The global screwdriver market, valued at USD 2.8 billion in 2023, is projected to grow at a CAGR of 4.6% through 2030, driven by rising demand in electronics, precision manufacturing, and DIY sectors—according to Grand View Research. A notable segment within this growth is small star (Torx) screwdrivers, essential for compact and high-precision applications in smartphones, wearables, and medical devices. As demand for miniaturized tooling increases, especially in Asia-Pacific’s expanding electronics supply chains, manufacturers specializing in precision screwdrivers are gaining strategic importance. This growth trajectory, supported by Mordor Intelligence’s projection of over 5% CAGR in hand tool markets amid industrial automation trends, underscores the rising relevance of niche players focused on small star screwdriver production. Here, we examine the top 7 manufacturers leading innovation, quality, and market share in this specialized segment.

Top 7 Small Star Screwdriver Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 T

Domain Est. 1995

Website: toolsource.com

Key Highlights: In stock Rating 3.0 (1) Compact and Lightweight: Measuring 122mm in length, this screwdriver is compact and well-suited for delicate or confined spaces where precision work is …..

#2 Star/Torx Bit Sets

Domain Est. 1998

Website: chapmanmfg.com

Key Highlights: 45-day returnsChapman tools Star/Torx Screwdriver Bit sets are made, hand assembled & inspected in Durham, CT from USA materials….

#3 Starrett Products

Domain Est. 1998

Website: starrett.com

Key Highlights: Discover premium precision measuring tools and cutting solutions including micrometers, calipers, band saw blades and much more. Many American-made since ……

#4 VENTURA star screwdriver set

Domain Est. 2000

Website: messingschlager.com

Key Highlights: star screwdriver size. T20; T25; T30; T10; T15. Tool application area. frame. colour. silver. details. short and long end; suitable for security screws….

#5 Genius Tools Star Screwdriver T9 Size 150mm Length Precision …

Domain Est. 2004

Website: geniustoolsusa.com

Key Highlights: In stock Free delivery over $75This T-9 star precision screwdriver is built for controlled fastening where tip fit and handle comfort matter. The 150 mm overall length helps balanc…

#6 NEW Pro 25Pc Mini Screwdriver Set Hand Tool Repair Kit

Domain Est. 2019

Website: magicnailspaparma.com

Key Highlights: In stock Rating 4.3 (135) Lightweight and Portable Batch Bayonet with Internal Batch Head, Not Easy to Scatter, Unlike the Traditional Plastic Box, Easy to Crush, Scattered….

#7 Screwdriver

Website: wera.de

Key Highlights: Professional filter · With flexible shaft · Ball tip · Torsion zone · Hollow shaft · Reduced blade and handle diameter · Halfmoon and HIOS · Suitable for Wera 2go….

Expert Sourcing Insights for Small Star Screwdriver

H2: 2026 Market Trends for Small Star Screwdriver

The global market for small star (Torx) screwdrivers is expected to experience steady growth and notable shifts by 2026, driven by evolving manufacturing standards, technological advancements, and rising demand across key industries. As precision tools become increasingly essential in compact and high-tech device assembly, the small star screwdriver segment is poised for transformation across multiple dimensions.

-

Rising Demand in Electronics and Consumer Devices

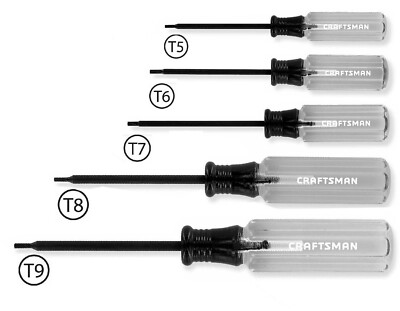

The proliferation of compact electronics—such as smartphones, wearables, tablets, and IoT devices—continues to fuel demand for small star screwdrivers. These devices often use Torx T5, T6, and T8 screws to prevent tampering and ensure precise assembly. By 2026, the electronics repair and DIY markets are expected to expand, especially with growing right-to-repair movements in North America and Europe, increasing consumer and technician reliance on specialized tools like small star drivers. -

Growth in Automotive and Aerospace Applications

Automotive manufacturers are increasingly adopting Torx screws in engine components, interiors, and electronic control units due to their high torque tolerance and tamper resistance. The shift toward electric vehicles (EVs), which require more intricate electronics and battery pack assemblies, will further boost demand for precision screwdrivers. Similarly, aerospace applications requiring high reliability will drive industrial-grade small star driver usage. -

Expansion of the Aftermarket and Repair Ecosystem

With sustainability concerns and regulatory pressures pushing longer product lifespans, the repair and refurbishment market is gaining momentum. This trend supports the sale of small star screwdriver kits, particularly multi-bit models compatible with various Torx sizes. Online marketplaces and tool subscription services are expected to play a growing role in tool distribution by 2026. -

Innovation in Ergonomics and Smart Tools

Tool manufacturers are investing in ergonomic designs, anti-slip grips, magnetic tips, and modular systems to improve user experience. Additionally, smart screwdrivers with torque sensors and Bluetooth connectivity are emerging, especially in industrial settings. While high-end smart tools may not dominate the small star segment yet, their integration into precision workflows could influence standard tool design by 2026. -

Regional Market Dynamics

Asia-Pacific, particularly China, Japan, and South Korea, will remain the largest manufacturing and consumption hub for small star screwdrivers due to concentrated electronics production. Meanwhile, North America and Western Europe are expected to see growth in premium and professional-grade tools, driven by higher disposable income and repair regulations. -

Sustainability and Material Innovation

Environmental considerations are prompting tool makers to adopt recyclable materials and sustainable manufacturing processes. By 2026, brands emphasizing eco-friendly packaging and long-lasting, repairable tools may gain competitive advantage in environmentally conscious markets.

