The global 3D printing filament market is experiencing robust expansion, driven by rising adoption across industries such as automotive, healthcare, and consumer goods. According to a 2023 report by Mordor Intelligence, the market is projected to grow at a CAGR of over 20% from 2023 to 2028, fueled by advancements in material science and increasing demand for eco-friendly printing solutions. Soft PLA, a biodegradable and user-friendly thermoplastic, has emerged as a preferred choice for hobbyists and professionals seeking ease of printing, reduced warping, and improved layer adhesion. With sustainability becoming a key purchasing driver, Grand View Research reported in 2022 that the biopolymers segment—which includes PLA—is expected to expand at a CAGR of 14.5% through 2030. As demand for high-quality, consistent Soft PLA filament rises, manufacturers are innovating to deliver enhanced flexibility and print reliability. Below are the top 10 Soft PLA filament manufacturers leading this evolution through material performance, production scalability, and strong customer feedback.

Top 10 Soft Pla Filament Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Fiberlogy

Domain Est. 2015

Website: fiberlogy.com

Key Highlights: European 3D filament manufacturer for professionals and enthusiasts. PLA, PETG, ABS, ASA, Flex. Tested materials, consistent quality….

#2 SliceWorx Official Store

Domain Est. 2021

Website: sliceworx.com

Key Highlights: Free delivery 30-day returnsSliceWorx is a manufacturer of high quality desktop 3D printers and premium 3D printer filaments like PLA, TPU, ABS, PETG, ASA and PLA Wood and Carbon F…

#3 All 3D Printing Materials

Domain Est. 2008

Website: flashforge.com

Key Highlights: Free deliveryDiscover flexible 3D printer filament in various materials and colours. Shop PLA filament like HS PLA, PLA Basic, PLA Pro and more for reliable prints….

#4 High

Domain Est. 2012

#5 Flexible Soft PLA (1KG)

Domain Est. 2012

#6 Polymaker

Domain Est. 2013

Website: polymaker.com

Key Highlights: Polymaker is an international team passionate about 3D printing. We produce the very best 3D printing materials by controlling every stage of production….

#7 Protopasta Brand 3D Printer Filament

Domain Est. 2013

#8 HATCHBOX

Domain Est. 2015

#9 Overture

Domain Est. 2019

#10 Flexible 3D Printing Filament

Domain Est. 2019

Expert Sourcing Insights for Soft Pla Filament

Market Trends for Soft PLA Filament in 2026

By 2026, the market for Soft PLA (Polylactic Acid) filament is poised for significant growth and transformation, driven by advances in material science, expanding applications, and heightened consumer and industrial demand for sustainable 3D printing solutions. This analysis explores key trends shaping the soft PLA filament market in the coming years.

Rising Demand for Flexible and User-Friendly 3D Printing Materials

One of the most prominent trends driving the soft PLA market is the growing preference for flexible yet easy-to-print materials. Traditional flexible filaments like TPU can be challenging for beginners due to stringing, oozing, and retraction issues. Soft PLA, engineered to offer moderate flexibility (typically 60A–85A Shore hardness) while maintaining PLA’s ease of use, bridges the gap between rigid PLA and highly elastic TPU. By 2026, this balance is expected to attract hobbyists, educators, and small manufacturers seeking plug-and-play flexibility without complex printer calibration.

Expansion in Consumer and Educational Applications

Soft PLA is increasingly finding use in consumer goods such as phone cases, wearable prototypes, toys, and artistic models. Its non-toxic, biodegradable nature makes it ideal for educational environments and home use. By 2026, integration into STEM curricula and maker spaces will likely accelerate, supported by simplified printing profiles and compatibility with low-cost desktop 3D printers. This democratization of flexible printing will broaden the user base and stimulate recurring filament sales.

