The global solar panel mounting systems market is experiencing robust growth, driven by rising solar installations and increasing demand for efficient, durable rooftop energy solutions. According to Mordor Intelligence, the market was valued at USD 16.2 billion in 2023 and is projected to grow at a CAGR of over 6.8% through 2029. This expansion is fueled by government incentives, declining solar technology costs, and a global shift toward renewable energy. As rooftop solar adoption accelerates—especially in residential and commercial sectors—the need for high-quality, reliable solar panel mounts has never been greater. For roof manufacturers, integrating compatible, code-compliant mounting systems is now a strategic imperative. In this data-driven landscape, selecting the right mounting solution impacts installation speed, structural integrity, and long-term system performance. Below, we analyze the top 10 solar panel mounts tailored for roof manufacturers, evaluating each on load capacity, compatibility, ease of integration, and compliance with evolving building standards.

Top 10 Solar Panel Mounts For Roof Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Solar PV mounting systems for every roof!

Domain Est. 2012

Website: roof-tech.us

Key Highlights: Roof Tech Inc brings you the most innovative, waterproof mounting systems ever developed for solar photovoltaic systems. We offer versatile PV mounting ……

#2 APA Solar

Domain Est. 2021

Website: apasolar.com

Key Highlights: APA Solar is a leading U.S.-based solar racking manufacturer specializing in engineered foundation and mounting solutions for commercial and utility-scale ……

#3 Unirac: World

Domain Est. 1999

Website: unirac.com

Key Highlights: Better Solar Starts Here with Unirac. We Make World-Class Solar Mounting & Racking Solutions and Provide Everything You Need to Make Solar Happen….

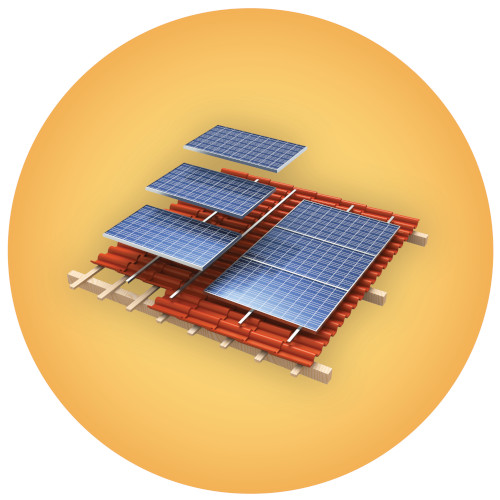

#4 Solar Roof Mounting System

Domain Est. 2000

Website: clenergy.com

Key Highlights: Clenergy PV-ezRack SolarRoof Tile is a robust and universal tile roof solar mounting system which is built with high-strength aluminum and stainless steel….

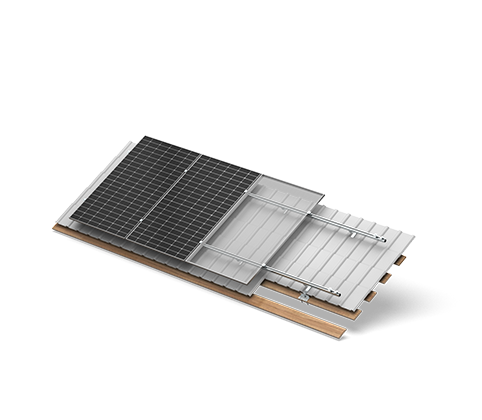

#5

Domain Est. 2007

Website: k2-systems.com

Key Highlights: With K2 Systems mounting systems, you can make strong and enduring connections for almost all roof types. We are also happy to find the right solutions together ……

#6 SnapNrack

Domain Est. 2008

Website: snapnrack.com

Key Highlights: Say goodbye to fumbling with T-bolts and rail hardware! With our innovative Clamp Mounts, all of our roof attachments come rail-ready right out of the box….

