The global market for small screws—critical components in electronics, automotive, medical devices, and consumer goods—has experienced steady growth driven by rising miniaturization trends and increasing demand for precision engineering. According to Grand View Research, the global fasteners market was valued at USD 104.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, with small screws representing a significant segment due to their widespread use in high-tech applications. Mordor Intelligence further highlights that advancements in the automotive and aerospace sectors, coupled with growing production of compact electronic devices, are key drivers fueling demand for high-precision, miniature fasteners. As industries continue to prioritize reliability, strength-to-weight ratios, and space efficiency, sourcing from capable and innovative small screw manufacturers has become a strategic imperative. This report identifies the top 10 manufacturers excelling in quality, scalability, and technological innovation in the small screws space.

Top 10 Small Screws Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

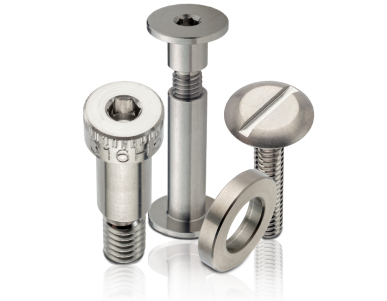

#1 AMPG

Domain Est. 1997

Website: ampg.com

Key Highlights: AMPG is a trusted USA manufacturer of high-quality fasteners. We provide precision-engineered sex bolts, shoulder screws, washer, shims and other industrial ……

#2 Star Drive Wood Screws – Screw Products, Inc.

Domain Est. 1999

Website: screw-products.com

Key Highlights: Screw Products Inc. specializes in star drive stainless steel and heat treated wood screws for decks, log homes, remodeling, kitchen cabinets, docks, ……

#3 Screws Industries, Inc.

Domain Est. 2000

Website: screwsindustries.com

Key Highlights: Since September of 1983, we’ve been manufacturing high-quality screws and fasteners, and growing to be a full service supplier that our customers can count on….

#4 FURNITURE SCREWS MANUFACTURER

Domain Est. 2000

Website: zyhyin.com

Key Highlights: A leading manufacturer of screws for furniture, offers products with professional techniques, high efficiency, excellent quality and prompt service….

#5 Pro-Twist

Domain Est. 2003

Website: pro-twist.com

Key Highlights: Pro-Twist is an industry-leading manufacturer of professional-grade fasteners that are used for a wide variety of applications. Get started with us today!…

#6 Fasco Fastener & Industrial Supply Corp

Domain Est. 2012

Website: fascofas.com

Key Highlights: Fasco Fastener & Industrial Supply is your one stop shop for durable, high-quality fasteners for many types of construction projects….

#7 Small Screw Manufacturers, Micro Screws Supplier

Domain Est. 2017

Website: sstls.com

Key Highlights: 24 Years Of Professional Production Of Screw Supplier · tel +86 13143444311 email [email protected] · Small Screw Manufacturers, Micro Screws Supplier….

#8 Micro Fasteners

Domain Est. 1996

Website: microfasteners.com

Key Highlights: … Micro Fasteners offers a wide selection of affordable fasteners including locknuts, washers, wood screws, and self-tapping screws in both U.S. and metric sizes….

#9 HOLO

Domain Est. 2003

Website: holo-krome.com

Key Highlights: Since its formation in 1929, HOLO-KROME has been at the forefront of fastener development and innovation. All HOLO-KROME products are made in the USA and ……

#10 Screws

Domain Est. 2017

Website: mwcomponents.com

Key Highlights: $15 delivery 30-day returnsFind shoulder screws, thread cutting screws & other specialized options or order custom screws in a range of materials from MW Components….

Expert Sourcing Insights for Small Screws

H2: 2026 Market Trends for Small Screws

The global small screws market is poised for steady growth and transformation by 2026, driven by evolving end-user industries, technological advancements, and shifting supply chain dynamics. Here’s a breakdown of the key trends expected to shape the market:

1. Growth in High-Tech and Miniaturized Electronics

- Trend: The continued miniaturization of consumer electronics (smartphones, wearables, IoT devices) and the expansion of advanced electronics in automotive (ADAS, infotainment) and medical devices demand increasingly smaller, more precise, and reliable fasteners.

- Impact: Rising demand for miniature screws (e.g., M1 to M3 sizes), specialty thread designs, and high-tolerance manufacturing. This favors suppliers with advanced precision engineering and cleanroom production capabilities.

2. Automotive Electrification Driving Innovation

- Trend: The surge in electric vehicle (EV) production requires robust, heat-resistant, and lightweight small screws for battery packs, power electronics, and electric motors.

- Impact: Increased use of corrosion-resistant materials (e.g., stainless steel, titanium, specialized coatings) and screws designed for high-vibration environments. Demand for fasteners that support modular battery assembly is rising.

