The global solar panel optimizer market is experiencing robust growth, driven by rising solar photovoltaic (PV) installations and the increasing need for enhanced energy output and system monitoring. According to a 2023 report by Mordor Intelligence, the solar optimizer market was valued at USD 2.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of over 12.5% from 2023 to 2028. This surge is attributed to advancements in module-level power electronics (MLPE), growing adoption of distributed solar energy systems, and supportive government policies promoting renewable energy integration. As system efficiency and reliability become critical in both residential and commercial applications, solar panel optimizers play a pivotal role in mitigating shading losses, panel mismatch, and soiling effects. With key players innovating in digitalization and smart monitoring capabilities, the competitive landscape is evolving rapidly. In this dynamic environment, the following nine manufacturers have emerged as leaders, combining technological innovation, global reach, and strong performance metrics to shape the future of solar energy optimization.

Top 9 Solar Panel Optimizer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Power optimizer solutions

Domain Est. 1999

Website: infineon.com

Key Highlights: Infineon enables power optimizer manufacturers by offering optimized, efficient solutions for single-panel and multi-panel optimizer designs….

#2 Trinasolar

Domain Est. 2004

Website: trinasolar.com

Key Highlights: Trinasolar tops Wood Mackenzie’s Global Solar Module Manufacturer Ranking for H1 2025 · Trinasolar, a global leader in smart PV and energy storage solutions ……

#3 Manage risks and maximize ROI for your PV and energy storage …

Domain Est. 2012

Website: sinovoltaics.com

Key Highlights: On-site PV factory audits, quality inspections, and laboratory tests. Implement Zero Risk Solar and secure your solar quality supply chain….

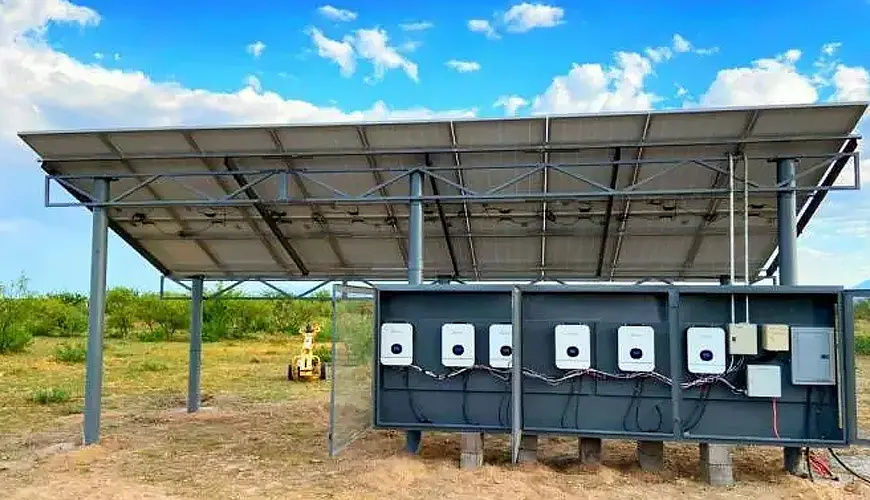

#4 Solis

Domain Est. 2018

Website: solisinverters.com

Key Highlights: Solis is one of the world’s largest and most experienced manufacturers of solar inverters supplying products globally for multinational utility companies, ……

#5 SolarEdge

Domain Est. 2005

Website: solaredge.com

Key Highlights: And with our patented Power Optimizers attached to every module on the roof, businesses can see 10% more power over the system’s lifetime. Learn more….

#6 Tigo Energy

Domain Est. 2007

Website: tigoenergy.com

Key Highlights: Increase the energy output from your solar installation, improve visibility and enhance safety with Tigo Energy’s reliable & flexible MLPE solutions….

#7 Fluence

Domain Est. 2017

Website: fluenceenergy.com

Key Highlights: Fluence offers energy storage products that are optimized for common customer applications but can be configured for specific use cases and requirements….

#8 Fox ESS

Domain Est. 2019

Website: fox-ess.com

Key Highlights: Fox ESS offers all-in-one solar energy systems for homes and businesses … Constant Innovation and Meticulous Manufacturing to Build trust with Every Delivery….

