The global torque wrench market size was valued at approximately USD 350 million in 2023 and is projected to grow at a compound annual growth rate (CAGR) of around 5.2% from 2024 to 2030, according to Grand View Research. This steady expansion is driven by rising demand from the automotive, aerospace, and industrial manufacturing sectors, where precision tooling and compliance with tightening specifications are critical for safety and performance. As small and medium assembly (SMA) applications—especially in electronics, medical devices, and compact machinery—require increasingly accurate torque control, manufacturers are investing in high-precision, durable, and digitally integrated torque tools. Against this backdrop, a select group of global manufacturers has emerged as leaders in innovation, quality, and market reach. Based on market presence, product range, technological advancement, and industry reputation, here are the top 7 SMA torque wrench manufacturers shaping the future of precision assembly.

Top 7 Sma Torque Wrench Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SMA, 3.5mm, 2.92mm, 2.4mm, 1.85mm Torque Wrench

Domain Est. 2002

#2 SMA torque wrench Wrenches

Domain Est. 1995

#3 Torque Wrenches

Domain Est. 1996

Website: talleycom.com

Key Highlights: 5–9 day delivery 30-day returnsFull Description. Torque Wrench, SMA/Male 5/16in 8lb/inch. Page 1 of 1. Home · Favorites · Quick Form · Subscribe · Privacy Policy · Return ……

#4 WR

Domain Est. 1998

Website: we-online.com

Key Highlights: WR-ToolRF Torque Wrench for SMA & RPSMA Plugs ; Wrench Material, Stainless Steel ; Handle Material, Aluminium ……

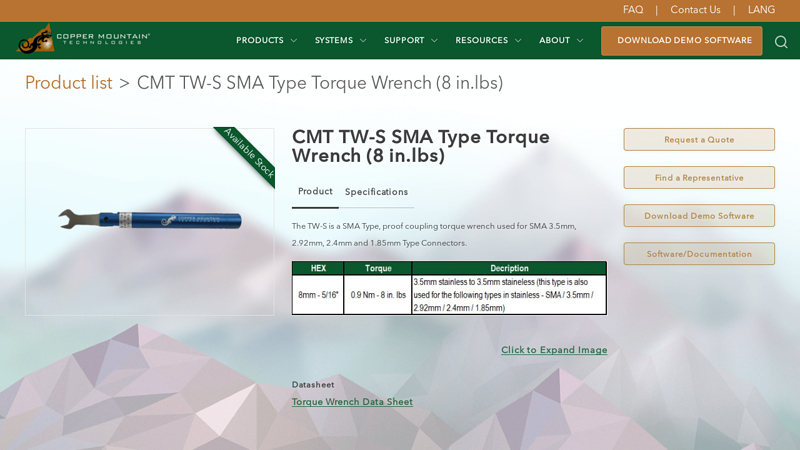

#5 CMT TW

Domain Est. 2011

Website: coppermountaintech.com

Key Highlights: The TW-S is a SMA Type, proof coupling torque wrench used for SMA 3.5mm, 2.92mm, 2.4mm and 1.85mm Type Connectors….

#6 SMA Torque Wrenches & Screwdrivers

Domain Est. 2015

Website: centricrf.com

Key Highlights: 1–4 day delivery 30-day returnsTorque Wrench for Stainless Steel SMA or any 2.92mm, 2.4mm, 3.5mm connectors. 8 in-lbs +/- 8%. Click type torque wrench….

#7 RP

Domain Est. 2023

Website: isohorns.com

Key Highlights: $99 delivery 30-day returnsThe RF torque wrench is a 5/16″ bit, screwdriver-style tool preset to 8 in-lbs, designed for use with RP-SMA connectors. It ensures precise mating force …

Expert Sourcing Insights for Sma Torque Wrench

H2: Analysis of 2026 Market Trends for SMA Torque Wrenches

The global market for precision hand tools, including SMA torque wrenches, is expected to experience significant evolution by 2026, driven by advancements in manufacturing technologies, tightening regulatory standards, and growing demand for accuracy in automotive, aerospace, and industrial maintenance sectors. SMA torque wrenches—recognized for their durability, precision calibration, and user-friendly design—are poised to benefit from several key market trends.

-

Increased Demand in Electric Vehicle (EV) Manufacturing

By 2026, the expansion of the electric vehicle industry is anticipated to be a major growth driver for SMA torque wrenches. EV assembly requires extremely precise torque application, especially in battery pack installation and electric motor assembly, where over-tightening can lead to component failure. SMA’s reputation for high accuracy and reliability positions its torque wrenches as preferred tools in EV production lines, especially in regions like North America, Europe, and China. -

Adoption of Smart and Digital Torque Tools

The integration of digital technology into traditional hand tools is accelerating. SMA is expected to expand its product line to include smart torque wrenches with Bluetooth connectivity, real-time data logging, and compatibility with Industry 4.0 systems. These features enable traceability and quality control in regulated industries, making them highly attractive to aerospace, defense, and medical device manufacturers. By 2026, digitally enhanced SMA torque wrenches could command a growing share of the premium tools market. -

