The global small circular battery market is experiencing robust growth, driven by rising demand for portable electronics, wearable devices, electric vehicles, and medical equipment. According to Grand View Research, the global primary battery market size was valued at USD 13.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A significant portion of this growth is attributed to small circular batteries—such as coin and button cells—used in applications ranging from smartwatches and hearing aids to IoT sensors and automotive key fobs. Mordor Intelligence projects the small battery market to grow steadily, with increased adoption in emerging economies and advancements in battery chemistry, including lithium-ion and silver oxide technologies. As demand surges, manufacturers are focusing on miniaturization, energy density improvements, and sustainable production practices. In this evolving landscape, a select group of ten leading small circular battery manufacturers are setting the pace through innovation, scale, and strategic global partnerships.

Top 10 Small Circular Battery Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 NEI Corporation

Domain Est. 2003

Website: neicorporation.com

Key Highlights: NEI Corporation is a leading manufacturer of protective and functional coatings, lithium-ion and sodium-ion battery materials, and custom specialty ……

#2 American Battery Technology Company

Domain Est. 2020

Website: americanbatterytechnology.com

Key Highlights: ABTC is an advanced technology, first-mover lithium-ion battery recycling and primary battery metal extraction company that utilizes internally developed ……

#3 KULR Technology

Domain Est. 2021

Website: kulr.ai

Key Highlights: With a rich 40-year heritage in advanced thermal management technologies, KULR creates safe, high-performance batteries for space, aerospace, and defense….