#9

Domain Est. 2023

Website: talonpv.com

Key Highlights: LECO Laser-Enhanced Contact Optimization … TALON PV is incorporating LECO into our current equipment adding a 0.50-0.75% efficiency increase. Better contact ……

Expert Sourcing Insights for Solar Panel Optimizer

H2: 2026 Market Trends for Solar Panel Optimizers

By 2026, the solar panel optimizer market is poised for significant transformation, driven by technological advancements, evolving market demands, and supportive policy landscapes. Key trends shaping the sector include:

-

Accelerated Adoption Driven by Module-Level Power Electronics (MLPE) Demand:

- Growth in Complex Installations: The surge in rooftop solar, especially on residential and commercial buildings with shading issues, complex roof geometries, and varying panel orientations, will fuel demand for optimizers. They remain the dominant MLPE solution for maximizing energy harvest in these suboptimal conditions.

- Safety Regulations (Rapid Shutdown): Stringent global safety codes (like NEC 690.12 in the US) mandating rapid shutdown at the module level will continue to be a primary driver. Optimizers inherently provide this functionality, making them essential for compliance, further solidifying their market position.

-

Integration of Advanced Monitoring and Smart Features:

- Enhanced Data Analytics: Optimizers will evolve beyond basic DC optimization to become sophisticated data hubs. Expect deeper integration with cloud platforms, providing granular, real-time performance monitoring per module, predictive maintenance alerts (e.g., identifying underperforming modules or potential faults), and detailed energy production reporting for system owners and O&M providers.

- AI and Machine Learning: AI-driven analytics will leverage optimizer data to optimize system performance dynamically, predict energy yield more accurately, and automate troubleshooting, reducing O&M costs and maximizing ROI.

- Grid Interaction & VPP Enablement: Optimizers will play a crucial role in enabling smarter grid integration. Features like dynamic voltage regulation, reactive power support, and seamless communication with inverters and grid operators will be essential for supporting grid stability and enabling participation in Virtual Power Plants (VPPs).

-

Technological Convergence and Competition:

- Blurring Lines with Microinverters: The functional gap between optimizers (DC-DC) and microinverters (DC-AC) will narrow. Optimizer manufacturers will focus on improving efficiency, reliability, and communication capabilities, while microinverter players may adopt similar monitoring and control features. Competition will intensify, focusing on total system cost, reliability, and feature sets.

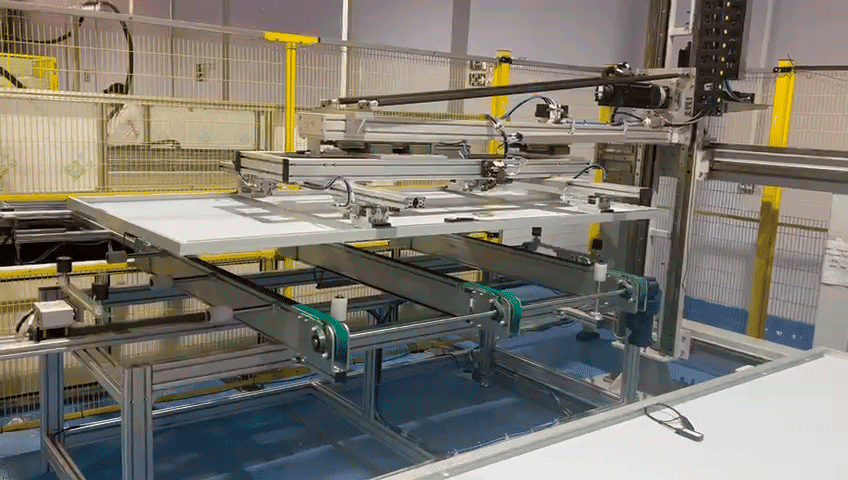

- Increased Efficiency and Power Density: Continuous R&D will push for higher conversion efficiencies (>99%) and more compact, lighter designs, reducing material costs and simplifying installation.

- Focus on Reliability and Longevity: As systems age, proven long-term reliability (25+ year warranties) and resistance to environmental stresses (heat, humidity) will be critical differentiators. Manufacturers will invest heavily in robust component selection and thermal management.

