The global slip-on flange market is experiencing steady growth, driven by rising demand across oil & gas, petrochemical, and water treatment industries. According to Grand View Research, the global flange market size was valued at USD 7.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by increased infrastructure investments, expanding pipeline networks, and the need for reliable, cost-effective piping solutions—where slip-on flanges are often preferred for their ease of assembly and lower upfront cost compared to weld neck variants. With Asia Pacific leading regional demand due to rapid industrialization and energy sector development, sourcing from reputable manufacturers has become critical for quality assurance and compliance with international standards like ASME, ANSI, and DIN. As procurement teams prioritize suppliers with consistent production capabilities, material traceability, and global certifications, identifying top-tier slip-on flange manufacturers is essential for maintaining supply chain integrity in high-stakes environments.

Top 9 Slip On Flanges Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Carbon, Steel, & Alloy Pipe Flanges

Domain Est. 1996

Website: coastalflange.com

Key Highlights: We’re an ISO 9001:2015 certified quality management system that’s specialized In large diameter steel pipe flanges, carbon, stainless and alloys….

#2 Slip-On Flanges for Industrial Piping

Domain Est. 1998

Website: apiint.com

Key Highlights: We offer carbon and stainless steel slip-on flanges in AWWA, ANSI/ASME and DIN standards, available in flat face and raised face designs….

#3 Slip

Domain Est. 2011

Website: diptimetal.com

Key Highlights: Rating 4.9 (285) Oct 20, 2025 · DIPTI METAL INDUSTRIES offers a comprehensive inventory of Slip-On Flanges in all standard sizes and pressure classes, ensuring immediate ……

#4 Slip on Flanges Manufacturer

Domain Est. 2016

Website: msflanges.com

Key Highlights: We Royal Steel India one of the leading Manufacturer, Exporter & Supplier of Slip on Flanges. Slip on Flanges are a popular type of pipe flanges….

#5 Slip on Flanges

Domain Est. 2018

Website: aspirinox.com

Key Highlights: Aspirinox Alloys Inc is a renowned manufacturer and trader of wide range of SORF Flanges. We design slip on Raised Face Flanges with various grades and ……

#6 Cangzhou Haoguan Pipe Fittings Flanges Manufacturing Co.,Ltd

Domain Est. 2018

Website: hgffgroup.com

Key Highlights: HGFF is a manufacturer of butt weld pipe fittings and flanges which has more 20 years’ experience, also a stockiest of carbon steel pipes….

#7 BFN Forgings

Domain Est. 2020

Website: bfnf.in

Key Highlights: BFN Forgings Pvt. Ltd is a well-known stainless steel SS flange manufacturer and suppliers in India. Contact us to get high quality SS flanges according to ……

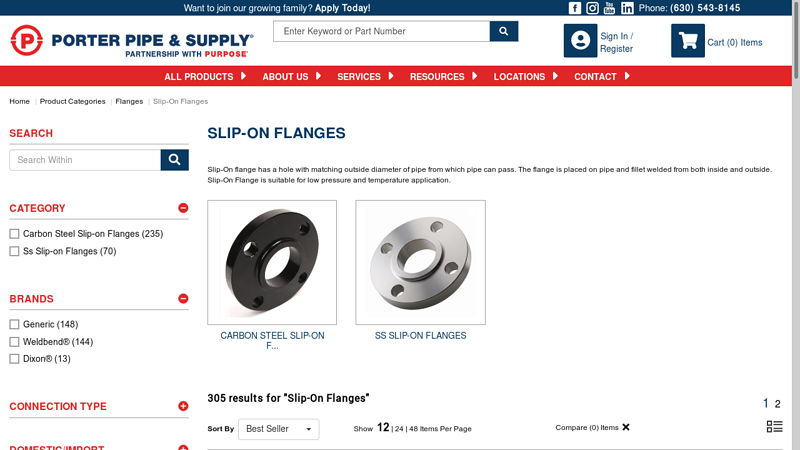

#8 Slip-On Flanges

Domain Est. 1996

#9 Slip

Domain Est. 1997

Website: texasflange.com

Key Highlights: Slip-on flanges are cost-effective pipe fittings, ideal for low-pressure applications. Discover our high-quality flanges….

Expert Sourcing Insights for Slip On Flanges

H2: 2026 Market Trends for Slip-On Flanges

The global Slip-On Flanges market in 2026 is expected to reflect significant shifts driven by evolving industrial demands, technological advancements, and macroeconomic factors. These versatile components, known for their ease of installation and cost-effectiveness in low-pressure, non-critical applications, are adapting to meet the needs of a rapidly transforming industrial landscape.

1. Steady Growth Driven by Infrastructure and Energy Expansion:

The primary driver for slip-on flanges in 2026 remains the expansion of infrastructure and energy sectors globally. Increased investments in water treatment, HVAC systems, and commercial construction—particularly in developing economies across Asia-Pacific, the Middle East, and Africa—are fueling demand. Additionally, ongoing maintenance and upgrade projects in aging oil & gas and chemical processing facilities continue to require reliable, economical flange solutions for auxiliary and non-critical piping lines where slip-ons are well-suited.