Stringent Regulatory and Quality Compliance Requirements

Global standards such as ISO 6789:2017 (updated for calibration and accuracy) will continue to influence tool specifications. Manufacturers and maintenance facilities will increasingly require tools that are certified and regularly recalibrated. SMA’s commitment to compliance and its established calibration services will strengthen its competitive advantage, particularly in markets where audit trails and tool certification are mandatory. -

Growth in Renewable Energy and Infrastructure Projects

The push toward renewable energy—particularly wind and solar installations—requires robust and reliable torque tools for turbine assembly and maintenance. SMA torque wrenches, known for performance in high-torque applications, are well-suited for such environments. Government investments in green infrastructure across Europe, North America, and parts of Asia will likely boost demand for industrial-grade tools like those offered by SMA. -

Expansion in Aftermarket and Calibration Services

Beyond tool sales, SMA is expected to grow its service offerings by 2026, including mobile calibration units, digital certification platforms, and extended warranties. As companies seek to reduce downtime and maintain compliance, the aftermarket service segment will become a critical revenue stream, enhancing customer loyalty and lifetime value. -

Competitive Landscape and Regional Growth

While facing competition from established brands like Snap-on, Stahlwille, and Norbar, SMA differentiates itself through innovation, cost-efficiency, and strong distribution networks in emerging markets. Regions such as Southeast Asia, India, and Latin America are expected to see rising demand due to industrialization and local manufacturing initiatives, providing SMA with new growth opportunities.

In conclusion, the 2026 market outlook for SMA torque wrenches is highly favorable, supported by technological innovation, regulatory tailwinds, and expanding industrial applications. Strategic focus on digital integration, sustainability, and service expansion will be key to maintaining market leadership in an increasingly competitive and precision-driven global tools market.

Common Pitfalls When Sourcing SMA Torque Wrenches (Quality & IP)

Sourcing SMA (Small) torque wrenches—commonly used in precision applications like electronics, aerospace, and medical devices—requires careful attention to quality and intellectual property (IP) concerns. Overlooking these aspects can lead to product failure, safety risks, compliance issues, and legal exposure. Below are key pitfalls to avoid:

Poor Build Quality and Accuracy

One of the most significant risks when sourcing SMA torque wrenches is receiving tools with substandard build quality. Low-cost suppliers may use inferior materials, imprecise manufacturing processes, or lack proper calibration. This leads to inconsistent torque delivery, which can result in under-tightened or over-tightened fasteners—potentially causing equipment failure or safety hazards.

Inadequate or Missing Calibration Certification

Many budget SMA torque wrenches lack traceable calibration certificates compliant with international standards (e.g., ISO 6789). Without proper certification, it’s impossible to verify accuracy or ensure compliance with quality management systems. Purchasing uncalibrated tools may violate industry regulations, especially in regulated sectors like aerospace or medical manufacturing.

Non-Compliance with International Standards

Some suppliers offer SMA torque wrenches that claim to meet ISO 6789 or other standards but fail to undergo proper testing or certification. Using non-compliant tools can void warranties, fail audits, and expose your organization to liability. Always verify compliance through third-party test reports or accredited certification bodies.

Counterfeit or Clone Products

The market includes counterfeit or cloned versions of reputable brands. These copies mimic the appearance of genuine tools but use inferior components and lack proper IP licensing. They often fail prematurely and offer no technical support or warranty. Sourcing from unauthorized distributors increases this risk significantly.

Intellectual Property Infringement

Manufacturing or distributing SMA torque wrenches that replicate patented designs, logos, or proprietary technology can lead to IP violations. Even when sourcing as a buyer, purchasing such tools may indirectly support infringing activities and expose your company to reputational or legal risk—especially if used in high-liability applications.

Lack of After-Sales Support and Service

Low-cost suppliers, especially those overseas, may not offer repair, recalibration, or spare parts services. SMA torque wrenches require periodic maintenance and recalibration to remain accurate. Without accessible support, the total cost of ownership increases, and downtime can disrupt operations.

Inconsistent Batch Quality

Some suppliers exhibit high variability between production batches due to poor quality control. One batch may perform adequately, while the next fails prematurely or delivers inaccurate torque. This inconsistency undermines process reliability and increases inspection and rejection rates.

Misleading Specifications and Marketing

Certain vendors exaggerate torque range accuracy, durability, or material quality in their product listings. For example, claiming “±2% accuracy” without proper testing or using vague terms like “industrial grade” without substantiation. Always request verifiable technical documentation before purchase.

Ignoring Supply Chain Transparency

Failing to audit the supplier’s manufacturing process, material sourcing, and quality controls increases the risk of receiving subpar products. A lack of transparency may also hide unethical labor practices or non-compliance with environmental regulations (e.g., RoHS, REACH).

Overlooking Long-Term Total Cost of Ownership

While initial price is tempting, low-quality SMA torque wrenches often require frequent replacement, recalibration, and cause rework due to errors. Investing in high-quality, IP-compliant tools from reputable suppliers typically results in lower long-term costs and greater reliability.

