components for the can making industry focusing on three-piece and two-piece can production lines and end making ……

#10 Laser welders for precious metals

Website: sisma.com

Key Highlights: Our range of laser welders for precious metals: integratable sources, manual work bench systems and automatic systems for repetitive work cycles….

Expert Sourcing Insights for Solda A Laser

H2: Market Trends for Solda A Laser in 2026

As the industrial manufacturing and metal fabrication sectors continue to evolve, Solda A Laser, a company specializing in laser welding and cutting solutions, is poised to navigate a dynamic market landscape in 2026. Driven by technological innovation, sustainability imperatives, and shifting global supply chains, several key trends are expected to shape the market environment for laser-based manufacturing solutions.

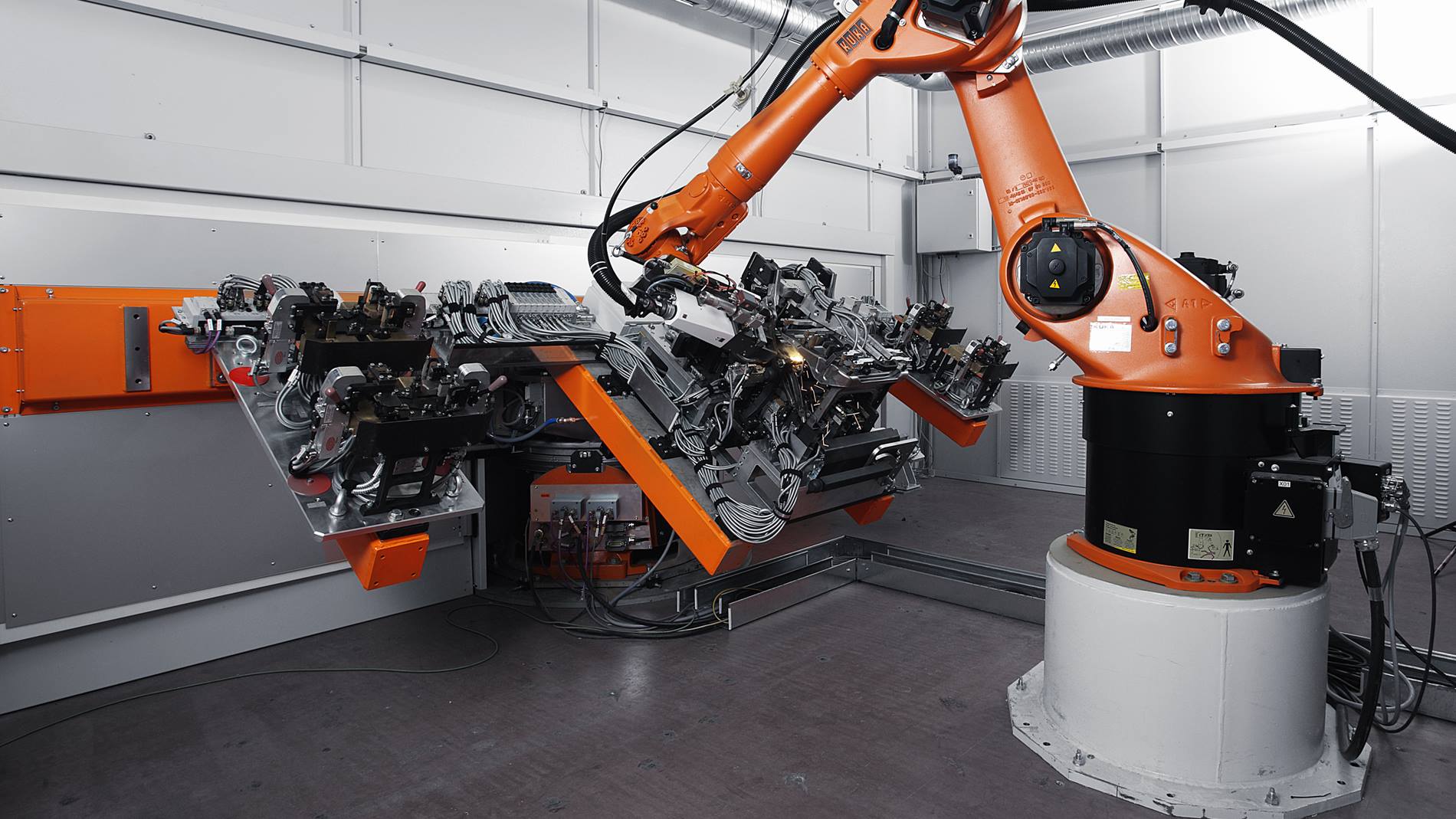

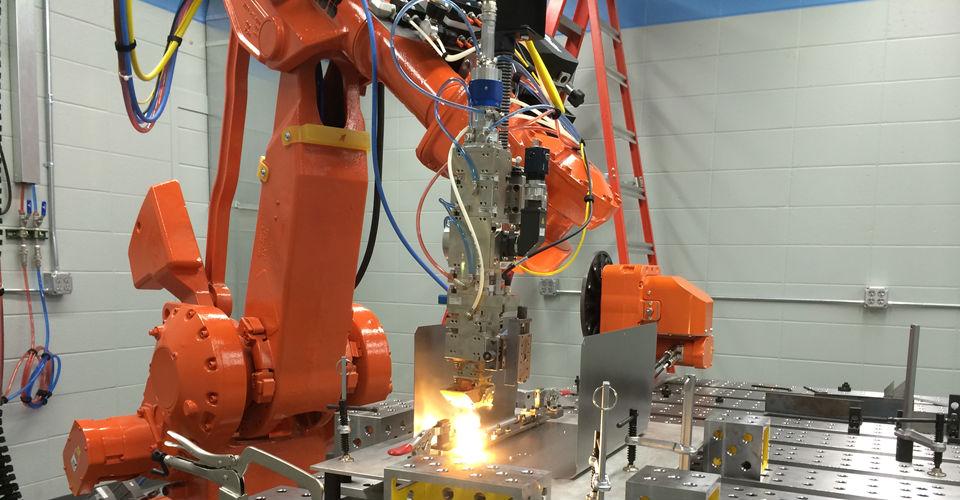

1. Accelerated Adoption of Automation and Industry 4.0 Integration

By 2026, manufacturers across automotive, aerospace, and consumer electronics are increasingly integrating smart, connected systems into production lines. Solda A Laser will benefit from rising demand for automated laser welding cells that interface seamlessly with IoT platforms, AI-driven quality control, and real-time monitoring systems. The push toward predictive maintenance and data-driven process optimization will elevate the value proposition of intelligent laser systems.

2. Growth in Electric Vehicle (EV) and Battery Manufacturing

The global expansion of EV production is a major catalyst for precision laser welding. Solda A Laser is well-positioned to serve Tier 1 suppliers and battery manufacturers requiring high-accuracy, high-speed welding for battery tabs, busbars, and structural components. Trends toward solid-state batteries and cell-to-pack (CTP) designs will further increase demand for reliable, scalable laser solutions.

3. Emphasis on Energy Efficiency and Sustainability

Environmental regulations and corporate ESG goals are pushing industries to adopt cleaner, more energy-efficient processes. Fiber lasers, known for their low power consumption and minimal waste, will see increased adoption. Solda A Laser can leverage this trend by promoting eco-friendly systems with reduced carbon footprints and compliance with EU Green Deal and similar regulations.

4. Regional Manufacturing Reshoring and Nearshoring

Geopolitical tensions and supply chain vulnerabilities have prompted a shift toward localized production in North America and Europe. This reshoring trend creates opportunities for Solda A Laser to supply advanced laser systems to new or expanding domestic fabrication hubs, particularly in the U.S. and Eastern Europe.

5. Advancements in Hybrid and Multi-Function Laser Systems