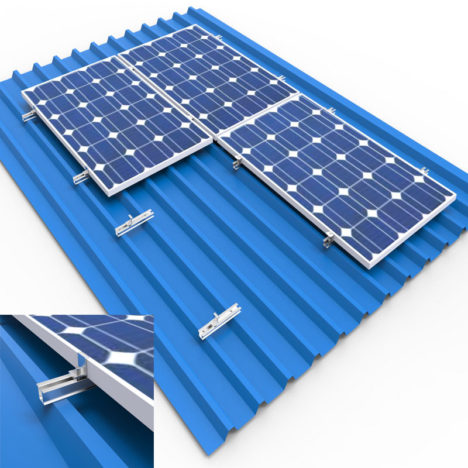

#7 Antai Solar

Domain Est. 2010

Website: antaisolar.com

Key Highlights: Antaisolar’s roof mounting systems provide secure, lightweight solutions for all roof types – including metal, tile, concrete, TPO, BIPV, and balconies….

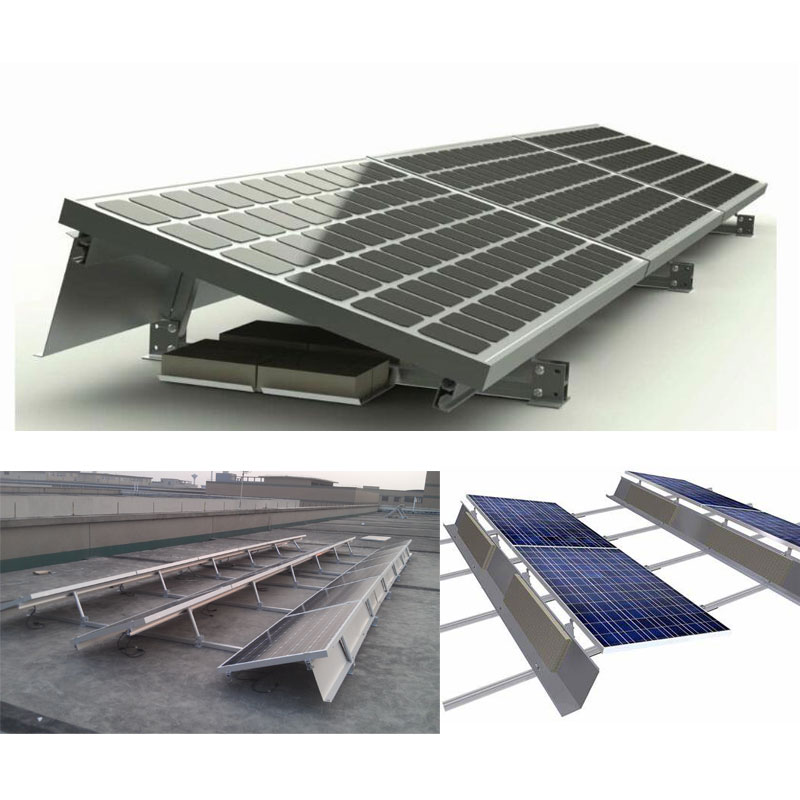

#8 Flat Roof System

Domain Est. 2010

Website: dynoraxx.com

Key Highlights: Our state-of-the-art fiberglass solar mounting system features a toolless, universal design for easier, faster, and more profitable solar panel installations….

#9 Solar Stack:

Domain Est. 2013

Website: solarstack.com

Key Highlights: Solar Stack is an innovative and damage-free solar panel mounting system that revolutionizes the way solar panels are installed on roofs….

#10

Domain Est. 2015

Website: tamaracksolar.com

Key Highlights: Tamarack Solar Products manufactures innovative solar module mounting structures that are designed to install quickly and provide a secure mounting….

Expert Sourcing Insights for Solar Panel Mounts For Roof

H2: 2026 Market Trends for Solar Panel Mounts for Roof

As the global transition toward renewable energy accelerates, the market for solar panel mounts for roofs is poised for significant evolution by 2026. Driven by technological innovation, policy support, and shifting consumer demand, several key trends are shaping the future of rooftop solar mounting systems.

