The global weather stripping market is experiencing steady growth, driven by rising demand for energy-efficient building solutions and increased residential and commercial construction activities. According to Mordor Intelligence, the weather stripping market was valued at USD 2.1 billion in 2023 and is projected to grow at a CAGR of 5.8% from 2024 to 2029. A key segment within this market—sliding window weather stripping—is seeing heightened demand due to its effectiveness in reducing air leakage, improving thermal efficiency, and minimizing noise infiltration. With North America and Europe leading adoption due to stringent energy regulations, and Asia-Pacific emerging as a fast-growing region, manufacturers are investing in innovative materials such as silicone, EPDM rubber, and brush seals to meet performance and durability requirements. As competition intensifies, identifying top-tier sliding window weather stripping manufacturers with a strong track record in product quality, R&D, and global supply capabilities becomes critical for distributors, contractors, and OEMs alike.

Top 10 Sliding Window Weather Stripping Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Protecting the Essential

Domain Est. 1996

Website: trelleborg.com

Key Highlights: For over a century, we have pioneered applied polymer engineering, growing from a rubber manufacturer into a world leader in engineered polymer ……

#2 PEMKO

Domain Est. 1995 | Founded: 1952

Website: pemko.com

Key Highlights: Since 1952, Pemko, a leader in weatherstripping, has expanded its expertise to provide a diverse selection of high-quality architectural door accessories….

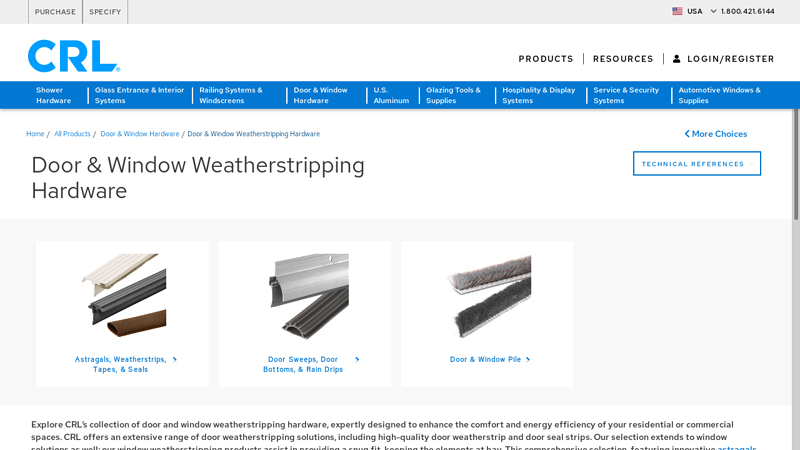

#3 Door & Window Weatherstripping Hardware

Domain Est. 1995

Website: crlaurence.com

Key Highlights: Explore our door & window weatherstripping hardware for optimal comfort & efficiency. Shop CRL, the industry leader in architectural hardware, today….

#4 seal ‘n peel original weatherstripping

Domain Est. 1995

Website: dap.com

Key Highlights: Removeable, seasonal weatherstripping product for temporarily sealing drafty windows, doors, air conditioners, vents or fans to save energy and improve comfort….

