The global small dozer market is experiencing steady growth, driven by rising demand in construction, mining, and agricultural sectors. According to Mordor Intelligence, the Dozer Market was valued at USD 8.15 billion in 2024 and is projected to reach USD 10.33 billion by 2029, growing at a CAGR of approximately 4.8% during the forecast period. Small dozers, in particular, are gaining traction due to their maneuverability, lower operating costs, and suitability for compact job sites. Their increasing adoption in infrastructure development across emerging economies further amplifies market expansion. As demand rises, a select group of manufacturers has emerged as leaders in innovation, reliability, and market share. Below are the top 10 small dozer manufacturers shaping the industry today.

Top 10 Small Dozer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Bulldozers/Crawler Dozers

Domain Est. 1990

Website: deere.com

Key Highlights: Trust John Deere for your next bulldozer. Our durable and efficient bulldozers are perfect for any heavy-duty construction or landscaping needs….

#2 Small Dozers

Domain Est. 1993

Website: cat.com

Key Highlights: 2-day deliveryUnder 105 hp (78 kW), Cat® small dozers are designed to optimize speed, transportability, maneuverability, versatility and finish grading accuracy….

#3 Dingo Mini Skid Steer and Track Loader

Domain Est. 1994

Website: toro.com

Key Highlights: Toro Dingo compact skid steer and track loaders help landscape professionals complete work more productively. Our loaders are designed to be easy to operate ……

#4 Dozers

Domain Est. 1995

Website: komatsu.com

Key Highlights: Our dozers have been engineered to be a workhorse of your fleet. For power and finesse for grading to slot dozing. Available options with innovative integrated ……

#5 Dozers

Domain Est. 1995

Website: casece.com

Key Highlights: The CASE 750M dozer is the perfect combination of power and size — big enough to get the job done, but small enough for easy transportation and access to ……

#6 Bobcat Company

Domain Est. 1997

Website: bobcat.com

Key Highlights: For more than 60 years, Bobcat Company has built compact equipment that helps you work more efficiently and effectively. You rely on the performance, ……

#7 ASV Compact Posi-Track & Skid-Steer Loaders

Domain Est. 1997

Website: asvi.com

Key Highlights: We design and manufacture premium compact track loaders, skid steers and attachments that are purpose-built to lead the industry in hydraulic performance….

#8 Demo Dozer

Domain Est. 2002

Website: demo-dozer.com

Key Highlights: The Demo-Dozer replaces six attachments in one unit. An Arsenal of attachments all at your finger tips. What makes us a better choice for you?…

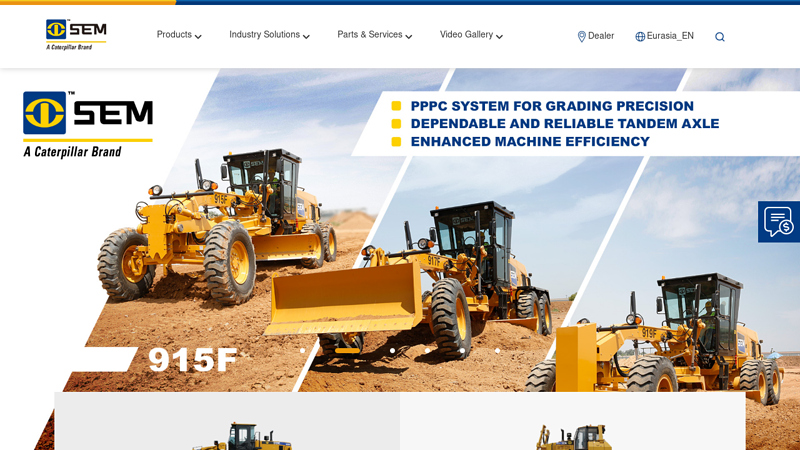

#9

Domain Est. 2008

Website: semmachinery.com

Key Highlights: SEM Wheel Loaders have been manufactured in China for nearly 60 years. We offer compact, small and midsize loaders to meet the needs of every application….

#10 Yanmar Compact Equipment

Domain Est. 2021

Website: yanmarce.com

Key Highlights: Explore Yanmar’s full line of compact construction equipment: mini excavators, compact track loaders, wheel loaders & tracked carriers….

