The global blast cabinet market is experiencing steady growth, driven by increasing demand for surface preparation and finishing solutions across industries such as automotive, aerospace, and metal fabrication. According to Grand View Research, the global sandblasting equipment market size was valued at USD 3.2 billion in 2022 and is projected to expand at a CAGR of 5.1% from 2023 to 2030. This growth trajectory creates significant opportunities for both established players and niche manufacturers—particularly small to mid-sized blast cabinet producers that offer specialized, high-quality solutions tailored to specific industrial needs. As manufacturers focus on efficiency, durability, and compliance with environmental and safety standards, innovation among smaller vendors has become a key differentiator. In this evolving landscape, identifying top-performing small manufacturers provides valuable insights for businesses seeking reliable, cost-effective surface treatment equipment.

Top 10 Small Blast Cabinet Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Quality Abrasive Blasting Cabinets

Domain Est. 1998 | Founded: 1978

Website: skatblast.com

Key Highlights: America’s leading manufacturer of affordable Made in USA abrasive sandblasting cabinets since 1978! Remove rust, paint & scale in minutes. View Blast Cabinets….

#2 Blast Cabinets

Domain Est. 1997

Website: blast-it-all.com

Key Highlights: Cube Blast Systems. Industrial blasting solution for large heavy objects with options for powered turn tables, tracks, and doors….

#3 Titan Abrasive Blast Cabinets

Domain Est. 1998

Website: titanabrasive.com

Key Highlights: Titan’s heavy-duty, industrial blast cabinet delivers high performance, reduced operating costs, and improved productivity — all in a user-friendly design ……

#4 Leading Blast Cabinet Manufacturers

Domain Est. 2000

Website: sandblastequipment.com

Key Highlights: Find the leading blast cabinet manufacturers and suppliers throughout the United States with standard and custom solutions and products at discount prices….

#5 Sand, Abrasive, Wet and Vapor Blaster Cabinets

Domain Est. 1996

Website: mediablast.com

Key Highlights: We have a blast cabinet for every application. Over 80 optional features for increased Mediablaster® productivity, part handling and operator safety….

#6 Econoline

Domain Est. 1997

Website: sandblasting.com

Key Highlights: Econoline Abrasive Products is the leader in sandblasting equipment, abrasive blast equipment, blast cabinets, and sandblast dust collectors….

#7 Manual Sandblast Cabinets

Domain Est. 1997

Website: empire-airblast.com

Key Highlights: These rugged, easy-to-use cabinets are available in five standard sizes with your choice of a dust bag or dust collector and can be ordered as either suction ……

#8 Blast Cabinets

Domain Est. 1999

Website: clemcoindustries.com

Key Highlights: Clemco Industries blast cabinets provide enclosed, efficient cleaning and finishing solutions. Compact, durable, and engineered for precision — Transforming ……

#9 Schmidt Abrasive Blasting Equipment

Domain Est. 2010

Website: schmidtabrasiveblasting.com

Key Highlights: Lightweight and most portable in the AmphiBlast family. Wet or dry blast with a single unit. Minimal water usage. Set and forget switching between machine ……

#10 Blast machines and sandblasting equipment

Domain Est. 2014

Website: clemco-international.com

Key Highlights: Clemco blast cabinets are ideal for the processing of small to medium sized workpieces. The sturdy yet compact design ensures that a minimum amount of space ……

Expert Sourcing Insights for Small Blast Cabinet

H2: Emerging Market Trends for Small Blast Cabinets in 2026

The small blast cabinet market is poised for significant evolution by 2026, driven by technological innovation, shifting industrial demands, and sustainability imperatives. As industries across manufacturing, automotive restoration, aerospace, and precision engineering seek efficient surface preparation solutions, compact blasting systems are gaining traction due to their versatility, cost-effectiveness, and space-saving designs. Below are key trends expected to shape the small blast cabinet market in 2026:

-

Increased Demand from SMBs and Niche Workshops

Small and medium-sized businesses (SMBs), along with specialized repair and restoration workshops, are increasingly adopting small blast cabinets. These compact systems offer an affordable entry point for surface treatment without requiring large capital investments or extensive floor space. The rise of micro-manufacturing and custom fabrication, especially in developed and emerging economies, is boosting demand for benchtop and portable blasting units. -

Integration of Automation and IoT Capabilities

By 2026, smart manufacturing trends are driving the integration of automation and Internet of Things (IoT) technologies into small blast cabinets. Features such as programmable blasting cycles, remote monitoring via mobile apps, and real-time performance analytics are becoming standard in premium models. These enhancements improve repeatability, reduce operator dependency, and optimize media consumption, making automated small cabinets attractive for high-mix, low-volume production environments. -

Focus on Dust Control and Environmental Compliance

Environmental regulations are tightening globally, particularly concerning airborne particulate matter and silica dust. In response, manufacturers are developing small blast cabinets with advanced dust collection systems, HEPA filtration, and closed-loop recirculation. These updates not only ensure compliance with OSHA and EU workplace safety standards but also appeal to environmentally conscious end users, supporting the shift toward cleaner manufacturing practices. -

Growth in Alternative Abrasives and Media Recycling

The use of eco-friendly blasting media—such as soda, crushed glass, and biodegradable compounds—is expected to rise in tandem with sustainability goals. Small blast cabinets are being redesigned to accommodate a wider range of media types and include improved media reclamation systems. This reduces operational costs and waste, aligning with circular economy principles increasingly adopted by industrial sectors. -

Expansion in Aerospace and Medical Device Manufacturing

High-precision industries like aerospace and medical device manufacturing are showing growing interest in small-scale blasting for delicate component finishing. These applications require consistent, repeatable surface finishes on small parts, where traditional large-scale systems are impractical. By 2026, expect to see specialized small cabinets engineered for ultra-fine media and cleanroom compatibility. -

Regional Market Growth in Asia-Pacific and Latin America

While North America and Europe remain strong markets due to mature industrial infrastructure, the Asia-Pacific region—particularly India, Vietnam, and Indonesia—is projected to witness the fastest growth. Rising investments in automotive, electronics, and tooling industries, coupled with government support for manufacturing, are fueling demand for affordable and reliable surface treatment equipment, including small blast cabinets. -

E-Commerce and Direct-to-Customer Distribution Models

Online sales channels are reshaping how small blast cabinets are purchased. By 2026, more manufacturers are expected to leverage e-commerce platforms to reach a broader customer base, especially hobbyists, DIY enthusiasts, and small job shops. Enhanced digital product configurators, virtual demos, and augmented reality (AR) support tools will improve user experience and shorten sales cycles.

In conclusion, the 2026 small blast cabinet market will be defined by smarter, cleaner, and more accessible technologies. As industries prioritize efficiency, precision, and sustainability, small blast cabinets will transition from simple tools to integral components of modern surface engineering workflows.

Common Pitfalls When Sourcing a Small Blast Cabinet (Quality, IP)

Sourcing a small blast cabinet may seem straightforward, but overlooking key quality and intellectual property (IP) aspects can lead to significant operational, legal, and financial issues. Here are common pitfalls to avoid:

1. Prioritizing Low Cost Over Build Quality

One of the biggest mistakes is selecting a cabinet based solely on the lowest price. Cheap models often use thin-gauge steel, inferior abrasives handling components, and substandard seals, leading to:

– Rapid wear and structural failure

– Poor containment, increasing dust and safety risks

– Frequent maintenance and downtime

Always inspect material thickness, weld quality, and component durability before purchasing.

