The global market for sustainable packaging solutions is expanding rapidly, driven by increasing consumer demand for eco-friendly and aesthetically appealing product containers. According to a report by Mordor Intelligence (2023), the global glass packaging market is projected to grow at a CAGR of 4.2% from 2023 to 2028, fueled by rising environmental concerns and regulatory support for recyclable materials. Within this landscape, small glass spray bottles—popular in personal care, cosmetics, essential oils, and household cleaning industries—are emerging as a high-growth segment. Their durability, chemical inertness, and premium look make them a preferred alternative to plastic sprayers. As brands prioritize sustainability without compromising on functionality, demand for high-quality, small-format glass spray bottles is surging, creating opportunities for specialized manufacturers worldwide. This growth trend, supported by Grand View Research, which notes the global spray bottle market size was valued at USD 3.1 billion in 2022 and expected to expand at a CAGR of 5.3% through 2030, underscores the importance of reliable, innovative glass bottle producers in meeting evolving market needs.

Top 10 Small Spray Bottles Glass Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Bulk Spray Bottles

Domain Est. 1998

Website: bottlestore.com

Key Highlights: $100 delivery 10-day returnsBottleStore.com is your go-to source for bulk spray bottles. We are a top supplier of wholesale glass and plastic bottles, jars, and containers….

#2 Glass Bottles and containers for Perfumes Wholesale, Perfume …

Domain Est. 2000

Website: bestbottles.com

Key Highlights: BestBottles is a distributor, wholesale supplier and manufacturer of perfume bottles, glass bottles, perfume atomizers, fine mist sprayers, lotion bottles, ……

#3 PGP Glass Bottle and Glass Container Manufacturers

Domain Est. 2021

Website: pgpfirst.com

Key Highlights: PGP Glass is a trusted name among glass bottle manufacturers and glass container manufacturers, delivering premium quality packaging solutions. Explore now!…

#4 Custom Glass Spray Bottle manufacturer

Website: tpglassbottle.com

Key Highlights: Discover our customizable glass spray bottles with premium mist sprayers. Sustainable packaging solutions for cosmetics, personal care, and wellness products….

#5 Small, Travel Sized Spray Bottles

Domain Est. 2008

Website: aromatools.com

Key Highlights: 2 oz. Blue Glass Bottle with Misting · $1.44 · $1.44 ; 1 oz. Blue Glass Bottles and Misting Sprayers (Pack of 6). $6.96 · $6.96 ; 1 oz. Amber Glass Bottles with ……

#6 4oz / 118ml frosted glass fine mist spray bottle

Domain Est. 2014

Website: makesy.com

Key Highlights: Rating 4.9 (77) · Free delivery over $199 · 30-day returns…

#7 Glass Bottles

Domain Est. 2017

Website: ucan-packaging.com

Key Highlights: Small glass bottles with droppers, pipettes, roll-on, sprayers, pump caps and more. Wholesale packaging for food and beverages, cosmetics, and perfume….

#8 8 oz Glass Spray Bottle

Domain Est. 2018

Website: woopdiy.com

Key Highlights: In stock Free delivery over $40These high quality 8 ounce glass spray bottles for essential oils, with a trigger or pump sprayer. are great to have for your household DIY cleaning …

#9 Fine Mist Spray Bottle

Domain Est. 2019

Website: roetell.com

Key Highlights: Roetell offers high-quality fine mist spray bottles in bulk at competitive wholesale prices, allowing you to save money and lower production costs….