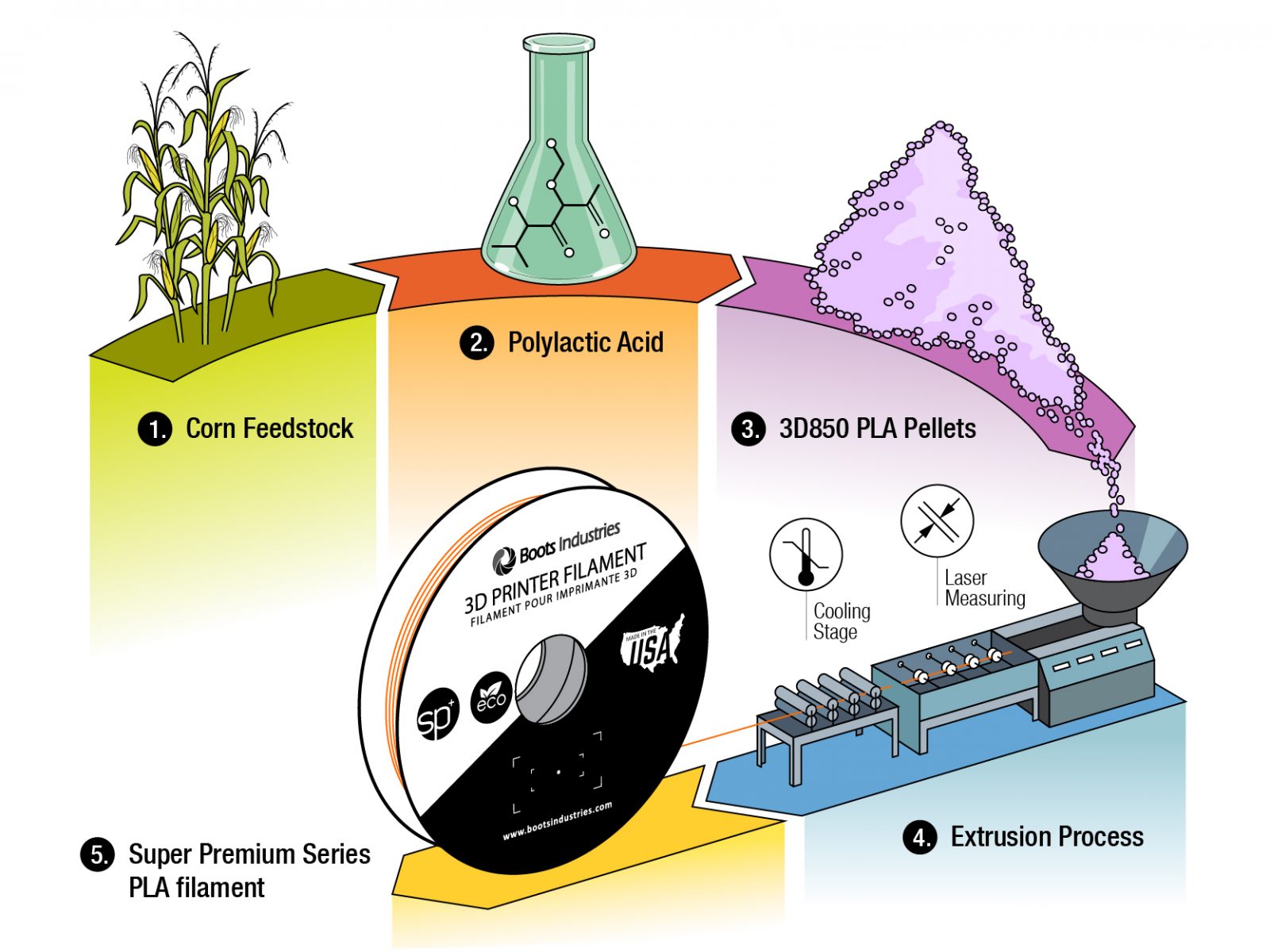

Sustainability and Eco-Conscious Consumerism

As global emphasis on circular economies and reduced plastic waste intensifies, soft PLA’s bio-based and compostable properties position it favorably. Unlike petroleum-based TPEs or TPUs, soft PLA is derived from renewable resources such as corn starch or sugarcane. In 2026, eco-labeling, carbon footprint disclosures, and certifications (e.g., OK Compost, ASTM D6400) will become key differentiators. Manufacturers adopting sustainable production practices and transparent supply chains will gain competitive advantage, especially in environmentally regulated markets like the EU and North America.

Innovation in Material Blends and Performance Enhancement

Ongoing R&D efforts are expected to yield advanced soft PLA formulations that improve durability, UV resistance, and interlayer adhesion. By 2026, hybrid materials combining PLA with bio-based plasticizers or nanocomposites will offer enhanced performance while preserving printability. These innovations will expand applications into semi-functional parts, such as gaskets, hinges, and ergonomic tools, traditionally dominated by engineering thermoplastics.

Growth in On-Demand Manufacturing and Customization

The rise of digital manufacturing and mass customization will further propel soft PLA adoption. Companies offering personalized products—custom-fit wearables, orthotics, or fashion accessories—will leverage soft PLA for its aesthetic finish and tactile comfort. In 2026, integration with cloud-based design platforms and AI-driven customization tools will streamline production, enabling rapid prototyping and small-batch runs with minimal waste.

Competitive Landscape and Price Dynamics

The soft PLA market will become increasingly competitive, with new entrants and established filament brands enhancing their portfolios. Economies of scale and improved manufacturing efficiency are expected to lower prices slightly by 2026, making soft PLA more accessible. However, premium variants with enhanced features (e.g., odorless printing, improved layer bonding) will command higher margins, fostering product differentiation.