3. Automation and Smart Manufacturing Integration

- Trend: Manufacturers are adopting Industry 4.0 principles, including automated assembly lines and robotics.

- Impact: Demand for standardized, high-consistency small screws compatible with automated feeding and screwdriving systems. Traceability and quality assurance (e.g., via RFID tagging or batch tracking) become critical for supply chain integration.

4. Sustainability and Circular Economy Pressures

- Trend: Regulatory and consumer pressure for sustainable manufacturing practices is growing.

- Impact: Increased demand for recyclable materials, reduced packaging waste, and screws made from recycled or low-carbon materials. OEMs may prioritize suppliers with ISO 14001 certification and transparent environmental reporting.

5. Supply Chain Diversification and Reshoring

- Trend: Geopolitical tensions and pandemic-related disruptions have prompted companies to diversify sourcing and bring production closer to end markets (e.g., North America, Europe).

- Impact: Opportunities for regional small screw manufacturers to gain market share. However, cost pressures remain, especially in price-sensitive sectors.

6. Material Innovation and Performance Enhancement

- Trend: Need for improved performance under extreme conditions (temperature, corrosion, wear).

- Impact: Growth in adoption of specialty alloys, composite materials, and advanced surface treatments (e.g., PVD coatings, black oxide, zinc-nickel plating) to enhance durability and functionality.

7. Consolidation and Strategic Partnerships

- Trend: Increasing competition and R&D costs are leading to consolidation among screw manufacturers and closer collaboration with OEMs.

- Impact: Larger players may acquire niche specialists in micro-fasteners or high-performance materials. Long-term supplier partnerships focused on co-development are becoming more common.

8. Digitalization of Sales and Distribution

- Trend: B2B e-commerce platforms and digital catalogs are streamlining procurement.

- Impact: Suppliers investing in online configurators, instant quoting, and inventory management systems gain competitive advantage. Data analytics help forecast demand and optimize inventory.

Conclusion:

By 2026, the small screws market will be characterized by precision, performance, and sustainability. Success will depend on a manufacturer’s ability to innovate in materials and processes, adapt to automation, respond to regional supply chain shifts, and meet the stringent requirements of high-growth sectors like EVs and advanced electronics. Companies that combine technical excellence with digital agility and environmental responsibility are best positioned to thrive.

Common Pitfalls When Sourcing Small Screws (Quality, IP)

Sourcing small screws may seem trivial, but overlooking key factors can lead to significant issues in product performance, compliance, and long-term reliability. Two critical areas prone to pitfalls are quality assurance and intellectual property (IP) concerns. Below are common mistakes to avoid:

Quality-Related Pitfalls

Inconsistent Material Specifications

Suppliers may claim compliance with standards like ISO or ASTM, but fail to provide verifiable material certifications. This can result in screws made from substandard alloys that corrode, strip, or fail under stress.

Poor Dimensional Accuracy

Small screws require tight tolerances. Inconsistent thread pitch, head size, or length can lead to assembly issues, equipment downtime, or product recalls—especially in precision industries like medical devices or aerospace.

Inadequate Surface Finish and Coating

Improper plating (e.g., zinc, nickel, or PTFE) can result in reduced corrosion resistance or outgassing in vacuum environments. Some coatings may also wear off quickly, exposing base metal to degradation.

Lack of Traceability and Testing

Reputable suppliers provide batch traceability and test reports (e.g., torque testing, salt spray resistance). Skipping this verification increases the risk of receiving non-conforming parts with no recourse.

Overlooking Packaging and Handling

Small screws are easily contaminated or damaged. Poor packaging can introduce dirt, moisture, or mix different screw types, leading to assembly errors.

Intellectual Property (IP) Pitfalls

Sourcing Proprietary or Patented Designs

Some small screws (e.g., Torx, Pentalobe, or specialized security drives) are protected by patents or trademarks. Unauthorized reproduction or use can expose your company to legal action, especially in international markets.

Counterfeit or Reverse-Engineered Components

Low-cost suppliers may offer “compatible” screws that infringe on IP. These components often mimic branded designs without licensing, posing legal and quality risks.

Inadequate Supplier Vetting

Failing to audit suppliers for IP compliance—such as requesting proof of licensing or original design documentation—can result in unintentional infringement and supply chain disruptions.

Ambiguous Contracts and Specifications

Contracts that don’t clearly define ownership of custom tooling or designs can lead to disputes. For instance, if a supplier creates a custom screw based on your specs, unclear terms may allow them to sell similar designs to competitors.

Best Practices to Avoid Pitfalls

- Require full material and test certifications from suppliers.

- Conduct first-article inspections and periodic audits.

- Verify IP status of screw designs before mass production.

- Use NDAs and clear IP clauses in supplier agreements.

- Partner with reputable, certified manufacturers who adhere to ISO or AS9100 standards.