Expert Sourcing Insights for Small Dozer

H2 2026 Market Trends for Small Dozers

The small dozer market (typically defined as machines under 90 horsepower or 67 kW) is expected to experience moderate but steady growth in H2 2026, shaped by a confluence of economic, technological, and regulatory factors. Key trends shaping the second half of 2026 include:

1. Resilient Demand in Infrastructure & Residential Construction:

Despite lingering concerns about global economic volatility, government infrastructure spending programs in North America, Europe, and parts of Asia-Pacific are expected to maintain strong demand for small dozers in H2 2026. These machines remain essential for site preparation, grading, and utility work. Additionally, continued growth in residential construction—especially in suburban and rural developments—will sustain demand, as small dozers are ideal for smaller job sites where maneuverability and lower impact are priorities.

2. Accelerated Shift Toward Electrification:

H2 2026 will mark a pivotal point in the adoption of electric small dozers. Major manufacturers (e.g., John Deere, Caterpillar, Komatsu) are expected to expand their electric or hybrid-electric small dozer offerings in response to tightening emissions regulations (Stage V/EPA Tier 4 Final) and increasing customer demand for sustainable operations. Battery technology improvements will enhance runtime and performance, making electric models more viable for longer shifts. Rental fleets are also anticipated to begin integrating more electric units, driven by corporate ESG (Environmental, Social, Governance) goals.

3. Growth in Rental and Fleet Utilization:

The rental market for small dozers is projected to grow in H2 2026 as contractors seek to manage capital expenditure and maintain flexibility amid uncertain project pipelines. Rental companies are investing in newer, more fuel-efficient, and technologically advanced models, including telematics-equipped and low-emission machines. This trend is particularly strong in developed markets where labor costs and equipment utilization efficiency are key concerns.

4. Integration of Smart Technology and Telematics:

Advanced telematics, machine control systems (2D and emerging 3D), and remote monitoring will become standard features on new small dozers by H2 2026. Contractors are increasingly leveraging data from these systems for predictive maintenance, fuel optimization, job site efficiency, and operator performance tracking. This digital integration enhances uptime and reduces operational costs, making technologically advanced models more attractive despite higher initial prices.

5. Supply Chain Normalization and Price Stabilization:

After years of component shortages and inflationary pressures, H2 2026 is expected to see a more stable supply chain for small dozer manufacturers. This should lead to improved delivery times and more predictable pricing. However, costs may remain elevated compared to pre-2020 levels due to increased material costs and investments in new technologies like electrification and automation.

6. Regional Market Divergence:

While North America and Western Europe will lead in adopting electric and smart dozers, emerging markets in Southeast Asia, Latin America, and Africa will continue to prioritize affordability and durability. In these regions, demand will be driven by urbanization and infrastructure development, with a preference for reliable diesel-powered models. Trade dynamics and local manufacturing incentives will influence regional availability and pricing.

Conclusion:

H2 2026 presents a balanced outlook for the small dozer market—characterized by innovation, sustainability, and steady demand. The sector is transitioning from traditional diesel machines toward smarter, cleaner, and more connected equipment. Manufacturers that successfully navigate this shift—by offering scalable technology, supporting rental channels, and meeting regional needs—will be best positioned to capitalize on evolving customer expectations and long-term industry transformation.

Common Pitfalls When Sourcing Small Dozers: Quality and Intellectual Property Risks

Sourcing small dozers—especially from emerging manufacturers or offshore suppliers—can present significant challenges related to product quality and intellectual property (IP) protection. Being aware of these pitfalls is crucial to avoiding costly delays, safety issues, and legal complications.

Quality-Related Pitfalls

Inconsistent Manufacturing Standards

Many small dozer suppliers, particularly in regions with less stringent regulatory oversight, may not adhere to international quality standards such as ISO or CE certifications. This can result in unreliable performance, increased downtime, and higher maintenance costs.

Substandard Materials and Components

To cut costs, some manufacturers use inferior steel, hydraulics, or engines. This compromises durability and safety, especially under demanding operating conditions.

Lack of Rigorous Testing

Reputable manufacturers conduct extensive field and stress testing. Sourcing from suppliers who skip these steps increases the risk of premature failures and safety hazards.

Inadequate After-Sales Support and Spare Parts Availability

Even if the initial product appears sound, poor service networks and limited spare parts can drastically reduce equipment uptime and lifecycle value.

Intellectual Property (IP) Risks

Counterfeit or Copycat Designs

Some small dozer models are blatant copies of established OEM designs. Purchasing such equipment may expose buyers to legal risks, especially if the units are imported into markets with strong IP enforcement.

Grey Market Imports

Dozers sourced through unofficial channels may infringe on territorial distribution rights or trademarks, potentially leading to customs seizures or legal action.

Unclear Ownership of Technical Documentation

When working with contract manufacturers, ownership of design specs, CAD files, or customizations may not be clearly defined, creating disputes over IP rights and limiting future development or repairs.