-

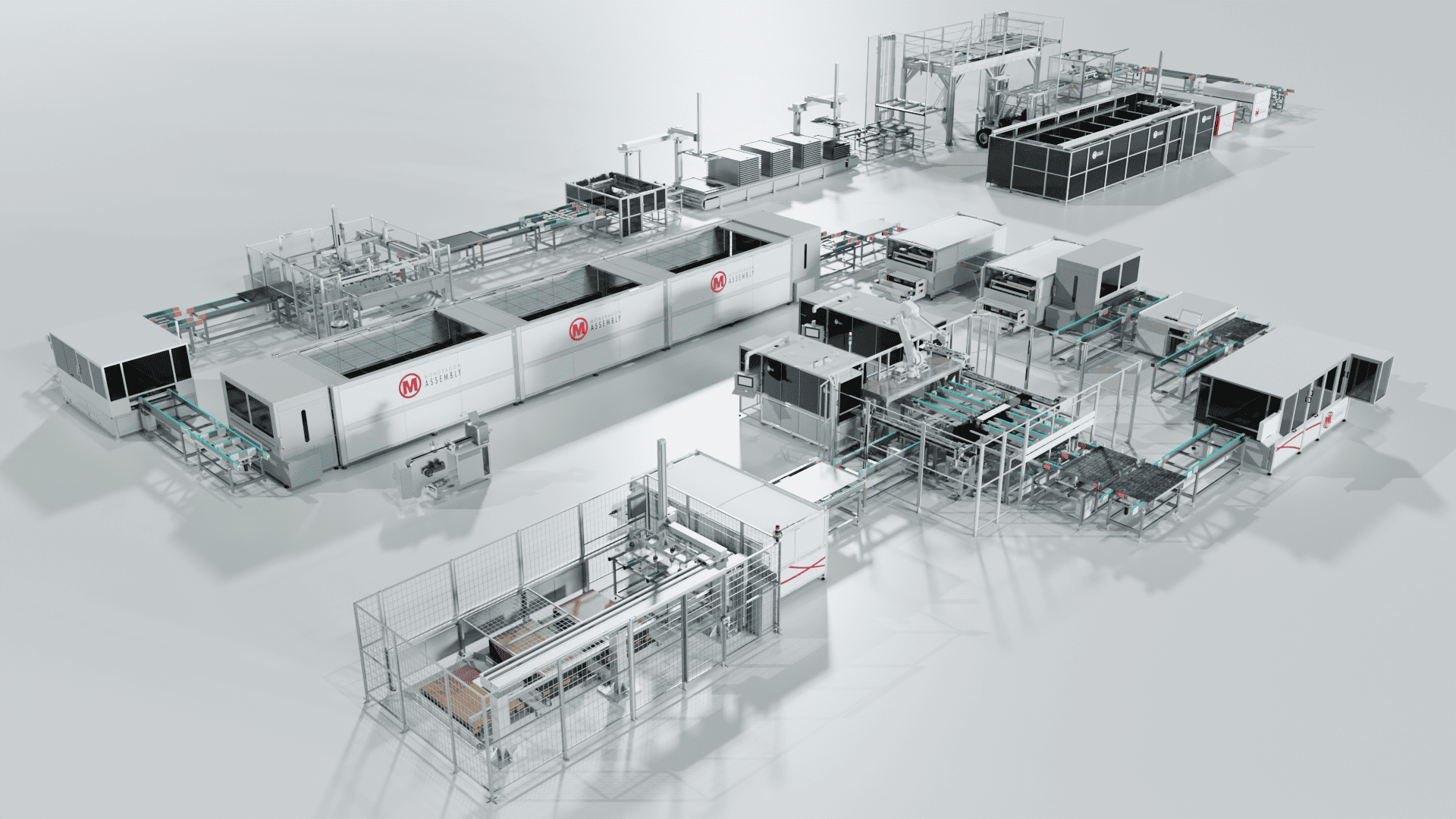

Cost Reduction and Market Expansion:

- Economies of Scale & Manufacturing Advancements: Increased global production volumes and manufacturing efficiencies (e.g., automation, improved supply chains) will drive down the $/W cost of optimizers, making MLPE solutions more accessible in price-sensitive markets.

- Expansion into Emerging Markets: As solar adoption grows in regions like Southeast Asia, Latin America, and parts of Africa, demand for cost-effective, reliable optimizers to handle diverse installation challenges will rise. Localized manufacturing or partnerships may emerge.

