The global solar textiles market is gaining significant momentum, driven by increasing demand for wearable technology, off-grid energy solutions, and sustainable materials across defense, outdoor, and fashion sectors. According to Mordor Intelligence, the Smart Textiles Market—which includes solar-integrated fabrics—is projected to grow at a CAGR of over 28% from 2024 to 2029. This surge is fueled by advancements in flexible photovoltaic technology and rising investments in energy-harvesting textiles. As innovations make solar fabrics more efficient, lightweight, and scalable, a handful of manufacturers are emerging as leaders in commercializing this transformative material. Below, we spotlight the top four solar fabric manufacturers pioneering this niche at the intersection of renewable energy and advanced textiles.

Top 4 Solar Fabric Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Solar fabric manufacturer

Domain Est. 2004

Website: sunscreen-mermet.com

Key Highlights: For 70 years, Mermet has been designing and manufacturing hi-tech fabrics to provide visual and thermal comfort to building occupants….

#2 Solar Fabric

Domain Est. 2005

Website: solarfabric.com

Key Highlights: Pvilion is at the forefront of solar fabric technology. Pvilion products range from stand-alone solar canopies, solar military tents, grid-tied long span ……

#3

Domain Est. 2021

Website: solar-textile.com

Key Highlights: SOLARTEXTILE, put your trust in solar power with us. The proven mamutec technology with a touch of sustainability….

#4 Solar Cloth

Domain Est. 2020

Website: solar-cloth.com

Key Highlights: A high quality photovoltaic textile: lightweight, foldable, furlable, and ‘Made in France’. It has already crossed oceans, breached the atmosphere and is ……

Expert Sourcing Insights for Solar Fabric

H2: Market Trends for Solar Fabric in 2026

By 2026, the solar fabric market is poised for significant growth and transformation, driven by advancements in photovoltaic (PV) technology, rising demand for sustainable energy solutions, and increasing integration of solar materials into diverse industries such as architecture, fashion, transportation, and consumer electronics. Solar fabric—textiles embedded with flexible solar cells capable of converting sunlight into electricity—is emerging as a key innovation in the broader renewable energy landscape.

-

Technological Advancements and Efficiency Improvements

By 2026, solar fabric technologies are expected to achieve notable improvements in energy conversion efficiency, driven by innovations in organic photovoltaics (OPVs), perovskite solar cells, and dye-sensitized solar cells (DSSCs). These thin-film technologies are being engineered for flexibility, lightweight properties, and durability under mechanical stress—making them ideal for integration into textiles. Efficiency rates for commercial solar fabrics could reach 15–18%, up from around 10–12% in earlier generations, narrowing the gap with traditional silicon-based solar panels. -

Expansion into Building-Integrated Photovoltaics (BIPV)

The construction sector is increasingly adopting solar fabric for façades, awnings, curtains, and roofing materials. By 2026, solar textiles are projected to play a critical role in smart building ecosystems, contributing to net-zero energy buildings and urban sustainability goals. Governments and municipalities offering incentives for green construction are accelerating this trend, particularly in Europe and parts of Asia. -

Growth in Wearable and Portable Applications

The wearable technology market is a major growth driver for solar fabric. By 2026, outdoor apparel, military gear, backpacks, and emergency shelters are expected to incorporate solar textiles to power integrated devices such as GPS trackers, health monitors, and communication tools. The defense and outdoor recreation sectors are leading early adoption due to the off-grid power advantages solar fabrics provide. -

Automotive and Transportation Integration

Automotive manufacturers are exploring solar fabric for use in convertible tops, sunroofs, and interior surfaces to supplement electric vehicle (EV) battery charging and power auxiliary systems. Prototype vehicles and concept cars featuring solar-integrated textiles are expected to enter limited production by 2026, especially in hybrid and solar-assisted EV models. -

Sustainability and Circular Design

With growing emphasis on circular economy principles, solar fabric developers are focusing on recyclability, reduced environmental impact during production, and non-toxic materials. By 2026, certifications such as Cradle to Cradle and EU Ecolabel are likely to become standard for premium solar textile products, influencing consumer and B2B purchasing decisions. -

