The global slide bolt latch market is experiencing steady growth, driven by rising demand across industrial, commercial, and residential applications. According to Grand View Research, the global latch and lock market was valued at USD 21.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030, fueled by increasing construction activities and enhanced security requirements. Similarly, Mordor Intelligence projects a CAGR of approximately 6.5% for the global lock and latch market over the forecast period 2023–2028, citing automation in industrial equipment and greater emphasis on mechanical safety as key drivers. Within this landscape, slide bolt latches—known for their reliability, simplicity, and secure locking mechanism—are gaining traction in sectors ranging from manufacturing and transportation to HVAC and access control. As demand grows, a select group of manufacturers has emerged as leaders, combining innovation, precision engineering, and global reach to dominate the space. Here, we spotlight the top 8 slide bolt latch manufacturers shaping the industry.

Top 8 Slide Bolt Latches Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Slide Latches

Domain Est. 1996

Website: southco.com

Key Highlights: 30-day returnsSouthco’s Slide Latches are a simple, intuititive, high strength latch designed for frequent access panels….

#2 Slide Bolts

Domain Est. 1996

Website: acornmfg.com

Key Highlights: Free delivery 120-day returnsSlide Bolts · 2-1/4″ Forged Iron Square Bolt · 3″ Forged Iron Curled Bolt · 12″ Forged Iron Cane Bolt….

#3 1880 Slide Bolt Padlock Latch

Domain Est. 1997

Website: abhmfg.com

Key Highlights: 1880 Slide Bolt Padlock Latch · Ideal for lockers and temporary locking situations · Used in numerous military base BEQS nationwide · Stainless Steel assembly · Non ……

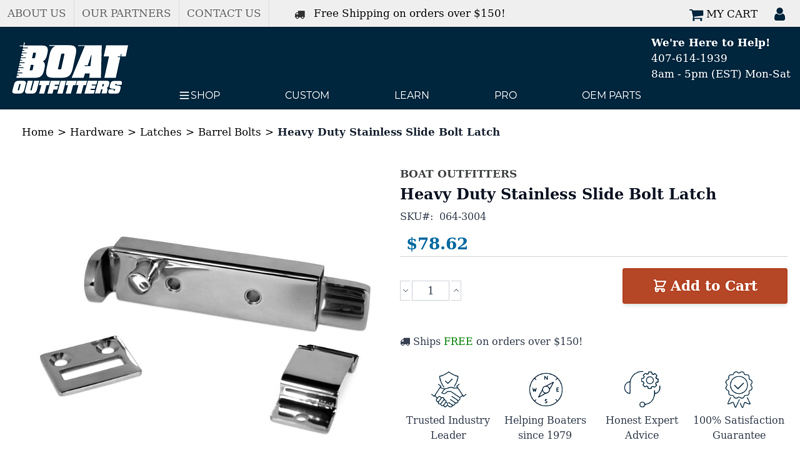

#4 Heavy Duty Stainless Slide Bolt Latch

Domain Est. 2002

#5 Buy Slide, Bolt & Gate Latches

Domain Est. 2004

Website: reidsupply.com

Key Highlights: Free delivery over $100 30-day returnsShop Slide, Bolt & Gate Latches at Reid Supply 70+ years of expertise. Download 3D CAD models. Buy online with next day delivery….