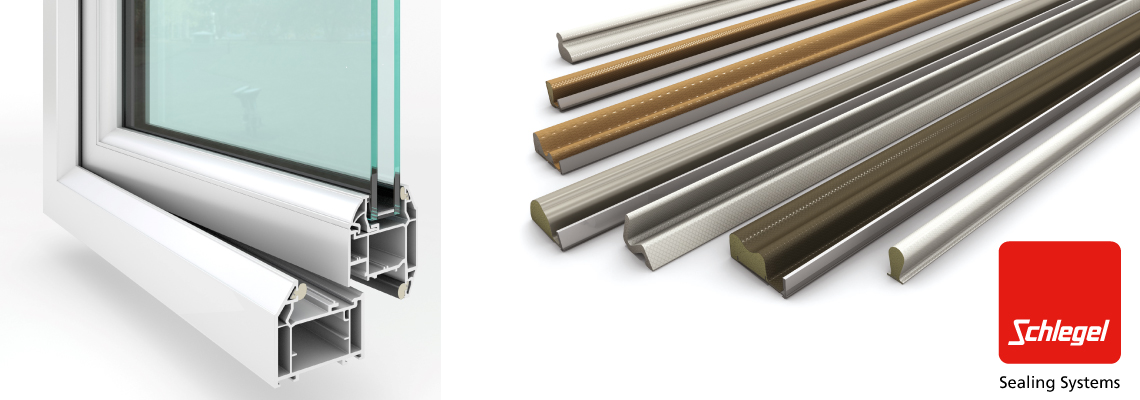

#5 Schlegel

Domain Est. 1997

Website: schlegel.com

Key Highlights: Schlegel: High performance sealing solutions · Gaskets and seals for windows, doors and furniture · About · Q-LON · Cradle to Cradle certified · Superior recovery….

#6 Quanex

Domain Est. 1998

Website: quanex.com

Key Highlights: Quanex is a global leader in building product solutions, specializing in window and door hardware, building access solutions, and fenestration components that ……

#7 Weather Seals

Domain Est. 1998

Website: sunwindows.com

Key Highlights: Complete weather-stripping and secure sash closure provide an air-tight seal. Our product air-infiltration ratings out-pace the industry standards….

#8 Self

Domain Est. 1999

Website: cooperstandard.com

Key Highlights: Cooper Standard ISG’s self-sealing weatherstrips are easy to install, locking glass securely in place while providing an effective seal from the elements….

#9 National Guard Products

Domain Est. 2000 | Founded: 1935

Website: ngp.com

Key Highlights: National Guard Products, based in Memphis and founded in 1935, is a privately held Life-Safety Products Company serving the commercial construction market….

#10 air

Domain Est. 2013

Website: air-lux.com

Key Highlights: air-lux is the unique sealing system for floor- and ceiling-flush sliding windows, descending windows, pivot doors and special solutions….

Expert Sourcing Insights for Sliding Window Weather Stripping

2026 Market Trends for Sliding Window Weather Stripping

The global market for sliding window weather stripping is poised for significant evolution by 2026, driven by heightened environmental awareness, technological advancements, and shifting construction practices. Key trends shaping the industry include:

Rising Demand for Energy Efficiency and Sustainability

With global energy costs remaining volatile and climate change initiatives gaining momentum, consumers and builders are prioritizing energy-efficient building materials. Sliding window weather stripping plays a crucial role in reducing air leakage, improving insulation, and lowering heating and cooling expenses. By 2026, demand will be heavily influenced by stricter building codes—such as those aligned with LEED, ENERGY STAR, and EU Green Deal standards—mandating higher thermal performance. This shift will favor eco-friendly, recyclable, and low-VOC (volatile organic compound) weather stripping materials like thermoplastic elastomers (TPE) and recycled silicone over traditional PVC.

Growth in Retrofit and DIY Markets

The residential retrofit segment is expected to dominate market growth through 2026, as homeowners seek cost-effective ways to improve comfort and reduce utility bills without replacing entire windows. The do-it-yourself (DIY) trend continues to expand, supported by online tutorials and easy-to-install peel-and-stick or compression-fit weather stripping products. Manufacturers are responding with user-friendly, tool-free solutions that cater to non-professionals, driving accessibility and market penetration.

Innovation in Smart and Adaptive Materials

Technological advancements are introducing smart weather stripping solutions capable of adapting to temperature and humidity changes. By 2026, early-stage adoption of responsive materials—such as shape-memory alloys or hydrogel-based seals—could emerge in high-end residential and commercial applications. While still niche, these innovations signal a move toward intelligent building envelopes that dynamically optimize sealing performance.

Expansion in Emerging Markets

Urbanization and rising disposable incomes in regions like Asia-Pacific, Latin America, and parts of Africa will fuel demand for modern housing and renovation. Countries such as India, Indonesia, and Mexico are seeing increased construction activity, creating opportunities for both budget-friendly and premium weather stripping products. Localized manufacturing and distribution partnerships will be key for market entry and competitiveness.