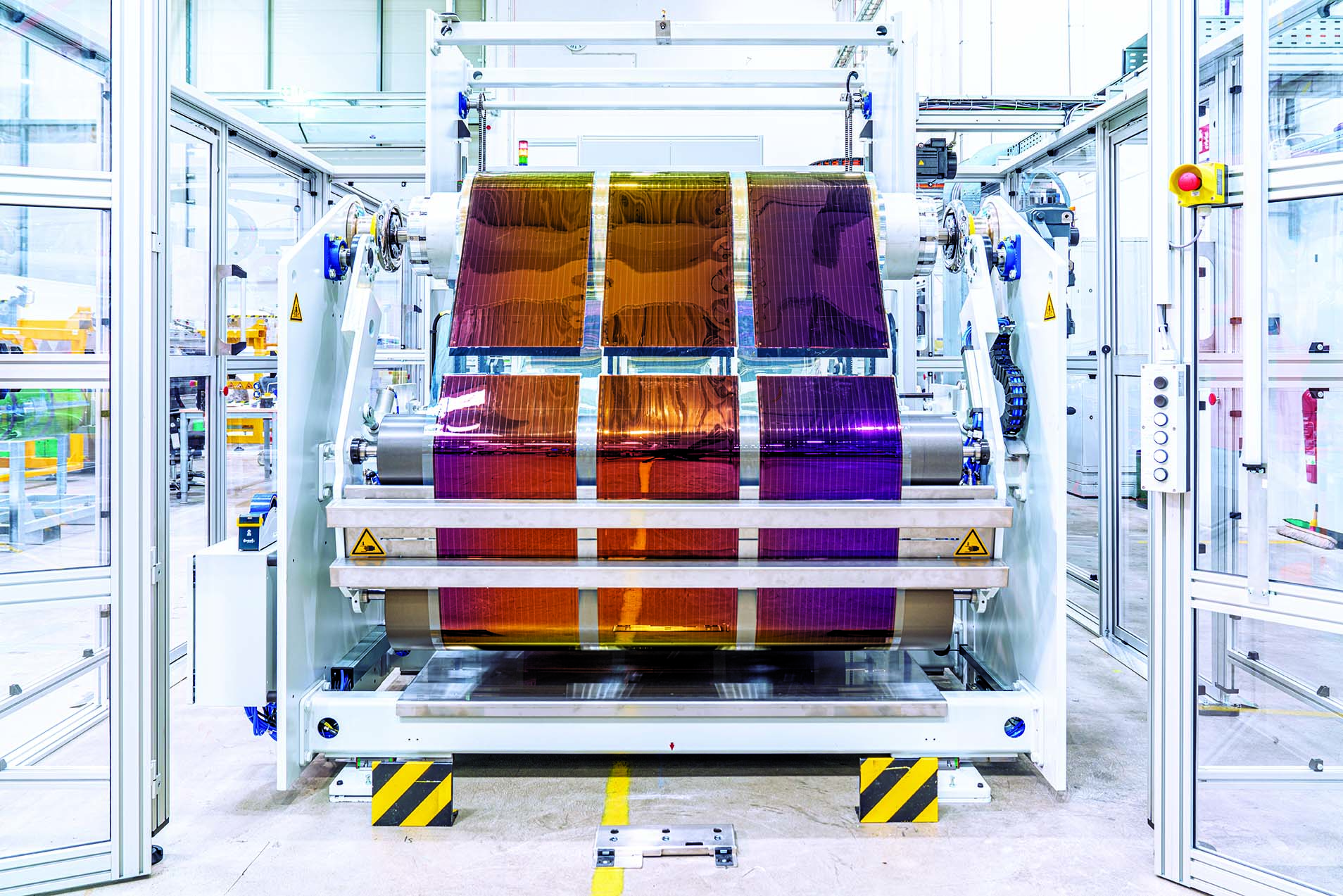

Cost Reduction and Scalability

Manufacturing processes such as roll-to-roll printing and large-scale textile coating are reducing production costs. As a result, solar fabric is becoming more economically viable for mass-market applications. By 2026, prices are projected to decline by 30–40% compared to 2022 levels, encouraging broader commercialization. -