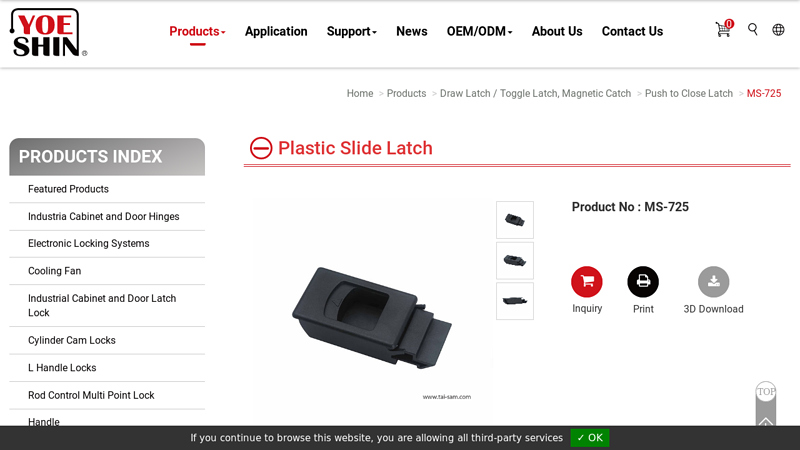

#6 Plastic Slide Latch MS

Domain Est. 2008

Website: tai-sam.com

Key Highlights: Right and Left Side Opening RoHS. Push to Close; Material: PA6+5%GF; Panel thickness: 1~2m/m; Maximum Static Load:200N. Cut Out. Diagram ……

#7 Bolt Latch

Domain Est. 2008

#8 Latches

Domain Est. 2012

Website: partitionsandstalls.com

Key Highlights: 3-day deliveryAll slide bolt latches are in stock for fast delivery. Surface mount slide latches are easy to install on your bathroom partition doors, we offer chrome ……

Expert Sourcing Insights for Slide Bolt Latches

H2: 2026 Market Trends for Slide Bolt Latches

The global market for slide bolt latches is poised for steady growth and transformation by 2026, driven by evolving industrial demands, technological advancements, and shifting consumer preferences across key end-use sectors. As a fundamental component in securing doors, enclosures, and access panels, slide bolt latches are witnessing increased adoption in construction, automotive, marine, and industrial equipment industries. The following analysis outlines the primary trends expected to shape the slide bolt latch market in 2026.

1. Rising Demand in Construction and Residential Security

With global urbanization accelerating and housing projects expanding—particularly in emerging economies—there is a growing need for reliable, cost-effective security hardware. Slide bolt latches are favored for their simplicity, durability, and ease of installation in both residential and commercial doors. In 2026, the construction sector is expected to remain a leading consumer of slide bolt latches, especially in developing regions such as Southeast Asia, Africa, and Latin America.

2. Integration with Smart Security Systems

While traditional slide bolt latches are manually operated, a notable trend emerging by 2026 is the integration of mechanical designs with smart locking mechanisms. Manufacturers are increasingly developing hybrid models that incorporate electronic actuators or IoT-enabled controls, allowing remote monitoring and automation. This convergence caters to the rising demand for smart homes and intelligent industrial enclosures, blending mechanical reliability with digital convenience.

3. Growth in Industrial and Equipment Applications

Slide bolt latches are extensively used in machinery, control panels, and electrical enclosures due to their robust performance in harsh environments. As industrial automation and Industry 4.0 initiatives expand globally, the need for secure, vibration-resistant fastening solutions will drive demand. In 2026, industries such as manufacturing, energy, and transportation are expected to prioritize high-grade stainless steel and corrosion-resistant slide bolt latches to ensure long-term reliability.

4. Emphasis on Material Innovation and Sustainability

Environmental regulations and consumer demand for sustainable products are prompting manufacturers to explore eco-friendly materials and production methods. By 2026, a shift toward recyclable metals, low-emission coatings, and energy-efficient manufacturing processes is anticipated. Additionally, lightweight yet durable materials such as zinc alloys and composite polymers are gaining traction, especially in automotive and portable equipment applications.

5. Regional Market Dynamics and Competitive Landscape

Asia-Pacific is projected to dominate the slide bolt latch market by 2026, fueled by rapid industrialization, infrastructure development, and a booming manufacturing sector—particularly in China, India, and Vietnam. North America and Europe will maintain steady growth, driven by retrofitting projects and high standards for safety and compliance. Key players are focusing on product differentiation, geographic expansion, and strategic partnerships to capture market share in this competitive landscape.

6. Customization and Niche Applications

As end-user requirements become more specialized, there is an increasing demand for customized slide bolt latches tailored to specific sizes, load capacities, and environmental conditions. Industries such as marine, aerospace, and medical equipment require latches with enhanced sealing, anti-tamper features, or cleanroom compatibility. By 2026, OEM-focused customization is expected to become a key differentiator among leading suppliers.