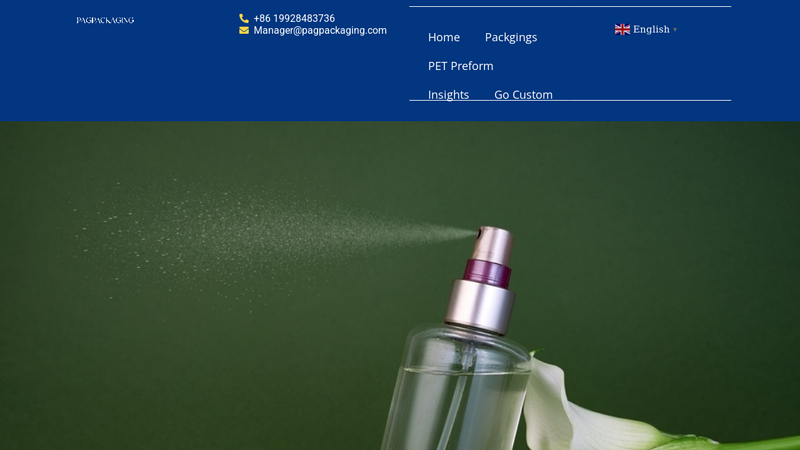

#10 Mist Spray Bottles

Domain Est. 2022

Website: pagpackaging.com

Key Highlights: Web / Catalog We offer over 300 bottle designs and specs. You can browse through our website or catalog to find the perfect spray bottle for your needs….

Expert Sourcing Insights for Small Spray Bottles Glass

H2: Projected Market Trends for Small Spray Bottles in Glass by 2026

By 2026, the market for small glass spray bottles is expected to experience steady growth, driven by evolving consumer preferences, sustainability trends, and innovations in packaging across personal care, home care, and specialty markets. Here are the key trends shaping this segment:

-

Rising Demand for Sustainable Packaging

Consumers and brands alike are increasingly prioritizing eco-friendly packaging solutions. Glass, being 100% recyclable and non-leaching, aligns with global sustainability goals. Small glass spray bottles are favored over plastic alternatives due to lower environmental impact, especially in refillable and reusable formats. Regulatory pressures and extended producer responsibility (EPR) laws in regions like the EU and North America are accelerating this shift. -

Growth in Niche and Premium Markets

The beauty, skincare, aromatherapy, and natural wellness sectors are major drivers for small glass spray bottles. Premium and clean-label brands use amber, cobalt blue, or clear glass bottles to convey product purity and luxury. The trend toward minimalist and aesthetically pleasing packaging further boosts demand, particularly in direct-to-consumer (DTC) and e-commerce channels. -

Innovation in Spray Mechanisms and Design

By 2026, advancements in fine mist sprayers, trigger heads, and pump durability will enhance functionality and user experience. Manufacturers are integrating tamper-evident seals, child-resistant caps, and ergonomic designs. Lightweighting of glass without compromising strength is also a focus, reducing shipping costs and carbon footprint. -

Expansion in Refill and Reuse Models

Circular economy initiatives are encouraging brands to adopt refillable glass spray bottle systems. Retailers and beauty brands are launching refill stations and subscription models, reinforcing brand loyalty and reducing single-use waste. This trend is especially strong in Europe and increasingly adopted in North America and parts of Asia-Pacific. -

Regional Market Dynamics

- Europe leads in adoption due to strict environmental regulations and high consumer awareness.

- North America sees rising demand in organic and natural product markets.

-

Asia-Pacific is an emerging growth region, with increasing urbanization and disposable income fueling demand, particularly in South Korea, Japan, and China.

-

Challenges and Considerations

Despite growth, challenges remain. Glass is heavier and more fragile than plastic, increasing logistics costs and breakage risks. Cost sensitivity in price-driven markets may limit adoption. However, innovations in protective packaging and supply chain optimization are mitigating these issues.

In conclusion, the 2026 outlook for small glass spray bottles is positive, with sustainability, premiumization, and innovation as key growth catalysts. Stakeholders across the value chain—from manufacturers to brands—will need to balance environmental goals with cost efficiency and functional performance to capitalize on this expanding market.

