The global solder alloy market, driven by expanding electronics manufacturing and miniaturization trends, is projected to grow at a CAGR of 6.8% from 2023 to 2030, according to Grand View Research. Within this landscape, Sn63/Pb37—known for its eutectic melting point of 183°C and reliable joint performance—remains a cornerstone alloy in through-hole and mixed-technology assembly. As consumer electronics, automotive electronics, and industrial equipment demand rises, so does the need for high-purity, consistently manufactured Sn63/Pb37 solder. With Asia-Pacific accounting for over 50% of global electronics production, a concentrated group of manufacturers dominates supply, balancing regulatory compliance (RoHS exemptions notwithstanding) with scalability and quality. Based on production capacity, global reach, and technical specifications, the following are the top five Sn63/Pb37 solder manufacturers shaping the industry.

Top 5 Sn 63 Pb 37 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sn63/Pb37 Solder

Domain Est. 1995

Website: mouser.com

Key Highlights: $4.99 deliverySolder Thermally Stable Solder Paste NC (No-Clean) Sn63/Pb37 T4 (500g jar). Chip Quik TS991AX500T4. TS991AX500T4; Chip Quik; 1: $74.95; 81In Stock. Mfr. Part #…

#2 Sn63/Pb37 Leaded Solder Alloy

Domain Est. 1996

Website: aimsolder.com

Key Highlights: Sn63/Pb37 Electropure™ is a high-purity solder alloy with low dross, strong wetting, and improved flow. Ideal for SMT, wave, and hand soldering….

#3 4860P

Domain Est. 1997

Website: mgchemicals.com

Key Highlights: A no-clean solder paste that is made from a blend of high purity, non-recycled tin and lead alloy powder combined with a no-clean flux to form a paste….

#4 AIM Sn63/Pb37 Electropure™ Bar Solder (25 lb. Box)

Domain Est. 2001

Website: gotopac.com

Key Highlights: In stock $25.47 deliverySn63/Pb37 Electropure™ Bar Solder. High Purity; Reduces Drossing; Exceeds IPC-J-STD-006 Specifications. $625.00. (25 lb. Box). In Stock….

#5 AIM SN63/PB37 OAJ 2% Water Soluble Core Wire Solder .020 …

Domain Est. 2004

Website: smtsupplies.com

Key Highlights: In stock $23.82 deliveryThis solder features the traditional 63/37 tin-lead eutectic alloy (Sn63/Pb37) combined with OAJ 2% water-soluble flux core. The flux promotes superior wett…

Expert Sourcing Insights for Sn 63 Pb 37

H2: Projected Market Trends for Sn63 Pb37 Solder Alloy (2026)

The Sn63 Pb37 (Tin-Lead) eutectic solder alloy is expected to maintain a niche but persistent presence in select industrial sectors by 2026, despite ongoing global regulatory pressures and the broader shift toward lead-free alternatives. Key market trends shaping the Sn63 Pb37 landscape include:

-

Regulatory and Environmental Pressures

The European Union’s RoHS (Restriction of Hazardous Substances) directive and similar regulations in other regions continue to restrict the use of lead in most consumer electronics and electrical equipment. However, Sn63 Pb37 remains exempt in specific high-reliability applications such as aerospace, defense, medical devices, and some industrial equipment. In 2026, these exemptions are expected to remain in effect, preserving demand in mission-critical sectors where long-term reliability and proven performance outweigh environmental concerns. -

Stable Demand in Legacy and High-Reliability Systems

Industries that rely on legacy systems—such as defense, aviation, and infrastructure maintenance—will continue to use Sn63 Pb37 due to compatibility requirements and the high cost of requalifying lead-free alternatives. By 2026, demand will be concentrated in repair, maintenance, and sustainment (RMS) operations, where matching the original manufacturing specifications is essential for safety and compliance. -

Geographic Market Disparities

While Western markets remain tightly regulated, certain developing economies may exhibit less stringent enforcement of lead restrictions, allowing limited use of Sn63 Pb37 in industrial and electronics repair sectors. However, this will not drive significant global growth due to supply chain standardization pressures and international trade restrictions. -