2. Overlooking IP Infringement in Design or Components

Many low-cost suppliers replicate patented designs or use counterfeit parts without authorization. Sourcing equipment that infringes on IP can result in:

– Legal liability for the buyer, especially in regulated industries

– Supply chain disruptions if the manufacturer is sued or shut down

– Inability to get spare parts or technical support

Verify that the manufacturer holds proper certifications and does not mimic well-known branded models.

3. Inadequate Dust Collection and Filtration (IP Rating Misinterpretation)

“IP” often refers to Ingress Protection ratings, but confusion arises when buyers assume high IP ratings (e.g., IP54) guarantee effective dust containment. Pitfalls include:

– Misinterpretation of IP ratings (e.g., IP54 protects against dust ingress into electrical components but doesn’t ensure operator safety from airborne particles)

– Poorly designed filtration systems that fail to capture fine particulates, risking OSHA/health compliance

Ensure the entire system—including viewing windows, glove ports, and door seals—meets industrial air quality standards, not just electrical enclosures.

4. Poor Visibility and Ergonomic Design

Low-quality cabinets often feature small or low-transparency viewing windows that quickly fog or scratch. Glove ports may be poorly sealed or made from low-grade rubber, reducing dexterity and safety. These issues impact:

– Operator efficiency and accuracy

– Long-term safety and repeatability of results

Look for anti-static, abrasion-resistant windows and replaceable glove systems from reputable suppliers.

5. Lack of Genuine Technical Support and Documentation

Some suppliers, especially those violating IP, provide incomplete or falsified manuals, lack spare parts availability, or offer no technical support. This leads to:

– Extended downtime during breakdowns

– Inability to validate safety or compliance

– Difficulty in training operators

Choose suppliers with verifiable customer support, clear documentation, and legitimate service channels.

6. Assuming All Cabinets Meet Safety and Compliance Standards

Not all small blast cabinets comply with regional safety standards (e.g., CE, OSHA, ANSI). Some imported units may falsely claim compliance or lack proper grounding, interlocks, or emergency stops. Always:

– Request certification documentation

– Verify third-party testing where applicable

– Avoid suppliers unwilling to provide compliance proof

By focusing on long-term value, verifying IP legitimacy, and ensuring robust design and compliance, buyers can avoid costly mistakes and secure a reliable, safe, and legally sound blasting solution.

