The global snack food market continues to expand rapidly, with soft pretzels emerging as a key segment driven by consumer demand for convenient, savory snacks. According to Grand View Research, the global pretzel market was valued at USD 5.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing snackification trends, innovation in flavors and packaging, and rising retail and e-commerce distribution channels. As consumer preferences lean toward indulgent yet affordable snack options, soft pretzel manufacturers are scaling production, investing in automation, and expanding product lines to meet demand across grocery, convenience, and foodservice sectors. In this competitive landscape, a select group of companies has risen to the forefront through strong brand recognition, nationwide distribution, and consistent product quality. Below, we highlight the top 10 soft pretzel manufacturers shaping the industry today.

Top 10 Soft Pretzel Companies Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Philly Pretzel Factory

Domain Est. 2005

Website: phillypretzelfactory.com

Key Highlights: Philly Pretzel Factory prides itself on being the go-to snack that everyone loves! All of our pretzels are made with the highest quality ingredients….

#2 Wetzel’s Pretzels

Domain Est. 1996

Website: wetzels.com

Key Highlights: Hand rolled, hand crafted & fresh squeezed ingredients with a dash of innovative deliciousness – so you can grab a little happiness….

#3 J&J Snack Foods

Domain Est. 1996

Website: jjsnack.com

Key Highlights: We take fun seriously! That means we really nerd out on what makes pretzels soft, why frozen treats inspire wonder, and how to make the most buzzworthy baked ……

#4 Freshly Baked Soft Pretzels

Domain Est. 1998

Website: auntieannes.com

Key Highlights: Auntie Anne’s is known for hand-baked pretzels to be enjoyed with a refreshing lemonade. Visit our website to stay up-to-date on current news & events!…

#5 Pretzelmaker

Domain Est. 1999

Website: pretzelmaker.com

Key Highlights: Pretzelmaker is the innovator of Pretzel Bites – made from scratch before your eyes with a recipe uniquely our own down to the dough….

#6 Tom Sturgis Pretzels

Domain Est. 2000

Website: tomsturgispretzels.com

Key Highlights: America’s First Commercial Pretzel Bakery – Tom Sturgis Pretzels – for crunchy, delicious stone-hearth baked pretzels….

#7 Julius Sturgis Pretzel Bakery

Domain Est. 2007

Website: juliussturgis.com

Key Highlights: The Julius Sturgis Pretzel Bakery is located in historic Lititz, Pennsylvania, in the middle of beautiful Pennsylvania Dutch Country….

#8 All Products

Domain Est. 2014

Website: thepretzelcompany.com

Key Highlights: Free deliveryAll Products · The Signature Box · The Twisted Perfection Box · The Triple Twist Box · The Braid Box · White Sharp Cheddar Spread · Legendary Favorites Combo Box · The…

#9 The Bavarian Pretzel Company

Domain Est. 2021

Website: bavarianpretzelcompany.com

Key Highlights: $0.01 deliveryOur all-natural Bavarian soft pretzels are made without preservatives, so to ensure they arrive fresh and delicious, orders shipped to California, Oregon, ……

#10 DC Pretzel Company

Domain Est. 2021

Website: dcpretzelcompany.com

Key Highlights: Our “baked to order”, soft pretzels and pretzel rolls are made individually using high quality ingredients. Each pretzel variety follows a precisely formulated ……

Expert Sourcing Insights for Soft Pretzel Companies

H2: 2026 Market Trends for Soft Pretzel Companies

As the soft pretzel market navigates the evolving consumer landscape of 2026, companies face a dynamic environment shaped by shifting tastes, economic pressures, and technological advancements. Building on the foundational trends of health consciousness and convenience, several key developments are emerging to define the competitive landscape.

1. Premiumization & Flavor Innovation (H3):

The demand for artisanal and gourmet offerings continues to intensify. Consumers in 2026 are seeking unique, high-quality ingredients and global flavor profiles. Soft pretzel companies are responding with:

* Savory Expansion: Umami-rich flavors like truffle, miso, smoked paprika, and gochujang are gaining traction, moving beyond traditional salt and mustard.