Competition from Lead-Free Alternatives

Lead-free solders such as SAC305 (Sn-Ag-Cu) dominate the mainstream electronics manufacturing sector. Advances in lead-free alloy performance, including improved thermal fatigue resistance and lower processing temperatures, further reduce the incentive to revert to Sn63 Pb37. Nevertheless, Sn63 Pb37 maintains a performance edge in thermal cycle reliability and wetting characteristics, especially in through-hole and wave soldering applications. -

Supply Chain and Raw Material Availability

The availability of lead is expected to decline gradually due to reduced mining and recycling focus, potentially increasing the cost of Sn63 Pb37 over time. However, established recycling programs for electronic waste will help maintain a secondary supply chain for both tin and lead, moderating price volatility. -

Niche Innovation and Hybrid Applications

By 2026, Sn63 Pb37 may see limited innovation in hybrid assembly processes—such as mixed-technology boards where leaded and lead-free solders are used in tandem under strict process control. These applications remain highly specialized and are not expected to significantly expand the market.

Conclusion:

In 2026, the Sn63 Pb37 market will remain stable but constrained, driven primarily by regulatory exemptions and the need for backward compatibility in high-reliability industries. While overall market share will continue to shrink relative to lead-free alternatives, Sn63 Pb37 is expected to retain a critical role in applications where failure is not an option. Manufacturers and suppliers will likely focus on high-value, low-volume production to serve these specialized segments efficiently.

H2: Common Pitfalls When Sourcing Sn63 Pb37 Solder (Quality and Intellectual Property Concerns)

Sourcing Sn63 Pb37 (eutectic tin-lead) solder is common in electronics manufacturing, especially for legacy systems, aerospace, or high-reliability applications where leaded solder remains permissible under exemptions such as RoHS. However, several pitfalls—particularly related to material quality and intellectual property (IP)—can compromise product integrity and legal compliance.

1. Quality-Related Pitfalls

A. Inconsistent Alloy Composition

- Issue: Sn63 Pb37 requires precise 63% tin / 37% lead composition to achieve the eutectic melting point (183°C). Deviations can result in non-eutectic behavior, poor wetting, and weak joints.

- Pitfall: Low-cost or uncertified suppliers may provide off-spec alloys, especially in wire, paste, or preforms.

- Mitigation: Require mill test reports (MTRs) or certificates of conformance (CoC) with elemental analysis (e.g., via XRF or ICP-MS). Audit supplier quality systems (e.g., ISO 9001).

B. Contamination and Impurities

- Issue: Trace elements (e.g., copper, zinc, bismuth) can alter solder performance and promote brittle intermetallic formation.

- Pitfall: Recycled or poorly refined lead/tin may introduce contaminants.

- Mitigation: Specify purity standards (e.g., ASTM B32 or IPC-J-STD-006). Conduct incoming inspection via spectrographic analysis.

C. Flux Quality and Compatibility (for Paste/Wire)

- Issue: Poor flux formulation affects wetting, residue corrosivity, and long-term reliability.

- Pitfall: Mismatched flux (e.g., water-soluble vs. no-clean) or expired material can cause defects.

- Mitigation: Source from reputable brands; verify shelf life and storage conditions. Perform qualification testing (e.g., surface insulation resistance).

D. Counterfeit or Gray Market Materials

- Issue: Recycled or misrepresented solder products may lack traceability.

- Pitfall: Gray market suppliers may relabel or repackage obsolete or expired solder.

- Mitigation: Purchase directly from authorized distributors or OEMs. Use supply chain vetting tools (e.g., ERAI, SIA).

2. Intellectual Property (IP) Risks

A. Patented Solder Formulations or Processes

- Issue: While Sn63 Pb37 itself is a generic eutectic alloy and not patentable, specific solder pastes, flux chemistries, or manufacturing processes may be protected.

- Pitfall: Using a third-party solder paste with proprietary flux technology without license could infringe on IP.