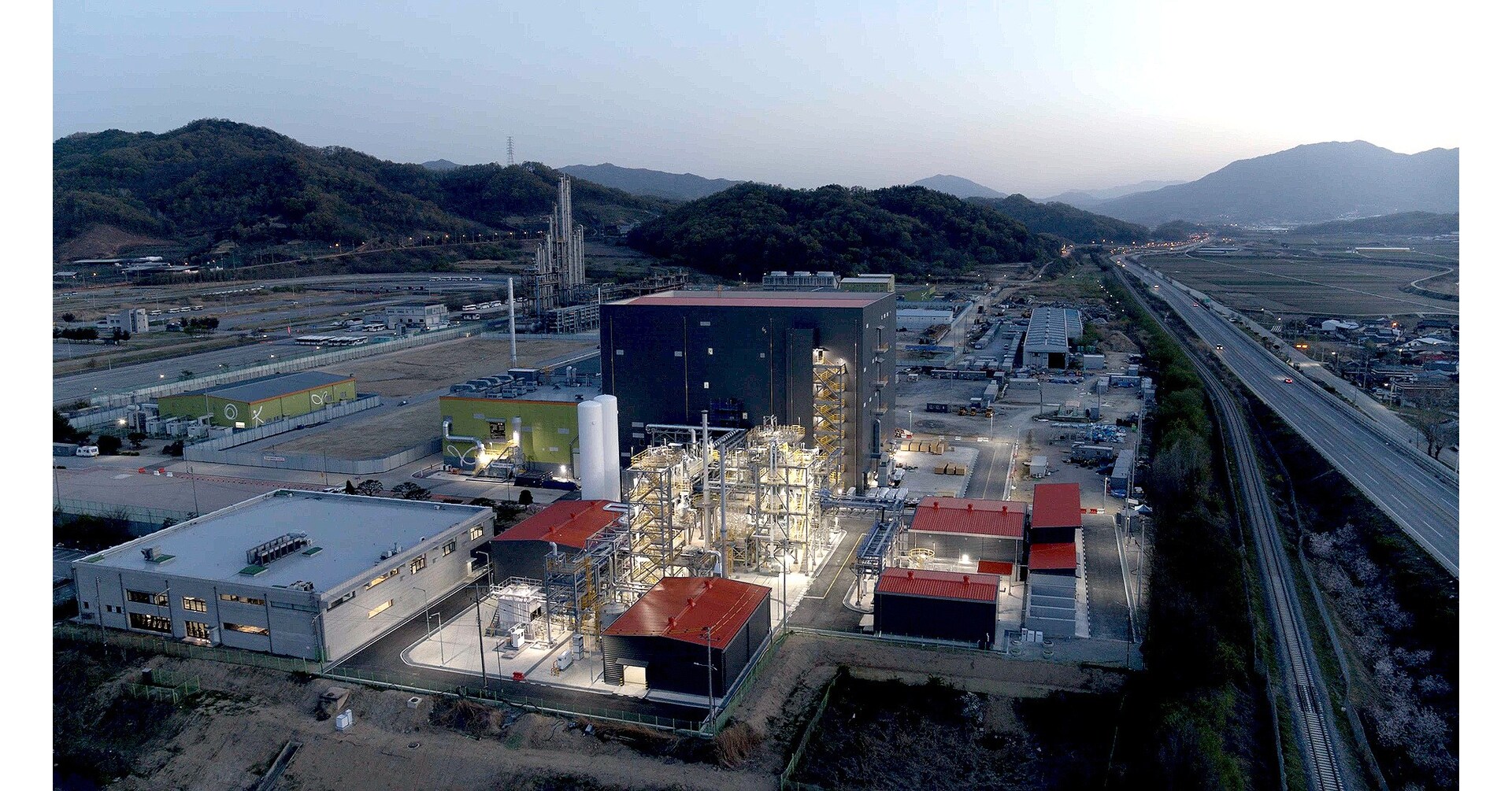

#4 Group14

Website: group14.technology

Key Highlights: Group14’s newest silicon battery material factory, BAM-3, is delivering SCC55® to Asia’s battery industry and strengthening the global battery supply chain….

#5 Lithium ion Coin Battery

Domain Est. 1997

Website: eemb.com

Key Highlights: 3.7 Volt – Coin Type – Secondary / Rechargeable Battery. Li-ion Coin Batteries are a type of small, cylindrical rechargeable lithium-ion batteries….

#6 BATCircle official

Domain Est. 2010

Website: batcircle.aalto.fi

Key Highlights: Finland-based Circular Ecosystem of Battery Metals, BATCircle, aims at improving the competitiveness of the Finnish battery value chain….

#7 Choose from a wide range of LiPo batteries by various specifications

Domain Est. 2018

Website: batterylipo.com

Key Highlights: Below are the lipo battery models listed according to battery size and tooling series, customer can select battery cell according to their requirements….

#8 Round Li Polymer Battery

Domain Est. 2019

Website: li-polymer-battery.com

Key Highlights: Our round li polymer battery range from 30mm to 50mm in diameter, 135mAh to 1500mAh in capacity with high quality and reliability….

#9 NanFu Battery,No.1 Battery Brand In China

Domain Est. 2021 | Founded: 1954

Website: nanfubatteries.com

Key Highlights: NanFu Battery,founded in 1954,focuses on the R&D and manufacturing of small batteries. We are committed to providing customers with products and services ……

#10 Livium Ltd

Domain Est. 2023

Website: liviumcorp.com

Key Highlights: At Livium, we lead in sustainable lithium production and battery recycling, driving the circular economy for a greener future….

Expert Sourcing Insights for Small Circular Battery

H2: Emerging Market Trends for Small Circular Batteries in 2026

By 2026, the global market for small circular batteries—commonly including coin cells and button cells such as lithium-based (e.g., CR2032), alkaline, silver oxide, and emerging solid-state variants—is expected to undergo significant transformation driven by technological innovation, regulatory changes, and shifting end-user demand. The following key trends are projected to shape the market landscape:

-

Rise in Demand from Wearable Technology and IoT Devices

The proliferation of wearable electronics—smartwatches, fitness trackers, hearables, and medical wearables—continues to be a primary growth driver. As IoT (Internet of Things) ecosystems expand into smart homes, industrial sensors, and asset tracking, small circular batteries remain essential due to their compact size, reliability, and long shelf life. By 2026, the integration of energy-efficient chips and low-power communication protocols (e.g., Bluetooth LE, NB-IoT) will further boost demand for miniature power sources. -

Shift Toward Rechargeable and Sustainable Chemistries

Environmental concerns and regulatory pressures are accelerating the transition from single-use to rechargeable small circular batteries. Lithium-ion coin cells (e.g., LIR2032) are gaining traction, particularly in premium consumer electronics. Additionally, emerging solid-state microbatteries offer higher energy density, improved safety, and longer cycle life, positioning them as promising alternatives. By 2026, OEMs are expected to increasingly adopt eco-design principles, favoring recyclable and less toxic materials. -

Regulatory Pressures and Material Restrictions

Stricter environmental regulations—such as the EU Battery Regulation, which mandates carbon footprint declarations, recycling efficiency targets, and restrictions on hazardous substances—are prompting manufacturers to reformulate battery chemistries. The phase-out of mercury and efforts to reduce cobalt and nickel dependency will influence R&D priorities. Compliance will be a key competitive differentiator, particularly in Europe and North America. -

Advancements in Miniaturization and Energy Density

Ongoing research in nanomaterials, thin-film batteries, and 3D electrode structures is enabling higher energy density in smaller footprints. By 2026, next-generation small circular batteries may support higher discharge rates and operate reliably across wider temperature ranges—critical for medical implants and automotive sensors (e.g., tire pressure monitoring systems). -