Risk of Technology Theft

Sharing proprietary requirements or modifications with unvetted suppliers can lead to unauthorized replication or resale of your innovations.

Mitigation Strategies

- Conduct thorough due diligence on suppliers, including factory audits and reference checks.

- Require certification to recognized quality standards (e.g., ISO 9001).

- Use legally binding agreements that specify quality expectations, warranty terms, and IP ownership.

- Work with trusted legal counsel to ensure compliance with international IP laws.

- Consider partnering with third-party inspection services for pre-shipment quality verification.

Avoiding these pitfalls ensures not only reliable equipment performance but also protects your organization from reputational and legal exposure.

Logistics & Compliance Guide for Small Dozer

This guide provides essential information for the safe, efficient, and legally compliant transportation, handling, and operation of small dozers. Adherence to these guidelines ensures regulatory compliance, worker safety, and equipment integrity.

Transportation Logistics

Ensure the small dozer is securely transported using a flatbed trailer or lowboy. Verify that the trailer has adequate weight capacity and proper tie-down points. Use appropriate heavy-duty chains or straps (rated for the dozer’s weight) and secure at multiple anchor points—typically front and rear frame locations. Confirm that the tracks are clean and free of debris that could damage the trailer or roadway. Obtain necessary permits if transporting oversized loads, and comply with state and local regulations for height, width, and weight restrictions.

Pre-Transport Inspection

Before moving the dozer, conduct a pre-transport inspection. Check fluid levels (engine oil, hydraulic fluid, coolant), ensure no leaks are present, and confirm the battery is secured and charged. Lower the blade completely and engage the parking brake. Inspect tracks for tension and damage, and verify that all lights and warning devices are operational if the unit is driven onto the trailer. Document the machine’s condition with photos to prevent liability disputes.

On-Site Handling & Placement

Upon arrival, assess the delivery site for ground stability, overhead clearance, and access routes. Use spotters when maneuvering the dozer off the trailer. Ensure the ground can support the machine’s weight to prevent sinking or tipping. Place the dozer on level, compacted terrain and chock the tracks if parked on a slope. Avoid placing the machine near excavations or unstable soil.

Regulatory Compliance

Comply with all local, state, and federal regulations, including OSHA (Occupational Safety and Health Administration) standards for heavy equipment operation. Operators must be trained, certified, and authorized per OSHA 29 CFR 1926. Operators should review site-specific safety plans and adhere to lockout/tagout (LOTO) procedures during maintenance. Ensure the dozer meets emissions standards (e.g., EPA Tier 4 Final) and carry relevant documentation, including registration, insurance, and compliance certifications.

Environmental & Safety Protocols

Follow environmental protection guidelines to prevent soil and water contamination. Use secondary containment for fueling operations and dispose of waste fluids (oil, coolant, filters) according to EPA and local hazardous waste regulations. Equip the dozer with required safety features: backup alarms, warning lights, fire extinguishers, and rollover protective structures (ROPS) where applicable. Conduct daily pre-operational checks using a standardized checklist.

Documentation & Recordkeeping

Maintain accurate logs for transportation, maintenance, inspections, and operator certifications. Keep records of equipment hours, repairs, parts replacements, and compliance training. These documents support regulatory audits, warranty claims, and incident investigations. Store records securely and ensure they are accessible for at least three years, per most industry standards.

Incident Reporting & Emergency Procedures

Establish clear procedures for reporting accidents, near misses, or equipment malfunctions. In the event of a spill, injury, or mechanical failure, follow emergency protocols immediately: secure the area, provide first aid if needed, and notify supervisors. Complete incident reports promptly and conduct root cause analysis to prevent recurrence. Ensure all personnel know emergency shutdown procedures and evacuation routes.

Conclusion for Sourcing a Small Dozer

In conclusion, sourcing a small dozer requires a thorough evaluation of operational needs, site conditions, budget constraints, and long-term maintenance considerations. After analyzing available options—whether new, used, or rental—purchasing a reliable and appropriately sized machine from a reputable manufacturer or dealer ensures optimal performance, fuel efficiency, and operator comfort. Factors such as brand reputation, warranty coverage, parts availability, and after-sales support play a crucial role in minimizing downtime and maximizing return on investment.

Additionally, considering total cost of ownership, rather than just the initial purchase price, leads to a more sustainable and cost-effective decision. By prioritizing durability, versatility, and ease of maintenance, the selected small dozer will effectively support earthmoving, grading, and site preparation tasks across various applications. Ultimately, a well-researched sourcing strategy ensures that the chosen equipment aligns with project demands and contributes to improved productivity and operational efficiency.