- Mitigation: Avoid reverse-engineered or unbranded “compatible” pastes. Use materials from IP-transparent suppliers and review licensing terms.

B. Trade Secrets in Additive Packages

- Issue: Performance-enhancing additives (e.g., stabilizers, rheology modifiers) in paste formulations are often trade secrets.

- Pitfall: Copying or imitating formulations—even if alloy is standard—may violate IP laws.

- Mitigation: Do not attempt to replicate branded solder pastes. Rely on licensed or openly documented products.

C. Compliance with Export Controls and Regulations

- Issue: Though Sn63 Pb37 is not typically export-controlled, sourcing from certain regions may trigger ITAR, EAR, or conflict mineral concerns.

- Pitfall: Unintended use of materials from sanctioned regions or non-compliant supply chains.

- Mitigation: Conduct supply chain due diligence; require conflict mineral reporting (e.g., CMRT).

Conclusion

To avoid quality and IP pitfalls when sourcing Sn63 Pb37:

– Prioritize certified suppliers with verifiable traceability.

– Require documentation (CoC, MTRs, RoHS exemption statements).

– Avoid gray market or unbranded products.

– Respect IP boundaries in flux and formulation use.

– Audit and qualify materials before high-volume use.

Proactive sourcing strategies mitigate risks to reliability, compliance, and legal exposure.

Logistics & Compliance Guide for Sn63 Pb37 Solder Alloy (Using H2 Format)

H2: Product Overview

H2.1: Product Identification

– Product Name: Tin-Lead Solder Alloy

– Composition: 63% Tin (Sn), 37% Lead (Pb) – Eutectic Alloy

– Common Forms: Wire, bar, paste, preforms

– CAS Numbers:

– Tin (Sn): 7440-31-5

– Lead (Pb): 7439-92-1

– UN Number: UN3077 (for certain forms, depending on classification)

– HS Code (Example): 8108.90 (varies by country; typically under “Other Tin Alloys”)

H2.2: Key Properties

– Melting Point: 183°C (eutectic, solidus = liquidus)