* Sweet-Savory Hybrids: Combinations such as sea salt & dark chocolate, honey-cinnamon crunch, or maple-bacon cater to adventurous palates.

* Clean Label Premium Ingredients: Emphasis on organic flours, non-GMO ingredients, and natural flavorings is essential for premium positioning. Artisanal branding and transparent sourcing are key differentiators.

2. Health & Wellness Integration (H3):

Despite being a baked good, soft pretzels are adapting to health-centric demands:

* Functional Additions: Integration of protein (e.g., pea or whey), fiber (inulin, chicory root), and plant-based nutrients appeals to health-focused consumers.

* Alternative Base Formulations: Growth in gluten-free (using rice, almond, or oat flour blends), low-carb/keto-friendly (almond flour, psyllium), and whole grain options continues to expand market reach.

* Reduced Sodium & Simple Ingredients: Clear labeling with fewer, recognizable ingredients and reduced sodium levels are becoming table stakes, especially in retail.

3. Expansion of Distribution Channels (H3):

Beyond traditional mall kiosks and stadiums, 2026 sees strategic diversification:

* Grocery & Convenience Retail: Frozen and refrigerated soft pretzels with improved quality are dominating supermarket bakery aisles and convenience store microwaves. Private label and co-manufacturing are growing.

* E-Commerce & Direct-to-Consumer (DTC): Subscription models, online snack boxes, and branded e-commerce platforms allow companies to reach national audiences with fresh, premium products and build customer loyalty.

* Foodservice Partnerships: Collaborations with fast-casual restaurants, coffee shops, and meal kit services for pretzel buns, dippers, or dessert components are increasing.

4. Sustainability & Ethical Sourcing (H3):

Environmental and social responsibility are no longer optional:

* Packaging Innovation: Investment in compostable, recyclable, or reusable packaging solutions is accelerating to meet consumer and regulatory expectations.

* Supply Chain Transparency: Companies are prioritizing traceable, ethically sourced ingredients and reducing carbon footprints through localized production and efficient logistics.

* Waste Reduction: Initiatives targeting zero waste in production and minimizing food waste through donations or upcycling are becoming standard practice.

5. Automation & Operational Efficiency (H3):

To combat labor shortages and inflationary pressures, investment in technology is critical:

* Smart Kiosks & Self-Service: Automated pretzel vending and self-service stations with digital ordering are expanding in high-traffic areas, reducing labor costs.

* AI in Production & Forecasting: AI-driven demand forecasting, automated mixing and shaping systems, and predictive maintenance optimize production efficiency and reduce waste.

* Data Analytics: Leveraging customer data from digital platforms to inform product development, marketing, and inventory management.

Conclusion (H2):

The 2026 soft pretzel market is defined by convergence: the convergence of indulgence and wellness, tradition and innovation, physical and digital retail. Success will belong to companies that embrace premiumization without sacrificing accessibility, leverage technology for efficiency, and embed sustainability into their core operations. Agility, authentic branding, and a relentless focus on evolving consumer values—particularly health, experience, and ethics—will be the key differentiators in this competitive and flavorful market.

Common Pitfalls When Sourcing Soft Pretzel Companies: Quality and Intellectual Property Risks

Sourcing soft pretzel suppliers can be a strategic move for foodservice operators, retailers, or private-label brands. However, several critical pitfalls—particularly around quality consistency and intellectual property (IP)—can undermine success if not carefully managed.

Quality Inconsistency and Lack of Standardization

One of the most common challenges is ensuring consistent product quality across batches and production runs. Soft pretzels are sensitive to variations in ingredients, dough handling, boiling time, baking conditions, and seasoning application. Sourcing from suppliers without robust quality control (QC) systems can lead to inconsistent texture (e.g., too dense or too dry), uneven browning, or inconsistent flavor. Additionally, some manufacturers may cut costs by using lower-grade flour, artificial preservatives, or inconsistent salt/specialty seasoning blends, affecting taste and consumer satisfaction. Without clear specifications and regular audits, brands risk damaging their reputation due to subpar or unpredictable product quality.