Customer demand for flexible, multi-tasking equipment is driving innovation in hybrid laser platforms—combining welding, cutting, and additive manufacturing in one system. Solda A Laser can differentiate itself by developing modular systems that adapt to evolving production needs, offering higher ROI for manufacturers.

6. Competitive Pressure and Technological Differentiation

The laser equipment market will remain highly competitive in 2026, with players from China, Germany, and the U.S. vying for market share. To maintain a competitive edge, Solda A Laser must focus on R&D, software integration, and after-sales service, emphasizing reliability, precision, and ease of use.

Conclusion

In 2026, Solda A Laser will operate in a market shaped by digitalization, electrification, and sustainability. By aligning its product development and strategic partnerships with these macro trends—particularly in automation, EVs, and green manufacturing—the company can strengthen its market position and capture growth in high-value industrial sectors.

Common Pitfalls When Sourcing Solder Paste for Laser Soldering (Quality and IP Considerations)

Sourcing high-performance solder paste for laser soldering applications demands careful attention to both material quality and intellectual property (IP) protection. Overlooking these aspects can lead to production failures, legal risks, and compromised product reliability.

Quality-Related Pitfalls

Inadequate Thermal Stability for Laser Processing

Laser soldering involves rapid, localized heating, requiring solder pastes that can withstand high peak temperatures without degrading. Sourcing pastes not specifically formulated for such thermal profiles may result in premature oxidation, flux spattering, inconsistent wetting, or incomplete reflow—leading to weak joints and defects.

Poor Flux Performance Under Fast Heating Cycles

Standard solder pastes may not activate properly under the short dwell times typical of laser soldering. This can cause incomplete oxide removal, poor wetting, and voiding. Sourcing flux systems without verifying compatibility with rapid heating cycles risks unreliable solder joints and reduced yield.

Inconsistent Particle Size and Distribution

Laser soldering often requires precise deposition (e.g., via pin transfer or jetting), which depends on uniform solder powder morphology. Sourcing pastes with inconsistent particle size or agglomeration leads to clogging, uneven volume deposition, and non-uniform joint formation—especially critical in fine-pitch or high-reliability applications.

Lack of Process Validation Data

Suppliers may provide generic data sheets that do not reflect performance under actual laser soldering conditions. Relying solely on standard reflow profiles without laser-specific validation data increases the risk of process instability and field failures.