By recognizing and addressing these common pitfalls, organizations can ensure they source SMA torque wrenches that meet both quality standards and intellectual property requirements, minimizing risk and maximizing performance.

Logistics & Compliance Guide for Sma Torque Wrench

Product Overview

The Sma Torque Wrench is a precision hand tool designed for accurate torque application in industrial, automotive, and mechanical applications. Ensuring proper logistics handling and compliance with international standards is essential for safe distribution and regulatory adherence.

Packaging & Labeling Requirements

- Primary Packaging: Each torque wrench must be securely packaged in a protective case or molded tray to prevent damage during transit.

- Secondary Packaging: Use sturdy corrugated cardboard boxes with sufficient cushioning (e.g., foam inserts or bubble wrap) to protect against shock and vibration.

- Labeling:

- Include product name, model number, torque range, and calibration date.

- Affix barcode/UPC for inventory tracking.

- Apply hazard labels if applicable (e.g., fragile, do not stack).

- Ensure labels are durable and legible under transport conditions.

Shipping & Handling

- Temperature & Humidity: Store and ship in a controlled environment (10°C to 30°C, humidity < 60%) to protect calibration integrity.

- Stacking Limit: Clearly mark maximum stack height (e.g., “Stack No Higher Than 5 Boxes”) to prevent box collapse.

- Transport Mode: Suitable for air, sea, and ground freight. Use tamper-evident seals for high-value shipments.

- Fragile Handling: Clearly mark packages as “Fragile—Precision Instrument” and “This Side Up.”

Import/Export Compliance

- HS Code: 8204.11.00 (Adjustable spanners and wrenches, hand-operated).

- Export Controls: Verify if the product contains materials or technology subject to export restrictions (e.g., EAR99 under U.S. Export Administration Regulations).

- Documentation:

- Commercial Invoice

- Packing List

- Certificate of Origin

- Bill of Lading or Air Waybill

- Customs Clearance: Ensure all documents include accurate product descriptions, value, weight, and country of origin.

Regulatory & Safety Compliance

- CE Marking: Required for EU markets. Confirm compliance with Machinery Directive 2006/42/EC and PPE Regulation (EU) 2016/425.

- UKCA Marking: Required for the UK market (post-Brexit).

- RoHS Compliance: Confirm that the product is free of restricted substances (e.g., lead, cadmium, mercury).

- REACH Regulation: Ensure no use of Substances of Very High Concern (SVHC) above threshold limits.

- Calibration Certification: Include a traceable calibration certificate (e.g., ISO/IEC 17025) with each unit.

Storage Requirements

- Environment: Store in a dry, clean area protected from dust, moisture, and extreme temperatures.

- Shelving: Use racks or shelves to avoid floor contact and ensure proper air circulation.

- Inventory Rotation: Apply FIFO (First In, First Out) to manage calibration cycles and shelf life.

Returns & Reverse Logistics

- Return Authorization: All returns require a pre-approved Return Merchandise Authorization (RMA) number.

- Inspection: Upon return, inspect for damage, calibration drift, or misuse.

- Refurbishment/Recycling: Follow internal procedures for testing, recalibration, or environmentally compliant disposal.

Certifications & Documentation Archive

- Maintain digital and physical records of:

- Test and calibration reports

- Material compliance certificates (RoHS, REACH)

- ISO 9001 quality management certification (if applicable)

- CE/UKCA Declaration of Conformity

- Retain documentation for a minimum of 10 years for audit and traceability purposes.

Contact Information

For compliance inquiries or logistics support, contact:

– Compliance Officer: [email protected]

– Logistics Coordinator: [email protected]

– Customer Service: [email protected]

Ensure all personnel involved in handling, shipping, or importing the Sma Torque Wrench are trained on this guide to maintain compliance and product integrity.

Conclusion: Sourcing an SMA Torque Wrench

In conclusion, sourcing an SMA torque wrench requires careful consideration of application requirements, quality standards, and supplier reliability. SMA (SubMiniature version A) connectors are commonly used in RF and telecommunications applications where precision and repeatability are critical. Therefore, selecting a torque wrench specifically calibrated for SMA connectors—typically requiring a torque value of 7–10 in-lb (0.8–1.1 Nm)—is essential to ensure proper connection integrity and prevent damage to delicate components.

When sourcing, prioritize torque wrenches from reputable manufacturers that comply with industry standards (such as ISO 6789) and offer traceable calibration. Features such as ergonomic design, accuracy, durability, and ease of calibration should be evaluated. Additionally, consider whether the tool will be used in a controlled production environment or in the field, as this may influence the choice between fixed and adjustable models.

Ultimately, investing in a high-quality SMA torque wrench from a trusted supplier not only ensures consistent performance and connection reliability but also reduces the risk of signal loss, connector failure, and costly rework. Proper sourcing supports long-term operational efficiency and maintains the integrity of high-frequency systems.