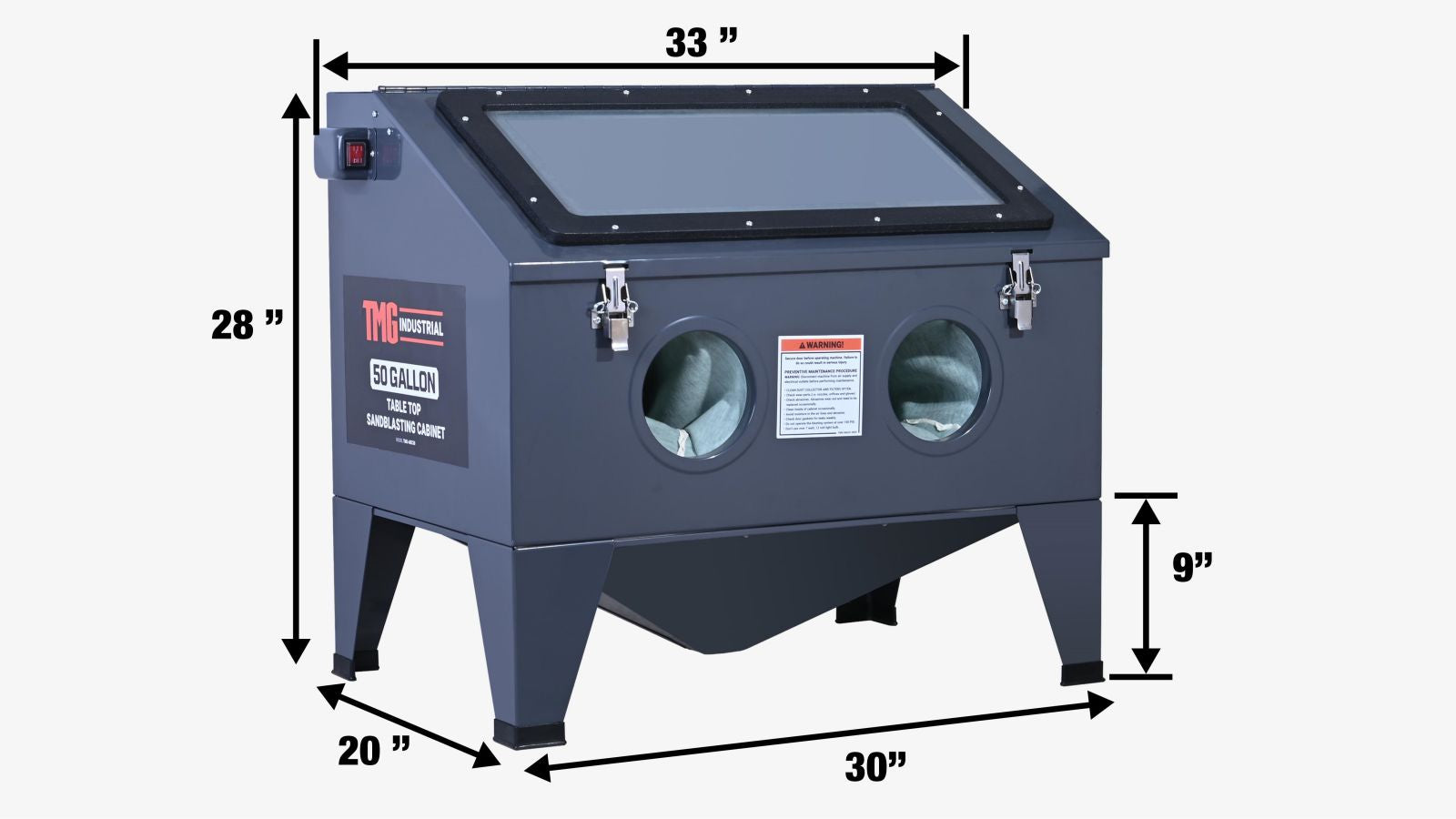

Logistics & Compliance Guide for Small Blast Cabinet

Product Overview

A Small Blast Cabinet is a contained system used for surface preparation and finishing through abrasive blasting. It typically includes a cabinet enclosure, viewing window, gloves for operator handling, abrasive media storage, and a dust collection system. Common applications include cleaning, deburring, smoothing, or texturing small to medium-sized parts.

This guide outlines key logistics considerations and compliance requirements to ensure safe, efficient, and legally compliant operation and transportation.

Shipping & Handling

- Packaging: Ensure the blast cabinet is shipped in a sturdy, wooden crate or heavy-duty cardboard with internal bracing to prevent movement during transit.

- Weight & Dimensions: Confirm the gross weight and external dimensions (L x W x H) for appropriate freight classification and handling equipment (e.g., forklift, pallet jack).

- Fragile Components: Protect the viewing window, gloves, and dust collector with protective film or padding. Mark packaging as “Fragile” and “This Side Up.”

- Assembly Requirements: Provide clear instructions and labeled hardware kits. Confirm if field assembly by technician or end-user is required.

- Delivery Access: Verify site access for delivery vehicles and ensure there is a clear path for moving the cabinet into the facility.

Import/Export Compliance

- HS Code Classification: Use Harmonized System (HS) code 8479.89 (Machines of a kind used in industrial/commercial processing, not elsewhere specified) for international shipping. Confirm with local customs authority for accuracy.

- Export Controls: Verify if the cabinet contains components subject to export restrictions (e.g., high-pressure systems, specialized filtration). No ITAR or EAR licensing typically required for standard models.

- Documentation: Prepare commercial invoice, packing list, bill of lading/airway bill, and certificate of origin. Include technical specifications (voltage, motor type, filtration class) as needed.

