The global slides and playground equipment market has experienced steady growth, fueled by increasing investments in public and private recreational infrastructure, rising urbanization, and growing emphasis on children’s physical development. According to Grand View Research, the global playground equipment market size was valued at USD 1.7 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. Similarly, Mordor Intelligence forecasts continued demand driven by expanding commercial and residential real estate developments, particularly in emerging economies, where new parks, schools, and community centers are incorporating modern, safe, and durable play solutions. Central to these installations are high-quality slide machines—precision-engineered systems used in the mass production of thermoplastic, metal, and composite slides that meet international safety and design standards. As demand for innovative and scalable playground systems rises, manufacturers specializing in slide production machinery are playing a pivotal role in shaping the next generation of play spaces. Here, we profile the top 10 slide machine manufacturers leading the charge in technology, reliability, and global supply.

Top 10 Slide Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Four

Domain Est. 2000

Website: four-slide.com

Key Highlights: Welcome to Four-Slide Technology, Inc. – a producer of clips, clamps, brackets, wire forms, stampings, assemblies and other assorted fasteners….

#2 Chambrelan

Domain Est. 1999 | Founded: 1956

Website: chambrelan.com

Key Highlights: Chambrelan, Manufacturer of heavy duty drawer slides and linear ball bearing guide rails for industrial professionals since 1956….

#3 Fourslide Spring & Stamping

Domain Est. 1996

Website: fourslide.com

Key Highlights: Fourslide Spring & Stamping specializes in fabrications from strip such as flat springs, steel spring clips, metal spring clips and battery contacts….

#4 Leading Machine Slide Manufacturers

Domain Est. 2015

Website: linearslides.net

Key Highlights: Find the leading machine slide suppliers who manufacture lightweight motion products, meant for a wide range of applications, at unbeatable prices….

#5 Linear Ball Slide

Domain Est. 1995

Website: thk.com

Key Highlights: The Linear Ball Slide is a lightweight, compact, limited stroke linear guide unit that operates with very low sliding resistance….

#6 Del

Domain Est. 1996

Website: deltron.com

Key Highlights: Del-Tron Precision manufactures high-performance linear motion slides and precision slides for automation, medical, and aerospace applications….

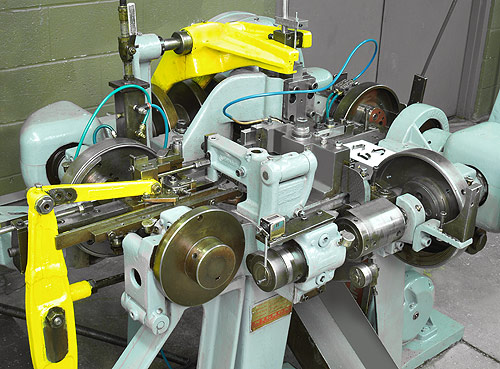

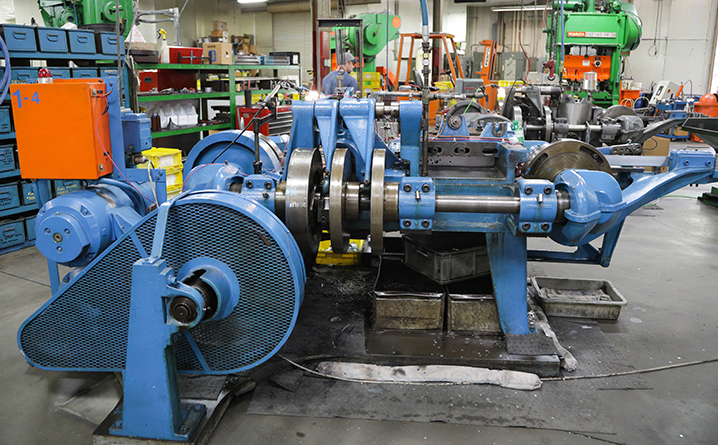

#7 Machine Slides

Domain Est. 1998

Website: setco.com

Key Highlights: Transform Your Machining Tasks with Our Industry-Leading Slides. Setco has been a global leader in manufacturing high-quality machine slides for decades….

#8 Slidematic Products

Domain Est. 1998

Website: slidematicproducts.com

Key Highlights: PRECISION STAMPING SERVICES. With over 40 different multi- and four-slide machines, we handle various wire diameters and various materials….