2. Material Innovation and Sustainability Focus:

Environmental regulations and sustainability goals are pushing manufacturers to innovate. In 2026, expect a growing preference for corrosion-resistant alloys (CRAs) and duplex stainless steels in slip-on flanges to extend service life and reduce maintenance. Simultaneously, there is increased scrutiny on manufacturing efficiency and carbon footprint, leading to investments in cleaner production processes and potentially recycled materials in lower-grade carbon steel flanges.

3. Regional Manufacturing Shifts and Supply Chain Resilience:

Geopolitical dynamics and supply chain disruptions have prompted a reevaluation of sourcing strategies. By 2026, there is a noticeable trend toward regionalization—especially in North America and Europe—where nearshoring and onshoring are gaining traction to mitigate risks. Meanwhile, Asia-Pacific remains a dominant manufacturing hub, with countries like India and Vietnam emerging as competitive alternatives to traditional suppliers, balancing cost and reliability.

4. Digital Integration and Quality Assurance:

The integration of digital technologies such as IoT-enabled quality control systems, blockchain for traceability, and AI-driven predictive maintenance planning is becoming more prevalent. In 2026, leading slip-on flange suppliers are leveraging digital twins and smart manufacturing to ensure consistent dimensional accuracy and compliance with international standards (ASME, API, EN), enhancing trust among end-users in critical applications.

5. Competitive Pricing Pressure and Value Engineering:

Despite rising raw material costs, intense competition—especially from Asian manufacturers—keeps pricing under pressure. This has led to increased value engineering, where customers and engineers assess total lifecycle costs. While weld neck flanges may be preferred for high-stress environments, slip-on flanges maintain strong market share in cost-sensitive projects due to lower material and labor costs during installation.

6. Niche Applications and Customization Demand:

Emerging applications in renewable energy (e.g., geothermal systems, hydrogen infrastructure) and modular construction are creating new opportunities. These sectors often require customized slip-on flanges with specific coatings, dimensions, or testing certifications. As a result, manufacturers offering agile production and customization capabilities are gaining a competitive edge in 2026.

Conclusion:

By 2026, the slip-on flange market is characterized by a balance between traditional reliability and modern innovation. While they remain a staple in low-pressure industrial piping, success will increasingly depend on adaptability, regional agility, sustainable practices, and digital integration. Companies that align with these trends are poised to capture growth amid evolving global demands.

Common Pitfalls Sourcing Slip On Flanges (Quality, IP)

When sourcing Slip On Flanges, buyers often encounter critical quality and inspection plan (IP) issues that can compromise system integrity, safety, and compliance. Recognizing these common pitfalls is essential for ensuring reliable performance and avoiding costly failures or rework.

Inadequate Material Certification and Traceability

A frequent issue is receiving flanges without proper material test reports (MTRs) or with incomplete documentation. Lack of full traceability (e.g., heat number matching) raises concerns about material authenticity and compliance with specified standards like ASTM A105, A350, or A182. Buyers may unknowingly receive substandard or non-conforming materials, increasing the risk of in-service failure.

Poor Dimensional Accuracy and Tolerances

Slip On Flanges must adhere to strict dimensional tolerances per standards such as ASME B16.5 or B16.47. Common quality issues include incorrect bore diameter, hub length, or bolt hole alignment. Inaccurate dimensions lead to misalignment, gasket leakage, or welding difficulties, compromising the integrity of the entire piping assembly.

Substandard Welding Preparation and Surface Finish

The hub of a Slip On Flange must have a proper bevel or preparation to ensure sound weld integrity. Poor surface finish, cracks, or insufficient machining can lead to incomplete fusion, porosity, or stress concentrations. These flaws are often missed during visual inspection and may only become apparent during hydrotesting or operational service.

Inconsistent or Missing Non-Destructive Testing (NDT)

Many suppliers skip or falsify required NDT procedures such as magnetic particle testing (MT) or ultrasonic testing (UT), especially for critical applications. Without a robust inspection plan (IP) that mandates and verifies NDT compliance, defects like subsurface cracks or laminations may go undetected, leading to catastrophic failures under pressure.

Misrepresentation of Pressure Ratings and Standards Compliance

Some suppliers mislabel flanges with incorrect pressure ratings (e.g., marking Class 300 instead of Class 150) or claim compliance with standards they do not meet. This can result in flanges being used in applications beyond their design limits, creating serious safety hazards.

Inadequate Quality Control and Certification Oversight

Sourcing from manufacturers with weak quality management systems increases the risk of inconsistent production quality. Lack of third-party inspections (e.g., by API 5L or ISO 9001 auditors) or failure to follow a defined IP reduces confidence in product reliability and regulatory compliance.

Overlooking Coating and Corrosion Protection

For flanges used in corrosive environments, inadequate or uneven protective coatings (e.g., anti-rust oil, paint, or galvanizing) can lead to premature degradation. Buyers often neglect to specify coating requirements in procurement documents, leaving them vulnerable to early field failures.