Common Pitfalls When Sourcing Small Glass Spray Bottles (Quality & IP)

Sourcing small glass spray bottles requires careful attention to both product quality and intellectual property (IP) considerations. Overlooking these aspects can lead to supply chain disruptions, customer dissatisfaction, legal disputes, and reputational damage. Below are key pitfalls to avoid:

Inadequate Quality Control

One of the most frequent challenges is receiving inconsistent or substandard glass spray bottles. Poor quality control from suppliers can result in:

- Glass Defects: Cracks, bubbles, or uneven thickness that compromise structural integrity and increase breakage risk during shipping or use.

- Spray Mechanism Failures: Clogged nozzles, inconsistent spray patterns, or leaky pumps due to low-grade internal components (e.g., springs, gaskets).

- Poor Finish and Aesthetics: Scratches, misaligned labels, or off-color glass that affect brand perception, especially for premium or cosmetic products.

- Inconsistent Dimensions: Variations in neck finish or bottle height can interfere with automated filling lines or packaging.

Mitigation: Require suppliers to provide detailed quality specifications, conduct on-site audits, and implement third-party pre-shipment inspections. Use clear quality acceptance criteria in contracts.

Ignoring Intellectual Property (IP) Risks

Many small glass spray bottles, especially those with unique designs or patented dispensing mechanisms, are protected by IP rights. Sourcing without due diligence can lead to:

- Design Patent Infringement: Replicating bottles with protected shapes, textures, or ergonomic features without authorization.

- Utility Patent Issues: Using spray mechanisms covered by functional patents (e.g., child-resistant sprayers, continuous mist systems).

- Trademark Confusion: Bottles that mimic branded packaging elements, leading to potential legal action or customs seizures.

- Counterfeit or Unauthorized Production: Suppliers may offer “look-alike” bottles produced without licensing, exposing buyers to legal liability.

Mitigation: Conduct IP clearance searches before finalizing designs. Require suppliers to warrant that products do not infringe third-party rights. Work with legal counsel to assess freedom-to-operate, especially for innovative or branded packaging.

Poor Material and Component Compatibility

Glass may interact negatively with certain formulations (e.g., essential oils, alcohol-based solutions), leading to:

- Chemical Degradation: Corrosion of pump components or leaching from glass over time.

- Permeability Issues: While glass is largely impermeable, improper seals can still allow evaporation or contamination.

Mitigation: Test final product-fill combinations under real-world storage conditions. Specify pharmaceutical-grade glass (e.g., Type I or III) and chemically resistant pump materials (e.g., PTFE seals).

Unreliable Supply Chain and Scalability

Small bottle suppliers, particularly in emerging markets, may lack the capacity or stability to support long-term demand:

- Production Delays: Inconsistent output or lack of raw materials (e.g., borosilicate glass).

- Minimum Order Quantity (MOQ) Mismatches: High MOQs may not suit startups or niche markets.

- Geopolitical or Logistics Risks: Customs delays, port congestion, or regulatory changes affecting glass shipments.

Mitigation: Diversify suppliers and maintain safety stock. Evaluate supplier financial health and scalability before long-term commitments.

By proactively addressing these pitfalls—focusing on rigorous quality assurance and comprehensive IP due diligence—buyers can secure reliable, compliant, and high-performing glass spray bottle supplies.

H2: Logistics & Compliance Guide for Small Spray Bottles (Glass)

-

Product Classification & Identification

Small glass spray bottles are typically classified under HTS (Harmonized Tariff Schedule) code 7010.90 for glass containers. Accurate classification ensures correct duty rates and compliance with import/export regulations. Confirm the exact HTS code with your customs broker based on capacity, use (e.g., cosmetic, household, pharmaceutical), and country of origin. -

Packaging & Handling Requirements

Due to the fragile nature of glass, packaging must meet international standards for shock resistance and containment: - Use corrugated cardboard with internal dividers or trays to prevent contact between bottles.

- Include cushioning materials (e.g., foam inserts, bubble wrap) to absorb impact.