Hidden Ingredient and Allergen Risks

Soft pretzels often contain common allergens like wheat, dairy (in butter coatings), and soy. Sourcing from facilities with poor allergen control practices increases the risk of cross-contamination, leading to undeclared allergens on packaging—a serious compliance and safety issue. Suppliers may not always disclose full ingredient traceability or may change formulations without notice, especially if they serve multiple clients. This lack of transparency can expose the buyer to regulatory penalties and consumer health risks.

Intellectual Property Infringement and Recipe Ownership

A significant but often overlooked pitfall involves intellectual property. When developing a private-label or branded pretzel product, companies may assume they own the recipe or unique formulation they commission. However, unless explicitly outlined in a contract, the supplier may retain ownership of the recipe, process, or even packaging design. This can prevent the buyer from switching manufacturers easily or using the formulation elsewhere. Worse, some suppliers may reuse similar recipes across multiple clients, diluting the brand’s uniqueness or inadvertently creating infringement risks if the recipe closely resembles a patented or trademarked product.

Lack of Scalability and Production Transparency

Many soft pretzel manufacturers, especially smaller or regional ones, may lack the infrastructure to scale production reliably. Seasonal demand spikes or unexpected growth can expose limitations in capacity, logistics, or cold chain management. Additionally, opaque supply chains—where sourcing of key ingredients (e.g., organic flour, kosher salt) isn’t fully disclosed—can conflict with brand values around sustainability, clean labeling, or certifications. Without site visits or third-party audits, buyers may overestimate a supplier’s capabilities.

Inadequate Contractual Protections

Verbal agreements or weak contracts often fail to address critical issues like minimum order quantities, delivery timelines, rejection criteria for off-spec products, or IP rights. Without clear terms, resolving disputes over quality failures or recipe ownership becomes difficult and costly. Including detailed specifications, audit rights, and IP assignment clauses in sourcing agreements is essential to protect the buyer’s interests.

By proactively addressing these pitfalls—through rigorous supplier vetting, comprehensive contracts, and ongoing quality monitoring—companies can ensure a reliable, high-quality, and legally secure soft pretzel supply chain.

Logistics & Compliance Guide for Soft Pretzel Companies

Supply Chain & Ingredient Sourcing

Soft pretzel companies must establish reliable supply chains for core ingredients such as flour, yeast, salt, baking soda, and specialty items like flavored seasonings or cheese toppings. Sourcing should prioritize suppliers with strong food safety certifications (e.g., SQF, BRCGS) and consistent quality standards. Maintaining documentation for ingredient traceability—including lot numbers, origin, and delivery records—is essential for compliance and rapid response during recalls.

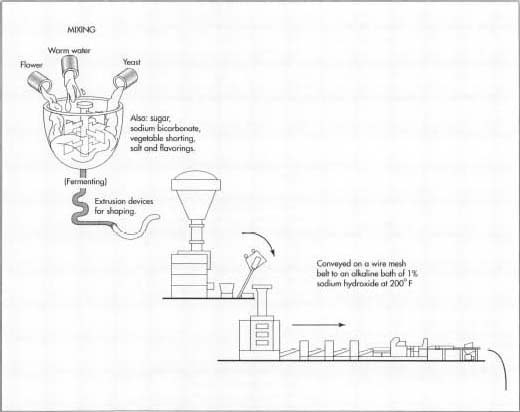

Production Facility Requirements

Production facilities must comply with FDA’s Current Good Manufacturing Practices (cGMPs) outlined in 21 CFR Part 110. This includes proper sanitation protocols, pest control, employee hygiene training, and facility design that prevents cross-contamination. All equipment used in mixing, shaping, boiling, baking, and packaging must be food-grade and regularly maintained. Facilities producing allergen-containing products (e.g., dairy, eggs, gluten) must implement strict allergen control programs.