Regulatory Support and Investment

Government policies promoting renewable energy and clean technology innovation—especially under initiatives like the European Green Deal and U.S. Inflation Reduction Act—are expected to boost R&D funding and public-private partnerships in solar fabric development. Venture capital and green tech investment are also flowing into startups specializing in energy-harvesting textiles. -

Challenges to Address

Despite progress, challenges remain, including long-term durability under UV exposure, washing resistance (for wearable applications), and energy storage integration. Standardization and safety regulations for electrical textiles are still evolving and may impact deployment speed in consumer markets.

Conclusion

By 2026, solar fabric is expected to transition from niche innovation to a commercially viable and scalable renewable energy solution. Its convergence with smart materials, IoT, and sustainable design principles positions it as a transformative technology across multiple sectors. With continued investment, regulatory support, and technological refinement, the global solar fabric market is projected to grow at a CAGR of over 25% through 2026, signaling a bright future for energy-generating textiles.

Common Pitfalls in Sourcing Solar Fabric: Quality and Intellectual Property Risks

Sourcing solar fabric—a hybrid material integrating photovoltaic cells into textiles or flexible substrates—offers exciting opportunities for renewable energy applications in architecture, wearables, and portable systems. However, buyers often encounter significant challenges related to quality consistency and intellectual property (IP) protection. Being aware of these pitfalls is crucial to ensuring reliable performance and avoiding legal complications.

Quality Inconsistencies and Performance Variability

One of the most prevalent issues in sourcing solar fabric is inconsistent product quality. Unlike standardized rigid solar panels, solar fabrics are often custom-engineered and produced in low volumes, leading to variability in:

-

Efficiency and Power Output: Small deviations in material composition, coating thickness, or cell integration can drastically affect energy conversion efficiency. Suppliers may quote optimistic lab-scale performance figures that aren’t replicable in real-world conditions or mass production.

-

Durability and Environmental Resistance: Solar fabrics must endure UV exposure, moisture, mechanical stress (e.g., folding, stretching), and temperature fluctuations. Poorly manufactured fabrics may delaminate, suffer from reduced conductivity, or degrade quickly when exposed to outdoor elements.

-

Material Homogeneity: Inconsistent lamination, uneven distribution of conductive materials, or misalignment of solar cells across the fabric can lead to hotspots, reduced lifespan, or outright failure.

Buyers should insist on third-party testing reports, request production samples under real-world conditions, and verify quality control processes before scaling up procurement.

Intellectual Property (IP) Risks and Infringement Concerns

Solar fabric technology often involves complex IP portfolios, including patents on cell integration methods, conductive textile designs, encapsulation techniques, and manufacturing processes. Key IP-related pitfalls include:

-

Unlicensed Technology Use: Some suppliers—particularly smaller or offshore manufacturers—may use patented technologies without proper licensing. Sourcing from such vendors exposes buyers to potential infringement claims, recalls, or legal liability.

-

Lack of IP Transparency: Suppliers may be unwilling or unable to disclose the origin of their technology, raising red flags about the legitimacy and freedom-to-operate of the product.

-

Custom Development Ambiguity: When co-developing a solar fabric solution, unclear IP ownership agreements can lead to disputes over rights to the design, improvements, or manufacturing know-how.

To mitigate these risks, conduct thorough due diligence on the supplier’s IP portfolio, require documentation of licensing agreements, and establish clear contractual terms regarding IP ownership and usage rights before entering into agreements.

Logistics & Compliance Guide for Solar Fabric

Overview

Solar fabric, a flexible photovoltaic material that integrates solar cells into textile substrates, presents unique opportunities and challenges in logistics and compliance. This guide outlines essential considerations for the safe, efficient, and legally compliant transportation, storage, and handling of solar fabric products across the supply chain.

Packaging Requirements

Solar fabric is sensitive to moisture, UV exposure, mechanical stress, and electrostatic discharge. Proper packaging is critical to preserve performance and safety.

– Use moisture-barrier vacuum-sealed bags with desiccants to prevent humidity damage.