#9 REPON SLIDES

Domain Est. 1998

Website: repon.com.tw

Key Highlights: Repon manufactures different server slides to be utilized in various server models form 1U to 3U and more!…

#10 Slide Sledge

Domain Est. 2001

Website: slidesledge.com

Key Highlights: Slide Sledge offers a 3-sided floor display or a wall display for Heavy Equipment Master Kits. The 3-sided floor display has wheels for ease of moving/ ……

Expert Sourcing Insights for Slide Machine

2026 Market Trends for Slide Machine

The global slide machine market is poised for significant transformation by 2026, driven by advancements in automation, increasing demand for precision engineering, and the integration of smart technologies across industrial sectors. Slide machines—mechanical systems used for linear motion in manufacturing, packaging, robotics, and material handling—are evolving to meet the needs of Industry 4.0 and sustainable production.

Rising Demand in Automation and Robotics

One of the most prominent trends shaping the slide machine market in 2026 is the surge in automation across manufacturing and logistics. As industries seek to improve efficiency, reduce labor costs, and enhance repeatability, the integration of slide machines in robotic arms, pick-and-place systems, and automated assembly lines continues to grow. The expansion of e-commerce is further accelerating demand for automated packaging and sorting systems, where linear slide mechanisms are essential for high-speed operation.

Adoption of Smart and Connected Slide Systems

By 2026, the integration of IoT (Internet of Things) and AI-driven predictive maintenance in slide machines is expected to become mainstream. Smart slide systems equipped with sensors can monitor load, speed, temperature, and wear in real time. This data enables predictive maintenance, reducing downtime and extending equipment lifespan. Manufacturers are increasingly offering connected slide solutions that interface with industrial control systems, supporting the broader trend toward digital twin and data-driven manufacturing.

Growth in Miniaturization and Precision Applications

In high-tech industries such as electronics, medical devices, and semiconductor manufacturing, there is a growing need for ultra-precise and compact slide mechanisms. The 2026 market will see increased demand for miniature linear slides with sub-micron accuracy, low friction, and cleanroom compatibility. These advancements are particularly critical in applications like lab automation, micro-assembly, and precision optics, where reliability and repeatability are paramount.

Sustainability and Energy Efficiency

Environmental considerations are influencing slide machine design. By 2026, manufacturers are expected to prioritize energy-efficient actuators, recyclable materials, and low-lubrication or lubrication-free systems to align with global sustainability goals. The use of high-performance polymers and self-lubricating components reduces maintenance needs and environmental impact, appealing to environmentally conscious industries.

Regional Market Dynamics

Asia-Pacific is projected to remain the fastest-growing region for slide machines in 2026, driven by industrial expansion in China, India, and Southeast Asia. Local production of electronics, automotive components, and industrial machinery fuels demand for cost-effective and reliable linear motion solutions. Meanwhile, North America and Europe are focusing on high-value applications in aerospace, medical technology, and advanced automation, favoring premium, high-precision slide systems.

Competitive Landscape and Innovation

The market is becoming increasingly competitive, with key players investing in R&D to differentiate through innovation. Companies are enhancing product portfolios with modular slide systems, customizable configurations, and improved sealing for harsh environments. Strategic partnerships with automation integrators and robotics firms are also on the rise, enabling broader market penetration.

Conclusion

By 2026, the slide machine market will be shaped by digitalization, precision engineering, and sustainability. As industries continue to modernize, slide machines will transition from simple mechanical components to intelligent, interconnected systems that support the next generation of smart factories. Manufacturers who embrace these trends—focusing on innovation, connectivity, and eco-design—will be best positioned to capture growing market opportunities.

Common Pitfalls When Sourcing Slide Machines: Quality and Intellectual Property Risks

Sourcing slide machines—particularly from overseas suppliers—can deliver significant cost savings but also presents notable challenges, especially concerning product quality and intellectual property (IP) protection. Organizations must remain vigilant to avoid these common pitfalls:

Quality Inconsistencies and Lack of Oversight

One of the most frequent issues in sourcing slide machines is inconsistent product quality. Suppliers may provide high-quality samples but deliver substandard units in bulk production. Without rigorous quality control processes, buyers risk receiving machines with poor tolerances, unreliable performance, or premature mechanical failure. Additionally, limited on-the-ground oversight often means defects go undetected until after shipment, leading to costly delays and repairs.

Inadequate Supplier Qualification

Many companies fail to conduct thorough due diligence on potential suppliers. This includes not verifying certifications (such as ISO standards), production capabilities, or past client references. Selecting a supplier based solely on price can result in partnering with manufacturers who lack the technical expertise or production infrastructure needed for precision equipment like slide machines.

Poorly Defined Specifications and Documentation

Ambiguous technical specifications or incomplete engineering drawings can lead to misunderstandings during manufacturing. Without clear, detailed documentation—covering materials, dimensions, tolerances, and performance criteria—suppliers may interpret requirements incorrectly, resulting in non-conforming products that fail to integrate with existing systems.