-

Increased Demand for Lightweight and Adaptable Mounting Systems

By 2026, manufacturers are prioritizing lightweight mounting solutions made from advanced materials such as aluminum alloys and composite polymers. These materials reduce structural load on rooftops, expand installation eligibility to older or less robust buildings, and simplify transport and handling. Modular and adjustable designs are becoming standard, allowing mounts to fit diverse roof types—tile, metal, shingle, and flat roofs—without custom fabrication. -

Integration with Building-Integrated Photovoltaics (BIPV)

Building-integrated solar mounting systems are gaining traction, especially in urban and residential construction. By 2026, more roof mounts are being designed as structural components themselves—replacing traditional roofing materials with solar-integrated tiles or panels. This trend reduces visual impact, improves aesthetics, and streamlines installation, appealing to homeowners and architects alike. -

Smart Mounting Systems with Monitoring and Optimization

The incorporation of IoT-enabled sensors into mounting structures is emerging as a key innovation. By 2026, smart mounts can monitor tilt angle, wind load, temperature, and panel alignment in real time. Some systems automatically adjust panel orientation (in limited tracking applications) to maximize energy yield. These data-driven features improve system efficiency and enable predictive maintenance. -

Focus on Rapid Installation and Labor Cost Reduction

With labor constituting a significant portion of solar installation costs, manufacturers are developing clip-based, tool-free, and pre-assembled mounting systems. By 2026, plug-and-play solutions that reduce installation time by 30–50% are becoming mainstream. This trend is supported by standardized rail systems and compatibility with leading panel brands, increasing installer adoption. -

Growth in Emerging Markets and Residential Segments

While commercial and industrial rooftops remain major markets, residential installations are expected to dominate growth by 2026—especially in regions like Southeast Asia, Latin America, and Africa. Governments are introducing subsidies and net metering policies, increasing affordability. Mounting systems tailored for small-scale, DIY-friendly installations are expanding market reach. -

Sustainability and Recyclability of Mounting Materials

Environmental concerns are driving demand for recyclable and low-carbon mounting solutions. By 2026, manufacturers are increasingly using recycled aluminum and implementing take-back programs for end-of-life mounts. Certifications such as EPDs (Environmental Product Declarations) are becoming competitive differentiators. -

Regulatory and Safety Standards Evolution

Stricter building codes and wind/snow load requirements in regions prone to extreme weather are shaping design standards. By 2026, mounting systems must comply with updated international certifications (e.g., IEC, UL, AS/NZS) and demonstrate resilience under diverse climatic conditions. Fire safety integration—such as improved ventilation and non-combustible components—is also a priority. -

Consolidation and Innovation in Supply Chains

The mounting systems market is seeing consolidation among suppliers, with larger players acquiring niche innovators. At the same time, digital supply chain tools—like AI-driven inventory management and 3D modeling for site-specific designs—are improving efficiency and reducing lead times.

In conclusion, the 2026 market for rooftop solar panel mounts is defined by smarter, lighter, and more sustainable solutions that enhance installation speed, system performance, and aesthetic integration. As solar adoption grows globally, mounting systems are evolving from passive supports into intelligent, value-adding components of the overall energy ecosystem.

Common Pitfalls When Sourcing Solar Panel Mounts for Roof (Quality, IP)

Sourcing solar panel roof mounts involves more than just selecting a low-cost option—overlooking critical quality and intellectual property (IP) factors can lead to long-term performance issues, safety hazards, and legal risks. Here are key pitfalls to avoid:

Poor Material Quality and Corrosion Resistance

Using substandard materials, such as low-grade aluminum or inadequate anti-corrosion coatings, can result in premature degradation—especially in coastal or high-humidity environments. Mounts that fail to meet international standards (e.g., IEC 61215, IEC 61730) may compromise structural integrity, leading to system failure or roof damage. Always verify material specifications and request salt spray test reports (e.g., ASTM B117) for corrosion resistance.

Inadequate Load and Wind Resistance Ratings

Many low-cost mounts lack proper engineering validation for local wind, snow, and seismic loads. Sourcing mounts without region-specific certifications (e.g., UL 2703 in the U.S. or AS/NZS 1170 compliance in Australia) can result in system failure during extreme weather. Ensure mounts are tested and rated for your project’s geographic and climatic conditions.