- Residential & C&I Focus: While utility-scale adoption remains limited due to cost sensitivity, the residential and commercial & industrial (C&I) segments will remain the primary growth engines for optimizers.

-

Sustainability and Supply Chain Focus:

- Circular Economy & Recycling: Growing emphasis on sustainability will push manufacturers to design for recyclability, use more sustainable materials, and establish take-back programs for end-of-life optimizers.

- Supply Chain Resilience: Geopolitical factors and past disruptions will lead to increased efforts to diversify component sourcing (especially semiconductors) and build more resilient, transparent supply chains.

In summary, by 2026, the solar panel optimizer market will be characterized by: Mature technology driven by regulatory mandates and complex installation needs, evolving into intelligent data platforms with advanced monitoring, AI, and grid-support features. While facing intensifying competition from microinverters, continuous cost reduction and improved reliability will solidify its crucial role in maximizing energy harvest and safety, particularly in the dominant residential and C&I sectors globally. Sustainability and supply chain resilience will become increasingly important competitive factors.

Common Pitfalls When Sourcing Solar Panel Optimizers (Quality and Intellectual Property)

Sourcing solar panel optimizers involves navigating complex technical, quality, and legal challenges. Overlooking key aspects related to product quality and intellectual property (IP) can lead to performance issues, financial losses, and legal liabilities. Below are common pitfalls to avoid:

Quality-Related Pitfalls

1. Selecting Based on Price Alone

Focusing solely on the lowest-cost optimizer often results in substandard components, reduced efficiency, and shorter lifespans. Low-cost units may use inferior semiconductors, inadequate heat dissipation, or poor encapsulation, increasing failure rates under real-world conditions.

2. Lack of Third-Party Certification

Optimizers must comply with international safety and performance standards (e.g., UL 1741, IEC 62109, IEC 61683). Sourcing from suppliers lacking these certifications risks system instability, safety hazards, and difficulty obtaining regulatory approvals or insurance.

3. Inadequate Environmental Durability Testing

Optimizers are exposed to extreme temperatures, humidity, UV radiation, and mechanical stress. Suppliers without rigorous environmental testing (e.g., salt mist, thermal cycling, damp heat) may deliver products prone to premature failure, especially in harsh climates.

4. Poor Integration and Compatibility

Not all optimizers work seamlessly with every inverter or monitoring platform. Choosing a unit without verifying compatibility with existing or planned system components can lead to communication failures, reduced system efficiency, and increased commissioning time.

5. Insufficient Warranty and Support

A long warranty (typically 10–25 years) is standard for high-quality optimizers. Suppliers offering short warranties or lacking technical support infrastructure may indicate low product confidence or unreliable after-sales service.

Intellectual Property-Related Pitfalls

1. Sourcing from IP-Infringing Suppliers

Many optimizer designs are protected by patents (e.g., on power electronics topology, communication protocols, or mounting mechanisms). Using products that infringe on existing IP—intentionally or not—can expose buyers to legal action, product recalls, or import bans.

2. Lack of Transparency in IP Ownership

Suppliers may not disclose whether their technology is licensed, developed in-house, or copied from competitors. Without clear documentation or legal assurances, buyers risk entanglement in IP disputes initiated by original patent holders.

3. Counterfeit or Grey Market Products

Unverified suppliers may offer “compatible” or “clone” optimizers that mimic branded products. These often violate IP rights and lack quality control, leading to performance issues and voided system warranties.

4. Inadequate Due Diligence on Supplier IP Status

Failing to conduct legal or technical due diligence—such as patent landscape analysis or supplier audits—can result in procurement of infringing technology. This is especially critical when sourcing from low-cost regions with weaker IP enforcement.

5. Contractual Gaps in IP Indemnification

Purchase agreements should include clauses where the supplier indemnifies the buyer against IP infringement claims. Omitting such protections leaves the buyer financially and legally vulnerable if third-party litigation arises.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Prioritize suppliers with recognized certifications and proven field performance.

– Conduct technical audits and request reliability test reports.

– Verify IP ownership and request written indemnification.

– Engage legal counsel to review supplier contracts and IP disclosures.

– Work with reputable distributors or directly with established manufacturers.

Proactively addressing quality and IP concerns ensures long-term system reliability, legal compliance, and return on investment in solar installations.