Challenges and Considerations

Despite positive momentum, challenges remain. Soft PLA’s mechanical properties—such as lower tensile strength and heat resistance compared to ABS or PETG—limit its use in high-stress or high-temperature environments. Additionally, inconsistent quality among low-cost suppliers may affect print reliability. By 2026, industry standards and third-party testing will play a crucial role in ensuring material consistency and building user trust.

In conclusion, the soft PLA filament market in 2026 will be shaped by innovation, sustainability, and expanding use cases. As 3D printing evolves from prototyping to functional production, soft PLA is set to become a go-to material for flexible, eco-conscious, and user-friendly applications across diverse sectors.

Common Pitfalls When Sourcing Soft PLA Filament (Quality, IP)

Sourcing Soft PLA filament for 3D printing presents unique challenges compared to standard PLA. While appealing for flexible applications, buyers often encounter quality inconsistencies and potential intellectual property (IP) issues. Being aware of these pitfalls is crucial for ensuring reliable prints and avoiding legal or reputational risks.

Inconsistent Material Quality and Performance

One of the most prevalent issues when sourcing Soft PLA is inconsistent filament quality. Many suppliers—especially budget or unbranded manufacturers—lack rigorous quality control, leading to variations in diameter, roundness, and flexibility. This inconsistency can result in failed prints, nozzle clogs, or poor layer adhesion. Additionally, some Soft PLA formulations degrade quickly when exposed to moisture, leading to brittle prints if not stored properly. Buyers may also find that the actual flexibility (measured in Shore hardness) doesn’t match the advertised specifications, making it difficult to achieve desired mechanical properties.

Misleading or Unverified Material Specifications

Suppliers—particularly on open marketplaces—often exaggerate or falsify material properties such as elongation at break, tensile strength, or Shore hardness. Claims like “60A softness” or “rubber-like flexibility” may not be backed by certified test data. Without access to third-party material test reports (e.g., ASTM standards), users risk purchasing underperforming filament. This lack of transparency makes it difficult to compare products reliably or ensure batch-to-batch consistency.

Lack of IP Protection and Risk of Counterfeit Formulations

Soft PLA blends often involve proprietary polymer modifications or additive packages designed to enhance flexibility while maintaining printability. Reputable manufacturers protect these formulations through patents or trade secrets. However, many generic suppliers reverse-engineer or copy these formulations without authorization, leading to IP infringement. Sourcing from such suppliers not only supports unethical practices but also exposes purchasers—especially commercial users—to potential legal liability if the filament is used in end products distributed publicly.

Poor Documentation and Lack of Traceability

Reliable filament should come with comprehensive technical data sheets (TDS), safety data sheets (SDS), and lot traceability. Many Soft PLA suppliers, particularly smaller or offshore vendors, fail to provide this documentation. The absence of lot numbers or manufacturing dates makes it difficult to troubleshoot print issues or conduct quality audits. This lack of traceability is a red flag for industries requiring compliance (e.g., medical, automotive) or those concerned with supply chain integrity.

Inadequate Support for Technical Issues

When print problems arise—common with flexible materials—users often need prompt technical support. Generic or no-name suppliers typically offer little to no customer or technical assistance. In contrast, reputable brands invest in support teams to help users optimize print settings, troubleshoot warping or stringing, and recommend compatible hardware (e.g., direct-drive extruders). Relying on unsupported filament increases downtime and waste, especially for inexperienced users.

Conclusion

To mitigate these risks, buyers should prioritize suppliers with verifiable quality certifications (e.g., ISO standards), transparent material data, and a clear stance on IP rights. Investing in branded, well-documented Soft PLA filament may carry a higher upfront cost but reduces long-term risks related to print failure, legal exposure, and operational inefficiencies.

Logistics & Compliance Guide for Soft PLA Filament

Overview

Soft PLA filament is a flexible variant of standard PLA (Polylactic Acid), designed for applications requiring elasticity and bendability. While it shares many characteristics with traditional PLA, its unique physical properties necessitate special considerations in logistics, handling, storage, and regulatory compliance.

Material Classification

Soft PLA is generally classified as a thermoplastic polymer. It is typically derived from renewable resources such as corn starch or sugarcane, making it biodegradable under industrial composting conditions. However, its flexibility is enhanced through additives or copolymerization, which may affect regulatory status and environmental claims. Always verify the specific formulation with the manufacturer.