– Employ rigid outer containers (corrugated or plastic) to prevent creasing, folding, or punctures.

– Include anti-static liners or packaging materials to protect electronic components.

– Clearly label packages with “Fragile,” “This Side Up,” “Protect from Moisture,” and “Do Not Fold.”

Storage Conditions

Optimal storage extends the shelf life and maintains the integrity of solar fabric.

– Store in a clean, dry, temperature-controlled environment (15°C to 25°C recommended).

– Avoid direct sunlight and high-humidity areas (relative humidity < 60%).

– Keep rolls or sheets flat or vertically supported to prevent deformation.

– Limit storage duration; follow manufacturer’s shelf-life recommendations (typically 6–12 months).

Transportation Guidelines

Ensure safe handling during domestic and international shipping.

– Use climate-controlled transport for long-distance or extreme climate routes.

– Secure loads to prevent shifting, rolling, or compression during transit.

– Avoid stacking heavy items on top of solar fabric shipments.

– For air freight, comply with IATA Dangerous Goods Regulations if batteries or energy storage components are included.

Regulatory Compliance

Solar fabric may be subject to multiple international and regional regulations due to its electronic and chemical components.

– REACH & RoHS (EU): Ensure compliance with restrictions on hazardous substances (e.g., lead, cadmium, phthalates). Maintain documentation for substance declarations.

– REACH SVHC: Declare any substances of very high concern above threshold levels.

– WEEE Directive (EU): Provide take-back and recycling instructions for end-of-life products.

– UL, IEEE, or IEC Standards: Meet electrical safety and performance standards (e.g., IEC 61215 for PV modules).

– Customs & Import Regulations: Provide accurate HS codes (e.g., 8541.40 for photovoltaic modules), Certificates of Conformity, and safety data sheets (SDS) where applicable.

Safety & Handling Procedures

Personnel must follow protocols to protect both the product and themselves.

– Use gloves to prevent skin oils from degrading surface coatings.

– Ground equipment and personnel to avoid electrostatic discharge (ESD).

– Do not cut, puncture, or modify solar fabric without manufacturer approval.

– Train staff on emergency procedures for damaged or leaking components (e.g., exposed circuitry or chemicals).

Documentation & Traceability

Maintain comprehensive records throughout the supply chain.

– Include batch numbers, manufacturing dates, and test certifications with each shipment.

– Provide compliance documentation (RoHS, REACH, safety certifications) to customers and regulators upon request.

– Implement a traceability system to track materials from production to delivery.

End-of-Life & Sustainability

Plan for responsible disposal and recycling.

– Partner with certified e-waste recyclers familiar with PV materials.

– Inform customers of proper disposal channels and recycling programs.

– Design for disassembly where possible to support circular economy goals.

Conclusion

Effective logistics and compliance management are vital for the successful deployment of solar fabric. By adhering to these guidelines, stakeholders can ensure product reliability, regulatory adherence, and environmental responsibility throughout the product lifecycle. Always consult the manufacturer’s specifications and local regulations for project-specific requirements.

Conclusion for Sourcing Solar Fabric

Sourcing solar fabric represents a forward-thinking approach to integrating renewable energy into versatile, lightweight, and innovative applications. As demand for sustainable and energy-efficient materials grows across industries such as architecture, wearable technology, transportation, and outdoor gear, solar fabric emerges as a promising solution that combines functionality with eco-conscious design.

Effective sourcing requires careful consideration of key factors including efficiency, durability, flexibility, cost, and scalability. Partnering with reputable manufacturers and technology providers who offer proven performance, quality certifications, and customization options is crucial to ensuring long-term success. Additionally, staying informed about emerging advancements in photovoltaic technologies—such as organic solar cells and perovskite-based fabrics—can open doors to more efficient and affordable solutions in the near future.

In conclusion, while challenges remain in terms of efficiency optimization and production costs, the potential of solar fabric to revolutionize energy harvesting in everyday surfaces is undeniable. With strategic sourcing, collaboration, and innovation, businesses and designers can leverage solar fabric to create sustainable, energy-generating products that meet the demands of a greener, more resilient world.