Intellectual Property-Related Pitfalls

Ambiguous IP Ownership in Custom Formulations

When developing tailored solder pastes for unique laser processes, unclear contractual terms may leave IP rights undefined. This can result in disputes over ownership of formulations, process optimizations, or performance data—potentially limiting your ability to scale or switch suppliers.

Inadequate Protection of Process-Sensitive Specifications

Sharing detailed thermal profiles, laser parameters, or joint design requirements with suppliers without proper non-disclosure agreements (NDAs) or IP clauses exposes proprietary process knowledge. Unprotected disclosures may enable competitors to replicate your technology or weaken your competitive edge.

Risk of Reverse Engineering by Suppliers

Sourcing from low-cost or untrusted suppliers increases the risk of formulation reverse engineering. If the supplier gains access to your paste specifications or usage data, they may replicate and sell similar products to your competitors, especially in regions with weak IP enforcement.

Supply Chain Transparency Gaps

Using third-party toll manufacturers or intermediaries without visibility into the actual production source can compromise IP. Without contractual safeguards, there’s a risk that critical know-how leaks through subcontractors or that formulations are used beyond agreed terms.

By proactively addressing these quality and IP pitfalls—through rigorous supplier vetting, detailed technical validation, and robust legal agreements—companies can ensure reliable performance and maintain control over their proprietary laser soldering processes.

Logistics & Compliance Guide for Solda A Laser

This guide outlines the essential logistics and compliance considerations for the safe handling, transportation, import/export, and regulatory adherence related to the Solda A Laser system.

Shipping & Handling Procedures

Ensure all Solda A Laser units are securely packaged in manufacturer-approved, shock-resistant containers with internal bracing to prevent movement. Use only certified logistics providers experienced in handling precision industrial equipment. Clearly label packages with “Fragile,” “This Side Up,” and “Protect from Moisture” indicators. Maintain a temperature-controlled environment (10°C to 35°C) during transit to prevent condensation and component damage.

Import/Export Regulations

Verify compliance with international trade laws before cross-border shipment. The Solda A Laser may be subject to export controls under national regulations such as the U.S. Export Administration Regulations (EAR) or EU Dual-Use Regulation, depending on technical specifications (e.g., laser class, power output). Obtain necessary export licenses or authorizations where required. Provide accurate Harmonized System (HS) codes and complete commercial documentation, including detailed technical specifications, end-use statements, and end-user certifications.

Laser Safety Compliance

The Solda A Laser must comply with relevant laser safety standards, such as IEC 60825-1 and FDA 21 CFR 1040.10 (if sold in the U.S.). Ensure all units are classified correctly (e.g., Class 1, Class 4) and carry appropriate warning labels. Include user manuals with safety instructions, interlock information, and protective measures. Confirm that installation procedures follow local occupational safety requirements, including controlled access zones and operator training.

Electrical & CE Marking Requirements

Verify that the Solda A Laser meets electromagnetic compatibility (EMC), low voltage (LVD), and machinery safety directives for the target market. Units distributed in the European Economic Area must carry the CE mark, indicating conformity with applicable EU directives. Maintain technical construction files and issue an EU Declaration of Conformity. Ensure power supply compatibility (voltage, frequency) with destination country standards.

Customs Clearance & Documentation

Prepare complete customs documentation including commercial invoice, packing list, bill of lading/air waybill, certificate of origin, and conformity certificates (e.g., CE, FDA). Declare accurate product descriptions and values to prevent delays. For high-value shipments, consider bonded transport or customs brokerage services to expedite clearance. Retain all documentation for a minimum of five years for audit purposes.

End-of-Life & Environmental Responsibility

Comply with environmental regulations such as the EU WEEE Directive for proper end-of-life handling. Provide clear instructions for decommissioning and recycling. Ensure that packaging materials are recyclable and minimize hazardous substances in accordance with RoHS (Restriction of Hazardous Substances) requirements. Offer take-back programs where legally mandated or contractually agreed.

Recordkeeping & Audit Preparedness

Maintain comprehensive records of all shipments, compliance certifications, export licenses, safety testing results, and customer training documentation. Implement a document control system to track revisions and ensure up-to-date compliance. Conduct periodic internal audits to verify adherence to logistics and regulatory standards.

Certainly! Here’s a professional conclusion for sourcing a laser cutter (assuming “solda a laser” refers to a laser welding or laser cutting machine, possibly a typo for “soldadura a láser” – Spanish for laser welding):

Conclusion:

Sourcing a laser cutting or welding machine is a strategic investment that can significantly enhance manufacturing precision, efficiency, and product quality. After evaluating key factors such as cutting/welding requirements, power capacity, automation compatibility, service support, and total cost of ownership, it is essential to select a supplier that offers reliable technology, proven performance, and strong after-sales support. By prioritizing quality, safety, and long-term scalability, companies can integrate laser solutions that drive competitiveness and innovation in their production processes. Careful due diligence in vendor selection and thorough consideration of technical specifications will ensure a successful implementation and a strong return on investment.

Let me know if you meant a specific type of laser equipment (e.g., fiber laser, CO2, for welding vs. cutting) or a particular industry, so I can tailor it further.