In conclusion, the 2026 market for slide bolt latches will be characterized by innovation, regional growth disparities, and a shift toward smarter, more sustainable solutions. While traditional applications will continue to anchor demand, the integration of technology and customization will define future competitiveness in this mature yet evolving segment.

Common Pitfalls When Sourcing Slide Bolt Latches (Quality, IP)

Sourcing slide bolt latches may seem straightforward, but overlooking key factors—particularly quality and Ingress Protection (IP) ratings—can lead to product failures, safety risks, and increased costs. Avoid these common pitfalls:

Poor Material Quality and Construction

Choosing latches made from substandard materials (e.g., low-grade zinc, weak plastics, or uncoated steel) can result in premature wear, corrosion, or mechanical failure. Inferior spring mechanisms or loose tolerances compromise reliability. Always verify material specifications and insist on samples or third-party test reports.

Misunderstanding or Ignoring IP Ratings

Many buyers assume “weather-resistant” means full environmental protection. However, without a proper IP rating (e.g., IP65, IP67), latches may not withstand dust, moisture, or high-pressure washdowns common in industrial or outdoor applications. Confirm the exact IP rating required for your environment and ensure the supplier provides certified test data.

Inadequate Testing for Real-World Conditions

Suppliers may claim durability without rigorous testing under real operational stresses (e.g., vibration, temperature extremes, repeated cycling). Request performance data such as cycle life tests (e.g., 10,000+ cycles) and environmental exposure reports to validate long-term reliability.

Inconsistent Quality from Low-Cost Suppliers

Sourcing from low-cost suppliers, especially in regions with lax quality control, often results in inconsistent manufacturing standards. Batch-to-batch variations can affect fit, function, and IP performance. Implement supplier audits and incoming inspection protocols to mitigate risk.

Overlooking Certification and Compliance

In regulated industries (e.g., medical, marine, transportation), slide bolt latches may need certifications such as UL, CE, or RoHS. Assuming compliance without documentation can lead to project delays or non-compliance penalties. Always verify certifications are current and applicable.

Design-Function Mismatch

Selecting a latch based solely on appearance or cost without considering installation constraints, operating force, or locking strength can lead to poor performance. Ensure the latch design matches the intended use—e.g., manual vs. automated actuation, indoor vs. outdoor exposure.

By addressing these pitfalls early, buyers can ensure the slide bolt latches they source deliver reliable performance, meet environmental demands, and comply with industry standards.

Logistics & Compliance Guide for Slide Bolt Latches

This guide outlines essential logistics and compliance considerations for the transportation, handling, storage, and regulatory adherence of Slide Bolt Latches across international supply chains.

Product Classification and HS Code

Slide Bolt Latches are typically classified under Harmonized System (HS) codes related to hardware and fittings. A common classification is 8302.41 or 8302.42, which covers “Base metal mountings, fittings, and similar articles suitable for doors, windows, and furniture.” However, the exact code may vary depending on the latch’s material composition (e.g., steel, zinc alloy), design, and intended use. It is critical to confirm the correct HS code with local customs authorities or a certified customs broker to ensure accurate duty assessment and compliance.

Packaging and Labeling Requirements

Slide Bolt Latches must be packaged to prevent damage during transit. Standard practices include:

– Interior Protection: Use of polybags, bubble wrap, or foam inserts to avoid scratches and corrosion.

– Outer Packaging: Sturdy corrugated cardboard boxes or wooden crates for bulk shipments, especially for international transport.

– Labeling: Each package must include:

– Product description and part number

– Quantity per package

– Net and gross weight

– Country of origin

– Handling symbols (e.g., “Fragile,” “This Side Up”)

– Compliance marks (e.g., CE, UKCA if applicable)

Ensure labels are printed in the official language(s) of the destination country where required.

Shipping and Transportation

- Mode of Transport: Slide Bolt Latches are commonly shipped via ocean freight (FCL/LCL), air freight, or ground transportation. The choice depends on order volume, urgency, and cost considerations.

- Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, EXW, DDP) to clarify who manages shipping, insurance, and customs clearance.

- Documentation: Essential shipping documents include:

- Commercial Invoice

- Packing List

- Bill of Lading (B/L) or Air Waybill (AWB)

- Certificate of Origin (if claiming preferential tariffs)

- Hazardous Materials: Slide Bolt Latches are generally non-hazardous, but confirm material safety data sheets (MSDS) are available if coatings or platings contain regulated substances.

Import and Export Compliance

- Export Controls: Verify if the product or materials are subject to export restrictions (e.g., ITAR, EAR). Most standard latches are not controlled, but specialized versions (e.g., for defense applications) may require licenses.

- Import Regulations: Comply with destination country requirements, including:

- Customs valuation

- Anti-dumping or countervailing duties (check for any applicable tariffs on hardware from specific countries)

- Product safety standards (e.g., REACH, RoHS in the EU)

- Duty and Tax Calculations: Accurately assess applicable import duties, VAT, or GST based on classification and origin.

Regulatory and Safety Compliance

- RoHS Compliance (EU/UK): Ensure latches do not contain restricted substances such as lead, cadmium, or hexavalent chromium above permitted levels, especially in metallic components or platings.

- REACH (EU): Confirm compliance with SVHC (Substances of Very High Concern) regulations. Provide documentation upon request.

- CE Marking: Required if the latch is intended for use in construction or safety-critical applications within the EU. A Declaration of Performance (DoP) may be necessary under the Construction Products Regulation (CPR) if applicable.

- UKCA Marking: Required for sale in Great Britain (England, Wales, Scotland) for relevant product categories.

- Other Regional Standards: Adhere to local standards such as:

- ANSI/BHMA (USA) for performance and durability

- AS/NZS (Australia/New Zealand) for mechanical hardware

Storage and Handling

- Environment: Store in a dry, temperature-controlled area to prevent rust or degradation, especially for steel or iron components.

- Stacking: Do not exceed recommended stack heights to avoid crushing lower packages.

- Inventory Rotation: Use FIFO (First In, First Out) to minimize exposure to environmental risks over time.

Sustainability and End-of-Life Considerations

- Recyclability: Design and document latches for disassembly and material recovery. Most base metal latches are recyclable.

- WEEE Compliance: While typically not classified as electrical equipment, inform customers of proper disposal methods if the latch contains electronic components (e.g., smart latches).

- Packaging: Use recyclable or biodegradable materials where possible to meet environmental regulations and customer expectations.

Record Keeping and Audits

Maintain records for at least 5–7 years (depending on jurisdiction), including:

– Compliance certifications (RoHS, REACH, etc.)

– Test reports and conformity assessments

– Shipping and customs documentation

– Supplier declarations of substance compliance

Regular internal audits help ensure ongoing compliance with evolving regulations.

By following this guide, manufacturers, distributors, and importers can ensure smooth logistics operations and full compliance when handling Slide Bolt Latches in domestic and international markets.

Conclusion:

In evaluating options for sourcing slide bolt latches, it is clear that selecting the right supplier involves balancing quality, cost, lead times, and reliability. After assessing multiple vendors, domestic suppliers offer faster delivery and better communication, while international suppliers—particularly in Asia—provide competitive pricing for large-volume orders. However, potential challenges such as longer shipping times, import regulations, and quality control must be carefully managed.

For short-term needs and critical applications requiring high durability and precision, partnering with trusted local or regional manufacturers is recommended. For long-term, high-volume projects where cost efficiency is a priority, establishing relationships with reputable overseas suppliers—supported by strict quality assurance protocols—can yield significant savings.

Ultimately, a hybrid sourcing strategy, combining the strengths of both domestic and international suppliers, offers the most resilient and flexible solution. This approach ensures supply chain continuity, cost optimization, and consistent product performance across applications. Regular supplier evaluations and strong procurement oversight will be key to maintaining quality and reliability in the supply of slide bolt latches.