Consolidation and Brand Differentiation

As competition intensifies, larger players are expected to consolidate through mergers and acquisitions, while niche brands focus on differentiation through sustainability credentials, product durability, and aesthetic design (e.g., low-profile or color-matched strips). Digital marketing and e-commerce will play an expanded role in reaching end consumers directly, particularly in North America and Europe.

In summary, by 2026, the sliding window weather stripping market will be characterized by a strong focus on sustainability, energy savings, user convenience, and technological refinement—positioning it as a critical component in the global push toward greener, more resilient buildings.

Common Pitfalls When Sourcing Sliding Window Weather Stripping (Quality and Intellectual Property)

Sourcing sliding window weather stripping can be deceptively complex, with several pitfalls related to both product quality and intellectual property (IP) concerns. Being aware of these issues helps ensure reliable performance, legal compliance, and long-term cost savings.

Poor Material Quality Leading to Premature Failure

Many low-cost weather stripping options use substandard materials such as low-grade PVC, inferior rubber compounds, or non-UV-stabilized plastics. These materials degrade quickly when exposed to sunlight, extreme temperatures, or moisture, resulting in cracking, hardening, or shrinking. This compromises the seal, increases energy loss, and necessitates frequent replacement—ultimately raising lifecycle costs.

Inaccurate Dimensional Tolerances

Weather stripping must fit precisely to create an effective seal. Sourcing from unreliable suppliers may result in products with inconsistent lengths, thicknesses, or profiles. Even minor deviations can prevent proper compression against the window frame, leading to air and water infiltration. This is especially critical in retrofit applications where replacement parts must match original equipment specifications.

Lack of Durability Under Repeated Use

Sliding windows operate frequently, requiring weather stripping that maintains elasticity and resilience over thousands of cycles. Poor-quality seals may compress permanently (set compression) or lose flexibility, reducing sealing effectiveness over time. Suppliers may not provide adequate cycle testing data, making it difficult to assess long-term durability.

Misrepresentation of Compatibility and Performance Claims

Some suppliers exaggerate performance claims—such as energy efficiency, noise reduction, or wind resistance—without third-party testing or certification. This misrepresentation can lead to unsuitable product selection, failing to meet building code requirements or performance expectations, especially in commercial or high-performance residential projects.

Intellectual Property Infringement Risks

Sourcing generic or unbranded weather stripping from certain manufacturers—especially overseas—can pose IP risks. Some products may replicate patented profiles, attachment mechanisms, or material formulations from established brands (e.g., Pemko, Saint-Gobain, or HOPPE) without authorization. Using such products could expose architects, contractors, or building owners to legal liability, recalls, or supply chain disruptions.

Inadequate Traceability and Compliance Documentation

Reputable suppliers provide material safety data sheets (MSDS), compliance certificates (e.g., RoHS, REACH), and performance test reports. Sourcing from opaque supply chains may result in undocumented materials that fail environmental, health, or fire safety standards—posing risks in regulated markets or green building certifications (e.g., LEED, BREEAM).

Overlooking Installation Compatibility

Weather stripping must integrate seamlessly with existing window tracks, glazing, and hardware. Poorly designed or improperly sourced products may not attach correctly, require custom modifications, or interfere with window operation. This increases labor costs and reduces system reliability.

Supply Chain and Long-Term Availability Issues

Sourcing from suppliers without proven track records can lead to inconsistent availability, long lead times, or discontinued products. This is problematic for maintenance, repairs, or large-scale projects requiring uniform components over time. IP-protected products often offer better assurance of ongoing support and availability.

By carefully vetting suppliers, requesting material and performance data, and verifying IP status, buyers can avoid these common pitfalls and ensure a durable, compliant, and cost-effective solution for sliding window weather stripping.

Logistics & Compliance Guide for Sliding Window Weather Stripping

Product Classification & Identification

Ensure accurate product classification using standardized systems such as the Harmonized System (HS) Code. Sliding window weather stripping typically falls under HS Code 8302.50 (Other articles of base metal, used as parts of machinery or structures). Confirm exact classification based on material composition (e.g., vinyl, rubber, silicone, or metal-reinforced) and regional tariff schedules to avoid customs delays.