Growth in Medical and Healthcare Applications

The healthcare sector is emerging as a high-growth segment, with demand for small batteries in hearing aids, glucose monitors, implantable devices, and smart patches. Stringent reliability and safety standards are driving innovation in biocompatible and long-lasting power solutions. Regulatory approvals for new battery technologies in medical devices are expected to increase by 2026. -

Regional Market Dynamics and Supply Chain Resilience

Asia-Pacific, led by China, Japan, and South Korea, will remain the dominant manufacturing hub. However, geopolitical factors and supply chain disruptions are prompting diversification efforts in North America and Europe. Localized production and strategic stockpiling of critical raw materials (e.g., lithium, manganese) are likely to become more common. -

Price Pressures and Competitive Landscape

While premium segments will embrace advanced battery technologies, price sensitivity in mass-market consumer electronics will sustain demand for cost-effective alkaline and silver oxide cells. Established players (e.g., Panasonic, Duracell, Varta) face competition from Chinese manufacturers offering lower-cost alternatives, driving consolidation and innovation in the mid-tier market.

Conclusion:

By 2026, the small circular battery market will be characterized by a dual trend—technological sophistication in high-value applications and cost optimization in high-volume consumer goods. Sustainability, regulatory compliance, and energy efficiency will be central to product development. Companies investing in rechargeable solutions, solid-state technologies, and circular economy models are best positioned to capture growth in this evolving landscape.

Common Pitfalls Sourcing Small Circular Batteries (Quality, IP)

Sourcing small circular batteries—such as coin or button cells (e.g., CR2032, LR44, AG13)—presents several critical challenges related to quality consistency and intellectual property (IP) risks. Buyers must be vigilant to avoid the following common pitfalls:

Poor Quality Control and Inconsistent Performance

Many suppliers, particularly in competitive low-cost markets, lack rigorous quality assurance processes. This can result in batteries with short shelf life, inconsistent voltage output, or premature failure. Low-quality cells may leak electrolytes, damaging end products and leading to costly warranty claims and brand damage.

Counterfeit and Misrepresented Products

The market is rife with counterfeit batteries falsely labeled as trusted brands (e.g., Duracell, Panasonic). These may use substandard materials, fail safety standards, and pose serious risks in sensitive applications like medical devices or IoT sensors. Buyers may unknowingly receive lower-capacity or reconditioned cells marketed as new.

Lack of Intellectual Property Compliance

Sourcing from manufacturers who produce near-identical copies of patented battery designs can expose buyers to IP infringement claims. Some suppliers replicate not just form factors but also proprietary sealing technologies or chemical formulations, creating legal exposure for both the supplier and the end buyer.

Non-Compliance with Safety and Environmental Standards

Many low-cost batteries fail to meet essential certifications such as IEC 60086, RoHS, or REACH. This non-compliance can prevent market entry in regulated regions (e.g., EU, North America) and increase liability, especially in consumer electronics or children’s products.

Unreliable Supply Chain and Traceability

Opaque supply chains make it difficult to trace battery origins or verify manufacturing conditions. Without transparency, ensuring ethical sourcing and consistent quality becomes nearly impossible, increasing risks of disruption or reputational harm.

To mitigate these risks, buyers should conduct thorough supplier audits, require third-party certifications, establish clear IP indemnification clauses, and prioritize long-term reliability over initial cost savings.

Logistics & Compliance Guide for Small Circular Batteries

Overview

Small circular batteries, commonly known as button cells or coin cells, are widely used in consumer electronics such as watches, calculators, hearing aids, and medical devices. Due to their chemical composition and potential hazards, the logistics and compliance requirements for shipping and handling these batteries are strictly regulated under international, national, and regional laws.

This guide outlines key logistics procedures and compliance standards applicable to the transport, storage, labeling, and disposal of small circular batteries.

Regulatory Framework

International Regulations

Small circular batteries are subject to international transport regulations, including:

- UN Manual of Tests and Criteria, Part III, Section 38.3: All lithium-based batteries must pass safety tests for vibration, pressure, temperature, and short circuit.

- IATA Dangerous Goods Regulations (DGR): Governs air transport of batteries. Button cell batteries are generally classified under UN 3090 (for lithium metal batteries) or UN 3496 (for lithium-ion button cells), depending on chemistry.

- IMDG Code: Applies to sea transport. Similar classification and packaging rules apply as per IATA.

- ADR: Governs road transport in Europe. Requires proper packaging, labeling, and documentation.

Note: Many small button cells are exempt from full dangerous goods requirements if shipped in equipment or as “excepted batteries” under certain conditions.