Food Safety & HACCP Plan

A Hazard Analysis and Critical Control Points (HACCP) plan is mandatory for identifying, evaluating, and controlling food safety hazards. Soft pretzel manufacturers must conduct hazard analysis for biological (e.g., Listeria, Salmonella), chemical (e.g., cleaning agents), and physical (e.g., metal fragments) risks. Critical Control Points (CCPs), such as boiling temperature and baking time, must be monitored, recorded, and verified to ensure product safety.

Packaging & Labeling Compliance

All soft pretzel packaging must include FDA-compliant labels with: product name, ingredient list (in descending order by weight), allergen declarations (e.g., “Contains: Wheat, Dairy”), net weight, name and address of the manufacturer, and the Nutrition Facts panel. If making health or nutrient content claims (e.g., “low fat”), compliance with FDA guidelines in 21 CFR Part 101 is required. Labels must be accurate, legible, and not misleading.

Temperature Control & Cold Chain Management

For refrigerated or frozen soft pretzels, strict temperature control is essential. Products must be cooled rapidly post-bake and stored, transported, and distributed within required temperature ranges (e.g., ≤40°F for refrigerated, ≤0°F for frozen). Temperature logs must be maintained throughout the distribution chain to prevent spoilage and ensure compliance with the FDA Food Code and customer specifications.

Transportation & Distribution

All carriers must be certified as food-grade and follow Sanitary Transportation Practices under the FDA’s Sanitary Transportation of Human and Animal Food rule (21 CFR Part 1, Subpart D). Vehicles must be inspected for cleanliness and proper refrigeration functionality before loading. Bills of lading and delivery records should include temperature data and timestamps to verify chain-of-custody and regulatory compliance.

Regulatory Registrations & Inspections

Soft pretzel manufacturers must register their food facility with the FDA under the Food Safety Modernization Act (FSMA). Annual renewals are required. Facilities are subject to FDA inspections to verify compliance with cGMPs, HACCP, and FSMA preventive controls. State and local health department permits may also be necessary depending on the location of operations.

Recall Preparedness & Traceability

Companies must have a written recall plan that includes procedures for identifying affected batches, notifying customers and regulators, and retrieving products from the market. Full traceability—from raw materials to finished goods—must be maintained through a robust lot coding system and recordkeeping. Mock recalls should be conducted annually to test the effectiveness of the plan.

Allergen Management

Given that soft pretzels commonly contain wheat, dairy, and eggs, allergen control is critical. Prevent cross-contact through dedicated production lines, thorough cleaning between runs, and validated sanitation procedures. Allergen labeling must be accurate and prominently displayed on packaging. Staff must be trained on allergen risks and handling protocols.

Recordkeeping & Documentation

Maintain records for a minimum of two years (or longer if specified by regulation), including: HACCP monitoring logs, supplier approvals, training records, sanitation schedules, temperature logs, and customer complaints. Digital recordkeeping systems are recommended to improve accuracy and audit readiness.

Export & International Compliance

For companies distributing internationally, compliance with destination country regulations is required. This may include EU Novel Foods regulations, Canadian Safe Food for Canadians Regulations (SFCR), or other local standards. Exporters must ensure labeling meets foreign language and nutritional labeling requirements and may need to obtain Certificates of Free Sale or export certificates from the FDA.

In conclusion, sourcing soft pretzel companies requires a strategic evaluation of product quality, production capacity, ingredient sourcing, compliance standards, distribution capabilities, and cost-effectiveness. By prioritizing suppliers with a proven track record of consistency, food safety certifications (such as SQF or BRC), and scalability, businesses can ensure a reliable supply chain that meets both consumer expectations and operational needs. Additionally, considering factors like customization options, sustainability practices, and responsiveness in communication can further strengthen long-term partnerships. Ultimately, a well-researched and thoughtful selection process will support brand integrity, drive customer satisfaction, and contribute to overall business success in the competitive snack food market.