Shipping & Transportation

- Packaging: Soft PLA filament must be vacuum-sealed with desiccant to prevent moisture absorption, which can degrade print quality. Use crush-resistant spools and protective outer cartons to avoid deformation during transit.

- Temperature Control: Avoid exposure to temperatures above 50°C (122°F) during transport to prevent spool warping or filament deformation. Do not leave in vehicles exposed to direct sunlight.

- Labeling: Packages should be labeled with “Fragile,” “Keep Dry,” and “Protect from Heat.” Include hazard communication if additives classify the material under GHS (Globally Harmonized System).

- Transport Regulations: Soft PLA is generally non-hazardous and can be shipped via standard ground or air freight under IATA and IMDG regulations for non-dangerous goods. Confirm with SDS (Safety Data Sheet) before international shipping.

Storage Requirements

- Environment: Store in a cool, dry place with temperatures between 15–25°C (59–77°F) and relative humidity below 50%.

- Moisture Protection: Keep filament in sealed containers with desiccants when not in use. Consider using dry boxes or filament storage cabinets for long-term storage.

- Shelf Life: Typically 12–24 months when stored properly. Check manufacturer recommendations for specific batch guidelines.

Regulatory Compliance

- RoHS & REACH: Soft PLA filament sold in the EU must comply with RoHS (restriction of hazardous substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals). Verify compliance through supplier documentation.

- Proposition 65 (California): Ensure the filament does not contain chemicals listed under California’s Proposition 65 without proper warning labels.

- Biodegradability Claims: Avoid unsubstantiated claims of compostability or biodegradability unless certified by recognized standards such as EN 13432 or ASTM D6400. Soft PLA may not degrade as readily as standard PLA due to additives.

- SDS & Product Documentation: Maintain up-to-date Safety Data Sheets and product specification sheets for all batches. These are essential for workplace safety and regulatory inspections.

Handling & Safety

- Ventilation: Use in well-ventilated areas. While PLA emits low levels of volatile organic compounds (VOCs), soft variants with additives may have different emission profiles.

- PPE (Personal Protective Equipment): Recommended PPE includes safety glasses and gloves during spool handling to prevent cuts or irritation.

- Waste Disposal: Dispose of waste filament according to local regulations. Although biobased, soft PLA should not be disposed of in standard recycling bins unless accepted by local facilities. Industrial composting may be required for proper degradation.

Import & Export Considerations

- Customs Classification: Typically classified under HS Code 3916.20 (plastic monofilament >1mm in diameter) or 3916.90 (other). Confirm with local customs authorities.

- Documentation: Provide commercial invoices, packing lists, certificate of origin, and SDS for international shipments. Biobased content documentation may be required for green tariffs or incentives.

- Country-Specific Regulations: Some countries restrict or tax bioplastics differently. Research destination requirements, especially in the EU, Japan, and Canada.

Quality Assurance & Traceability

- Batch Tracking: Maintain records of filament batch numbers, manufacturing dates, and supplier certifications for traceability.

- Incoming Inspection: Check packaging integrity, spool condition, and verify diameter consistency (typically ±0.05mm) upon receipt.

- Compliance Audits: Periodically audit suppliers for ongoing regulatory and quality compliance. Request updated certifications annually.

Conclusion

Proper logistics and compliance management for Soft PLA filament ensures product integrity, regulatory adherence, and end-user safety. Always consult manufacturer guidelines and stay updated on evolving regulations related to bioplastics and additive-containing polymers.

Conclusion for Sourcing Soft PLA Filament:

Sourcing soft PLA filament requires careful consideration of several key factors to ensure optimal print quality and performance. While standard PLA is widely available and reliable, soft or flexible PLA blends—designed to offer increased impact resistance and slight flexibility—can vary significantly in composition, quality, and printability depending on the supplier.

After evaluating various suppliers and product offerings, it is clear that consistency in material properties, manufacturer transparency, and user reviews are critical when selecting a source. Premium brands often provide better diameter accuracy, consistent feeding, and fewer print defects, which justify their higher cost, especially for precision applications. Conversely, budget options may introduce challenges such as nozzle clogging, stringing, or warping, particularly if filament tolerances are not tightly controlled.

Additionally, verifying compatibility with your specific 3D printer model and settings is essential, as soft PLA may require adjustments to print speed, retraction, and temperature compared to standard PLA. Direct purchase from reputable manufacturers or authorized distributors ensures authenticity and access to technical support.

In summary, the ideal source for soft PLA filament balances quality, reliability, and cost, with an emphasis on consistent material performance. For professional or frequent use, investing in high-quality filament from trusted suppliers leads to better print outcomes and long-term savings through reduced waste and downtime. Continuous evaluation and small-scale testing are recommended when introducing a new filament source into your workflow.