Intellectual Property Exposure

Sourcing slide machines often involves sharing proprietary designs, technical drawings, or custom configurations with suppliers. In jurisdictions with weak IP enforcement, this creates significant risks of design theft or unauthorized replication. Suppliers may reverse-engineer the product or sell copies to competitors, undermining the buyer’s market advantage.

Lack of IP Protection Agreements

Many organizations overlook the necessity of robust legal protections. Failing to execute non-disclosure agreements (NDAs), work-for-hire contracts, or IP ownership clauses before sharing sensitive information leaves the buyer vulnerable. Even with agreements in place, enforcing them across international borders can be difficult and expensive.

Dependency on Single Suppliers

Relying on a single source for slide machines increases supply chain vulnerability. If the supplier experiences quality issues, production delays, or refuses to honor IP agreements, the buyer has limited recourse. Diversifying the supplier base and establishing contingency plans are essential but often neglected.

Insufficient Post-Sourcing Support

After delivery, buyers may discover that suppliers offer limited technical support, spare parts, or warranty coverage. This is particularly problematic for complex machinery like slide machines, where maintenance and troubleshooting are critical for sustained operation.

To mitigate these risks, companies should implement comprehensive sourcing strategies that include supplier audits, third-party quality inspections, clear technical documentation, and enforceable IP protection measures. Proactive risk management ensures reliable performance and safeguards valuable intellectual assets.

Logistics & Compliance Guide for Slide Machine

This guide outlines the essential logistics and compliance considerations for the transportation, handling, installation, and operation of a Slide Machine. Adhering to these guidelines ensures safety, regulatory compliance, and optimal performance.

Shipping & Transportation

Ensure the Slide Machine is securely packaged and labeled according to international and domestic freight standards. Use crating or skid-mounting to protect components during transit. Confirm that weight, dimensions, and handling requirements are communicated to carriers. Utilize lift trucks or forklifts with appropriate capacity for unloading, and inspect the machine upon delivery for any transport-related damage.

Import/Export Compliance

Verify that the Slide Machine complies with export control regulations such as the International Traffic in Arms Regulations (ITAR) or Export Administration Regulations (EAR), if applicable. Secure required export licenses based on the machine’s technical specifications and destination country. For imports, ensure compliance with local customs requirements, including proper Harmonized System (HS) code classification, documentation (commercial invoice, packing list, certificate of origin), and payment of duties and taxes.

Safety Standards & Certifications

The Slide Machine must meet relevant safety standards such as ISO 13849 (safety of machinery), ANSI B11 series (machine tool safety), or IEC 60204-1 (electrical equipment of machines). Confirm presence of CE, UL, or other region-specific certifications required for operation. Provide users with safety manuals, emergency stop procedures, and machine guarding specifications.

Installation Requirements

Install the Slide Machine on a level, stable surface capable of supporting its operational weight and dynamic loads. Ensure adequate clearance around the machine for maintenance and operator access. Verify that power supply specifications (voltage, phase, frequency) match local utility standards. Follow manufacturer guidelines for anchoring, alignment, and initial calibration.

Environmental & Regulatory Compliance

Operate the Slide Machine in accordance with local environmental regulations, including noise emission limits (e.g., EU Directive 2000/14/EC) and air quality standards if exhaust or coolant mist is generated. Implement proper waste disposal procedures for lubricants, metal shavings, or other byproducts. Where applicable, comply with OSHA (U.S.) or equivalent workplace health and safety regulations.

Maintenance & Documentation

Maintain a documented maintenance schedule per manufacturer recommendations to ensure ongoing compliance and reliability. Retain records of inspections, repairs, safety tests, and software/firmware updates. Provide operators with training documentation and ensure logbooks are updated regularly. Retain compliance certificates and equipment manuals on-site or in a secure digital repository.

End-of-Life & Disposal

At end-of-life, decommission the Slide Machine in compliance with Waste Electrical and Electronic Equipment (WEEE) directives or local recycling regulations. Safely disconnect and dispose of hazardous components such as batteries, capacitors, or hydraulic fluids through certified e-waste handlers. Maintain records of disposal to demonstrate regulatory compliance.

Conclusion for Sourcing Slide Machine

After a comprehensive evaluation of available options, suppliers, and technical specifications, sourcing a slide machine represents a strategic investment to enhance production efficiency, precision, and overall operational capability. The selected machine meets critical requirements in terms of performance, reliability, and compatibility with existing manufacturing processes. Additionally, favorable cost-benefit analysis, coupled with strong after-sales support and warranty terms from the chosen supplier, ensures long-term value and minimal downtime.

In conclusion, proceeding with the procurement of the recommended slide machine will empower our production line with improved accuracy, faster turnaround times, and scalability for future demand—positioning us for greater competitiveness and operational excellence.