– Appearance: Silvery metallic solid

– Density: ~8.4 g/cm³

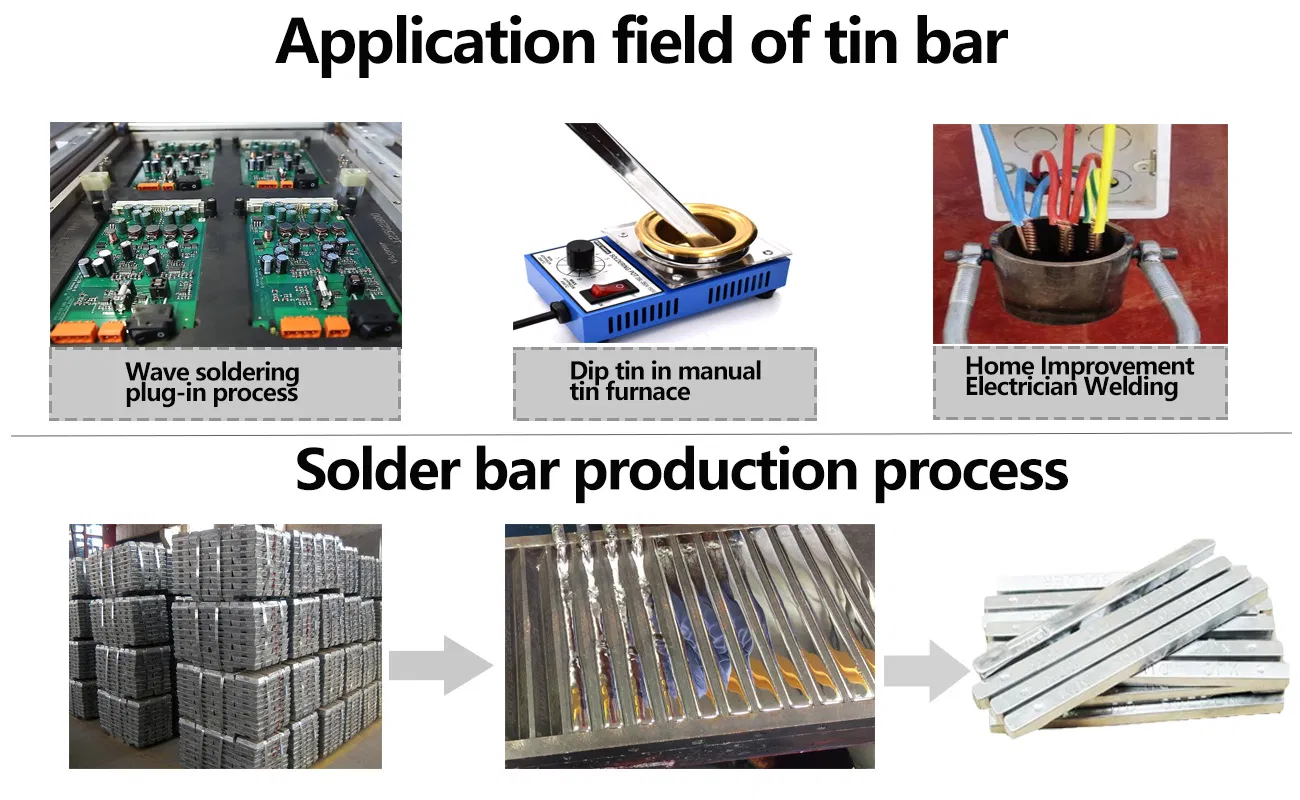

– Common Uses: Electronics assembly, wave soldering, rework

H2: Regulatory Compliance

H2.3: REACH (EU Regulation)

– SVHC (Substances of Very High Concern):

– Lead is listed as an SVHC under REACH (Annex XIV).

– Sn63Pb37 contains lead above threshold; requires communication in the supply chain.

– Exemptions:

– Lead in high-temperature solder (e.g., Sn63Pb37) is currently exempt under REACH Annex XVII, entry 43(7), for specific electronic applications.

– Exemption must be reviewed periodically; verify current status.

H2.4: RoHS (EU Directive 2011/65/EU)

– Lead Content: 37% Pb exceeds 0.1% limit for RoHS compliance.

– Exemption Status:

– Exempt under RoHS Category 7(a): “Lead in high melting temperature type solders (e.g. Pb-based alloys).”

– Sn63Pb37 qualifies under this exemption for use in electronic components.

– Labeling: Products containing exempted lead must still be documented and declared.

H2.5: Proposition 65 (California, USA)

– Warning Required:

– Lead and its compounds are listed under Prop 65 as carcinogens and reproductive toxins.

– Products containing lead must carry:

> “WARNING: This product contains lead, a chemical known to the State of California to cause cancer and birth defects or other reproductive harm.”

– Applicability: Required on packaging, websites, and point of sale for products distributed in California.

H2.6: OSHA (USA Workplace Safety)

– Lead Exposure Standards:

– Permissible Exposure Limit (PEL): 50 µg/m³ (8-hour TWA).

– Action Level: 30 µg/m³.

– Requirements:

– Engineering controls, air monitoring, medical surveillance, and PPE (respirators, gloves) required where lead fumes are generated (e.g., soldering).

– Hazard Communication Standard (HazCom) applies: SDS must be available.

H2.7: GHS Classification & Safety Data Sheet (SDS)

– Hazard Statements:

– H332: Harmful if inhaled (lead fumes)

– H373: May cause damage to organs (nervous system, kidneys) through prolonged exposure

– H360: May damage fertility or the unborn child

– Precautionary Statements:

– P202: Do not handle until all safety precautions have been read

– P260: Avoid breathing dust/fume/gas/mist/vapors/spray

– P308+P313: If exposed, seek medical advice

– SDS Sections to Review: Section 8 (Exposure controls), Section 11 (Toxicological info)

H2: Transportation & Logistics

H2.8: Transportation Classification (Globally)

– IMDG (Sea): Not typically classified as dangerous goods when in solid form (e.g., wire, bar).