Packaging & Labeling Requirements

Package weather stripping in moisture-resistant, durable materials to prevent deformation or damage during transit. Clearly label each package with:

– Product name and model number

– Dimensions (length, width, thickness)

– Material composition (e.g., EPDM rubber, PVC)

– Quantity per pack

– Manufacturer and importer information

– Country of origin

– Barcodes and SKU for inventory tracking

Ensure labels comply with destination market language and regulatory requirements (e.g., bilingual labeling in Canada).

Shipping & Transportation

Use standard pallet configurations suitable for the product’s length and flexibility (e.g., coiled rolls or straight strips). Secure loads with stretch wrap and corner boards to prevent shifting. Choose shipping methods based on order volume and delivery timelines—LTL (Less Than Truckload) for smaller orders, FTL (Full Truckload) for bulk shipments. Maintain temperature-controlled transport if specified, especially for rubber-based materials sensitive to extreme heat or cold.

Import/Export Documentation

Prepare complete documentation for international shipments, including:

– Commercial Invoice

– Packing List

– Bill of Lading (BOL) or Air Waybill

– Certificate of Origin

– Import licenses or permits if required by destination country

Verify compliance with Incoterms (e.g., FOB, CIF) agreed upon with trading partners.

Regulatory & Environmental Compliance

Adhere to material safety and environmental regulations in target markets:

– REACH (EU): Ensure no restricted substances (e.g., SVHCs) in materials.

– RoHS (EU): Applicable if product contains electrical components (rare for basic weather stripping).

– Prop 65 (California, USA): Provide warnings if product contains listed chemicals (e.g., certain phthalates).

– TSCA (USA): Confirm chemical substances are listed on the TSCA Inventory.

– REACH and UK REACH: For shipments to the UK post-Brexit.

Obtain third-party test reports as needed to verify compliance.

Customs Clearance

Work with licensed customs brokers to facilitate smooth clearance. Provide accurate product descriptions and valuations to avoid under/over-valuation penalties. Be prepared for customs inspections, especially for first-time shipments or high-risk classifications.

Storage & Inventory Management

Store weather stripping in a dry, cool environment away from direct sunlight to prevent UV degradation and material warping. Use FIFO (First In, First Out) inventory rotation. Protect from dust and physical compression to maintain sealing performance.

Product Certification & Standards

Ensure products meet relevant performance standards:

– ASTM E283: Standard test method for determining rate of air leakage in windows.

– AAMA 502: Voluntary specification for field testing of newly installed fenestration products.

– CAN/CGSB-18.4-M90 (Canada): Performance standard for windows and sliding glass doors.

Certification may be required for government or commercial construction projects.

Returns & Reverse Logistics

Establish a clear return policy for damaged or incorrect shipments. Inspect returned items for usability and recycle unusable weather stripping according to local waste regulations. Track return reasons to improve packaging or fulfillment processes.

Compliance Audits & Recordkeeping

Maintain records of material test reports, certifications, shipping documents, and compliance audits for a minimum of 5–7 years, depending on jurisdiction. Conduct periodic internal audits to ensure ongoing adherence to logistics and regulatory standards.

Conclusion for Sourcing Sliding Window Weather Stripping

In conclusion, sourcing high-quality sliding window weather stripping is a critical step in enhancing energy efficiency, reducing air and water infiltration, and improving overall indoor comfort. After evaluating various materials—such as vinyl, silicone, foam, and brush seals—it is evident that the optimal choice depends on specific climate conditions, window type, durability requirements, and budget constraints. Silicone and vinyl weatherstripping often offer the best balance of longevity and performance, particularly in extreme temperatures.

Sourcing from reputable suppliers ensures product consistency, compliance with industry standards, and access to technical support. Additionally, considering sustainability and ease of installation can further improve long-term value. By conducting thorough research, obtaining samples, and comparing pricing and lead times, organizations can make informed procurement decisions that balance cost-effectiveness with performance.

Ultimately, investing in the right sliding window weather stripping not only extends the lifespan of window systems but also contributes to energy savings and occupant comfort—making it a prudent and impactful sourcing initiative.