Insufficient Supplier Qualification and Audit Practices

Relying solely on price without vetting the supplier’s manufacturing capability, quality history, or audit performance is a major pitfall. Unqualified suppliers may cut corners on raw materials, machining, or inspection to reduce costs, directly impacting flange quality and long-term performance.

Avoiding these pitfalls requires a rigorous procurement process, including clear technical specifications, defined IP requirements, material traceability mandates, and regular supplier audits to ensure consistent quality and compliance.

Logistics & Compliance Guide for Slip On Flanges

Overview of Slip On Flanges

Slip On Flanges are commonly used in piping systems to connect pipes, valves, and equipment. They are designed to slip over the pipe and are typically welded on both the inside and outside for secure attachment. Due to their widespread use in industries such as oil & gas, petrochemical, and water treatment, strict logistics and compliance protocols must be followed to ensure safety, reliability, and regulatory adherence.

Material and Manufacturing Standards

Slip On Flanges must be manufactured in accordance with recognized international standards to ensure compatibility and performance. Key standards include:

– ASME B16.5: Covers pipe flanges and flanged fittings for nominal pipe sizes (NPS) 1/2″ to 24″ and pressure classes from 150 to 2500.

– ASME B16.47: Applies to larger diameter flanges (NPS 26″ to 60″).

– ASTM Standards: Materials must comply with relevant ASTM specifications (e.g., ASTM A105 for carbon steel, ASTM A182 for stainless steel).

– EN 1092-1: European standard for steel flanges, used in EU markets.

Manufacturers must provide Material Test Certificates (MTCs) and ensure traceability of raw materials.

Quality Control and Inspection Requirements

To ensure compliance, the following quality controls are essential:

– Dimensional inspection per ASME or EN standards.

– Non-destructive testing (NDT), including visual, dye penetrant, magnetic particle, and ultrasonic testing where applicable.

– Positive Material Identification (PMI) for critical applications.

– Third-party inspection (e.g., SGS, BV, or customer-appointed inspectors) may be required based on project specifications.

Packaging and Marking

Proper packaging prevents damage during transit:

– Flanges should be protected with anti-rust oil or VCI (Vapor Corrosion Inhibitor) paper.

– Wooden crates or steel捆扎 are recommended for bulk shipments.

– Each flange must be permanently marked with:

– Manufacturer’s name or trademark

– Material grade

– Size and pressure class

– Standard designation (e.g., ASME B16.5)

– Heat number or batch ID

Logistics and Transportation

Careful handling and shipping procedures are critical:

– Use padded lifting slings to avoid damaging flange faces.

– Secure loads on flatbed trucks or in containers to prevent shifting.

– Avoid exposure to moisture; use waterproof tarpaulins or sealed containers.

– For international shipments, ensure compliance with IMDG Code (for sea freight) or ADR (for road transport in Europe) if hazardous coatings are used.

Import/Export Compliance

When shipping across borders:

– Prepare accurate commercial invoices, packing lists, and certificates of origin.

– Ensure adherence to destination country’s import regulations (e.g., CE marking for EU, CRN for Canada).

– Include necessary certifications: ISO 9001, PED (Pressure Equipment Directive) for EU, or API monogram if applicable.

– Sanctions screening and customs classification (HS Code: typically 7307.21 or 7307.23 for steel flanges) must be verified.

Environmental, Health, and Safety (EHS) Considerations

- Workers handling flanges must use appropriate PPE (gloves, safety glasses) due to sharp edges.

- Storage areas should be dry, level, and free from contaminants to prevent corrosion.

- Follow local regulations for disposal of packaging materials and protective coatings.

Documentation and Traceability

Maintain complete documentation for compliance audits:

– Mill Test Reports (MTRs)

– Inspection and test records

– Packing and shipping documents

– Certificates of Compliance (CoC)

– Traceability logs linking heat numbers to individual flanges

Conclusion

Adhering to logistics and compliance guidelines for Slip On Flanges ensures product integrity, regulatory acceptance, and operational safety. By following established standards and maintaining thorough documentation, suppliers and end-users can minimize risks and ensure seamless integration into piping systems worldwide.

Conclusion for Sourcing Slip-On Flanges

Sourcing slip-on flanges requires a strategic approach that balances quality, cost, compliance, and supplier reliability. These flanges, valued for their ease of installation and weldability, are widely used in piping systems across industries such as oil and gas, petrochemicals, and water treatment. When sourcing, it is essential to prioritize certified suppliers who adhere to international standards such as ASME B16.5, API, and material specifications like ASTM A105, ASTM A350, or stainless steel grades.

Key considerations include material compatibility with the operating environment, dimensional accuracy, traceability, and documentation (such as Mill Test Certificates). Additionally, evaluating the supplier’s production capabilities, quality control processes, and delivery timelines ensures consistent supply and reduces project delays.

Total cost of ownership—not just purchase price—should guide decisions, factoring in logistics, lead times, and potential risks from substandard products. Establishing long-term partnerships with reputable manufacturers enhances supply chain resilience and supports compliance with safety and operational requirements.

In conclusion, effective sourcing of slip-on flanges hinges on due diligence, clear technical specifications, and strong supplier relationships, ultimately contributing to the safety, reliability, and efficiency of piping systems.