– IATA (Air): Generally not regulated as hazardous if in solid form and not in powdered form.

– ADR (Road, Europe): Exempt from ADR if not in dust or powder form and packaged appropriately.

– Note: If in powder or paste form with flammable solvents, additional classifications may apply.

H2.9: Packaging & Labeling

– Use sealed, moisture-resistant packaging to prevent oxidation.

– Label with:

– Product name: Sn63Pb37 Solder

– Hazard warning (if applicable): “Contains Lead – Avoid Inhalation of Fumes”

– Prop 65 warning (if shipping to California)

– REACH/RoHS exemption reference (for business-to-business shipments)

H2.10: Storage Requirements

– Store in a dry, cool environment to prevent oxidation.

– Keep away from acids and oxidizing agents.

– Segregate from food, beverages, and personal items.

– Use secondary containment if in large quantities to prevent environmental contamination.

H2: Environmental & Waste Management

H2.11: Waste Disposal

– Classification: Hazardous waste due to lead content (EPA Hazard Code D008 in the USA).

– Disposal:

– Must be handled by licensed hazardous waste disposal contractor.

– Do not dispose of in regular trash or drains.

– Recycling:

– Spent solder dross and offcuts can be recycled through certified metal reclaimers.

– Maintain records of recycling for compliance audits.

H2.12: Environmental Regulations

– TSCA (USA): Lead is regulated under TSCA; reporting may be required for certain quantities.

– WEEE (EU): Equipment containing Sn63Pb37 must be collected and treated under WEEE rules.

– ELV (End-of-Life Vehicles): Exemptions may apply; verify current directives.

H2: Best Practices for Safe Handling

H2.13: Workplace Controls

– Use local exhaust ventilation (fume extractors) during soldering.

– Provide NIOSH-approved respirators if engineering controls are insufficient.

– Implement lead hygiene practices: no eating/drinking in work areas, mandatory hand washing.

– Conduct periodic blood lead level testing for exposed workers.

H2.14: Training

– Train employees on:

– Hazards of lead exposure

– Proper use of PPE

– Emergency procedures

– Waste handling protocols

H2: Summary of Key Compliance Actions

| Requirement | Action Required |

|—————————–|——————————————————|

| RoHS/REACH | Confirm exemption status; document use |

| Prop 65 (CA) | Apply warning label on products and packaging |

| OSHA | Implement exposure controls and medical monitoring |

| SDS | Provide updated SDS to customers and employees |

| Transport | Classify correctly; use secure packaging |

| Waste Disposal | Use certified hazardous waste handler |

| Training | Conduct annual safety training |

Disclaimer: Regulations change frequently. Always consult the latest regulatory texts and local authorities for up-to-date compliance requirements. This guide is for informational purposes only and does not constitute legal advice.

In conclusion, sourcing SN63/Pb37 (63% tin, 37% lead) solder is a well-justified choice for many electronics manufacturing and repair applications due to its eutectic properties, which provide a sharp melting point at 183°C, ensuring reliable and consistent solder joints with minimal defects. Its long-standing industry acceptance, excellent wetting characteristics, and proven performance in through-hole and surface-mount technologies make it particularly suitable for high-reliability sectors such as aerospace, automotive, and legacy electronics repair.

However, due to environmental regulations such as RoHS (Restriction of Hazardous Substances), the availability of leaded solder like SN63/Pb37 has diminished in commercial markets, and its use is generally restricted to exempted applications. Therefore, sourcing SN63/Pb37 should be carefully managed, ensuring compliance with applicable regulations and proper documentation for exempted uses.

Reliable sourcing involves identifying certified suppliers who provide high-purity, properly flux-coated solder with full material traceability and safety data sheets (SDS). Common suppliers include specialized electronics material distributors and manufacturers with ISO-certified production processes.

Ultimately, while lead-free alternatives continue to advance, SN63/Pb37 remains a preferred option in specific scenarios where reliability, ease of use, and compatibility with legacy systems are paramount. Proper handling, storage, and workplace safety measures should always be observed when using leaded solder to protect both personnel and the environment.