In conclusion, the 2026 outlook for small star screwdrivers reflects a convergence of precision engineering, regulatory trends, and consumer behavior shifts. Companies that focus on innovation, sustainability, and adaptability to evolving repair ecosystems are likely to lead the market.

Common Pitfalls Sourcing Small Star Screwdriver (Quality, IP)

When sourcing small star (Torx) screwdrivers, especially for precision applications or environments requiring specific ingress protection (IP) ratings, several common pitfalls can compromise performance, safety, and compliance. Being aware of these issues helps ensure reliable procurement.

Poor Build Quality and Material Selection

Many low-cost small star screwdrivers use substandard steel that lacks proper heat treatment, leading to tip deformation or stripping of fasteners. Inferior handles may crack or offer poor ergonomics, reducing control and increasing user fatigue. Always verify material specifications such as S2 steel or equivalent and ensure tips meet ISO 1174 standards for Torx compatibility.

Inaccurate Tip Dimensions and Tolerance

Small Torx drivers (e.g., T1 to T10) require precise tip geometry. Sourcing from unreliable suppliers often results in mismatched sizes or out-of-tolerance tips that don’t fully engage the screw, increasing the risk of cam-out and damage. Confirm dimensional accuracy through sample testing or supplier certifications.

Misrepresentation of Ingress Protection (IP) Ratings

Some suppliers falsely claim IP ratings (e.g., IP67) for insulated or non-insulated tools. True IP-rated screwdrivers undergo rigorous testing for dust and water resistance. Without independent certification (such as IEC 60900), these claims may be misleading—especially critical in electronics or hazardous environments.

Lack of Electrical Insulation or Safety Certification

For applications involving live circuits, non-insulated drivers pose serious safety risks. Even when insulated, many imported tools lack proper VDE or CAT rating certification. Always demand test reports and compliance with safety standards to avoid liability and ensure user protection.

Inconsistent Quality Control from OEM Suppliers

OEMs, particularly in low-cost regions, may lack consistent quality control, resulting in batch-to-batch variation. Implement supplier audits, request production samples, and conduct incoming inspections to maintain reliability.

Overlooking Long-Term Durability and Warranty Support

Cheaper tools may appear cost-effective initially but often fail prematurely, increasing total cost of ownership. Evaluate warranty terms and supplier responsiveness to defects. Reliable vendors offer traceability and replacement policies that support long-term use.

Logistics & Compliance Guide for Small Star Screwdriver

Product Classification & HS Code

Identify the correct Harmonized System (HS) code for international shipping and customs clearance. For a small star (Phillips) screwdriver, a common HS code is 8205.40 (“Hand tools, n.e.s., of base metal”). Confirm the exact 8-10 digit code based on your country’s tariff schedule and tool composition (e.g., steel shaft, plastic handle).

Packaging & Labeling Requirements

Ensure packaging is durable and suitable for transit. Label each unit or package with:

– Product name: “Small Star (Phillips) Screwdriver”

– Model or SKU number

– Country of origin (e.g., “Made in China”)

– Manufacturer or distributor name and address

– CE mark (if applicable for EU markets)

– Any safety warnings (e.g., “Use with care to avoid injury”)

Import/Export Regulations

- Export Controls: Verify if the screwdriver is subject to export restrictions. Hand tools are generally not controlled, but check EAR (Export Administration Regulations) or equivalent.

- Import Duties & Taxes: Research duty rates and VAT/GST requirements in the destination country using the HS code. Some countries offer duty-free entry for basic hand tools.

- Customs Documentation: Prepare a commercial invoice, packing list, and bill of lading/air waybill. Include product description, quantity, weight, value, and HS code.

Safety & Compliance Standards

- CE Marking (EU): Comply with the EU Machinery Directive or General Product Safety Directive. Documentation may include a Declaration of Conformity.

- UKCA Marking (UK): Required for UK market; similar requirements to CE.

- RoHS Compliance: Ensure the product complies with restrictions on hazardous substances (e.g., lead, cadmium), especially in electronic tools or metal alloys.

- REACH (EU): Confirm no restricted substances in materials used.

Transport & Handling

- Use standard parcel or LTL (Less Than Truckload) shipping methods depending on volume.

- Stack packages securely; avoid excessive weight per carton.

- Label packages as “Fragile” if necessary, though screwdrivers are typically robust.

- Maintain records of shipping manifests and tracking numbers.

Environmental & Disposal Compliance

- Provide end-of-life guidance: Metal components are recyclable; separate plastic handles if required by local regulations.

- Comply with WEEE (Waste Electrical and Electronic Equipment) if the screwdriver includes electronic components (e.g., illuminated handle), though standard tools are usually exempt.

Recordkeeping & Documentation

Maintain copies of:

– Supplier compliance certificates (RoHS, REACH, etc.)

– Customs filings and import/export declarations

– Product conformity documentation

– Shipping and delivery records

Ensure all documentation is retained for a minimum of 5–7 years, depending on jurisdiction.

In conclusion, sourcing a small star (Torx) screwdriver requires careful consideration of quality, durability, precision, and intended use. Whether for electronics repair, eyewear adjustments, or other delicate tasks, selecting the right screwdriver involves evaluating factors such as tip size accuracy, magnetic properties, handle ergonomics, and overall build material. Sourcing from reputable suppliers or brands ensures reliability and reduces the risk of damaging sensitive screws. Additionally, opting for a multi-bit set can offer greater versatility and long-term value. By balancing cost, availability, and performance, individuals and businesses can effectively source a small Torx screwdriver that meets both technical requirements and practical needs.