Regional and National Compliance

United States (DOT & FAA)

- Regulated by the Department of Transportation (DOT) and Federal Aviation Administration (FAA).

- Compliance with 49 CFR (Code of Federal Regulations) is mandatory.

- Exemptions may apply for small lithium cells when shipped for consumer use, provided packaging and quantity limits are observed.

European Union (EU)

- Batteries Directive (2006/66/EC) governs environmental and safety aspects.

- Requires proper labeling (e.g., crossed-out wheeled bin symbol), collection, and recycling.

- REACH and RoHS directives restrict hazardous substances (e.g., mercury, cadmium).

- CLP Regulation requires classification, labeling, and packaging of hazardous chemicals.

China & Other Regions

- China’s MIIT and CCC certification may apply for battery-containing products.

- Local regulations often mirror UN/IATA standards but may include additional labeling or import documentation.

Packaging & Labeling Requirements

Packaging

- Use rigid, non-conductive inner packaging to prevent short circuits.

- Each battery must be individually protected (e.g., in plastic clamshells or with insulated terminals).

- Outer packaging must be strong enough to withstand handling and stacking.

- Avoid mixing different battery types or used batteries with new ones.

Labeling

- Proper Shipping Name & UN Number (e.g., “Lithium metal coin cells contained in equipment, UN 3091”).

- Class 9 Miscellaneous Hazard Label for lithium batteries if required.

- “Lithium Battery Mark”: Required for air shipments unless exempt.

- Markings for “Excepted” Shipments: May include “UN 3090, Batteries, lithium metal, button type, excepted”.

- Consumer warning labels (e.g., “Do not insert in mouth – risk of serious injury if swallowed”).

Transport & Handling

Air Transport

- Most button cells can be shipped as “excepted” under IATA Section II if:

- Lithium content ≤ 1g per cell.

- Packaged to prevent short circuits and damage.

- Shipped in small quantities (e.g., ≤ 2 kg net lithium content per consignment).

- Batteries packed with or contained in equipment have different rules than standalone shipments.

Ground & Sea Transport

- Follow IMDG (sea) or ADR (road in Europe) classifications.

- Use certified packaging and ensure documentation is complete.

- Segregate from flammable or reactive materials.

Temperature & Storage

- Store batteries in a cool, dry place (15–25°C recommended).

- Avoid exposure to extreme heat, moisture, or direct sunlight.

- Do not store near flammable materials.

Worker Safety & Training

- Personnel involved in handling or shipping must be trained in:

- Hazard identification.

- Proper packaging and labeling.

- Emergency procedures (e.g., for leaks or fires).

- Training should be refreshed annually or when regulations change.

- Provide safety data sheets (SDS) for all battery types.

Environmental & End-of-Life Compliance

Recycling & Disposal

- Small circular batteries must not be disposed of in household waste.

- Comply with local take-back and recycling programs.

- In the EU, producers must finance battery collection and recycling.

- In the U.S., follow state-specific rules (e.g., California requires recycling).

Mercury Restrictions

- Many jurisdictions limit mercury content in button cells (e.g., < 2% or fully mercury-free).

- Ensure supplier certifications confirm compliance.

Documentation & Recordkeeping

- Maintain records of:

- Safety Data Sheets (SDS).

- Test summaries (per UN 38.3).

- Shipping declarations and air waybills.

- Training logs and compliance certifications.

- Keep records for at least 3 years, or as required locally.

Best Practices

- Work with certified suppliers who provide full compliance documentation.

- Conduct regular audits of packaging and shipping processes.

- Label consumer products with battery safety warnings (especially for households with children).

- Use tracking and serialization for high-risk or high-value shipments.

Conclusion

Proper logistics and compliance management for small circular batteries ensures safety, legal adherence, and environmental responsibility. By following international standards and local regulations, businesses can mitigate risks, avoid penalties, and support sustainable battery use. Always verify the latest regulatory updates from IATA, UN, and regional authorities before shipping.

In conclusion, sourcing small circular batteries requires careful consideration of several key factors including battery specifications (voltage, capacity, size), chemistry type (such as lithium coin cells, alkaline, or rechargeable options), quality and reliability of suppliers, compliance with safety and environmental standards (e.g., RoHS, REACH), and overall cost-efficiency. It is essential to establish relationships with reputable manufacturers or distributors—whether domestic or international—while ensuring consistent supply chain reliability and adherence to regulatory requirements. Additionally, evaluating long-term availability and potential obsolescence of specific battery models can help mitigate future risks. By conducting thorough due diligence and maintaining a strategic sourcing approach, businesses can secure a dependable supply of small circular batteries that meet performance needs and support the integrity of their end products.