Non-Compliance with IP (Ingress Protection) Standards

Roof mounts must protect against dust and moisture ingress, especially at connection points and grounding interfaces. Mounts lacking proper IP65 or IP68 ratings for associated clamps and grounding components risk electrical faults and reduced system lifespan. Confirm that the entire mounting system, including accessories, meets appropriate IP ratings.

Counterfeit or IP-Infringing Products

Sourcing from unverified suppliers increases the risk of counterfeit mounts that mimic reputable brands. These copies often lack proper testing and may infringe on patented designs (e.g., unique grounding mechanisms or rail profiles). Using such products can expose installers and developers to legal liability and void equipment warranties. Always source from authorized distributors and verify product authenticity through manufacturer documentation.

Lack of Traceability and Certification Documentation

Reputable solar mounts come with full traceability—batch numbers, test reports, and compliance certificates. Suppliers who cannot provide documentation may be selling uncertified or non-compliant products. This absence of traceability complicates warranty claims and can jeopardize project approvals from utilities or inspectors.

Insufficient Warranty and After-Sales Support

Low-cost mounts often come with limited or unenforceable warranties. Without reliable after-sales support, resolving issues like part failures or design incompatibilities becomes difficult. Prioritize suppliers offering minimum 10–12-year product warranties and responsive technical support.

Avoiding these pitfalls requires due diligence: verify certifications, inspect samples, audit suppliers, and prioritize long-term reliability over initial cost savings.

Logistics & Compliance Guide for Solar Panel Mounts for Roof

Product Classification & HS Code

Solar panel roof mounts typically fall under HS Code 7610.90 (Aluminum structures and parts thereof) or 7308.90 (Structures of iron or steel and parts thereof). Confirm the exact classification based on material composition to ensure accurate customs clearance and tariff application.

Import Regulations & Documentation

Ensure compliance with destination country regulations by preparing essential documents: commercial invoice, packing list, bill of lading/air waybill, certificate of origin, and product conformity certificates (e.g., CE, UL, or TÜV). Some markets may require additional technical specifications or engineering drawings.

Transportation & Packaging Requirements

Use robust, weather-resistant packaging to prevent damage during transit. Secure mounts on pallets with protective wrapping and corner boards. Label packages clearly with handling instructions (e.g., “Fragile,” “This Side Up”). Choose freight modes (sea, air, or land) based on shipment size, urgency, and cost efficiency.

Customs Clearance & Duties

Provide accurate product descriptions, declared value, and applicable tariffs at customs. Be aware of anti-dumping or countervailing duties in some regions. Engage a licensed customs broker to facilitate timely clearance and avoid delays.

Regulatory & Safety Standards

Ensure mounts comply with local building codes and structural safety standards (e.g., IBC, ASCE 7 in the U.S., Eurocode in Europe). Verify load ratings for wind, snow, and seismic conditions specific to installation regions. Mounts must support relevant certifications indicating compliance with mechanical and corrosion resistance standards.

Environmental & RoHS Compliance

Confirm that materials used (e.g., aluminum, stainless steel, coatings) meet RoHS (Restriction of Hazardous Substances) requirements, especially for shipments to the EU. Provide material declarations upon request to demonstrate environmental compliance.

Installation & User Documentation

Include multilingual installation manuals with clear diagrams, torque specifications, and safety warnings. Ensure documentation addresses regional installation practices and complies with local regulatory language requirements.

Warranty & After-Sales Support

Define warranty terms clearly and ensure logistics for spare parts and replacements are in place. Maintain records of shipped batches to support product traceability and compliance audits.

In conclusion, sourcing solar panel mounts for rooftop installations requires careful consideration of several key factors, including roof type, structural integrity, local weather conditions, material durability, and compliance with building codes and standards. Selecting high-quality, corrosion-resistant mounts—typically made from aluminum or stainless steel—ensures long-term reliability and performance. It is essential to choose mounting solutions that offer flexibility in installation, ease of maintenance, and compatibility with your chosen solar panels. Additionally, working with reputable suppliers or manufacturers, obtaining professional installation, and considering warranties can significantly impact the efficiency and lifespan of your solar energy system. Ultimately, a well-sourced and properly installed mounting system is a critical foundation for maximizing energy output, ensuring safety, and achieving a strong return on investment in solar technology.