Logistics & Compliance Guide for Solar Panel Optimizers

This guide outlines key logistics and compliance considerations for the international shipment and deployment of solar panel optimizers. Adhering to these guidelines ensures smooth transportation, regulatory approval, and market access.

Regulatory Compliance

Ensure solar panel optimizers comply with regional and international safety, performance, and environmental standards. Key certifications include:

- IEC 62109: Safety of power converters for use in photovoltaic power systems.

- IEC 61727: Grid interface characteristics for photovoltaic systems.

- UL 1741: Standard for inverters, converters, and controllers for use in distributed energy systems (required in the U.S.).

- CE Marking: Required for sale in the European Economic Area (EEA), indicating compliance with EU directives such as the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive.

- RoHS and REACH: Compliance with restrictions on hazardous substances (RoHS) and chemical registration (REACH) in the EU.

- FCC Part 15 (U.S.): Electromagnetic interference (EMI) requirements.

Verify country-specific certifications (e.g., KC for South Korea, RCM for Australia, INMETRO for Brazil) before distribution.

Packaging and Labeling

Optimize packaging to protect devices during transit while complying with international shipping standards:

- Use anti-static, shock-absorbent materials to safeguard sensitive electronics.

- Clearly label packages with:

- Product name and model number

- Input/output electrical specifications

- Compliance marks (e.g., CE, UL, RoHS)

- Handling symbols (e.g., “Fragile,” “This Side Up”)

- Barcodes or QR codes for traceability

Ensure multilingual labeling where required by destination markets.

International Shipping and Customs

Prepare accurate documentation to facilitate customs clearance:

- Commercial invoice detailing product description, value, quantity, and harmonized system (HS) code (typically 8504.40 or 8543.70 for power converters/electronic controllers).

- Packing list

- Certificate of Origin

- Test reports and compliance certificates

Classify optimizers correctly under the Harmonized System to avoid delays or duty miscalculations. Work with freight forwarders experienced in renewable energy equipment.

Import Regulations and Duties

Research import regulations, tariffs, and potential exemptions in target markets:

- Some countries offer reduced or zero tariffs on solar components under green energy initiatives (e.g., U.S. Section 301 exclusions, EU’s GSP).

- Maintain records of component origin for preferential tariff treatment under free trade agreements.

Environmental and End-of-Life Compliance

Adhere to environmental regulations governing product lifespan and disposal:

- Comply with WEEE (Waste Electrical and Electronic Equipment) Directive in the EU, which mandates producer responsibility for collection and recycling.

- Implement take-back or recycling programs where legally required.

- Provide disposal instructions to end users.

Documentation and Recordkeeping

Maintain comprehensive records for at least five years, including:

- Product test reports and certification documents

- Technical specifications and user manuals

- Shipping and customs documentation

- Supplier compliance attestations (e.g., conflict minerals, REACH)

Proper documentation supports audits, recalls, and regulatory inquiries.

In-Field Compliance and Monitoring

Ensure ongoing compliance after deployment:

- Monitor regulatory updates in operating regions.

- Provide software/firmware updates to maintain safety and performance standards.

- Train installers on correct handling, grounding, and system integration to meet local electrical codes (e.g., NEC in the U.S., IEC in Europe).

Adhering to this logistics and compliance framework minimizes risks, ensures market access, and supports the sustainable deployment of solar panel optimizers worldwide.

Conclusion for Sourcing Solar Panel Optimizers

After a comprehensive evaluation of technical requirements, supplier capabilities, cost considerations, and long-term performance, sourcing solar panel optimizers emerges as a strategic decision to enhance the efficiency, reliability, and scalability of photovoltaic systems. Optimizers play a critical role in mitigating power losses due to shading, panel mismatch, and soiling, thereby maximizing energy yield and improving return on investment.

Key factors such as compatibility with existing inverters, warranty terms, ease of monitoring and maintenance, and proven field performance must guide the selection process. Engaging with reputable suppliers offering certified, high-quality products—backed by strong technical support and service networks—ensures system longevity and meets project sustainability goals.

Ultimately, sourcing the right solar panel optimizer not only boosts energy production but also future-proofs solar installations in dynamic environmental and regulatory landscapes. A well-informed procurement strategy, aligned with project-specific needs and industry best practices, will deliver optimal performance, reduce downtime, and support the broader transition to resilient, clean energy systems.