By addressing quality and IP concerns proactively, businesses can ensure reliable performance, regulatory compliance, and legal safety in their supply chain.

Logistics & Compliance Guide for Small Screws

Overview

Small screws, though minor in size, play a critical role in manufacturing, construction, electronics, and various industrial applications. Efficient logistics and strict compliance with international and regional regulations are essential to ensure timely delivery, product integrity, and legal adherence. This guide outlines key considerations for the transportation, packaging, labeling, and regulatory compliance of small screws.

Packaging Requirements

Proper packaging is vital to prevent loss, contamination, and damage during transit.

– Material Selection: Use moisture-resistant, anti-static (for electronic applications), and durable packaging such as poly bags, blister packs, or sealed cartons.

– Unitization: Group screws in appropriate quantities (e.g., by weight, count, or torque specification) and clearly label each unit.

– Bulk Handling: For large shipments, use sealed plastic totes or fiberboard drums with internal dividers to minimize movement.

– Tamper-Evidence: Include tamper-evident seals when required for quality or security reasons.

Labeling and Documentation

Accurate labeling ensures traceability and regulatory compliance.

– Product Information: Clearly display screw type, material (e.g., stainless steel, zinc-plated), size (diameter, length, thread pitch), grade, and compliance marks (e.g., ISO, ASTM).

– Barcodes/QR Codes: Implement scannable identifiers for inventory management and tracking.

– Shipping Labels: Include sender/recipient details, handling instructions (e.g., “Fragile,” “Keep Dry”), and any hazardous material disclaimers if applicable.

– Commercial Invoice & Packing List: Provide detailed documentation for customs, including HS code, country of origin, and declared value.

Regulatory Compliance

Small screws are subject to various international and industry-specific regulations.

– Customs Classification: Use the correct Harmonized System (HS) code—typically under 7318.15 (screws of iron or steel) or 7616.10 (aluminum screws).

– Country of Origin Marking: Ensure all packages and invoices state the manufacturing country per destination regulations (e.g., “Made in Germany”).

– RoHS and REACH Compliance: For shipments to the EU, confirm screws are free of restricted substances (e.g., lead, cadmium).

– ITAR/EAR: If screws are used in defense or aerospace applications, verify export control requirements under U.S. regulations.

– Customs Duties and Tariffs: Research import duties based on destination country and material composition.

Transportation and Handling

Efficient logistics minimize risk and cost.

– Mode of Transport: Choose between air (fast, costly), sea (economical for bulk), or ground (regional). Air freight may require compliance with IATA regulations if packaged with batteries or tools.

– Environmental Controls: Protect screws from humidity, extreme temperatures, and corrosive atmospheres. Use desiccants if necessary.

– Stacking and Palletization: Secure packages on pallets using stretch wrap or strapping. Ensure load stability to prevent shifting during transit.

– Tracking and Visibility: Utilize shipment tracking systems for real-time monitoring and proof of delivery.

Quality and Safety Standards

Adherence to quality benchmarks ensures customer satisfaction and regulatory acceptance.

– ISO Standards: Follow ISO 898 (mechanical properties), ISO 965 (thread tolerances), and ISO 4042 (electroplated fasteners).

– ASTM Standards: Apply relevant ASTM specifications (e.g., ASTM A325 for structural bolts, if applicable).

– Testing Documentation: Maintain records of tensile strength, corrosion resistance, and dimensional accuracy testing.

– Supplier Certification: Source from ISO 9001-certified manufacturers to ensure consistent quality.

Special Considerations for International Shipments

Cross-border logistics require extra diligence.

– Incoterms®: Clearly define responsibilities using standardized trade terms (e.g., FOB, EXW, DDP).

– Import Restrictions: Verify destination country rules—some nations restrict metal imports or require pre-shipment inspections.

– Language Requirements: Provide labels and documents in the official language of the recipient country if required.

– Customs Brokerage: Engage a licensed customs broker to handle clearance, especially for high-value or regulated shipments.

Conclusion

Managing the logistics and compliance of small screws demands precision, documentation, and proactive planning. By following industry standards, adhering to regulatory requirements, and using proper packaging and tracking methods, businesses can ensure reliable delivery and maintain compliance across global supply chains. Regular audits and supplier evaluations further support long-term success in fastener distribution.

In conclusion, sourcing small screws requires a careful balance of quality, cost, reliability, and scalability. It is essential to evaluate suppliers based on material specifications, manufacturing precision, compliance with industry standards, and lead times. Establishing strong relationships with reputable suppliers—whether local or global—can ensure consistent supply and reduce risks related to delays or defects. Additionally, leveraging bulk purchasing, long-term contracts, and supply chain diversification can enhance cost-efficiency and resilience. By implementing a strategic sourcing approach, businesses can secure high-quality small screws that meet technical requirements while supporting overall production efficiency and product reliability.