- Clearly label packages with “Fragile,” “This Way Up,” and “Do Not Stack” markings.

-

Comply with ISTA (International Safe Transit Association) or ASTM D4169 testing standards for shipping performance.

-

Hazardous Materials Considerations

If the spray bottle contains or will contain hazardous substances (e.g., alcohol-based cleaners, essential oils), compliance with transportation regulations is required: - Check compatibility with IATA (air), IMDG (sea), or 49 CFR (ground) depending on mode of transport.

- Use UN-certified packaging if shipping hazardous liquids; glass bottles must pass drop, leakproofness, and stacking tests.

-

Include proper hazard labels, Safety Data Sheets (SDS), and shipping documentation.

-

Import/Export Documentation

Ensure complete and accurate documentation for cross-border shipments: - Commercial invoice specifying product description, value, quantity, and country of origin.

- Packing list detailing box contents and weights.

- Certificate of Origin (if claiming preferential tariffs under trade agreements).

-

Import permits may be required in some countries for glass or specific end uses.

-

Regulatory Compliance by Region

- United States: FDA does not regulate empty spray bottles, but if used for food, drug, or cosmetic contact, the glass must comply with 21 CFR for food-grade materials. EPA may regulate if used for pesticides.

- European Union: Must comply with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and may require CE marking if part of a regulated device. Packaging must follow Directive 94/62/EC on packaging waste.

- Canada: Complies with Health Canada’s requirements for consumer product safety under the Canada Consumer Product Safety Act (CCPSA) if used in household products.

-

Other Markets: Check local standards such as UKCA (UK), PSB (Singapore), or INMETRO (Brazil) as applicable.

-

Labeling Requirements

- Include manufacturer name and address, capacity, material type (e.g., “Soda-Lime Glass”), and recycling symbol (if applicable).

- If the bottle is sold pre-filled, labeling must meet product-specific regulations (e.g., CLP in EU for chemicals, EPA for pesticides).

-

Avoid misleading claims such as “eco-friendly” or “recyclable” unless substantiated.

-

Sustainability & Disposal

Glass is 100% recyclable but must be separated from pumps and caps (typically plastic). Provide end-user guidance: - Encourage disassembly before recycling.

- Comply with Extended Producer Responsibility (EPR) schemes where implemented (e.g., in EU, Canada).

-

Consider lightweighting or using recycled glass content to meet environmental goals.

-

Storage & Transportation Best Practices

- Store in dry, temperature-stable environments to avoid thermal shock.

- Limit stack height during warehousing and shipping to prevent crushing.

-

Use climate-controlled transport if shipping to regions with extreme temperatures.

-

Quality Assurance & Testing

- Conduct routine quality checks for defects (cracks, uneven walls, spray mechanism function).

- Perform leakage, spray pattern, and durability tests.

-

Maintain records of compliance testing for audits.

-

Supplier & Manufacturer Due Diligence

- Verify suppliers comply with ISO 9001 (quality management) and ISO 14001 (environmental management).

- Audit manufacturing facilities for labor practices and safety standards, especially in high-risk regions.

By adhering to this guide, businesses can ensure safe, compliant, and efficient logistics for small glass spray bottles across global markets.

In conclusion, sourcing small glass spray bottles requires careful consideration of quality, durability, supplier reliability, and cost-effectiveness. Glass offers advantages such as chemical resistance, environmental sustainability, and an upscale aesthetic, making it ideal for premium products in the beauty, essential oil, and cosmetic industries. When selecting suppliers, it’s important to evaluate factors such as material quality (e.g., borosilicate or soda-lime glass), spray pump functionality, customization options, and compliance with safety and shipping standards. Sourcing from reputable manufacturers—whether domestic or overseas—can ensure consistency and minimize potential issues related to breakage or leakage. Ultimately, a well-informed sourcing strategy that balances cost, quality, and supply chain reliability will support brand integrity and customer satisfaction.