- Destination Regulations: Research country-specific import duties, conformity standards (e.g., CE for EU, UKCA for UK), and labeling requirements.

Safety & Regulatory Compliance

- OSHA Standards (USA):

- Comply with 29 CFR 1910 Subpart G (General Environmental Controls) for ventilation and dust control.

- Ensure operator exposure to silica dust is below PEL (Permissible Exposure Limit) via proper dust collection and PPE.

-

Follow lockout/tagout (LOTO) procedures per 29 CFR 1910.147 during maintenance.

-

Dust Collection & Air Quality:

- Equip cabinet with HEPA-filtered dust collector meeting NIOSH or equivalent standards.

- Perform regular filter maintenance; document change intervals.

-

Monitor ambient air quality if blasting toxic or silica-based media.

-

Electrical Compliance:

- Ensure wiring and motor meet NFPA 70 (NEC) standards.

- Confirm voltage (110V/220V) compatibility with site power supply.

-

Use ground-fault circuit interrupters (GFCIs) where applicable.

-

Noise Levels:

- Confirm sound pressure level (SPL) is below OSHA 8-hour TWA limit (90 dBA). Typical small cabinets range 75–85 dBA.

- Provide hearing protection if SPL exceeds 85 dBA.

CE Marking (Europe)

- Ensure conformity with:

- Machinery Directive 2006/42/EC – Includes risk assessment, safety interlocks, and user manuals in local language.

- EMC Directive 2014/30/EU – For electrical interference.

- RoHS Directive 2011/65/EU – Restriction of hazardous substances.

- Issue an EU Declaration of Conformity and affix CE mark visibly on the unit.

Environmental & Waste Management

- Abrasive Media Disposal:

- Classify spent media as hazardous or non-hazardous based on composition (e.g., steel grit, aluminum oxide, plastic).

- Follow EPA regulations (40 CFR) or local waste codes for disposal.

-

Recycle media when possible using a reclaimer system.

-

Secondary Contamination:

- Prevent cross-contamination of materials (e.g., lead-based paint residue).

- Use appropriate containment and cleaning procedures.

Operator Training & Documentation

- Provide comprehensive user manual including:

- Safe operating procedures

- Maintenance schedule

- Emergency shutdown steps

- PPE requirements (respirator, safety glasses, gloves)

- Conduct initial operator training on hazards, lockout procedures, and media handling.

Maintenance & Recordkeeping

- Maintain logs for:

- Filter replacements

- Media changes

- Safety inspections

- Dust collector performance

- Retain compliance documents (test reports, certifications) for minimum 5 years.

Summary

Proper logistics planning and adherence to compliance standards are essential for the safe and legal operation of a Small Blast Cabinet. Key actions include correct classification for shipping, compliance with regional safety and environmental regulations, proper operator training, and diligent maintenance recordkeeping. Always consult local authorities and safety professionals to ensure full compliance with jurisdiction-specific rules.

Conclusion:

After evaluating various options, sourcing a small blast cabinet requires a balanced consideration of size, functionality, durability, and cost-effectiveness. For small-scale operations, hobbyists, or businesses with limited space, a compact blast cabinet offers an efficient solution for surface preparation, cleaning, and finishing tasks. Key factors to consider include abrasive compatibility, cabinet material (typically steel or polyurethane-coated variants), visibility and lighting, dust collection integration, and ease of maintenance.

Purchasing from reputable suppliers ensures quality construction, warranty support, and access to spare parts. While initial cost is important, long-term value—gained through durability and reduced downtime—should guide the decision. Whether opting for new or reconditioned units, prioritizing safety features and user ergonomics enhances productivity and operator comfort.

In summary, investing in a well-designed small blast cabinet tailored to specific application needs leads to improved workflow efficiency, consistent finish quality, and cost savings over time, making it a valuable addition to any workshop or production environment.